Patents

Literature

53results about How to "Guaranteed burnout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

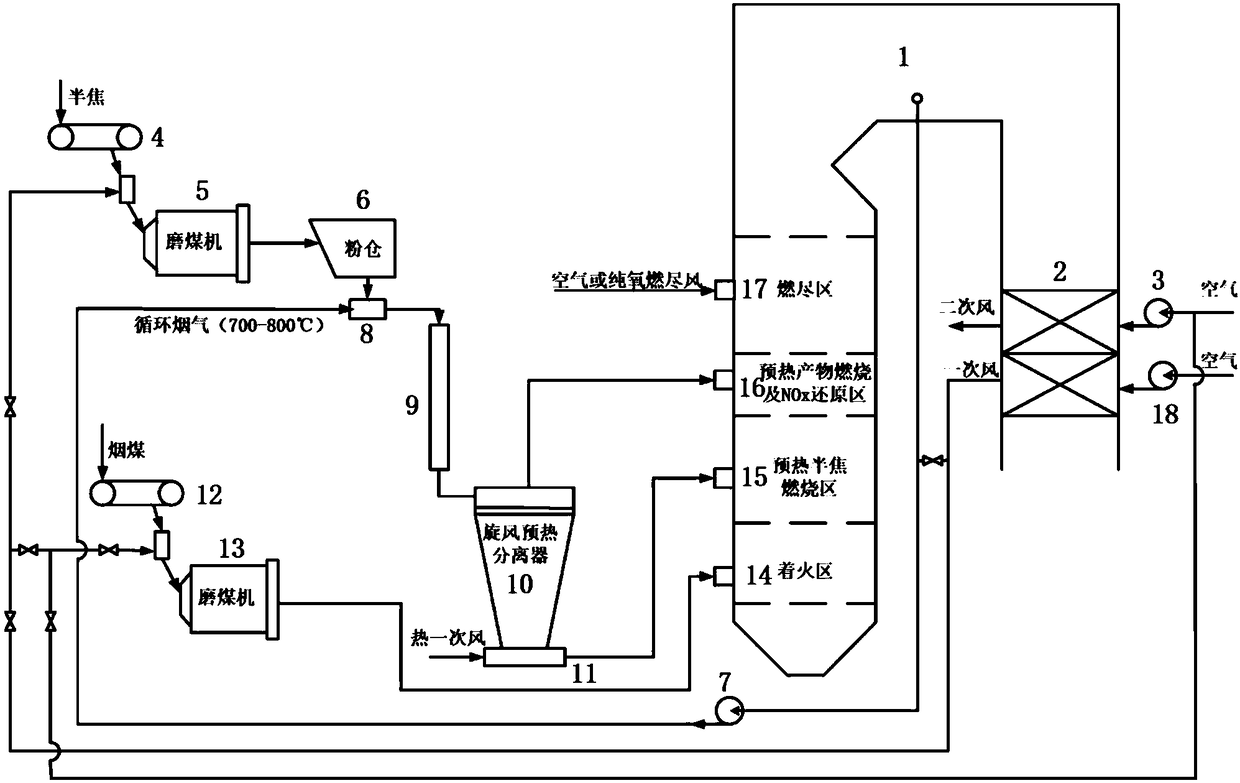

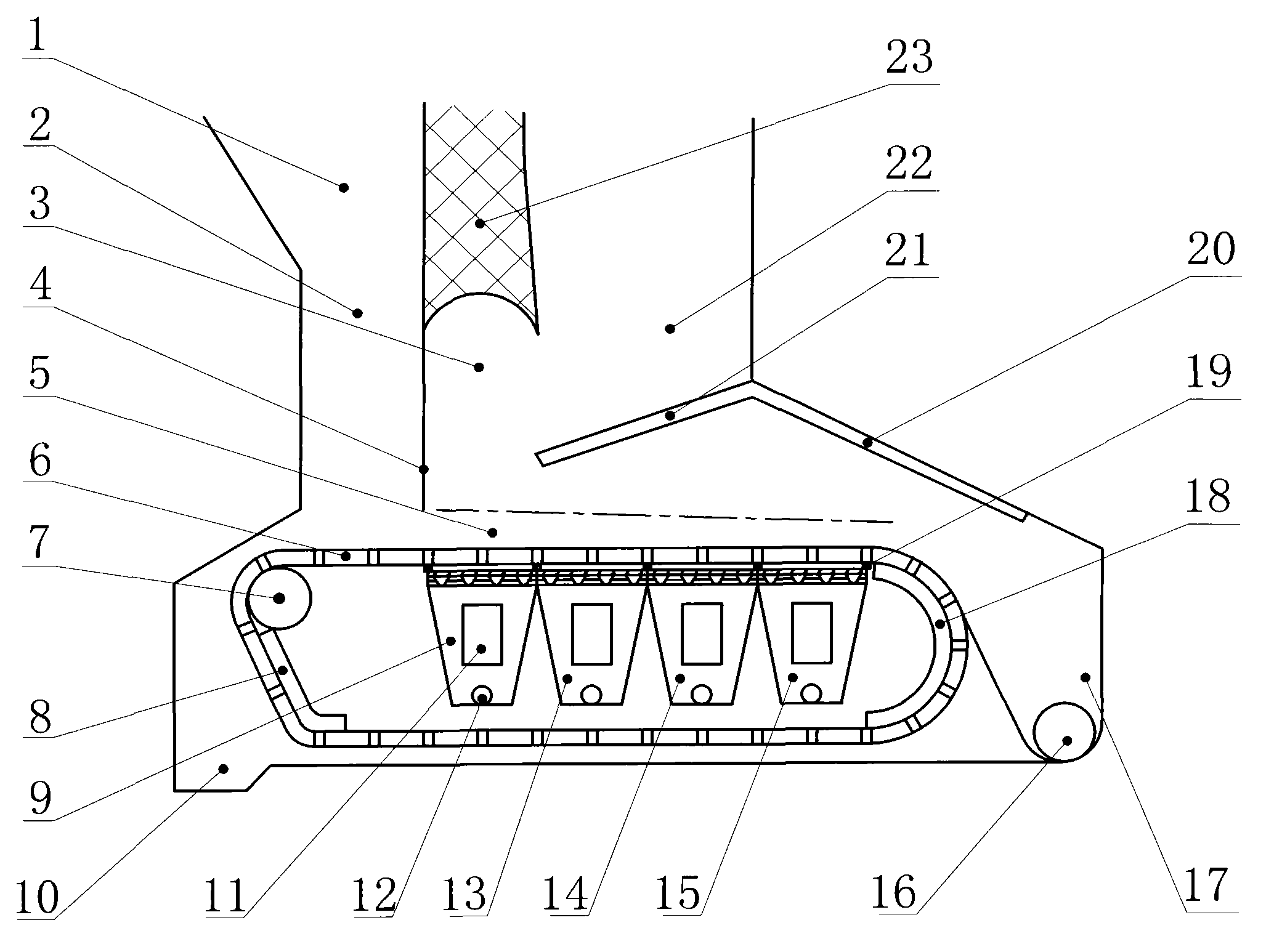

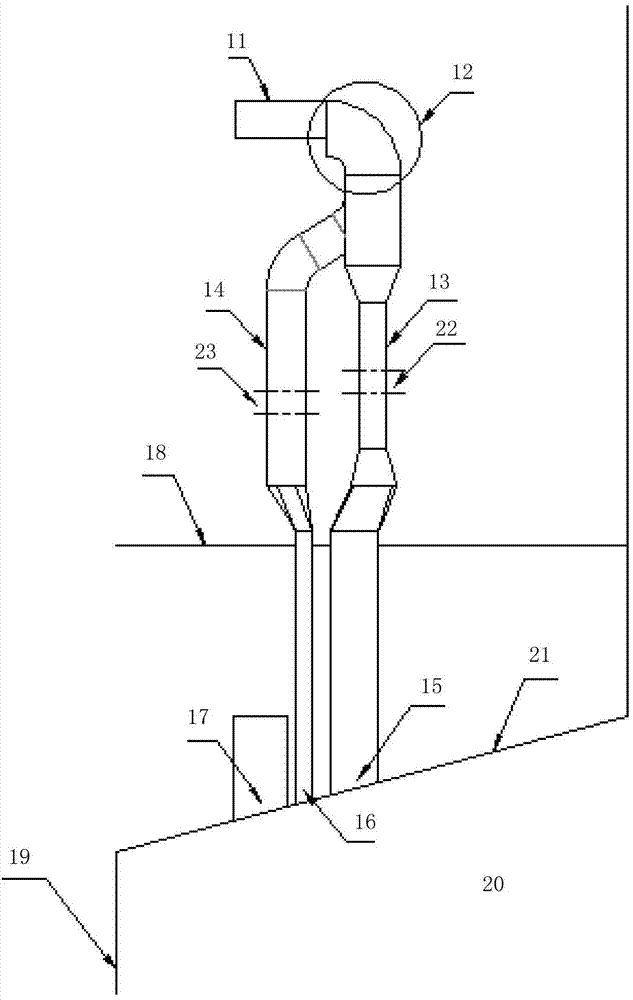

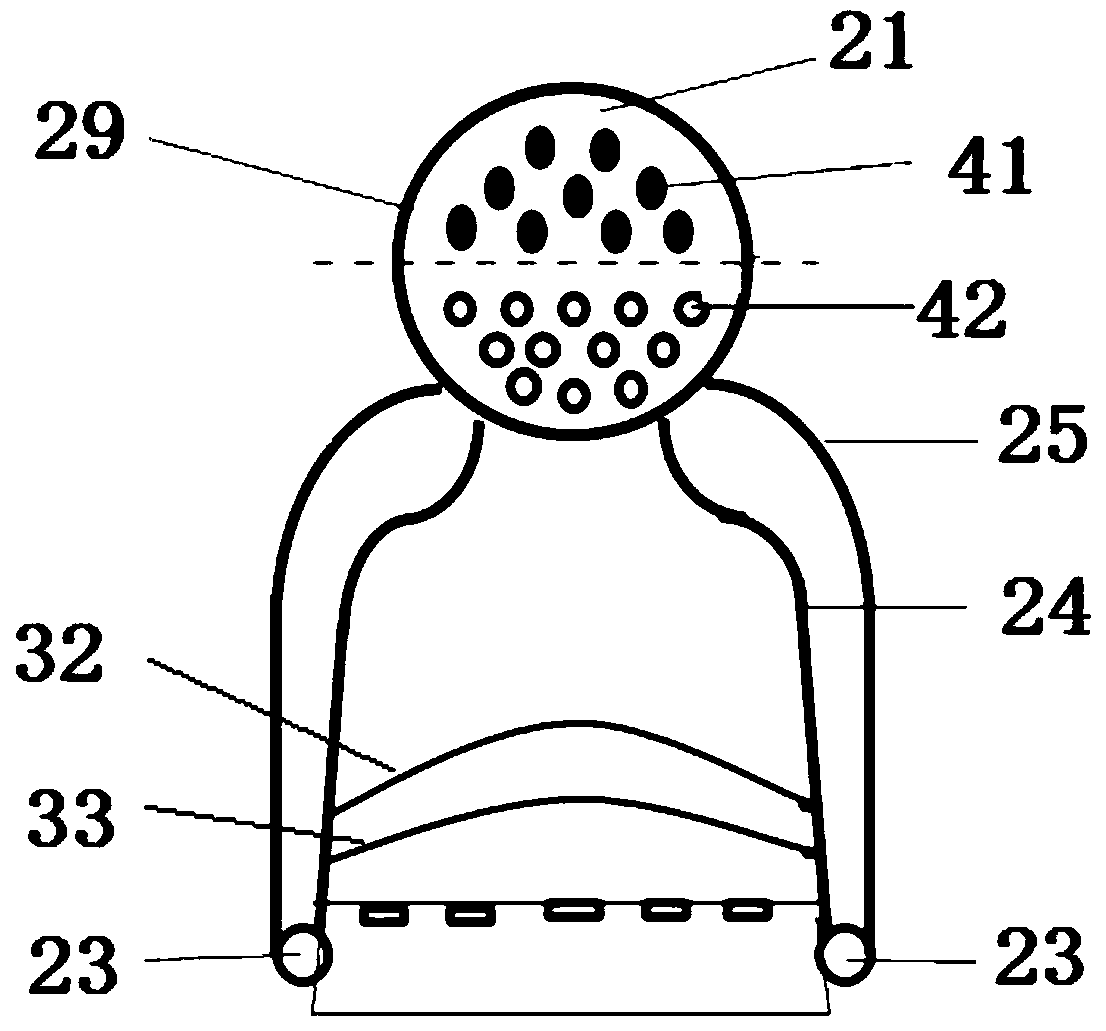

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

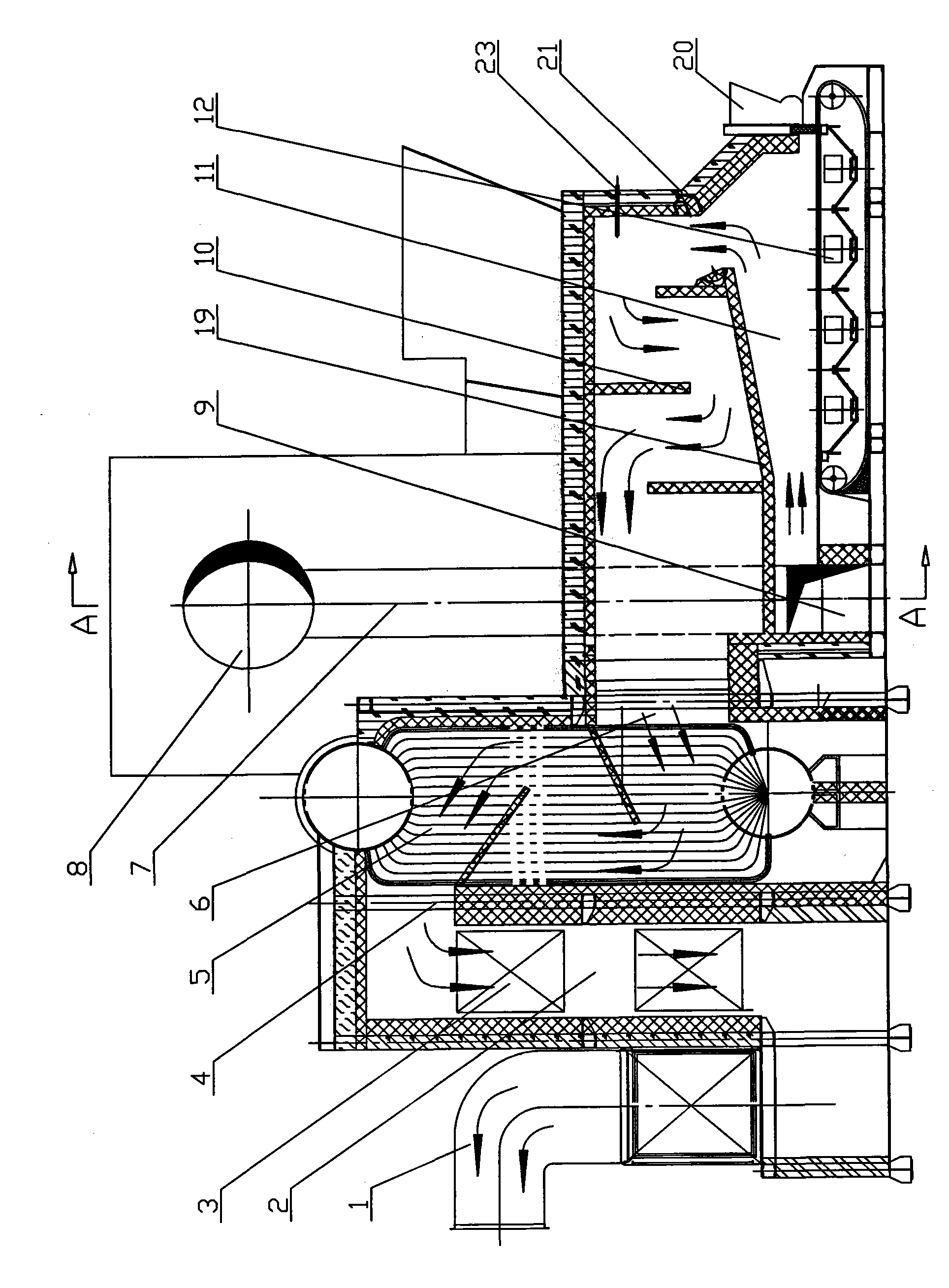

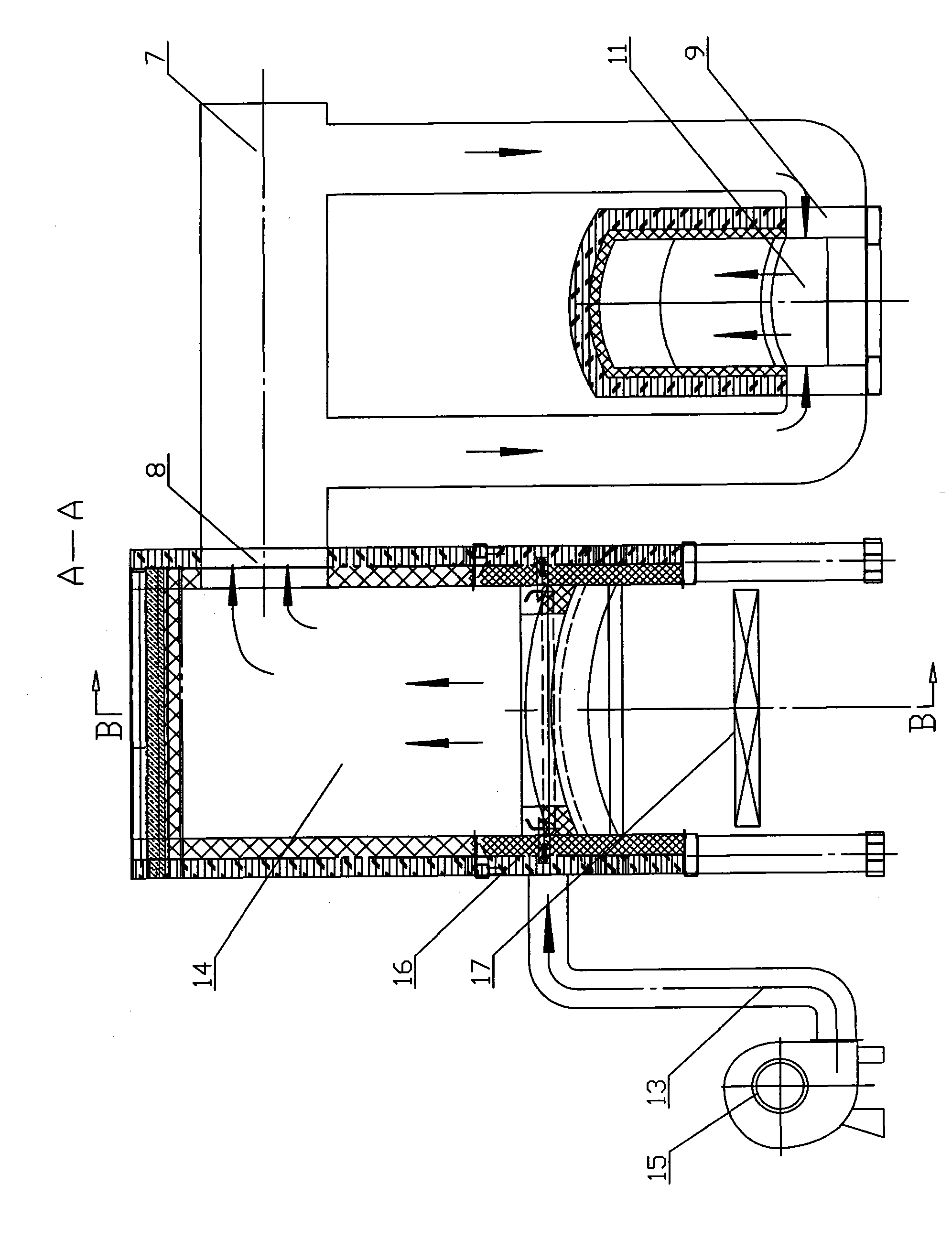

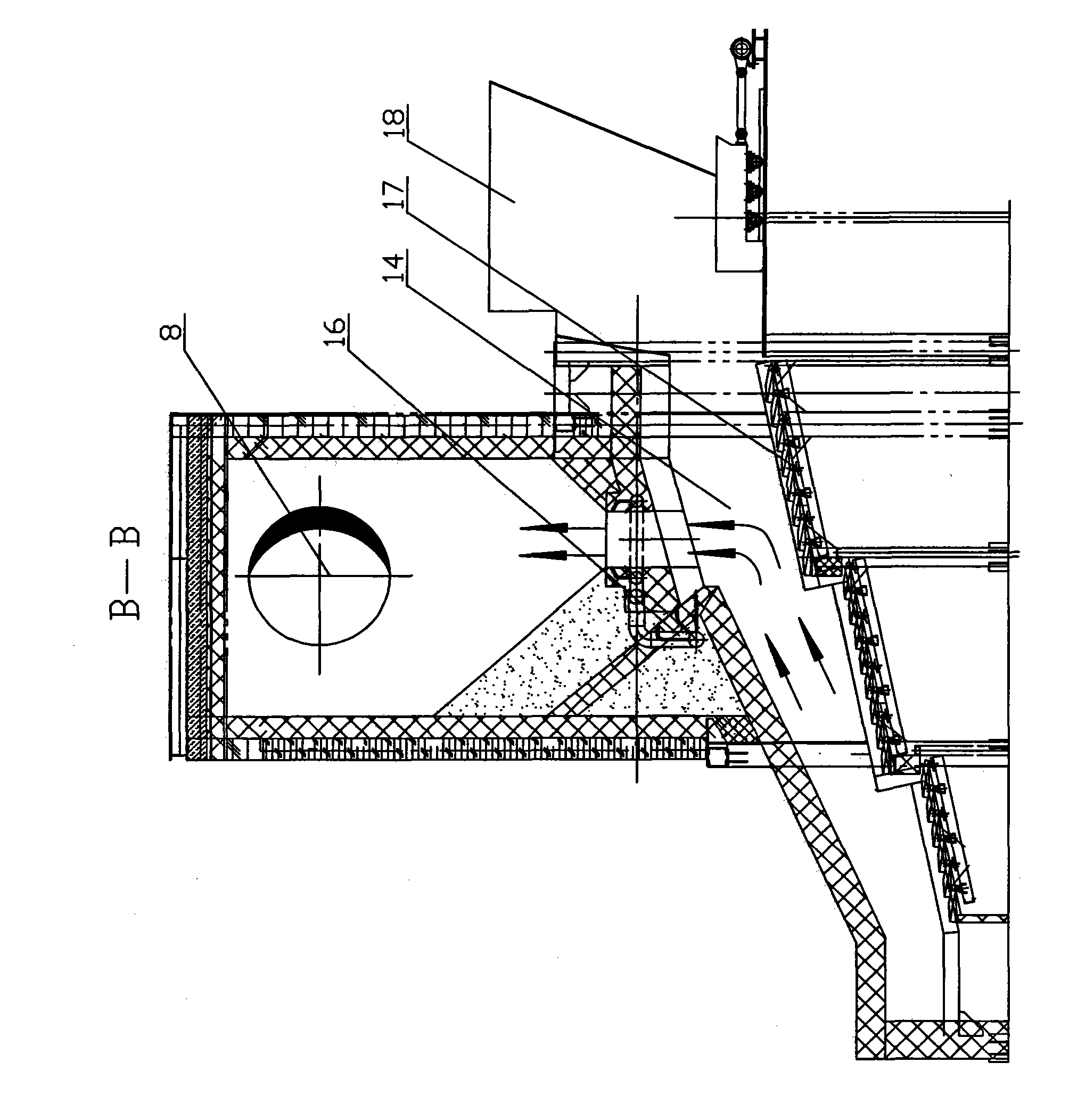

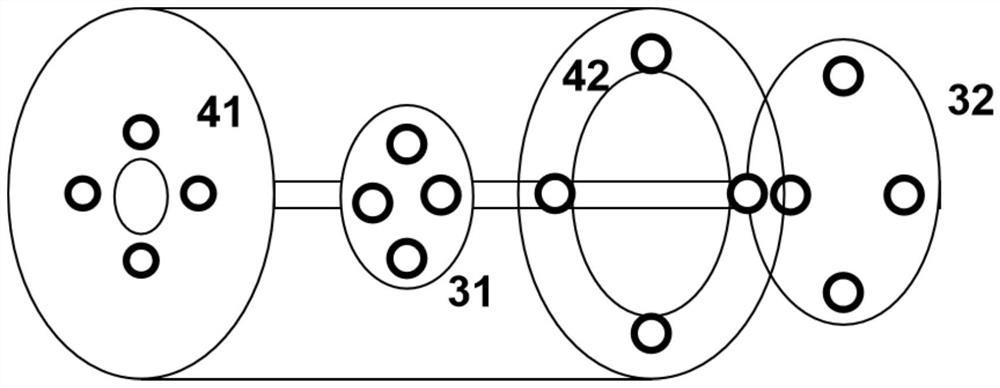

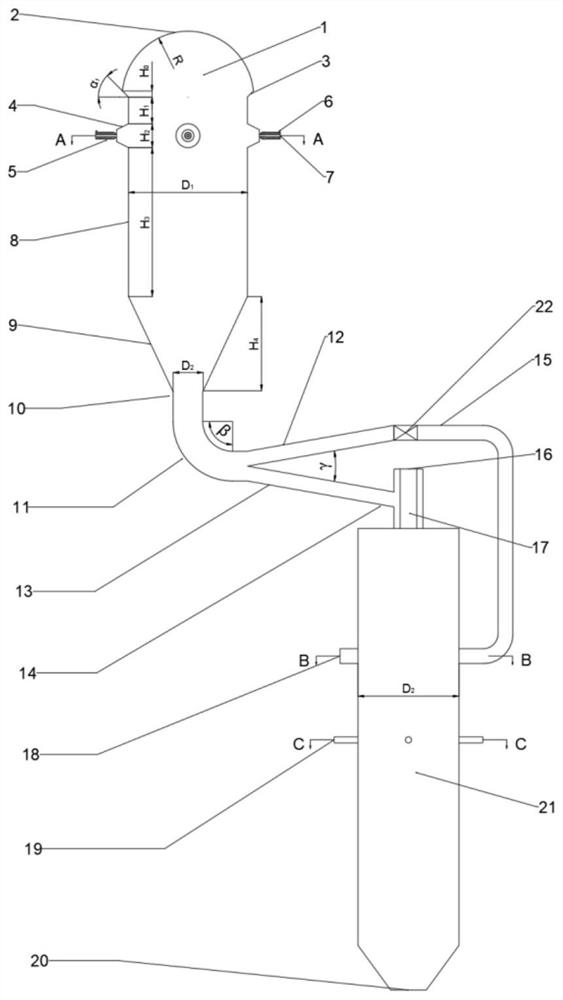

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

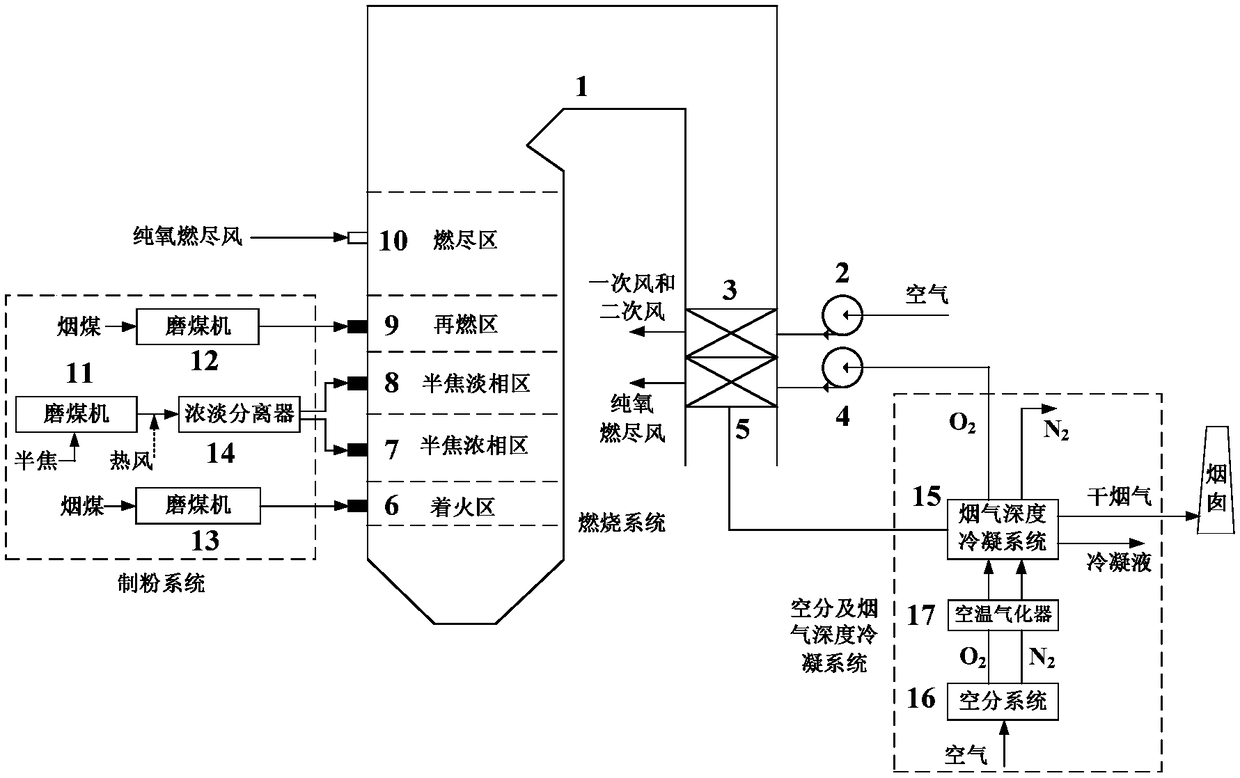

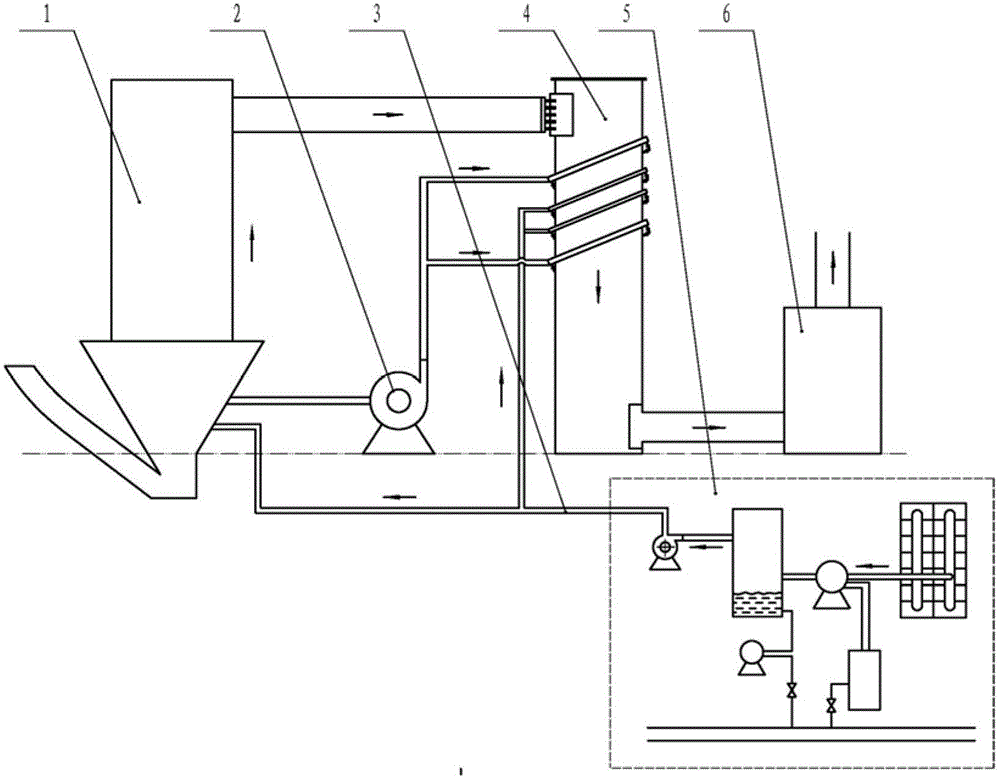

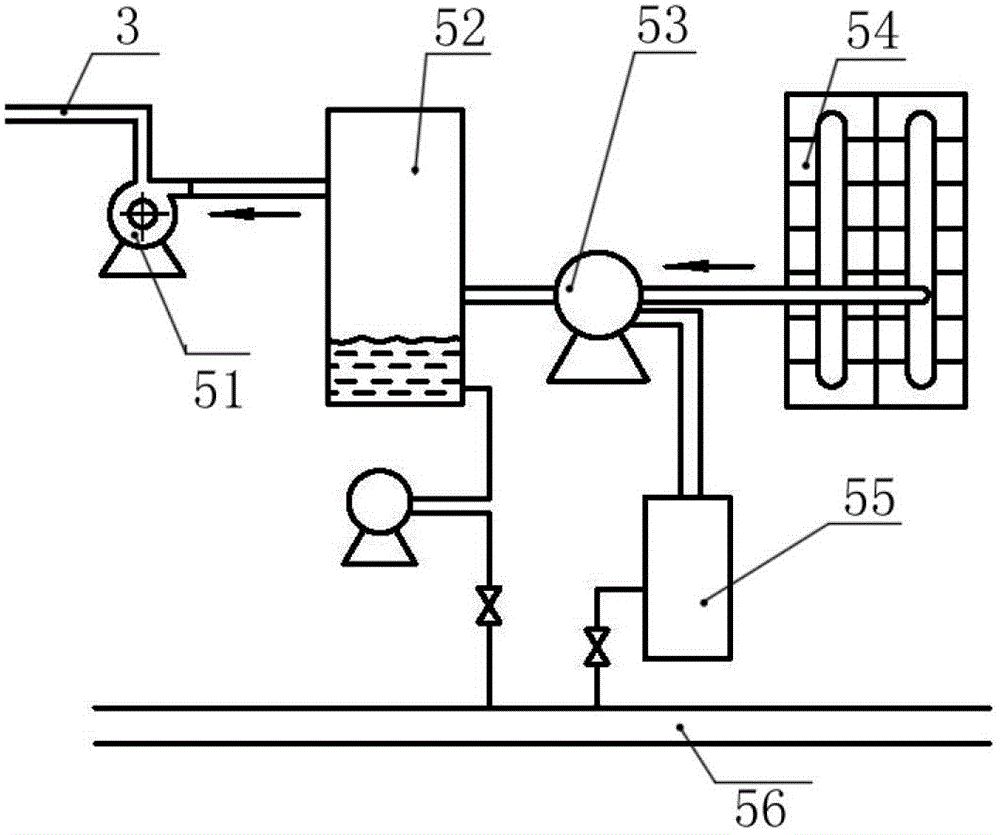

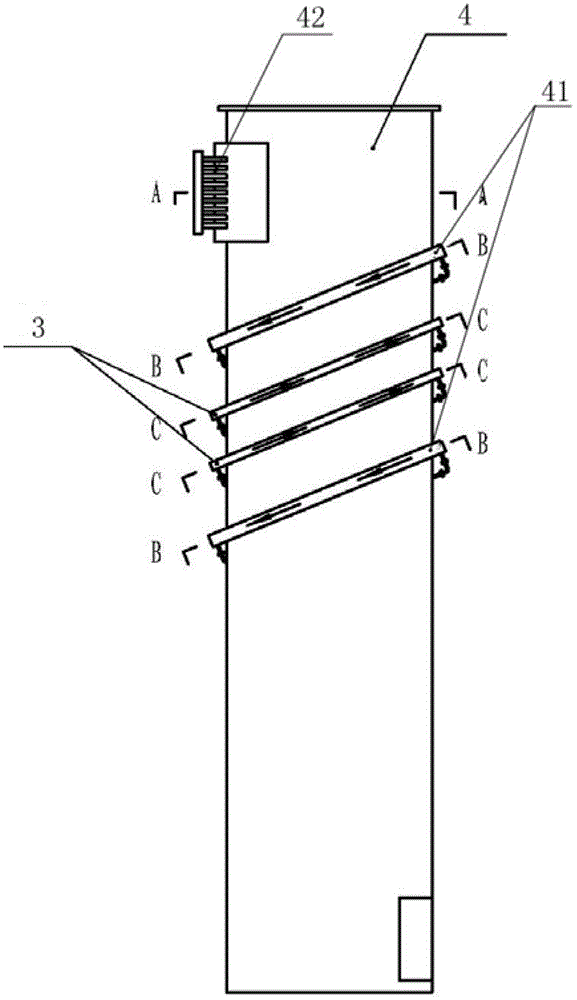

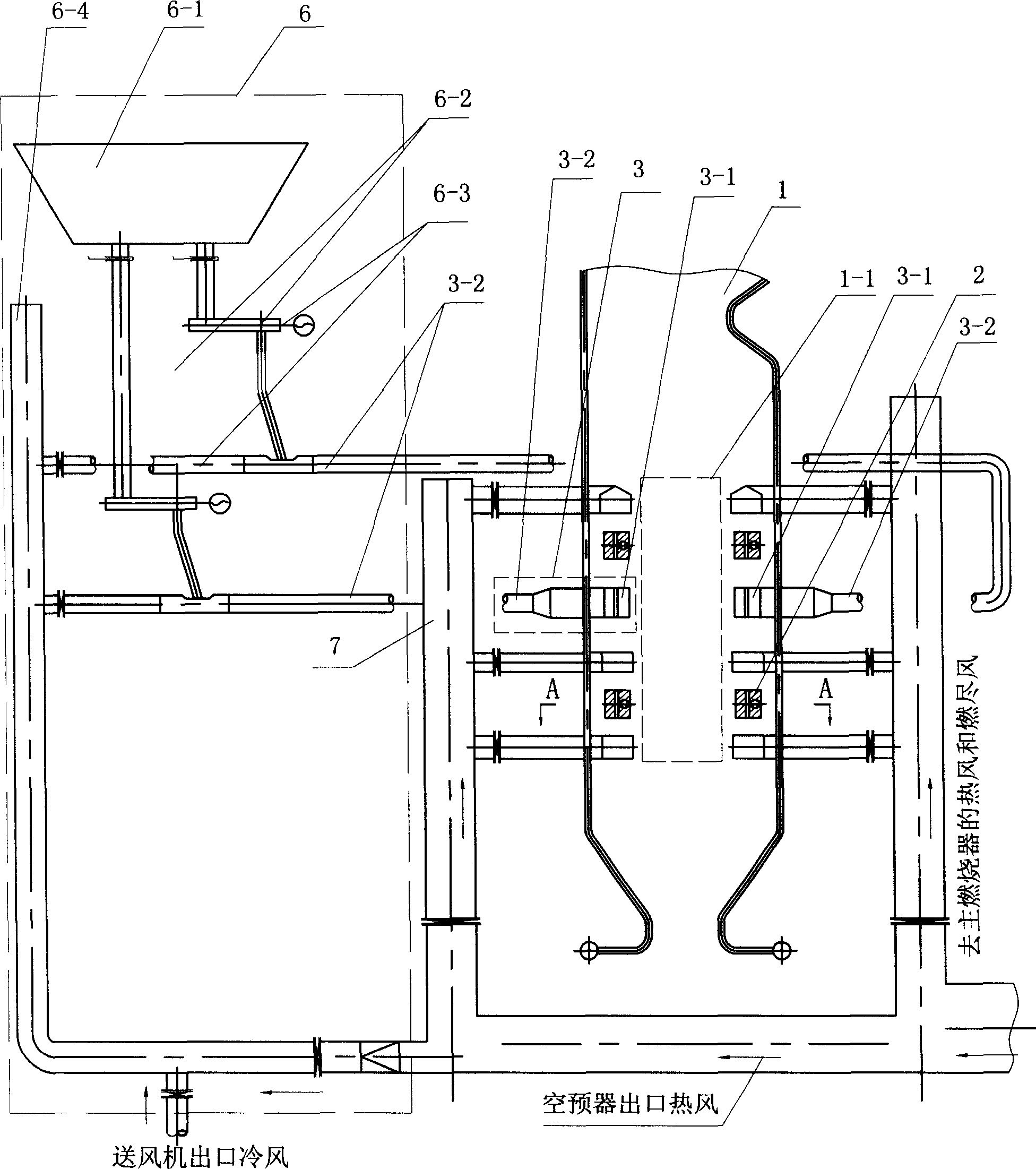

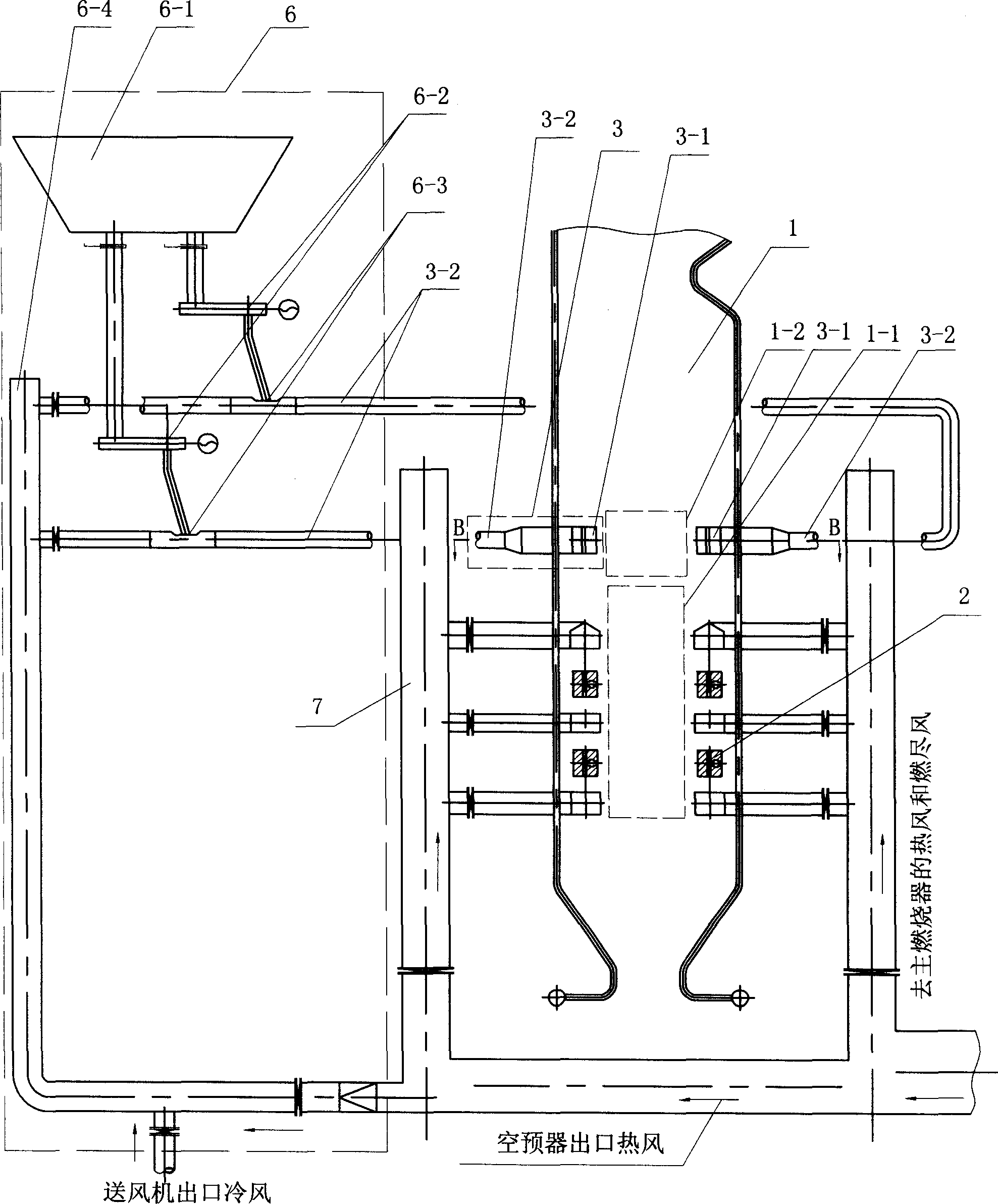

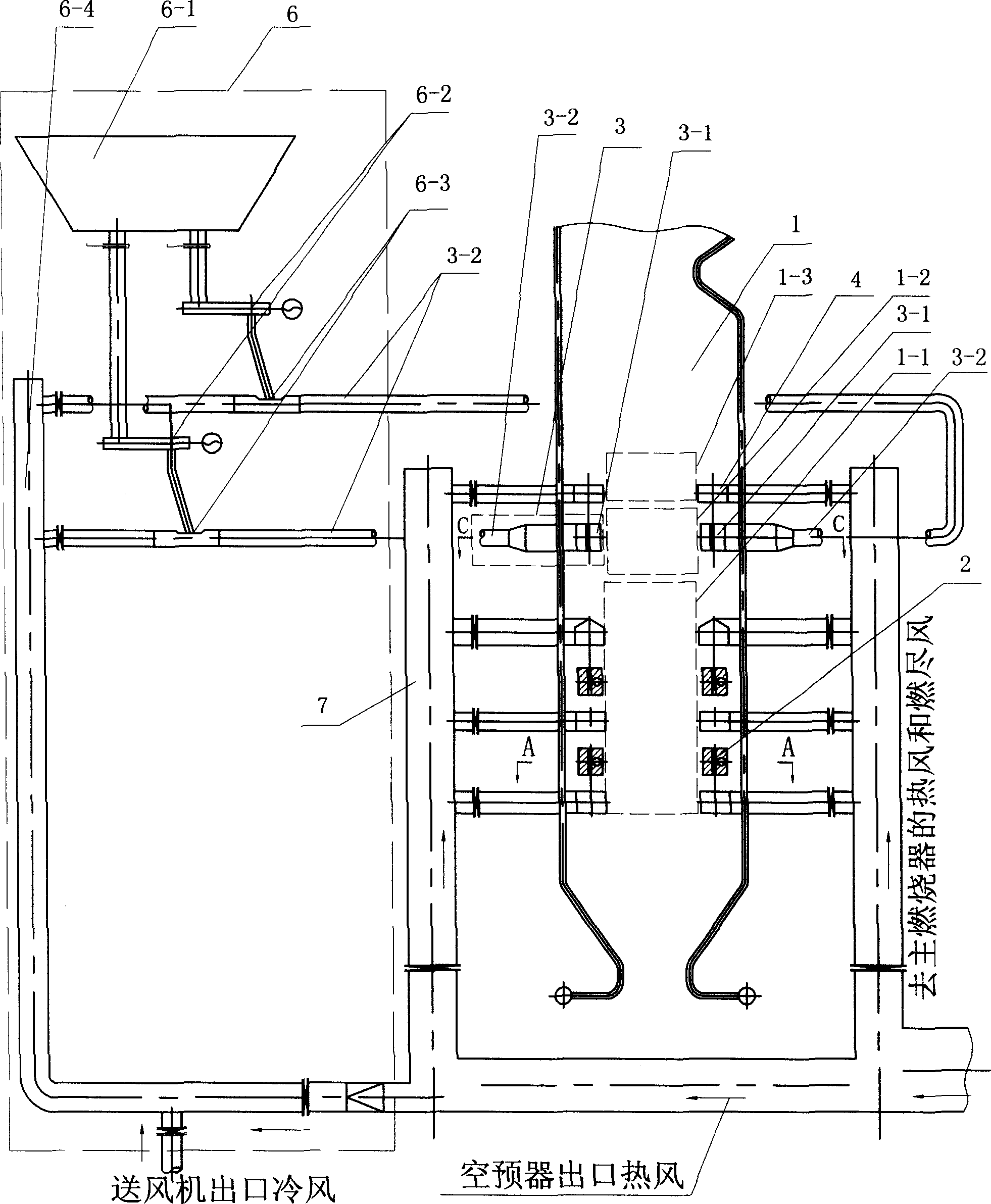

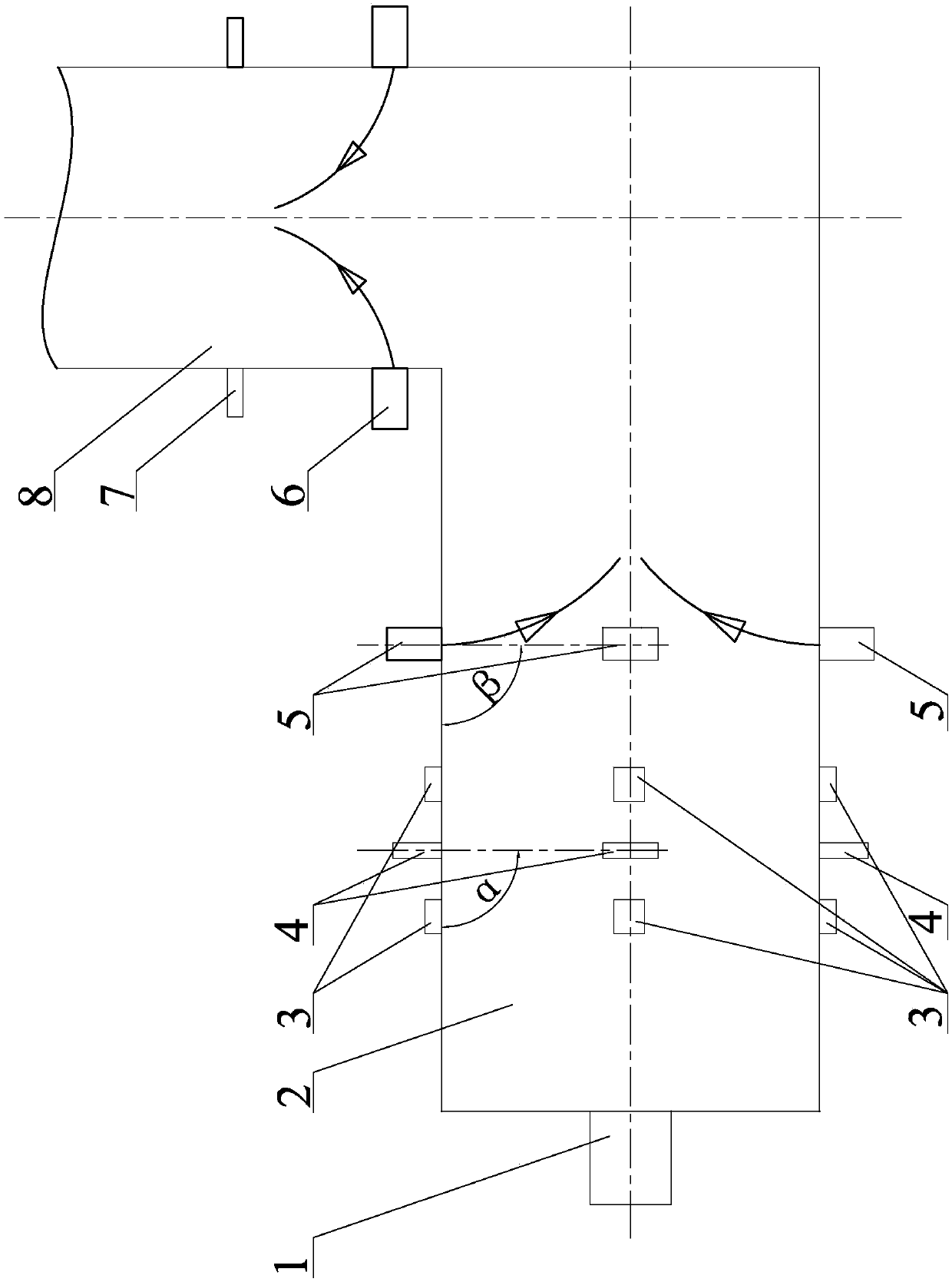

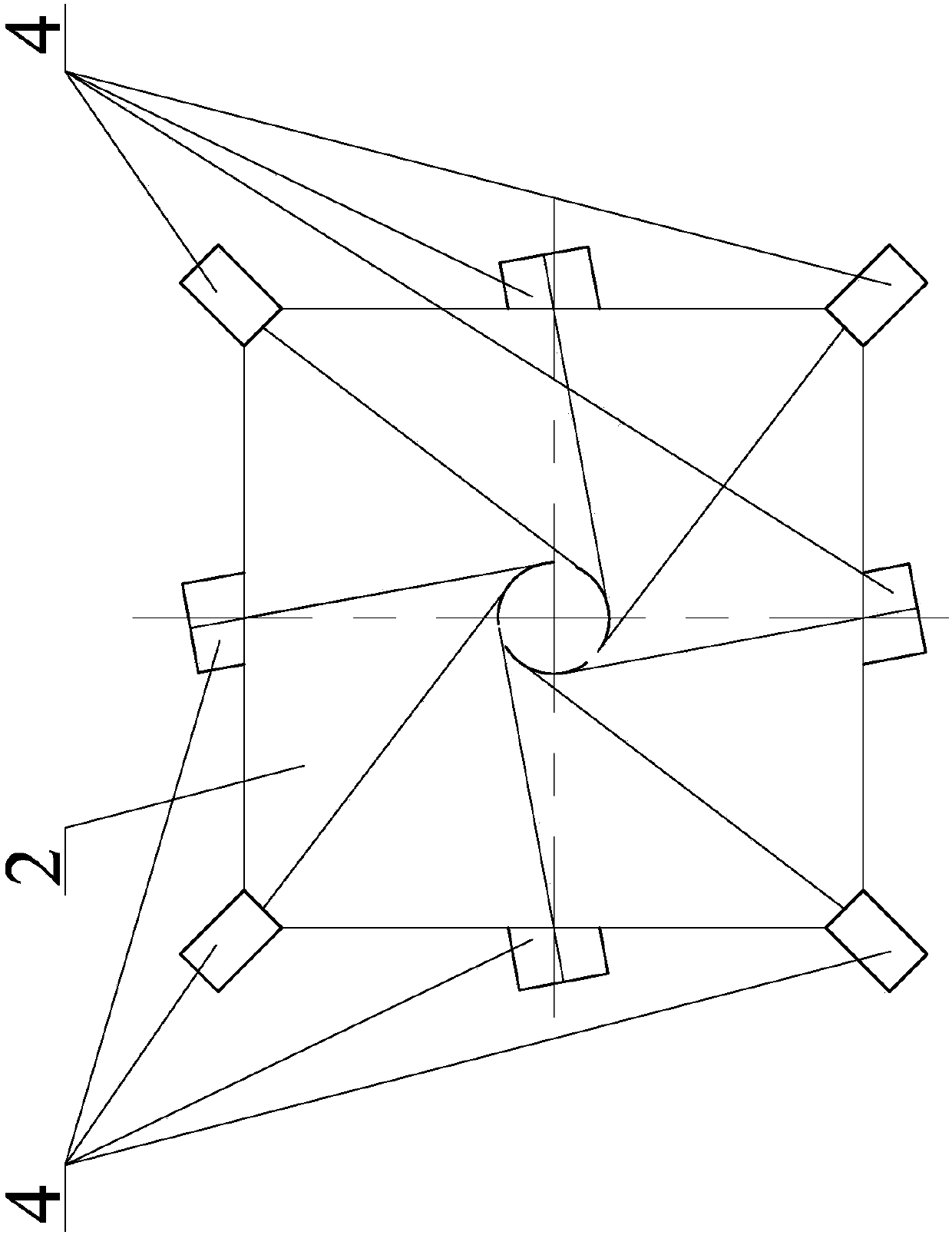

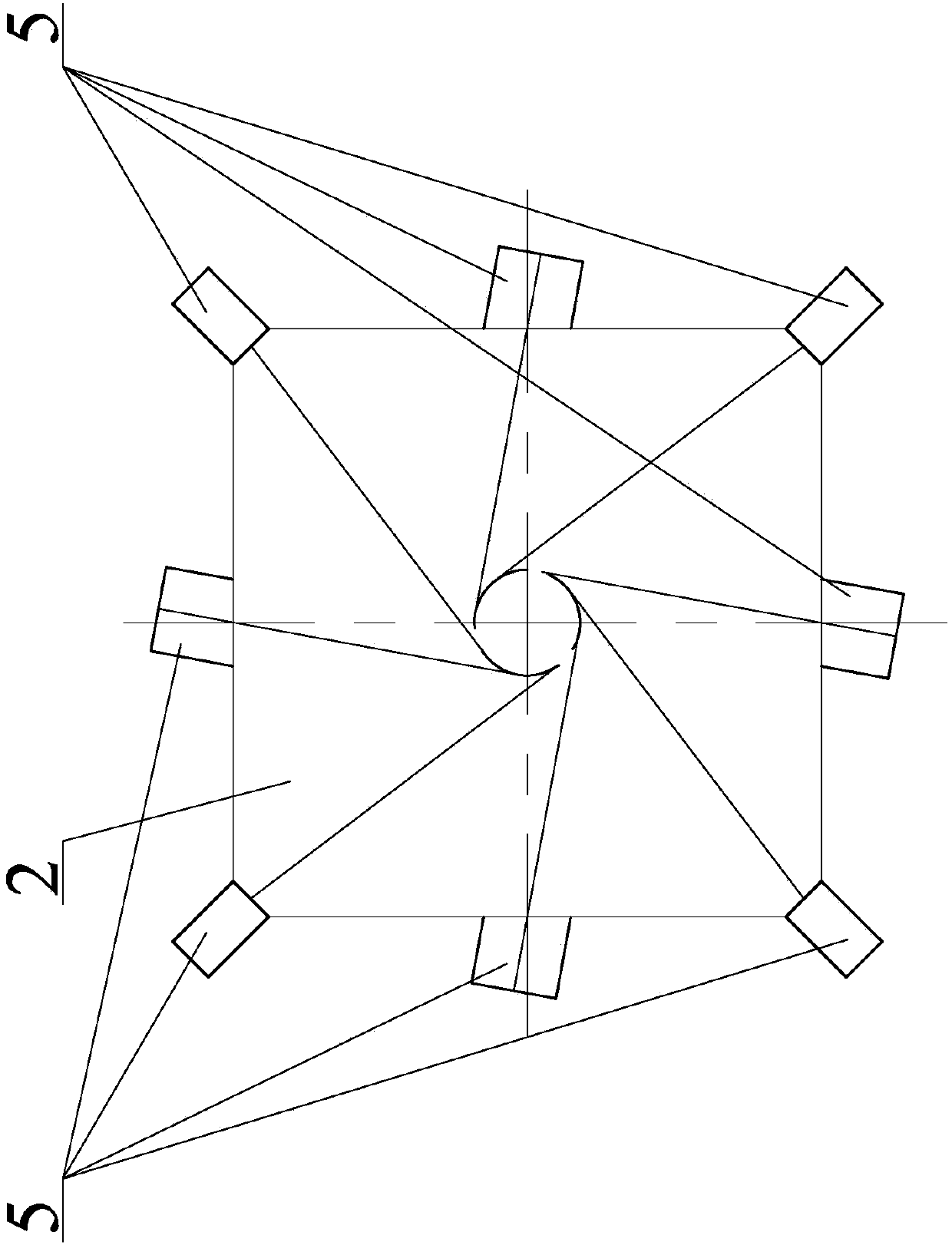

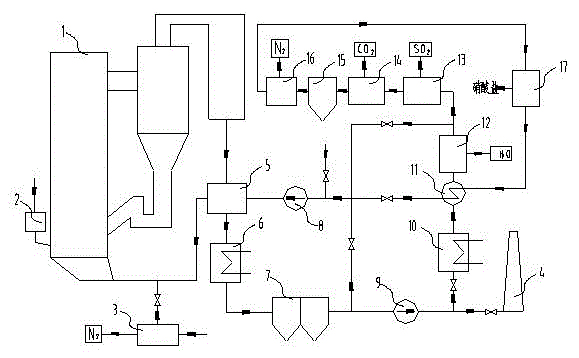

