Integrated butt joint furnace of biomass shaped pellet fuel for flue-cured tobacco

A pellet fuel and biomass technology, applied in application, tobacco, tobacco preparation, etc., can solve problems such as air pollution, and achieve the effect of reducing the use of steel, reducing costs, and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

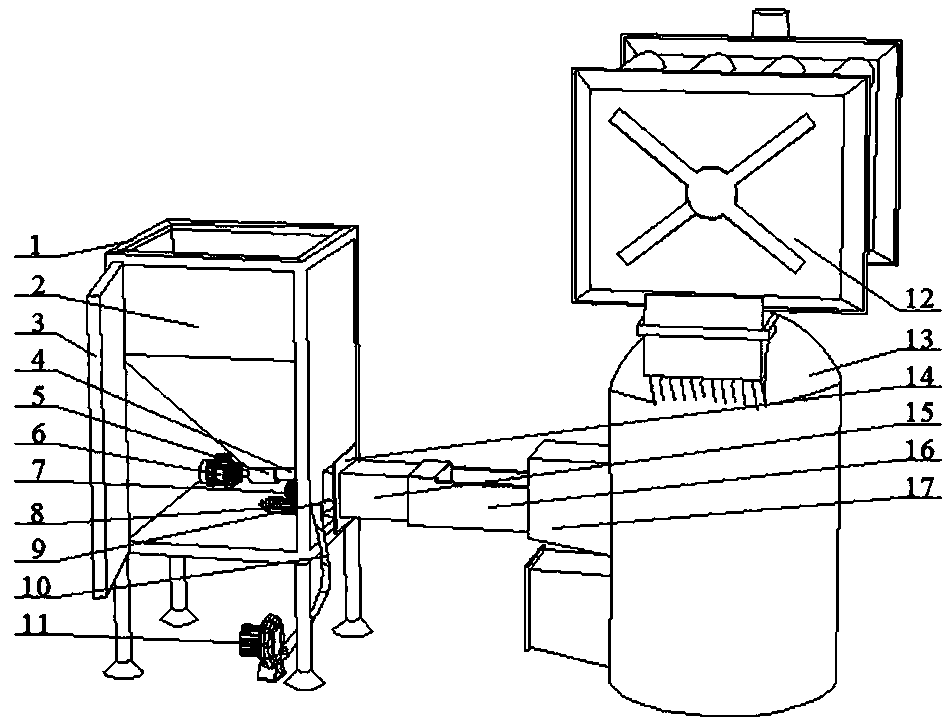

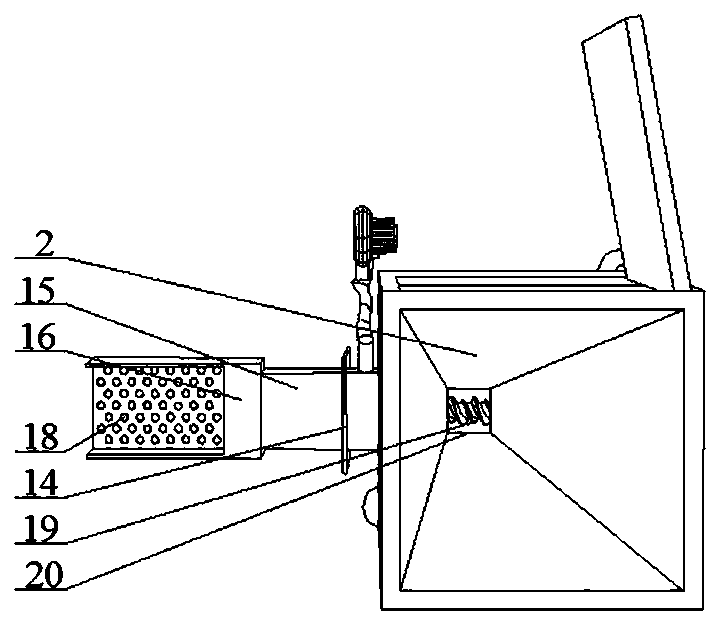

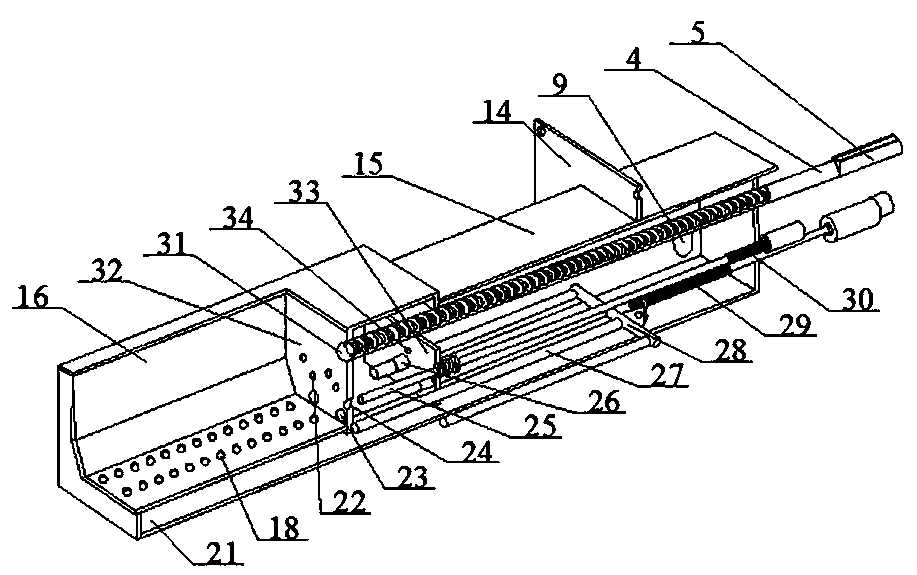

[0053] Embodiment 2, an integrated butt joint furnace for biomass molding pellet fuel for flue-cured tobacco, including an equipment frame 1 and a hopper 2 installed on the top inside of the equipment frame 1. The equipment frame 1 is in the shape of a cuboid, and its six sides are the upper surface, the Bottom surface, front surface, rear surface, left side, right side, the maintenance door 3 is hinged on one side of the front surface of the equipment frame 1, four legs are welded at the four corners of the bottom surface of the equipment frame 1; the bottom of the hopper 2 is provided with The feeding port 20, the feeding channel 4 is installed at the feeding port 20 of the hopper 2, the material receiving U-shaped plate 5 is installed between the hopper 2 and the feeding channel 4, and the large and small auger plates are installed inside the feeding channel 4 Transmission bearing 19, the head of the large and small auger plate transmission bearings 19 is connected with a fe...

Embodiment 3

[0058] Embodiment 3, an integrated butt joint furnace for biomass molding pellet fuel for flue-cured tobacco, including an equipment frame 1 and a hopper 2 installed on the top inside of the equipment frame 1, and a feeding channel 4 is installed at the feeding port 20 of the hopper 2, A large and small auger plate transmission bearing 19 is clamped inside the feeding channel 4, and the head of the large and small auger plate transmission bearing 19 is connected with a feed power motor 6,

[0059] Taking each coal-fired intensive curing barn with 5,000 kg of tobacco as an example to calculate the required feed amount, the known parameters: the comprehensive thermal efficiency of the barn is 45%; the moisture content of fresh tobacco leaves is 85%; The extreme value of vaporization and dehumidification speed is 1.7% / h; the maximum moisture vaporization and dehumidification speed of tobacco leaves during curing is about 0.1% / h; the heat consumption of tobacco moisture vaporizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com