hydrogen burner

A burner, hydrogen technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of high flue gas outlet temperature, low ignition energy, burning of furnace heating surface, etc., to ensure safe and stable operation , the effect of preventing tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

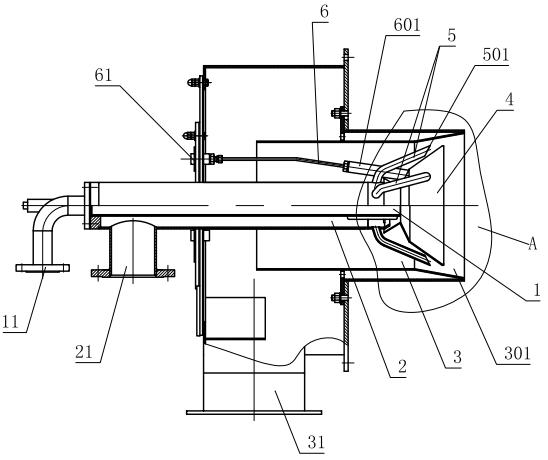

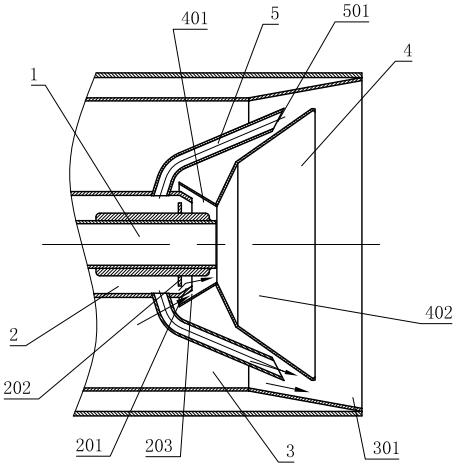

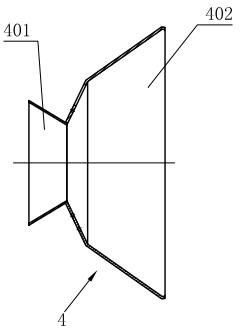

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as Figure 1~4 As shown, the hydrogen burner includes a central channel 1 located at the axis, a middle channel 2 placed outside the central channel 1, and an outer ring channel 3 placed outside the middle channel. The central channel 1 is a nitrogen or air purge channel, and the central channel The rear part of 1 is provided with a nitrogen or air inlet 11, which is used to fill the furnace with nitrogen or air through this channel to replace the residual combustible gas trapped in the furnace when the furnace is shut down for a long time; the middle channel 2 is a hydrogen channel , one side of the middle channel 2 is provided with a hydrogen inlet 21; the outer ring channel 3 is an air channel, and the front end of the outer ring channel 3 is provided with a flared flame tube 301, and the flared structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com