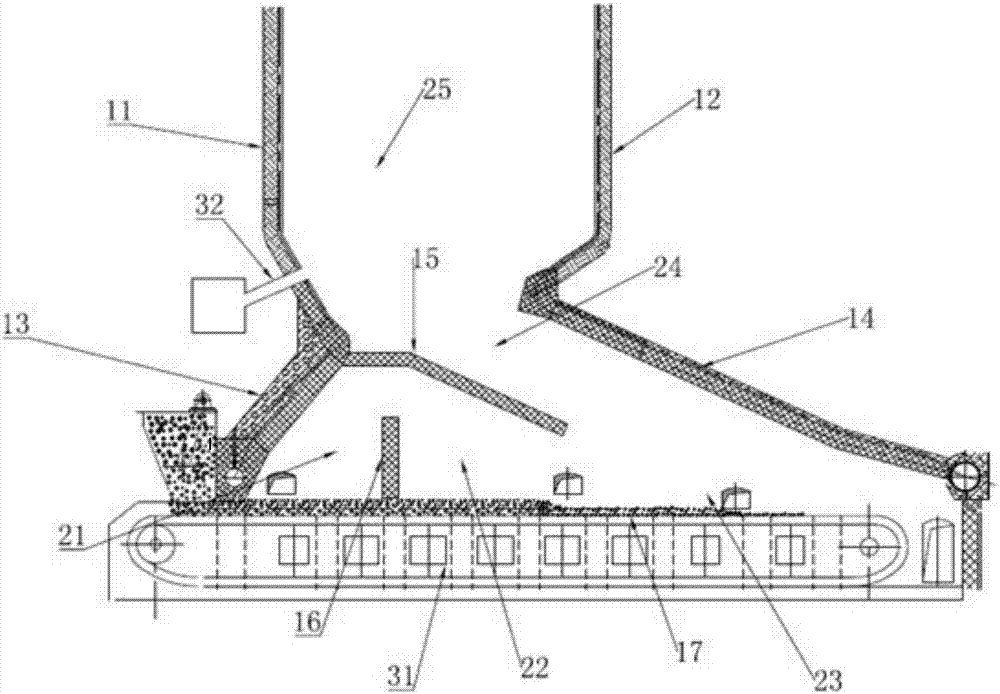

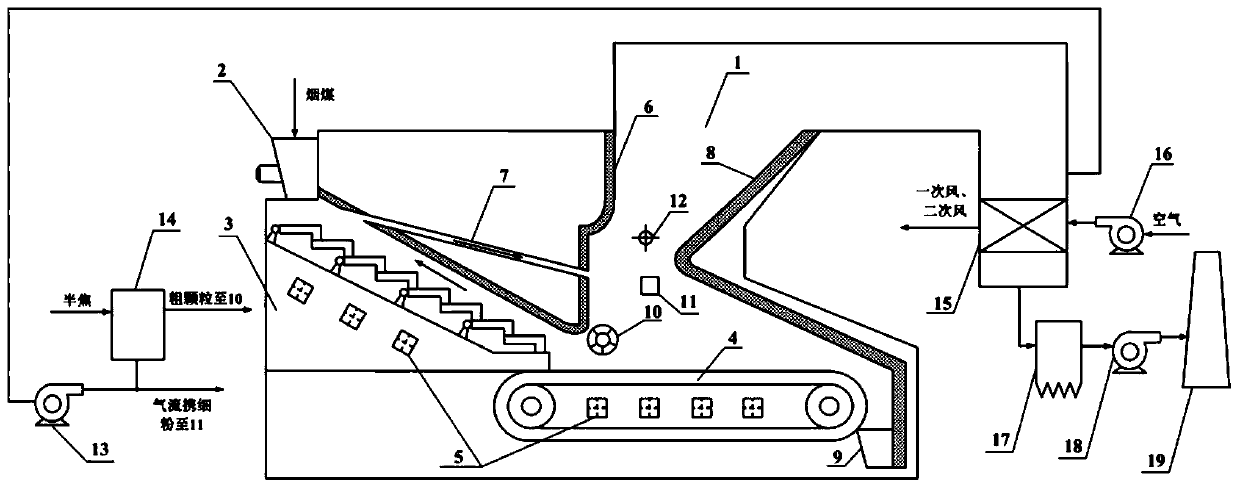

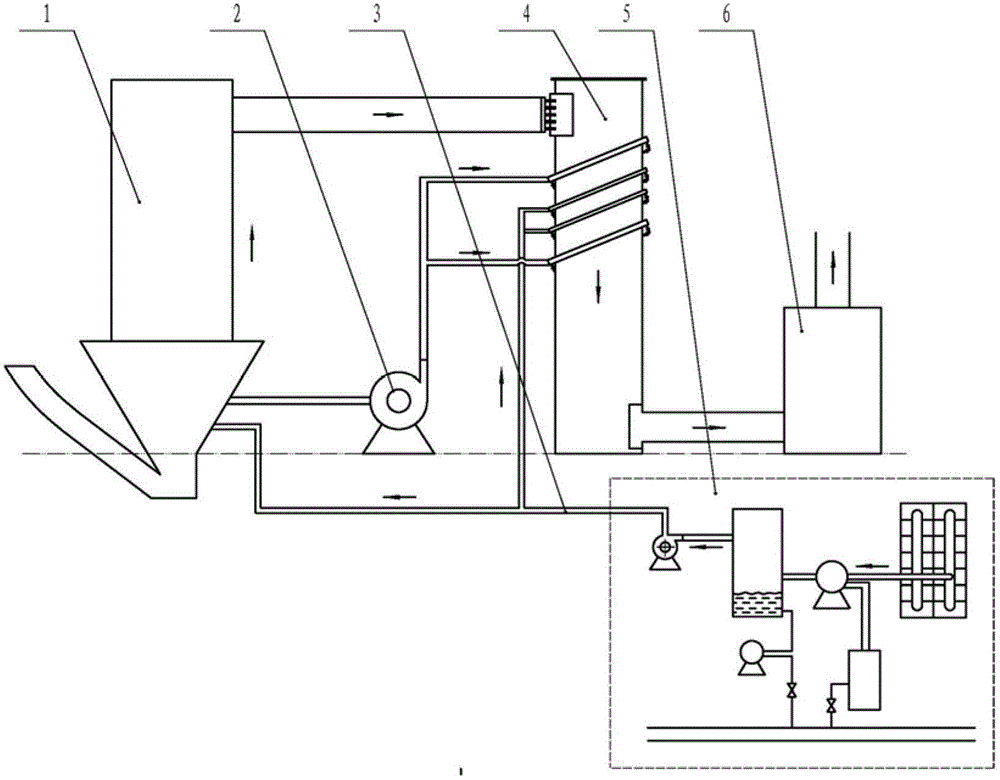

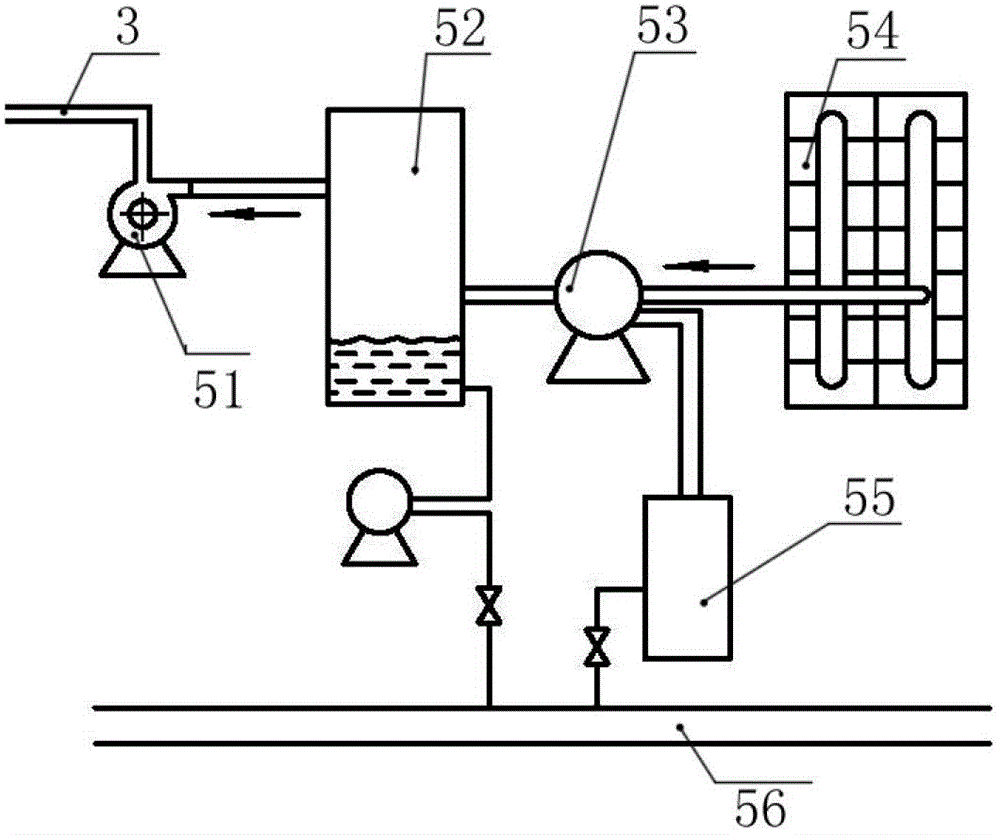

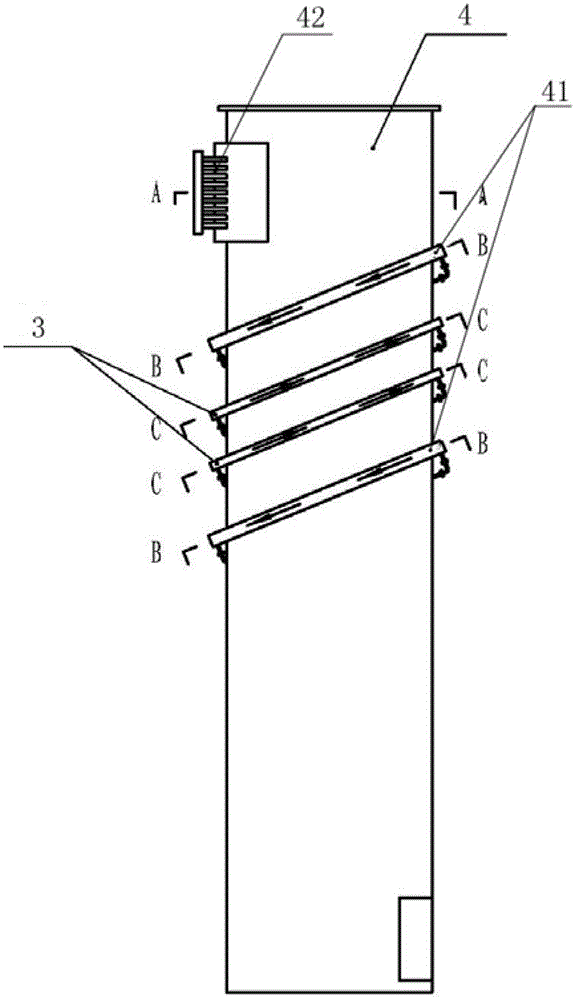

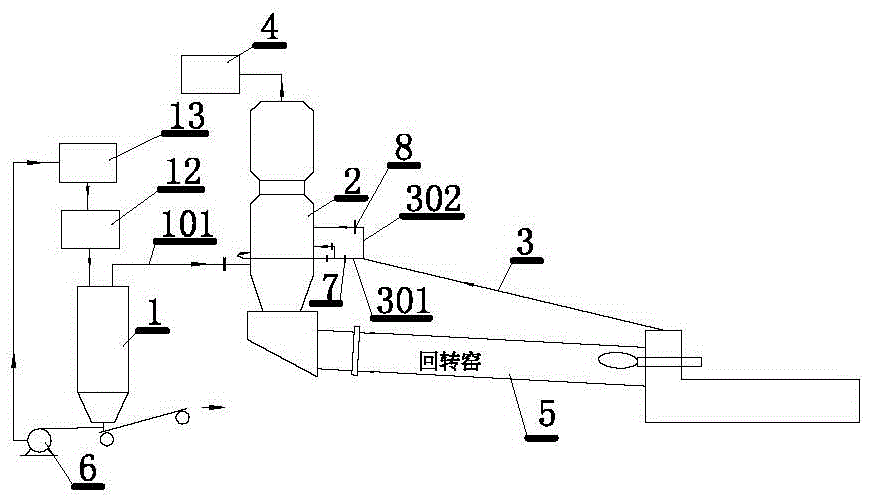

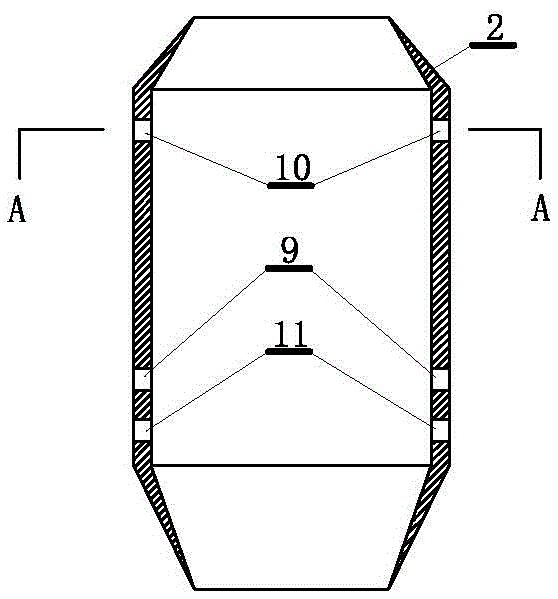

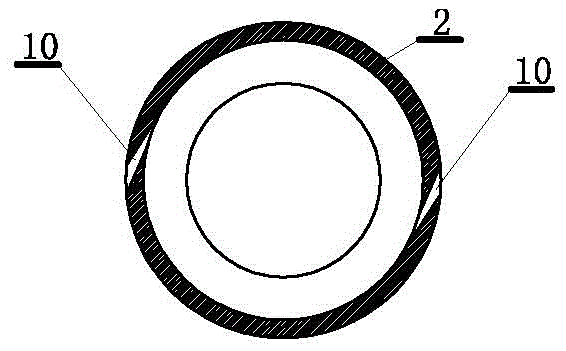

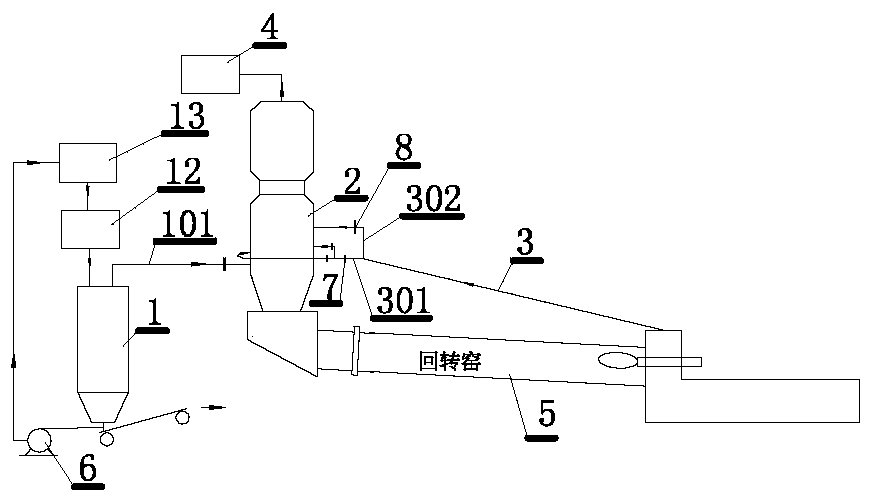

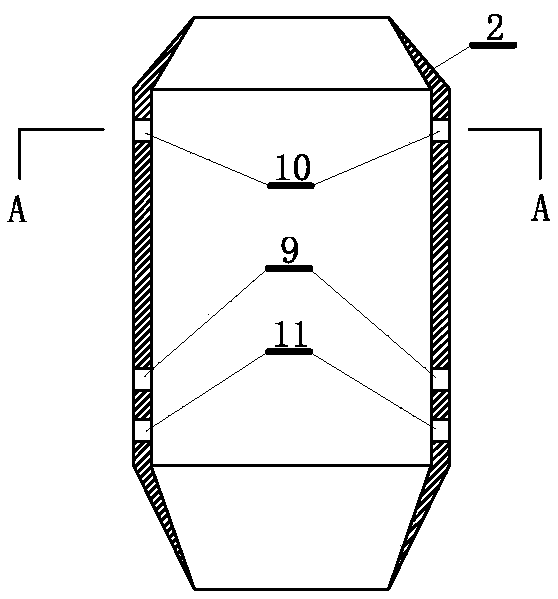

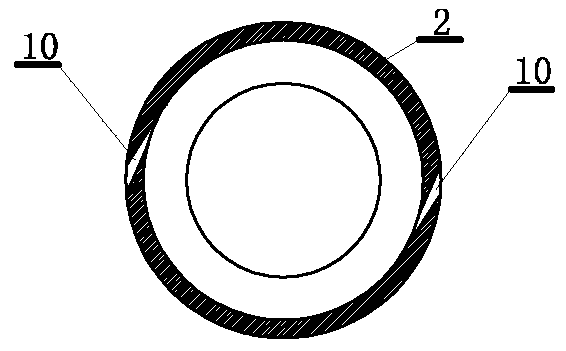

System and blending combustion method for coal-fired power station boiler for large-proportion blending combustion of semi-coke

ActiveCN108151051APromote fireImprove combustion characteristicsLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFlue gasEngineering

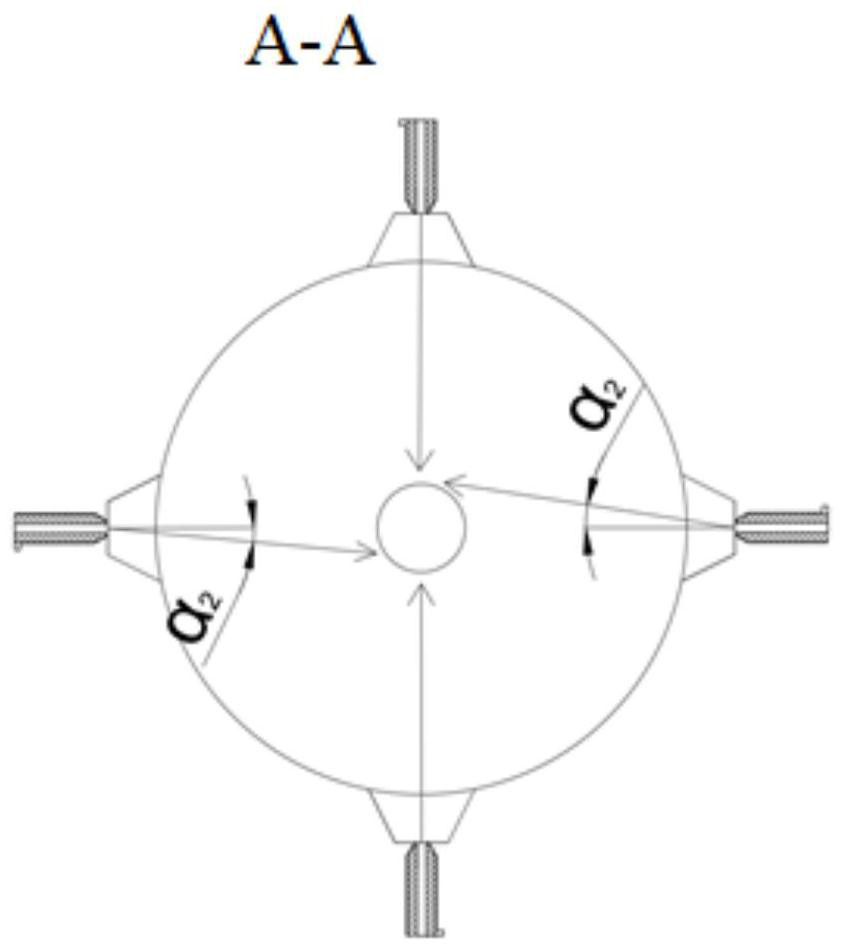

The invention relates to a system and a blending combustion method for a coal-fired power station boiler for large-proportion blending combustion of semi-coke. According to the system and the blendingcombustion method, the problems that the low-volatile semi-coke fuel is