Coke oven flue gas sharing

A technology for coke ovens and coke oven groups, which is applied to the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problem that coke cannot absorb moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

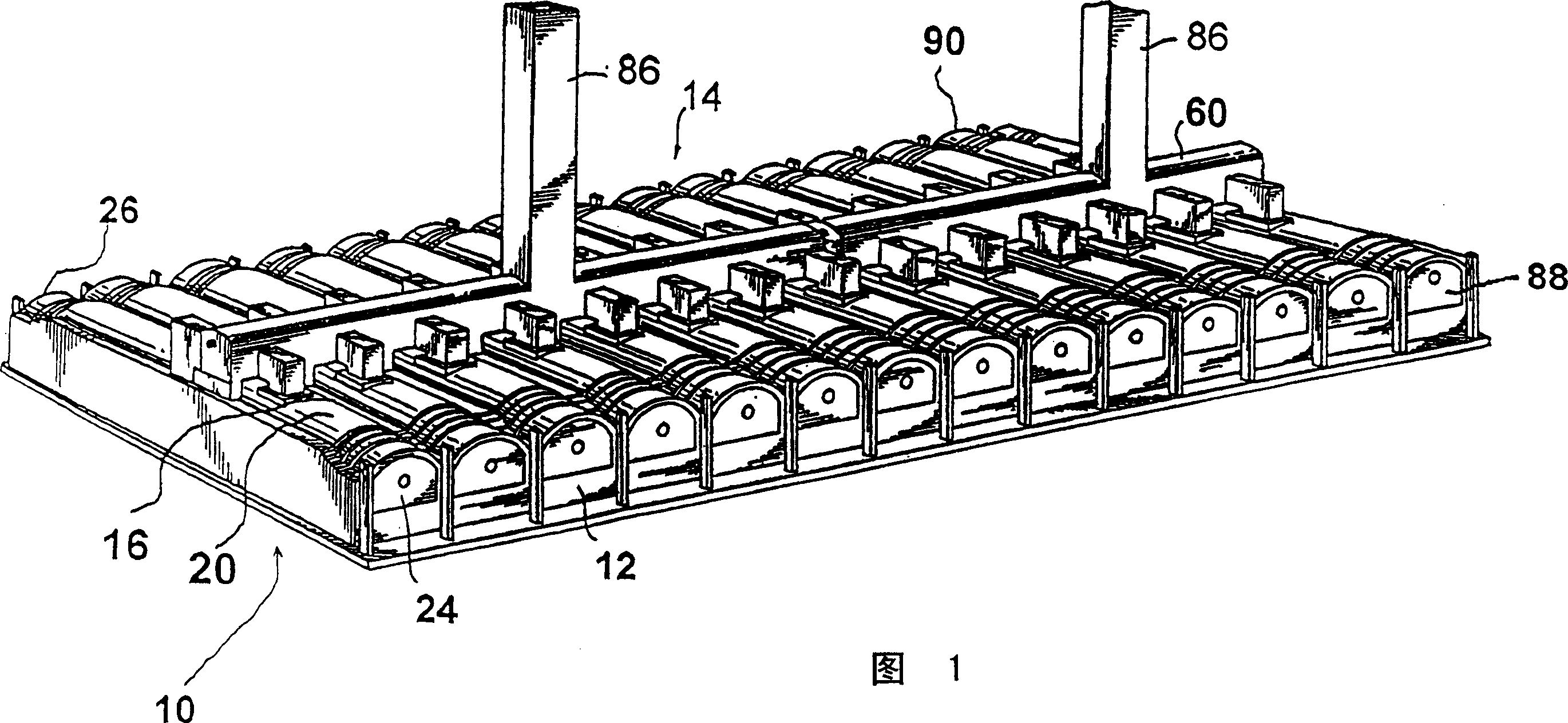

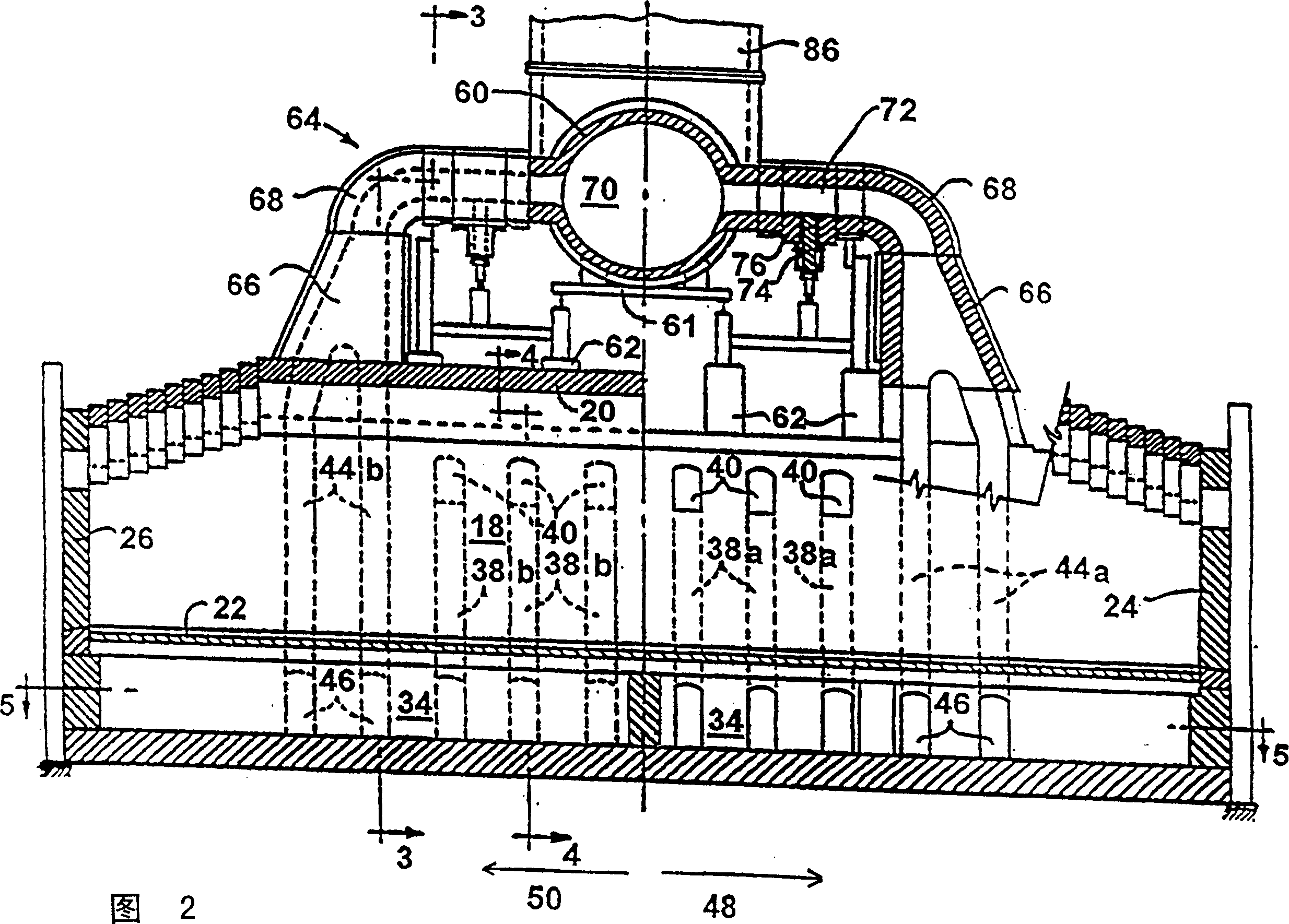

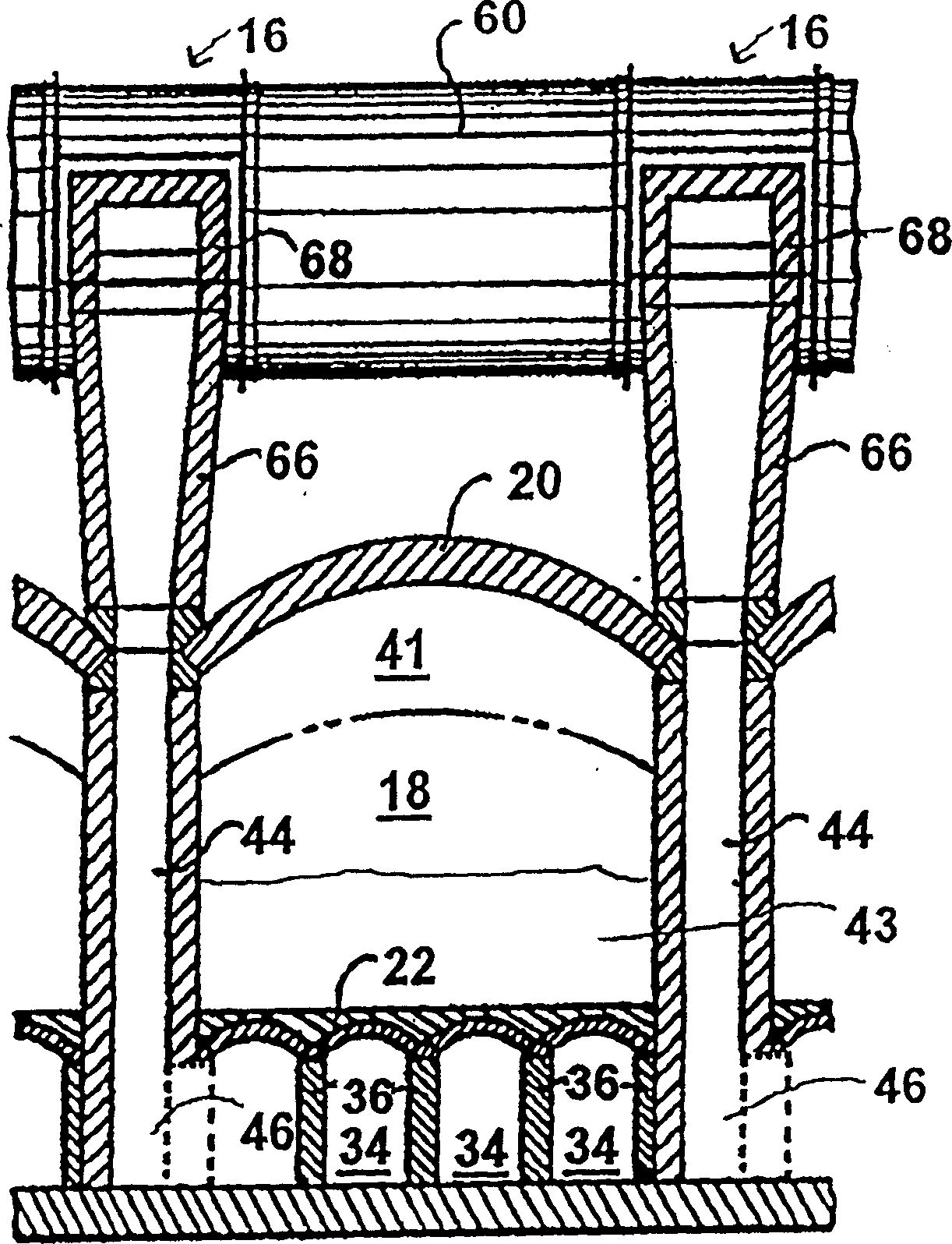

[0019] Illustrated in FIGS. 1 and 2 is a coal coking plant 10 comprising a plurality of coke ovens 12 , preferably configured in side-by-side relationship in a group 14 , with adjacent ovens 12 in the group preferably having a common side wall 16 . Each of the individual coke ovens 12 of the group 14 has an elongated coking chamber 18 defined by vertically oppositely extending side walls 16, a generally arcuate roof 20 supported on the side walls 16, and a support for the coal to be coked. Horizontal floor 22. The furnace is constructed such that chamber 18 is open at opposite ends and the ends are closable during coking by removable doors 24 and 26 (FIG. 2). Wherein the door 24 closes the charging end and the door 26 closes the coke discharge end of the furnace 12 . The side walls 16, roof 20, and floor 22 are formed of suitable heat resistant material, such as refractory bricks or castable refractory materials that are resistant to the high temperatures and thermal shock en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com