Device and method for cooperatively producing carbon and heat through gasification power generation of biomass fixed bed

A gasification device, biomass technology, applied in the direction of steam generation method, gasification process, combustion method, etc., can solve the problems of poor stability, low economic benefit, single product, etc., to meet heat demand, improve power generation efficiency, product Variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

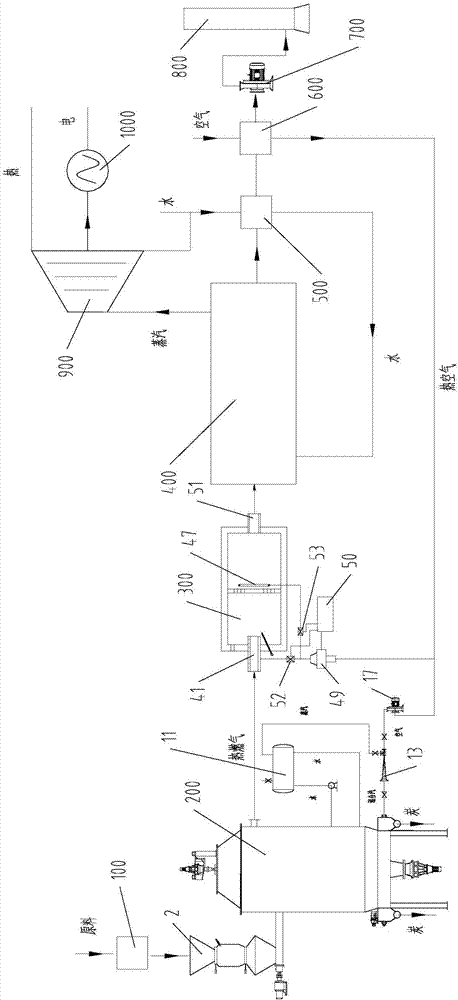

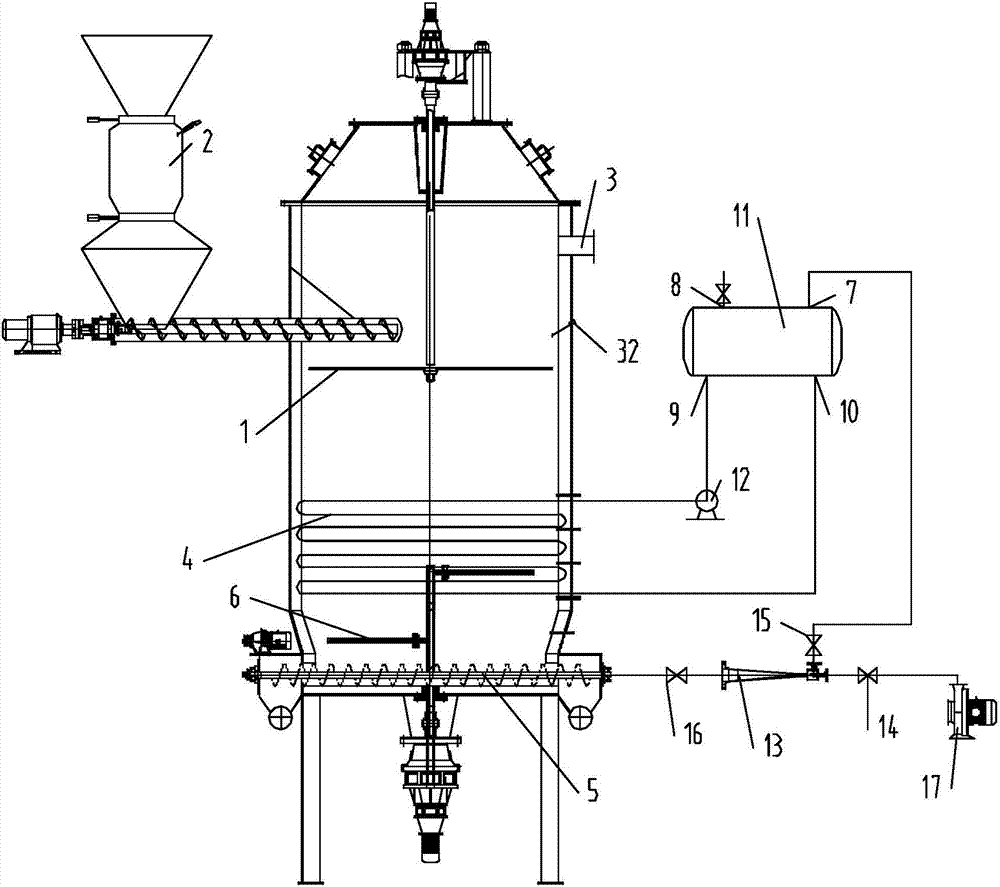

[0042] see figure 1 In the biomass fixed-bed gasification power generation and co-production of charcoal and heat shown, the combustible gas outlet in the gasification device 200 communicates with the combustion pipe in the environment-friendly combustion chamber 300, and the outlet high-temperature flue gas in the environment-friendly combustion chamber 300 The pipe communicates with the gas inlet of the high-temperature and high-pressure boiler 400; the steam outlet of the high-temperature and high-pressure boiler 400 communicates with the steam inlet of the steam turbine 900; connected. The air preheating pipe is connected to the inlet of the fan 17 in the gasification device 200 and the inlet of the air blower 49 in the environment-friendly combustion chamber 300 after passing through the tube side of the air preheater 600, so that hot air is sent into the combustion pipe, gas inside the device. The low-temperature water outlet of the steam turbine 900 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com