difficult to fire, poor in burnout performance and high in NOx emission during combustion are solved; optimization of a pulverizing system, dense-dilute regional combustion of semi-coke fuel, in-furnace layered blending combustion of the semi-coke and bituminous coal, pure oxygen over fire air arrangement and cold energy comprehensive utilization are comprehensively considered; a four-corner tangential combustion mode is adopted, a boiler hearth five-zone combustion environment is built, and a power station boiler systemfor large-proportion blending combustion of the semi-coke is developed, so that the proportion of blending combustion of the semi-coke is larger than or equal to 45%; low NOx emission of an outlet ofa hearth is realized while high-efficiency combustion of the semi-coke is realized; and low-temperature O2 and low-temperature N2 which are close to 0 DEG C and are obtained by air separation and obtained through an air-temperature type gasifier are used for realizing deep condensation of desulfurized clean flue gas, so that water in the clean flue gas is reduced to the maximum degree, corrosion of a chimney is reduced, white smoke is also eliminated, and visual pollution around a power station is reduced.

Owner:XI AN JIAOTONG UNIV

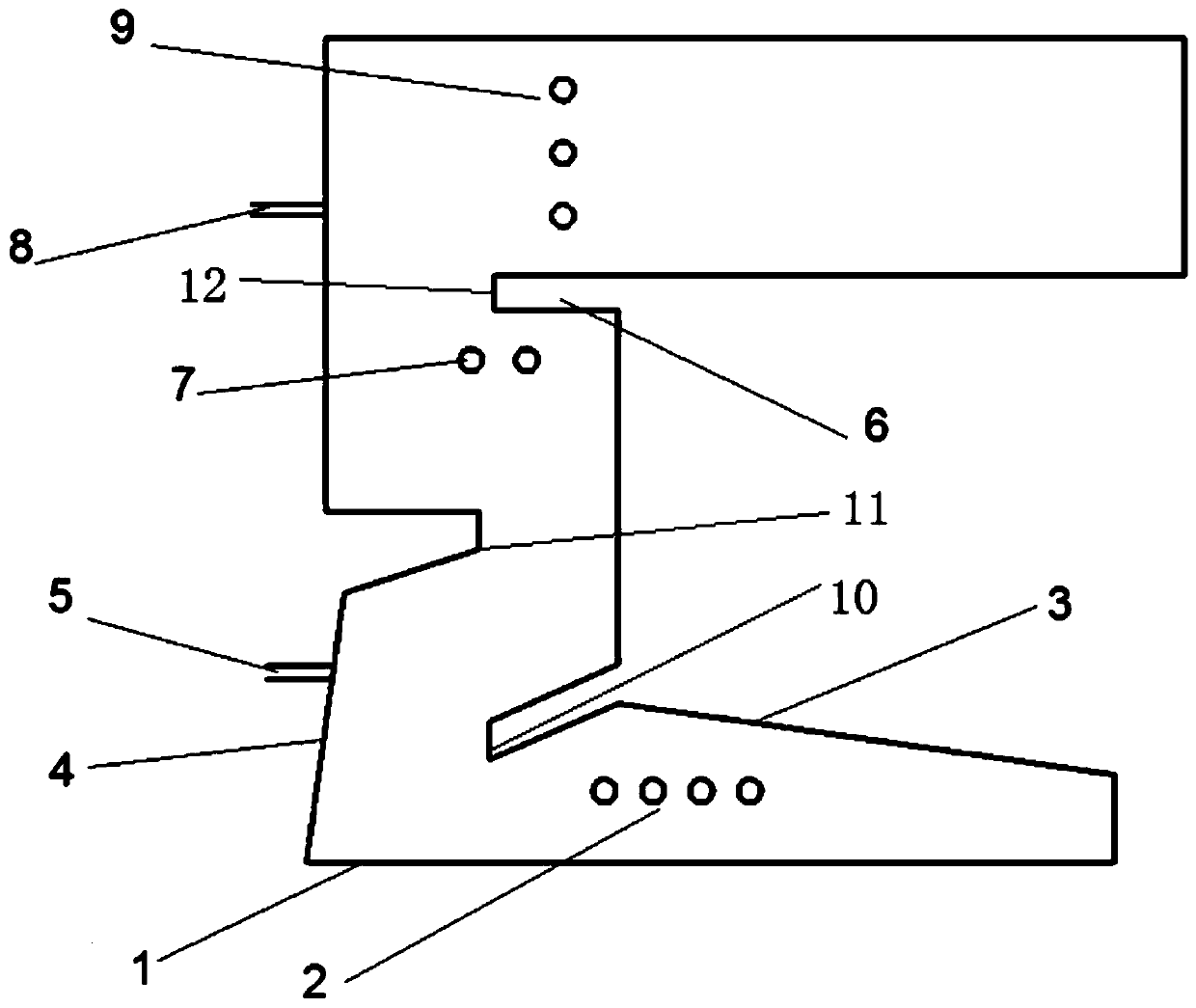

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

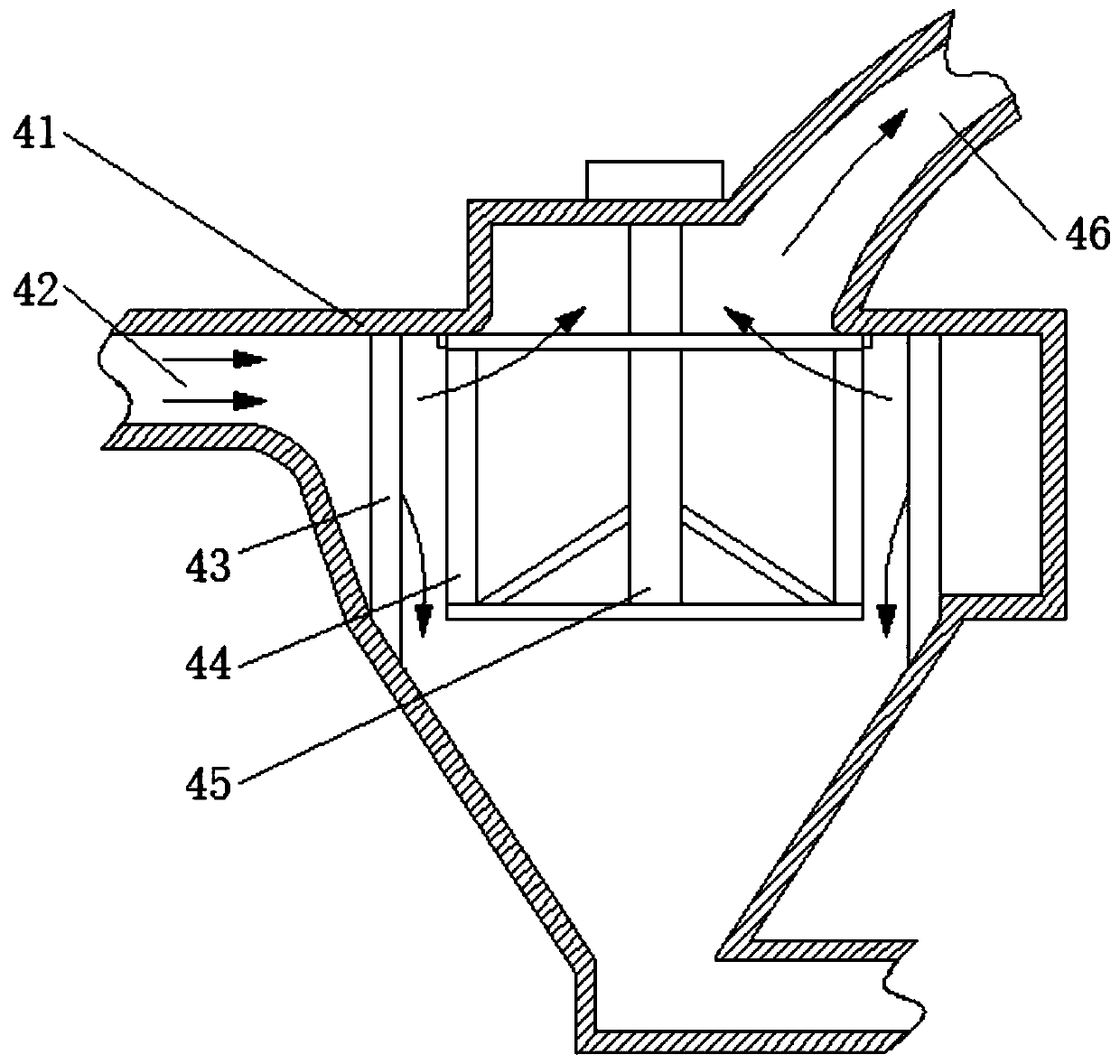

Medical waste incinerator applied with oxygen-enriched combustion technology

ActiveCN104006391AAvoid low temperatureBurn completelyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberCombustible gas

The invention discloses a medical waste incinerator applied with the oxygen-enriched combustion technology, and belongs to the field of environmental-friendly and energy-saving devices. The medical waste incinerator comprises an incinerator body, a second combustion chamber, a combustion air fan, an oxygen-enriched air supply system and a smoke tail processing system. Combustible components of medical waste are decomposed into combustible gas (smoke) in the incinerator body, and combustible gas enters a second combustion chamber body and flows downwards; the combustion air fan delivers combustion air into the incinerator body and the second combustion chamber body; the oxygen-enriched air supply system is used for generating oxygen-enriched gas and leading the oxygen-enriched gas into the second combustion chamber body; the smoke is contacted with the common combustion air and the oxygen-enriched gas which enters into the second combustion chamber respectively, turbulence and perturbation are formed in a main combustion zone by the smoke, and therefore the fact that waste gas burns out is facilitated. According to the medical waste incinerator applied with the oxygen-enriched combustion technology, the burning temperature of the waste gas of the incinerator is guaranteed to the maximum extent through oxygen-enriched equipment and a secondary air system, the second combustion chamber is facilitated to form turbulent flow, the staying time of the smoke in the second combustion chamber is prolonged, and therefore dioxin is decomposed.

