Heat recovery type heat pump oxygen generation air conditioning unit

An air-conditioning unit and heat recovery technology, which is applied in heat recovery systems, heat pumps, refrigerators, etc., can solve problems such as the inability of oxygen supply units to provide heating, and the waste heat of air compressors is not fully utilized, so as to improve oxygen concentration and humidity, Satisfy the effect of oxygen load and heating and cooling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

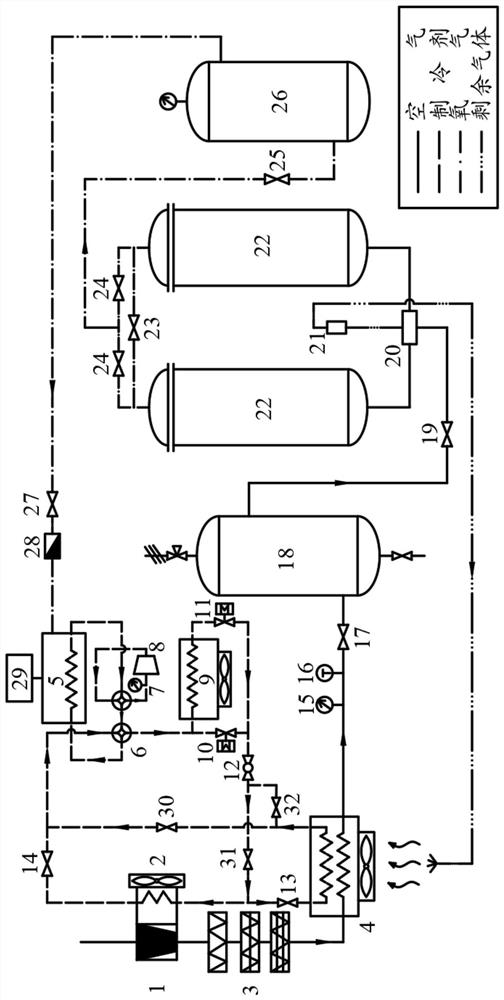

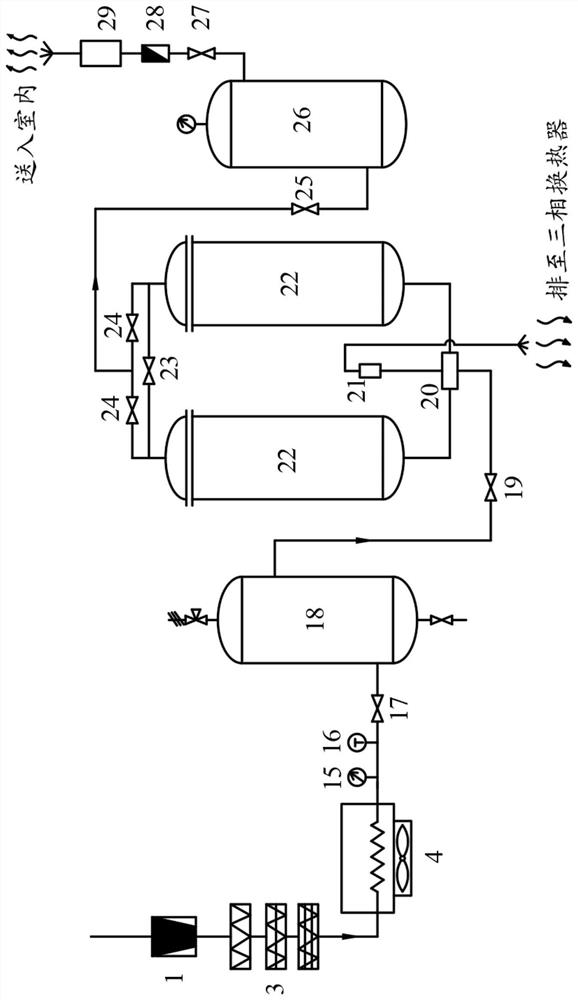

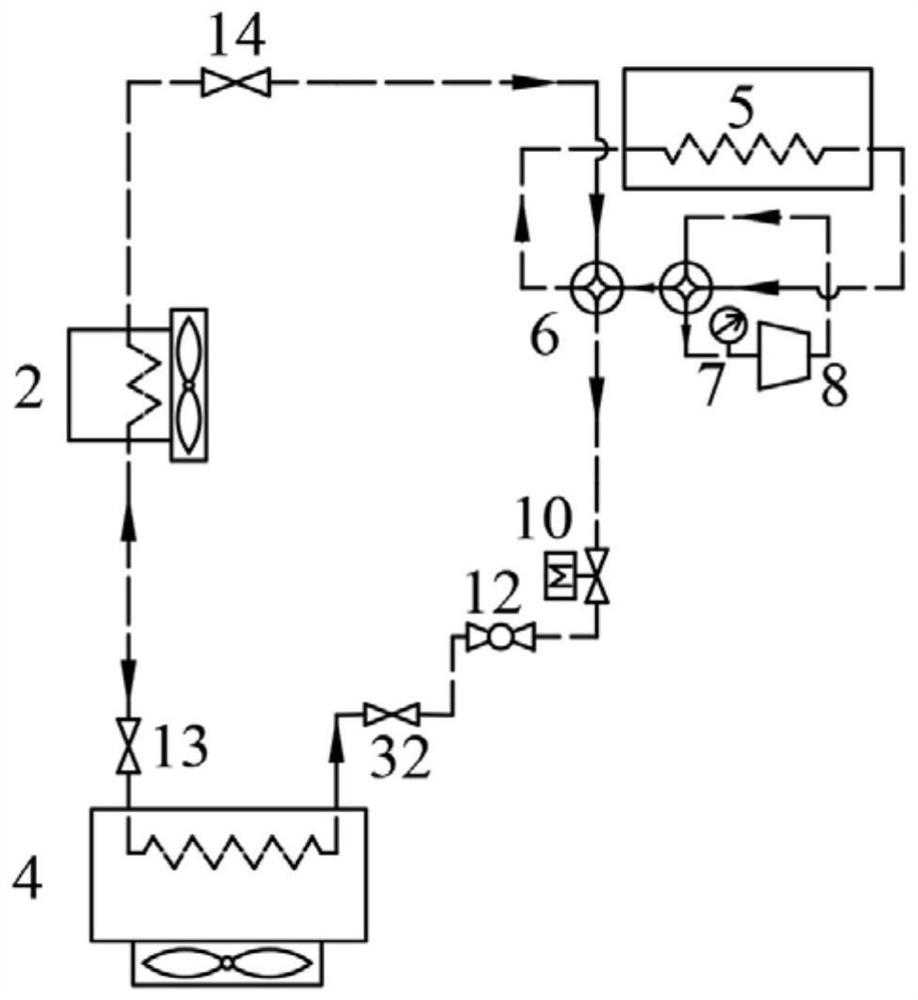

[0040] The present invention has the functions of oxygen supply, heating and cooling, and is designed for areas with heat load (cooling load) and oxygen deficiency. The schematic diagram of the working principle of the present invention is as figure 1 As shown, the orientation words and sequence numbers used in this description are based on the corresponding drawings in this description, and the corresponding components are based on the illustrations in the illustrations.

[0041] Such as figure 1 , the heat recovery type heat pump oxygen generating air conditioner unit of the present invention includes an oxygen supply module and a heat pump module, wherein:

[0042] The oxygen supply module is used to extract oxygen from the air and humidify it, provide sufficient oxygen and humidity to the indoor area, and store excess oxygen. The oxygen supply module includes an air compressor 1, a multi-stage high-pressure filter 3, a three-phase heat exchanger 4, a surge tank 18, two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com