System and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of cement kiln

A technology of electrolytic aluminum waste and co-processing, which is applied in the direction of cement production, etc., can solve the problems of building material products that need further evaluation, secondary pollution, production cost and high energy consumption, and achieve the elimination of environmental protection risks, reduction of energy consumption losses, The effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] The invention will be further described below in conjunction with the embodiments and accompanying drawings, but they are not used to limit the scope of the invention.

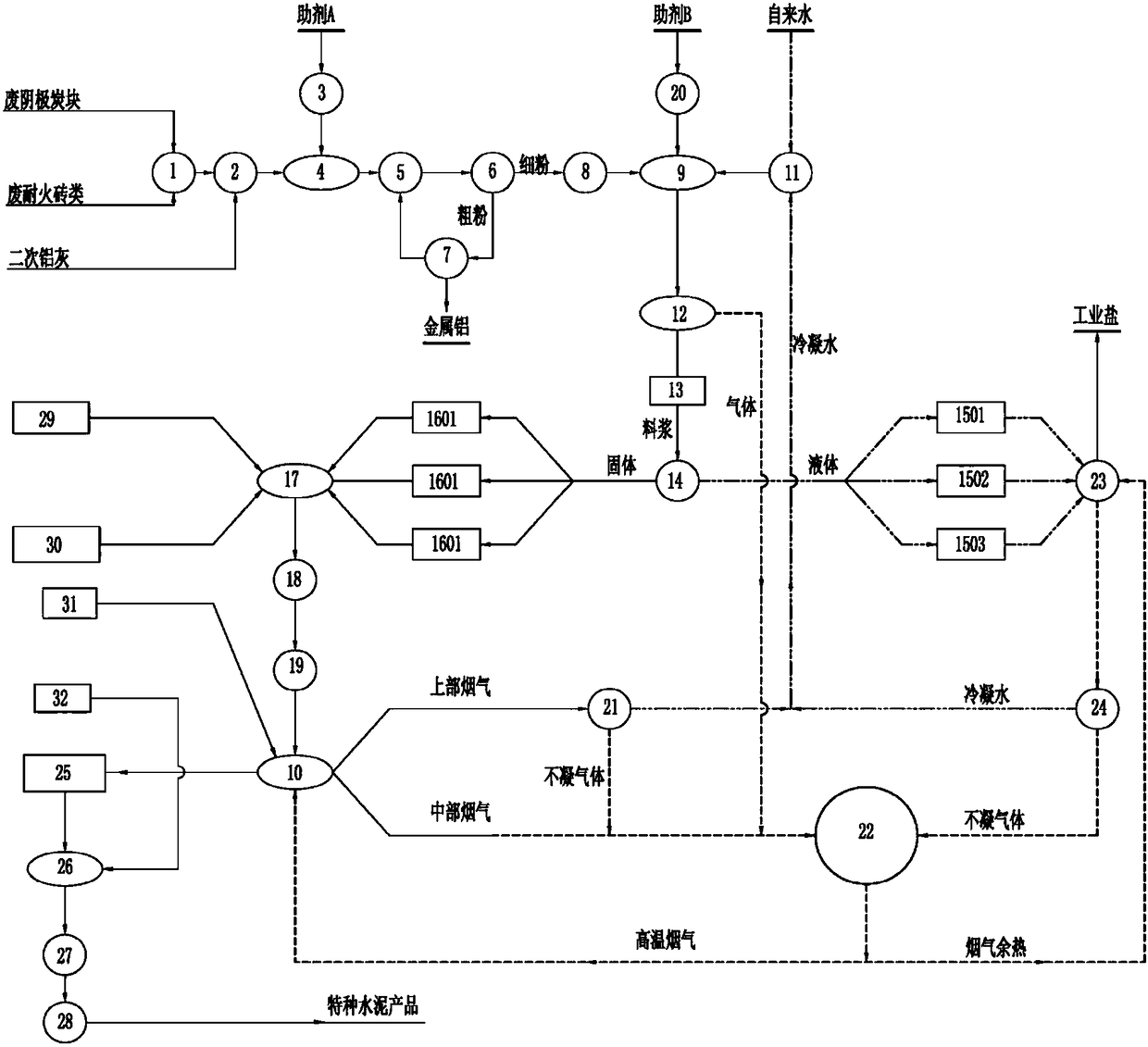

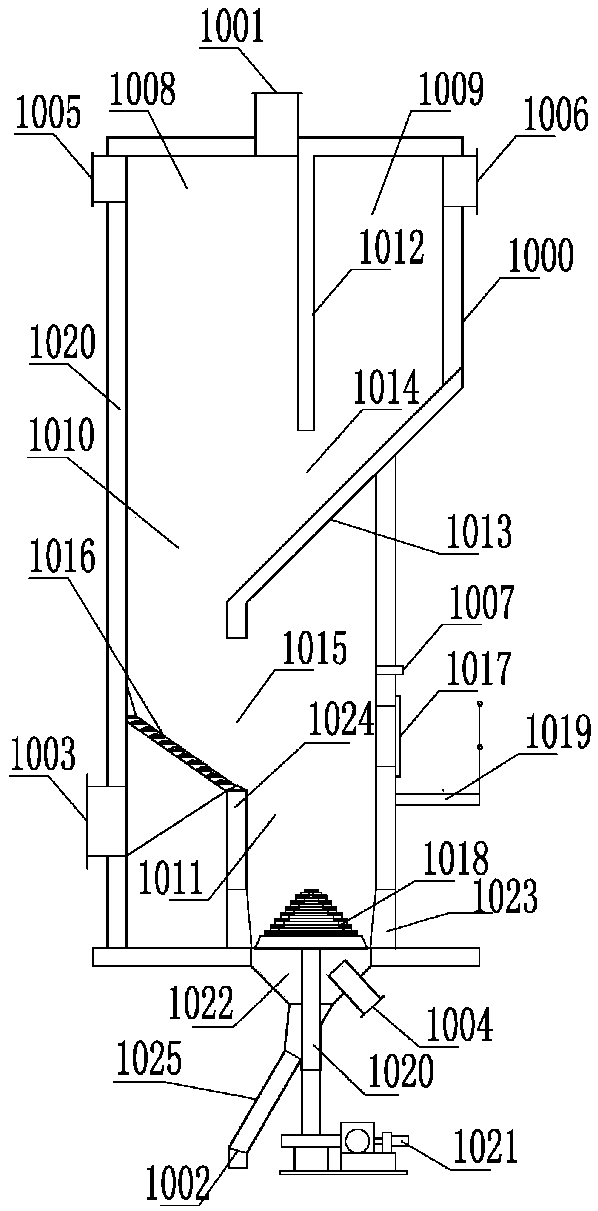

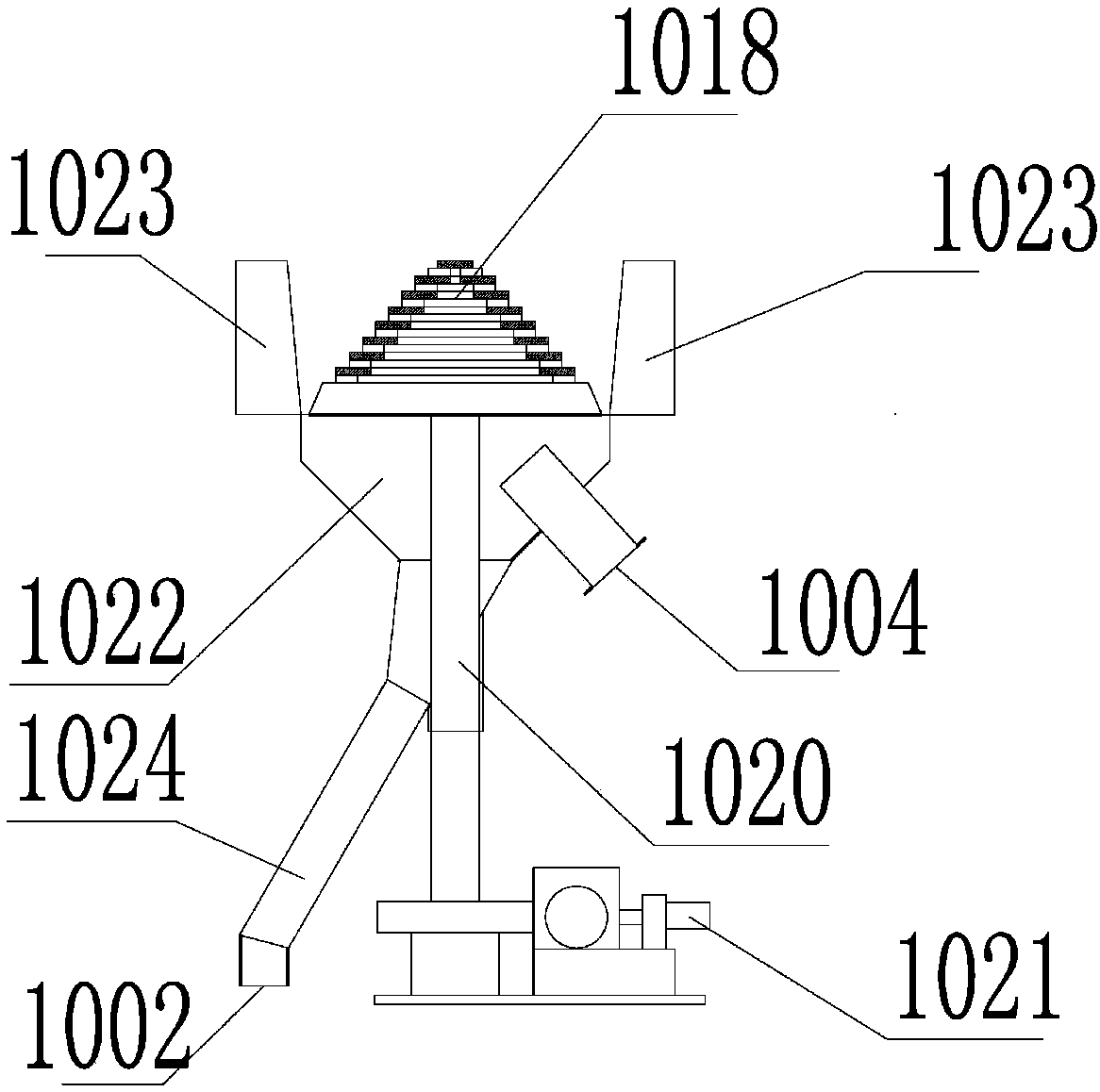

[0120] Such as Figure 1-3 As shown, this embodiment provides a cement kiln co-processing system for the production of double-fast cement by electrolytic aluminum waste slag, which specifically includes: a waste slag pretreatment system, a conversion reaction system, an alkali metal salt extraction system, and cement kilns connected in parallel to produce double-fast cement. cement system;

[0121] The waste slag pretreatment system includes sequentially connected: crushing system 1, several raw material bins 2 (including waste cathode carbon block raw material bins, waste refractory brick slag raw material bins, secondary aluminum ash bin raw material bins), the first metering system 4 , waste slag grinding system, several powder silos 8 (including waste cathode carbon block powder silo, waste refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com