Owner:路宁 +1

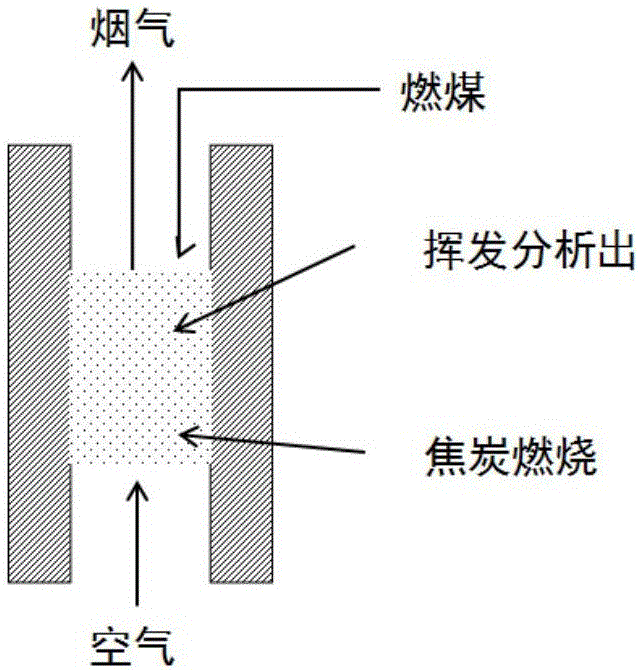

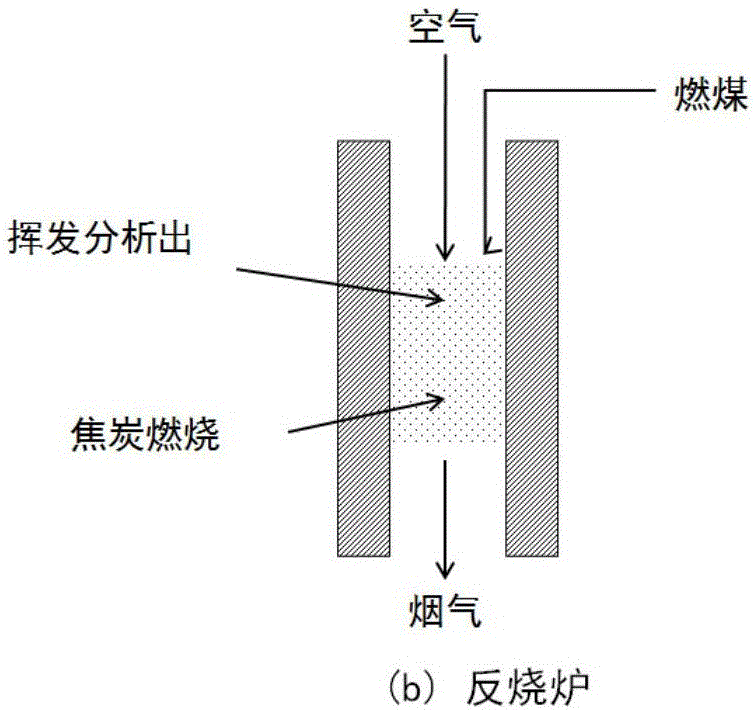

Stationary bed boiler preheated vertically and burnt sectionally at low temperature

ActiveCN103791486AImprove combustion thermal efficiencyImprove coal utilizationSolid fuel combustionCombustion apparatusSlagEngineering

The invention relates to a stationary bed boiler preheated vertically and burnt sectionally at a low temperature. A vertically-preheating and sectional low-temperature burning method is utilized. Coal is preheated to approach a burning temperature by a vertical preheating plate before falling into a fire grate and is subjected to destructive distillation, main burning, burning out and cooling after falling on the fire grate, and ash obtained after the coal is burnt out falls into a slag room and discharged by a slag discharging screw. Independent adjustable air blowers are adopted for air supplying in air chambers, so that every area in a coal layer can obtain different air sources optimal in air pressure and air capacity. In every stages from vertical preheating and falling into the fire grate of the coal, the highest temperature of the coal layer is controlled to be not over 1100 DEG C, ash softening is avoided during the whole process of burning, good ventilate performance of the coal layer is guaranteed throughout, and burning out of fuel is ensured. Burning heat efficiency of the stationary bed boiler preheated vertically and burnt sectionally at the low temperature is greatly improved and is comparable with that of a fluidized bed boiler, and the advantages like low power consumption, less abrasion and simplicity in operation of the stationary bed boiler are reserved.

Owner:GUOHUI ENVIRONMENTAL PROTECTION NEW ENERGY +1

Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

InactiveCN1673619AEmission reductionHigh volatile contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorRoom temperature

The present invention is one burning apparatus for the composite burning of biomass and coal powder and re-burning and denitrifying of biomass. The burning apparatus includes hearth, main coal powder burning area inside the hearth, main nozzles and biomass nozzles installed on the four corner of the hearth. The present invention has the following advantages: lower NOx exhaust rate, burning out of biomass fuel, large scale utilization of biomass, reduced room temperature CO2, and lowered SOx exhaust and simple apparatus structure.

Owner:HARBIN INST OF TECH

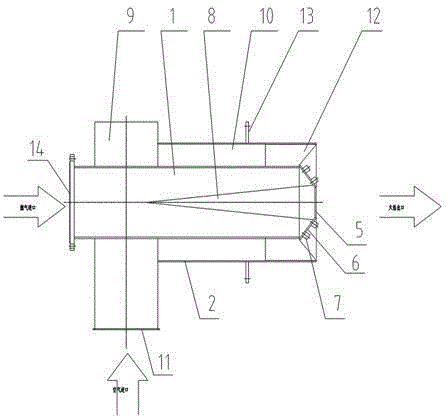

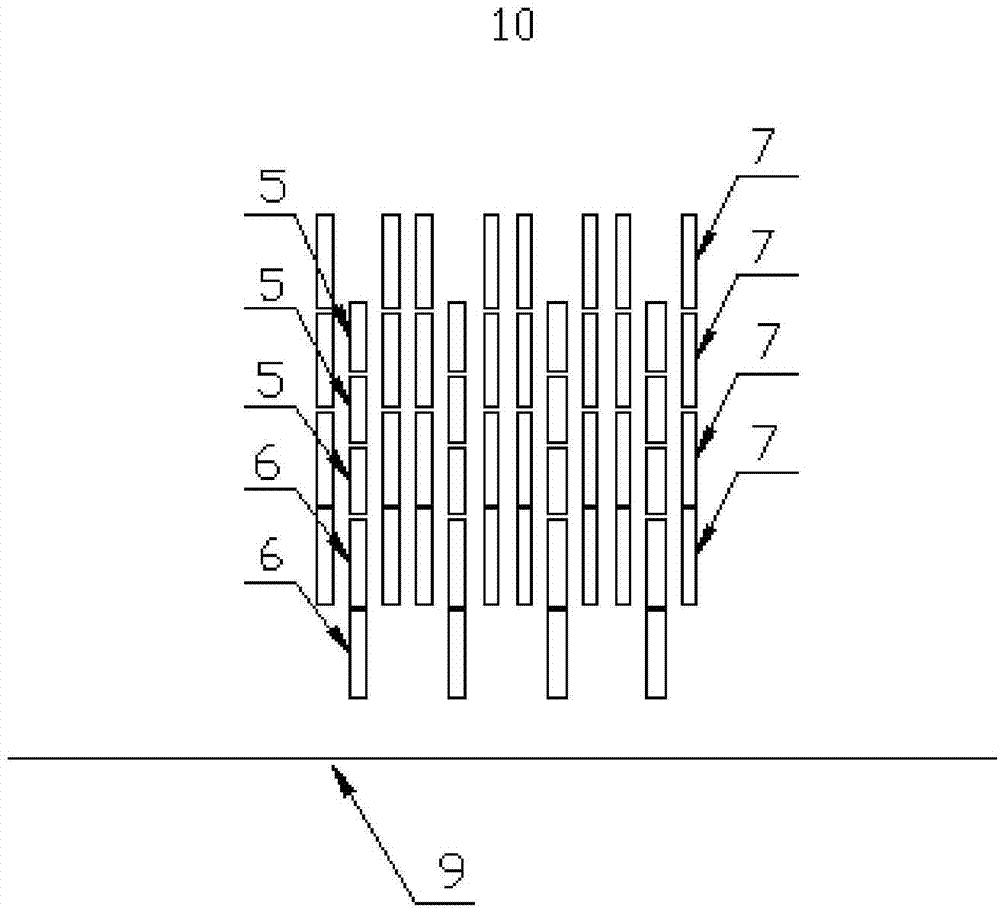

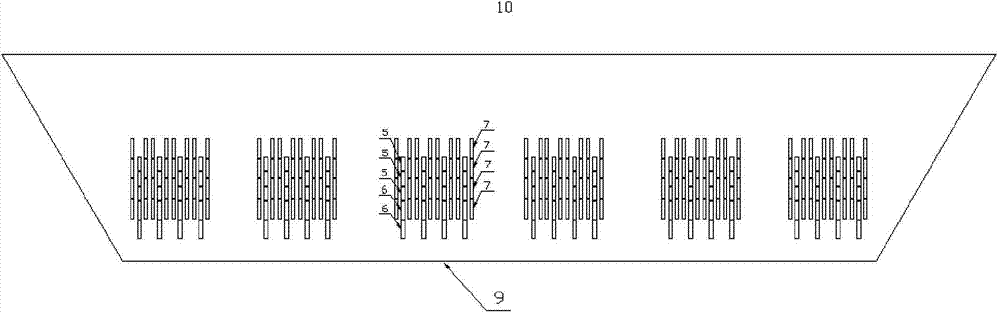

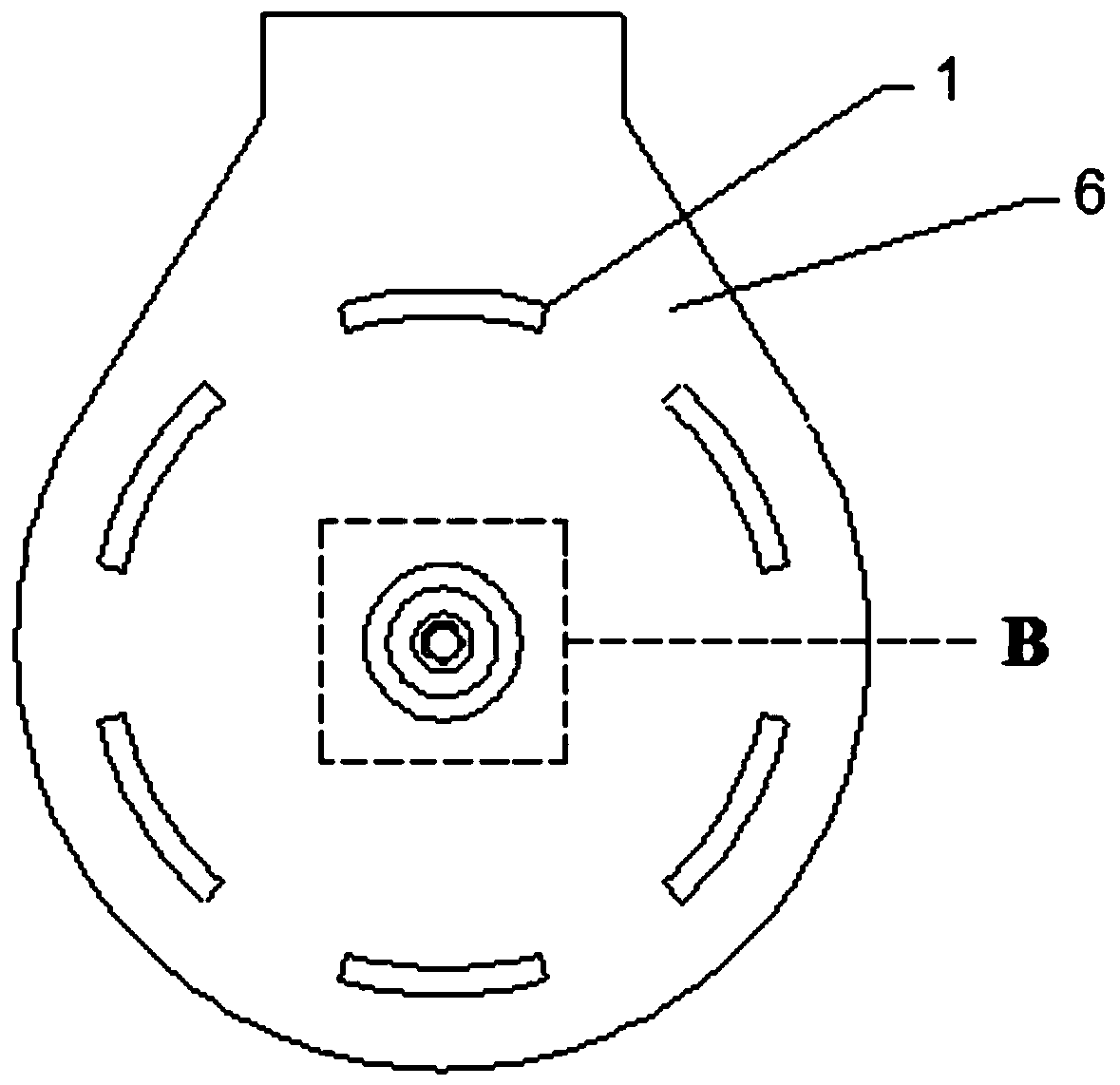

Biomass gas burner

The invention discloses a biomass gas burner. The biomass gas burner comprises a gas pipe (1) located at the axial center, an air pipe (2) arranged outside the gas pipe (1) in a sleeving mode, an ignition device (3) and a flame detection device (4), wherein a round sealing plate (5) with the front diameter smaller than the gas pipe (1) and a conical surface (6) connecting the front end edge of a pipe body with the round sealing plate (5) are arranged on the front end face of the gas pipe (1), and two circles of gas distribution nozzles (7) perpendicular to the conical surface (6) are arranged on the conical surface (6); a pressurization cylinder (8) is arranged in the gas pipe (1), and the ignition device (3) and the flame detection device (4) penetrate through the air pipe (2) and extend to the front end of the air pipe (2). The biomass gas burner has the beneficial effects that biomass gas is separated through the nozzles after being pressurized primarily, the pressure head of biogas gas is stable, flow balancing is achieved, and the diameter and length of a flame are guaranteed; burning is complete and sufficient, and heat efficiency is high.

Owner:广东宝杰环保科技有限公司

Method and device capable of inhibiting refuse incineration from generating dioxins

The invention relates to a method and a device capable of inhibiting refuse incineration from generating dioxins, which belongs to the field of environmental protection. The device is mainly characterized in that the hearth of the refuse incinerator is communicated with the hearth of a secondary heating furnace through a flue, a flue partition wall is arranged in the hearth of the secondary heating furnace, and a temperature measuring point is arranged in front of the furnace. The method mainly comprises the following steps: when being started or shut down, the refuse incinerator combusts part of coal, so that the furnace temperature is kept above 800 DEG C; fume, which is generated in the process of refuse incineration, directly enters the hearth of the secondary heating furnace through the flue to be combusted for the second time, under the monitoring control of the temperature measuring point, the furnace temperature is kept at 1100-1300 DEG C all the time by adjusting the fuel usage, and the fume can be stayed for more than 3 seconds, so that the dioxins in the fume are completely decomposed; and after being subject to secondary heating, the fume enters the convective region from the hearth to be processed in a convective heat exchange mode, and is discharged through the vertical shaft flue and the fume outlet on the tail of the vertical shaft flue. The invention has the advantages of obvious effects on inhibiting and eliminating dioxins, low operating cost and simple technological operation.

