Heating method of weak, micro-oxidation and oxidation combustion for ferrous metal steel slab

A ferrous metal and heating method technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of reducing and exceeding the standard scrap use quality and life, achieve energy saving thickness, reduce pit defects on the surface of steel plates, reduce thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

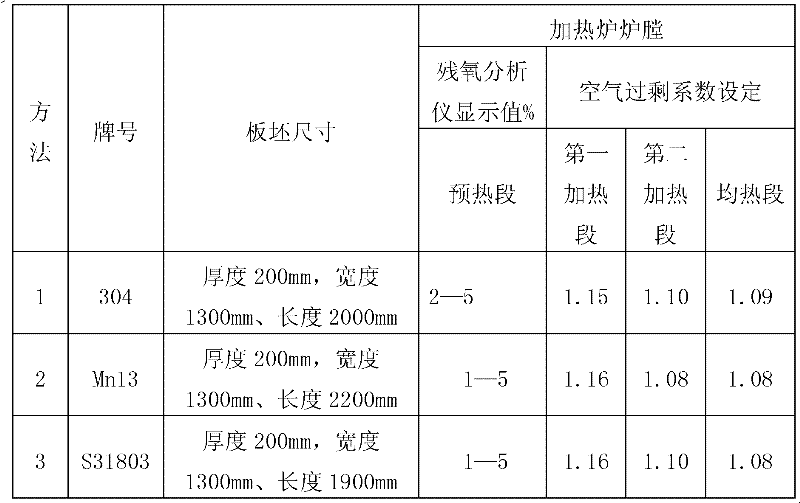

[0026] Example 1: 304 stainless steel slab heating

[0027] The thickness of the slab is 200mm, the width is 1300mm, and the length is 2000mm.

[0028] After the slab is weighed and measured on the furnace roller table, it enters the furnace for heating using natural gas as the fuel and air as the combustion aid. The first heating section, the second heating section, and the soaking section of the heating furnace adopt non-self preheating, Proportional combustion control type burner.

[0029] On the computer L1 screen, the operator of the heating furnace sets the excess air coefficient of the first heating section of the heating furnace to 1.18, the air excess coefficient of the second heating section of the heating furnace to 0.98, and the air excess coefficient of the soaking section of the heating furnace to 0.96 . In this way, the computer controls the weak oxidation, micro-oxidation, and oxidative combustion effects of natural gas and air in the furnace. At this time, t...

Embodiment 2

[0030] Embodiment 2: Wear-resistant Mn13 steel slab heating

[0031] The thickness of the slab is 200mm, the width is 1300mm, and the length is 2200mm.

[0032] After the slab is weighed and side-lengthened on the roller table entering the furnace, it enters the furnace for heating using natural gas as fuel and air as a combustion aid. The first heating section, the second heating section, and the soaking section of the heating furnace adopt non-self preheating, Proportional combustion control type burner. On the computer L1 screen, the operator of the heating furnace sets the excess air coefficient of the first heating section of the heating furnace to 1.20, the air excess coefficient of the second heating section of the heating furnace to 0.96, and the air excess coefficient of the soaking section of the heating furnace to 0.95 . In this way, the computer controls the weak oxidation, micro-oxidation, and oxidative combustion effects of natural gas and air in the furnace. At ...

Embodiment 3

[0033] Example 3: S31803 duplex stainless steel slab heating

[0034] The thickness of the slab is 200mm, the width is 1300mm, and the length is 1800mm.

[0035] After the slab is weighed and side-lengthened on the roller table entering the furnace, it enters the furnace for heating using natural gas as fuel and air as a combustion aid. The first heating section, the second heating section, and the soaking section of the heating furnace adopt non-self preheating, Proportional combustion control type burner.

[0036] On the computer L1 screen, the heating furnace operator sets the excess air coefficient of the first heating section of the heating furnace to 1.20, sets the air excess coefficient of the second heating section of the heating furnace to 0.97, and sets the air excess coefficient of the soaking section of the heating furnace to 0.95 . In this way, the computer controls the weak oxidation, micro-oxidation, and oxidative combustion effects of natural gas and air in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com