Owner:朴显泽 +2

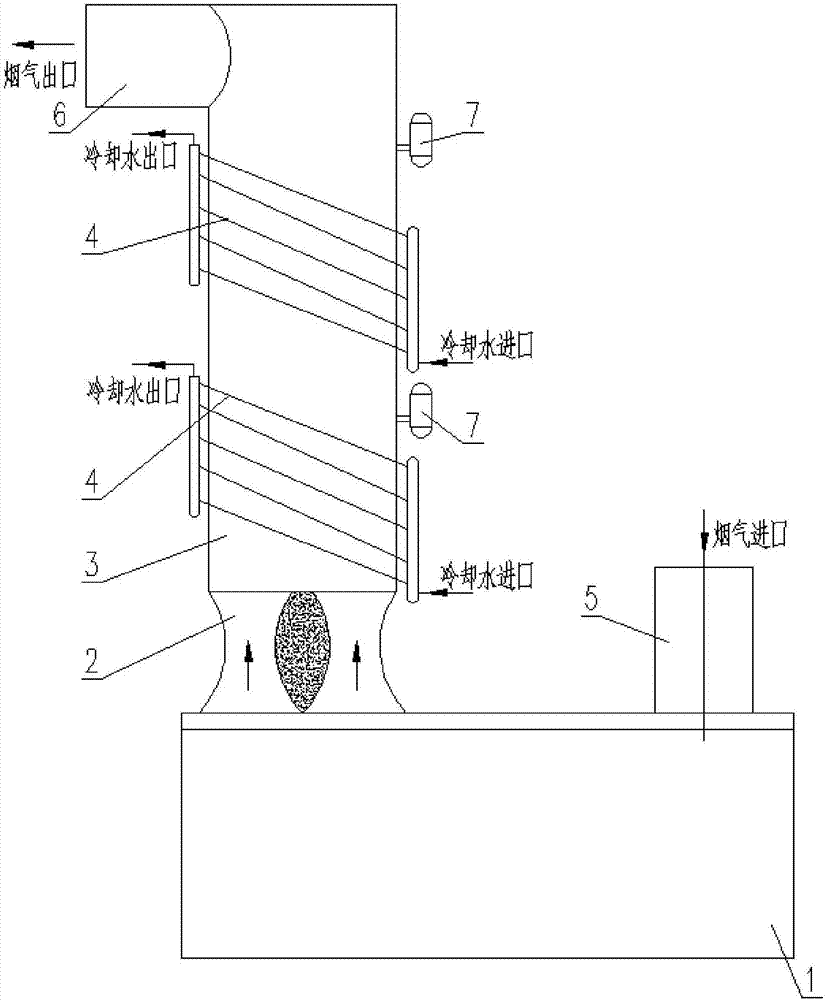

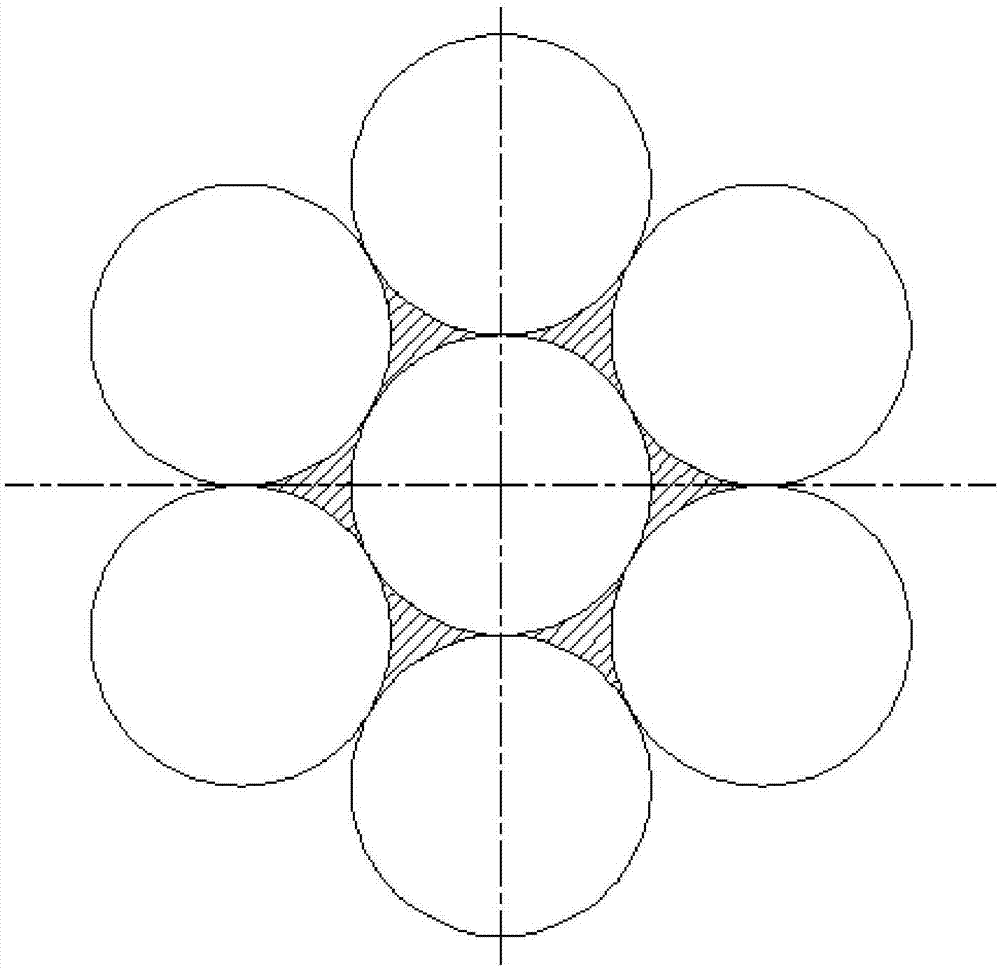

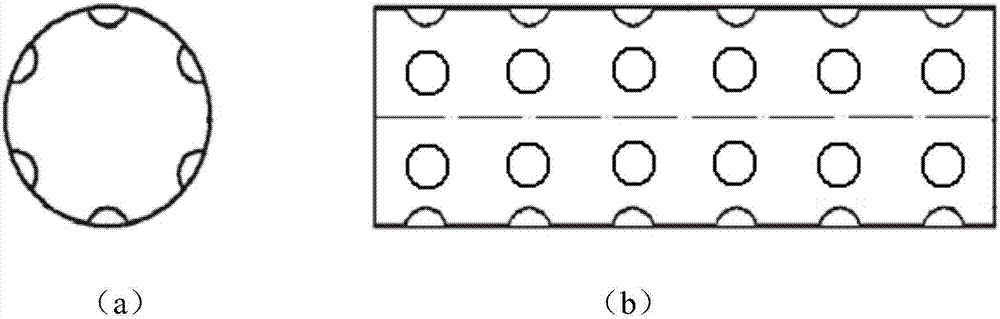

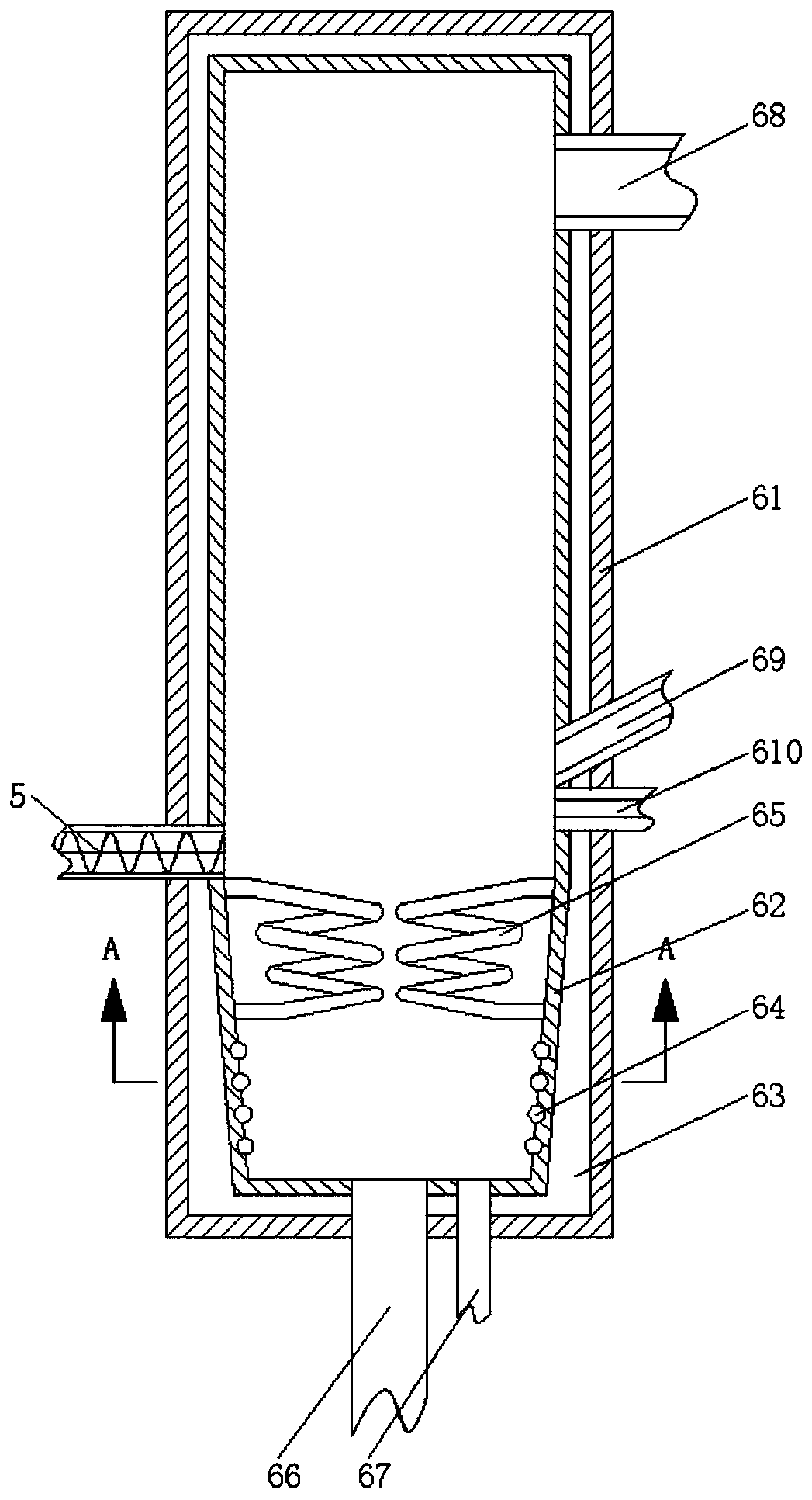

Quenching waste heat boiler

PendingCN108006686AGuaranteed current sharingCooling effectCombustion technology mitigationSolid removalCombustionPlate heat exchanger

The invention discloses a quenching waste heat boiler and belongs to the field of environmental protection. The quenching waste heat boiler comprises a flue gas inlet pipe, a combustion settling chamber, a quenching heat exchanger and a flue gas outlet pipe which are sequentially connected in the flowing direction of flue gas. The quenching heat exchanger vertically communicates with the top of the combustion settling chamber. The flue gas inlet pipe and the quenching heat exchanger are arranged at the same side relative to the combustion settling chamber. The bottom, communicating with the combustion settling chamber, of the quenching heat exchanger is provided with at least one Laval jet tube. By adoption of the quenching waste heat boiler, the high-temperature flue gas of 800 DEG C canbe quickly cooled to 200 DEG C or below within 2 seconds, dioxin synthesis is restrained and meanwhile flue gas waste heat can be recovered.

Owner:CISDI ENG CO LTD +1

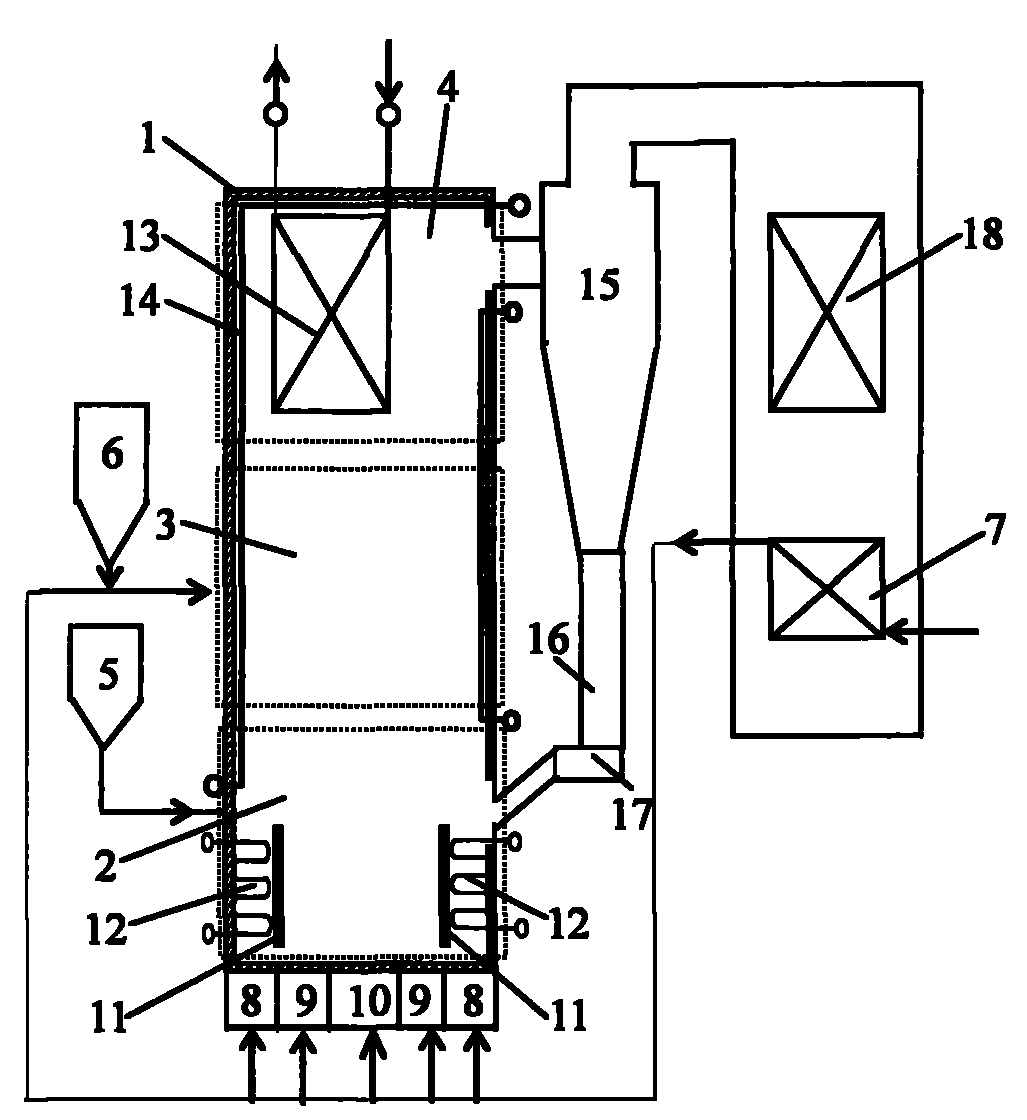

Staged high-temperature combustion circulating fluidized bed system and combustion method

InactiveCN101806451AEfficient use ofImprove gasification efficiencyFluidized bed combustionApparatus for fluidised bed combustionCombustion systemThree stage

The invention discloses a staged high-temperature combustion circulating fluidized bed system and a combustion method. The method and the system adopt a staged combustion technology. The system is divided into three stages along the hearth height direction and comprises a lower-part internal circulating fluidized bed combustion stage, a middle high-temperature suspension firing stage and an upper-part cooling stage; fuel (coal or organic waste) with a larger grain diameter is sent into the lower-part internal circulating fluidized bed combustion stage to combust at the temperature of 800-900 DEG C; coal with a smaller grain diameter is sent into the middle high-temperature suspension firing stage to combust at the temperature of 1000-1300 DEG C; and a screen-type heating surface is distributed on the upper part of a hearth at the hearth outlet temperature of 800-900 DEG C. The staged high-temperature combustion system of the invention can burn the coal and the organic waste, can carry out coal gasification, can improve combustion efficiency or gasification efficiency, also can solve the discharge problem of harmful substances, such as Dioxin and the like in the combustion process of the organic waste and has wide application prospect.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

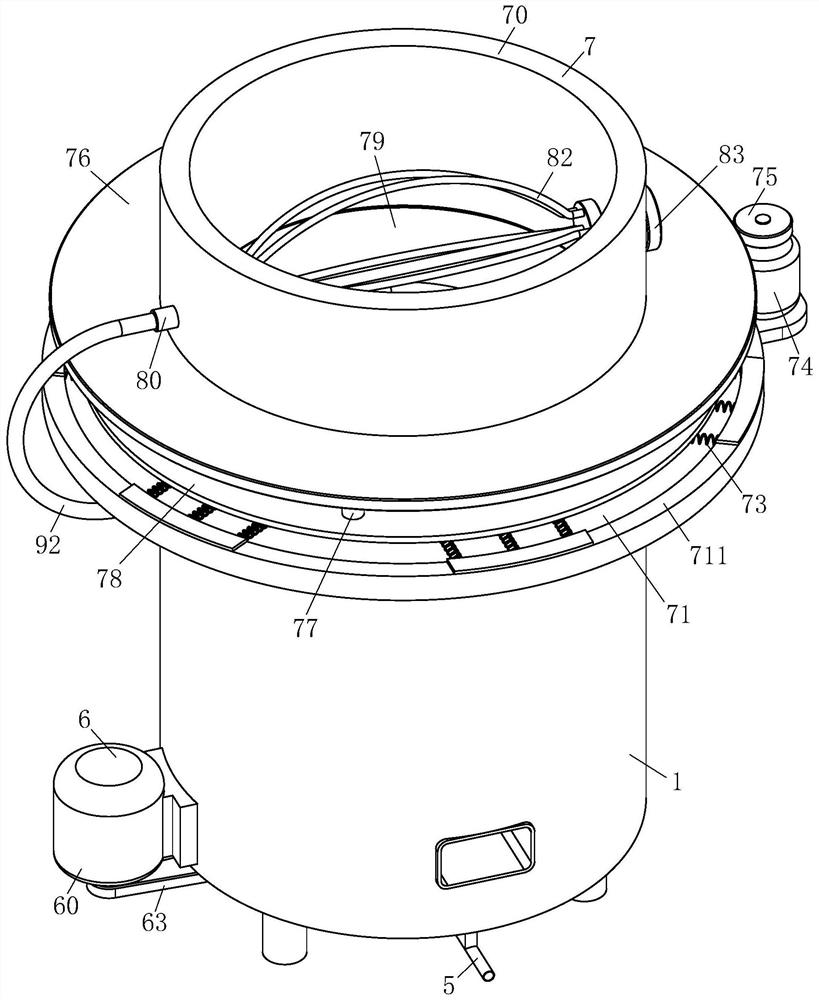

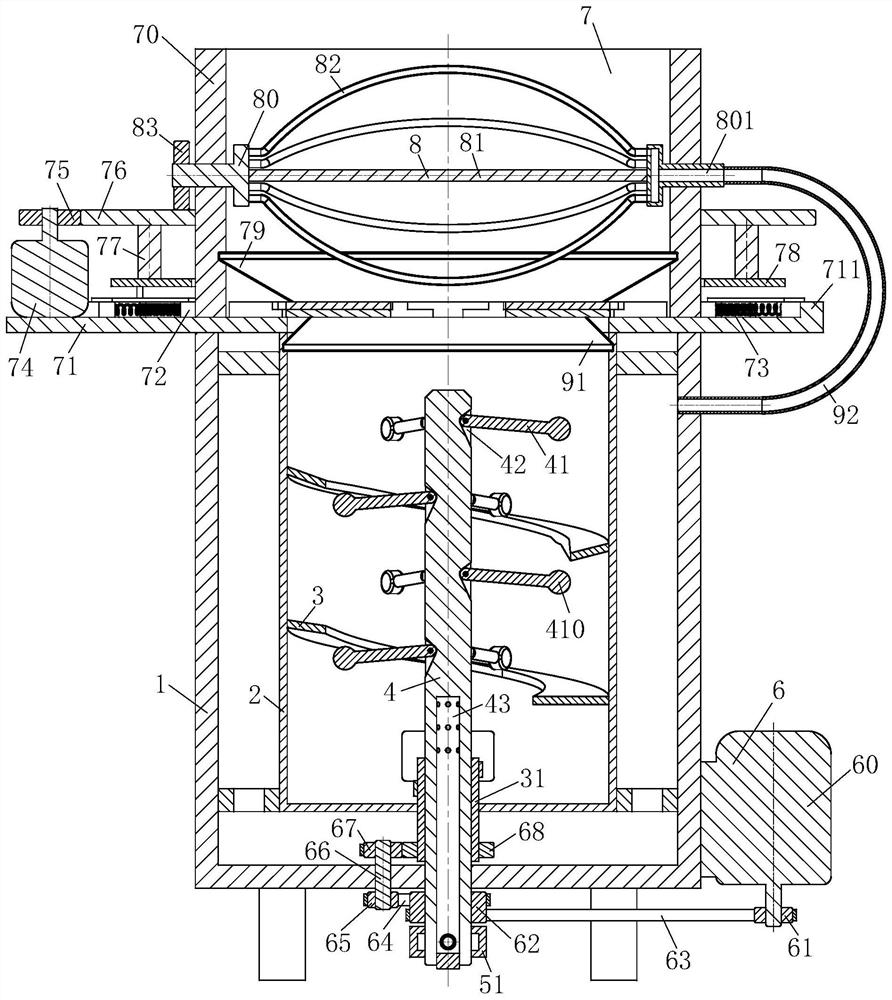

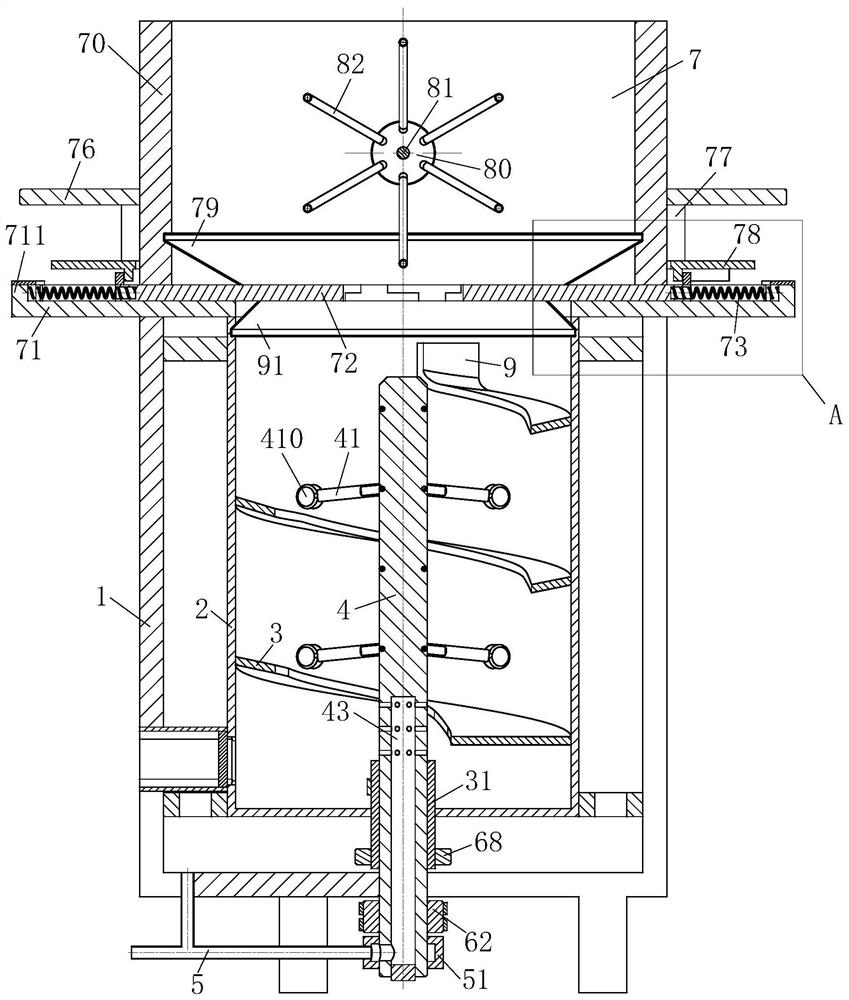

Centrifugal dispersion type efficient garbage incinerator

InactiveCN112032739AImprove incineration efficiencyExtension of timeIncinerator apparatusEngineeringCentrifugal force

The invention belongs to the technical field of garbage environment-friendly treatment equipment, and particularly relates to a centrifugal dispersion type efficient garbage incinerator which comprises an incinerator body, an incinerator container, a spiral plate, a rotating sleeve, a first rotating shaft, a supporting rod, an air pipe, a rotating air connector, a power part and a feeding part. Supporting rods are driven to rotate through the first rotating shaft, then garbage falling onto a supporting layer composed of the supporting rods is driven to rotate, the garbage is dispersed under the action of centrifugal force generated during rotation, the contact area between the garbage and air is increased, sufficient incineration of the garbage is facilitated, and then garbage incinerationefficiency is improved; and meanwhile, the rotating sleeve drives the spiral plate to rotate, the rotating spiral plate drives the garbage which falls at the bottom and is not completely burnt out tospirally ascend along the spiral plate, then the garbage which is not completely burnt out is prevented from being accumulated at the bottom of the incinerator container, then the garbage which is not completely burnt out is incinerated again, and then it is guaranteed that the garbage in the incinerator container is completely burnt out.

Owner:李辉

Horizontal boiler with SNCR and OFA arranged in staggered manner

ActiveCN107606602AEmission reductionComplete restorationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPoor adaptive skills

The invention provides a horizontal boiler with SNCR and OFA arranged in a staggered manner and relates to an industrial boiler. The horizontal boiler with the SNCR and the OFA arranged in the staggered manner aims at solving the problems that a horizontal industrial coal powder boiler in the prior art is high in denitration cost, consequently, the NOx emission amount of an industrial coal powderboiler is high, the coal powder over-fire effect is poor, the adaptive capacity on load changes is poor, and the heat efficiency is low. The horizontal boiler with the SNCR and the OFA arranged in thestaggered manner comprises a combustor, a hearth, an upstream flue, a set of primary amino reducing agent spraying ports, a set of primary over-fire air spraying ports, a set of secondary over-fire air spraying ports, a set of secondary amino reducing agent spraying ports and two sets of temperature sensors; the combustor is installed at the front end of the hearth; the upstream flue is communicated with the top of the rear end of the hearth; the primary amino reducing agent spraying port and the primary over-fire air spraying port are fixedly installed on the side wall, from the front end tothe back end, of the hearth; and the secondary over-fire air spraying port and the secondary amino reducing agent spraying port are sequentially installed on the side wall of the upstream flue from bottom to top. The invention is used in the industrial boiler coal powder combustion field.

Owner:HARBIN INST OF TECH

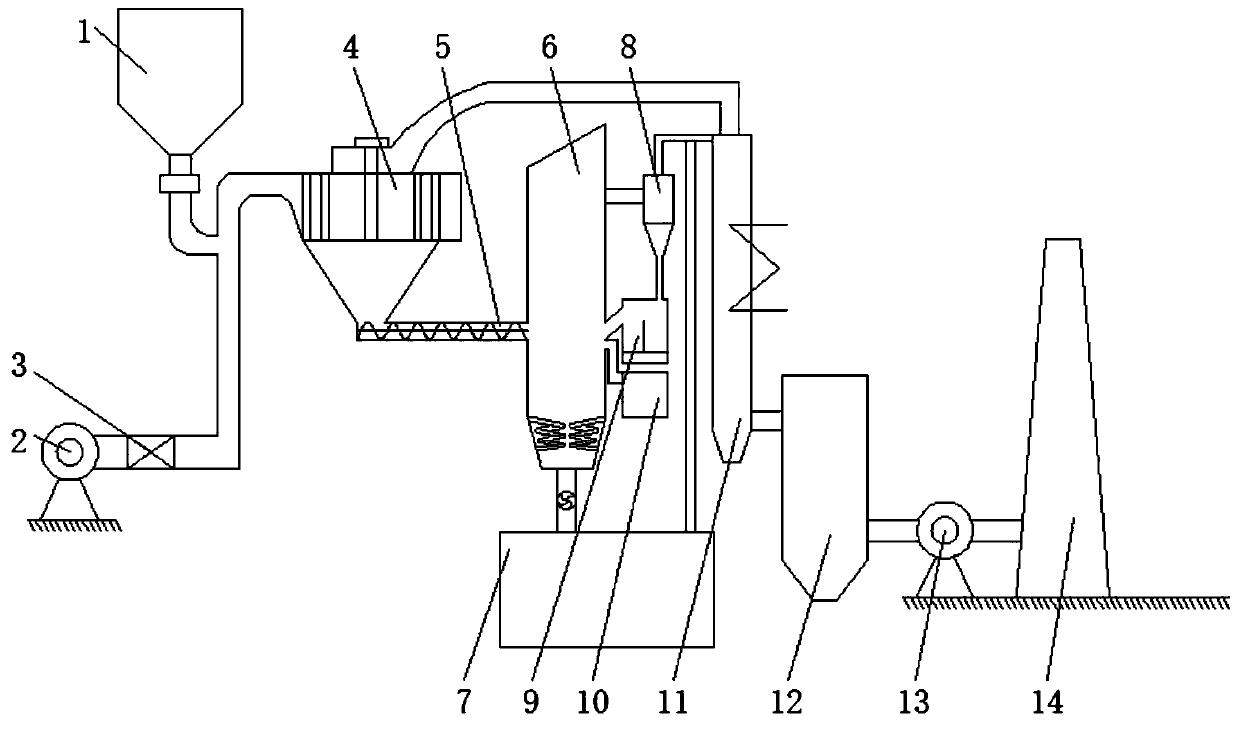

Fly ash fluidized bed combustion decarburizing device

PendingCN110762517AHigh carbon contentCarbon content increased and decreasedFluidized bed combustionGas current separationHearthAir blower

The invention relates to the technical field of fly ash decarburization and discloses a fly ash fluidized bed combustion decarburizing device comprising a fly ash material bin, an air blower, an electric heating device, an air powder concentrator, a spiral feeding machine, a hearth, an ash cooler, a cyclone separator, a material return valve, an air heat exchanger, a dust remover, an induced draftfan and a chimney. According to the differences in the aspects of specific gravity and particle size between carbon not burned out and burned-out carbon in the fly ash, the fly ash is carried by hotair to enter an air powder concentrator to be screened, the large-particle and high-carbon-content fly ash falls into the bottom of the air powder concentrator to undergo a next procedure, so that only a part of fly ash needs to be re-combusted, and the work efficiency of reducing the carbon content of the fly ash is improved; and meanwhile, the carbon content in the fly ash combusted in the hearth is increased, the fly ash in the hearth can be stably combusted to emit a large amount of heat, and the utilization ratio of the fly ash is improved.

Owner:JIANGSU XINFANGYUAN ELECTRIC EQUIP MFG

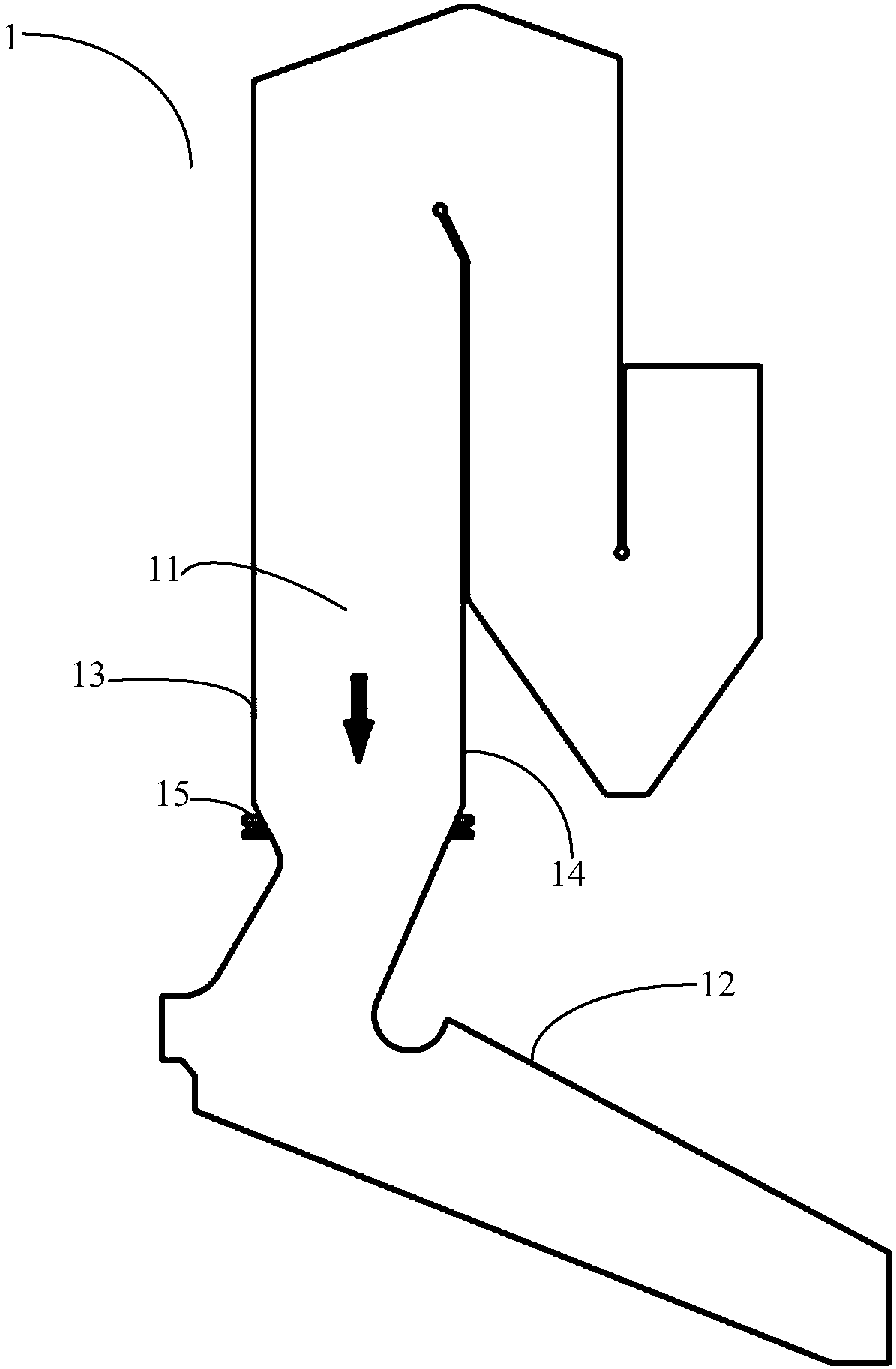

Combustion device of W flame boiler and W flame boiler

InactiveCN104748107AReduce NOx formationDelay mixingLump/pulverulent fuel feeder/distributionGas pipelineCombustion chamber

The invention discloses a combustion device of a W flame boiler and the W flame boiler. The combustion device comprises a pulverized coal pipeline, a pulverized coal concentration separation device, a pulverized coal airflow pipeline and a secondary air pipeline. The pulverized coal airflow pipe comprises a main air pipeline and an air lack pipeline; the tail end of the main air pipeline is provided with a main air spraying opening connected with a combustion chamber, and the tail end of the air lack pipeline is provided with an air lack spraying opening connected with the combustion chamber; the tail end of the secondary air pipeline is provided with a secondary air spraying opening connected with the combustion chamber; and the main air spraying opening, the air lack spraying opening and the secondary air spraying opening are formed in a furnace arch, and the air lack spraying opening is formed between the main air spraying opening and the secondary air spraying opening. The secondary air spraying opening is close to a front wall or a rear wall, and the main air spraying opening is close to a center of the combustion chamber. According to the combustion device of the W flame boiler and the W flame boiler, mixing of main air and secondary air is postponed, and generation of NOx is reduced; burning off of pulverized coal particles is ensured; and the problems that the pulverized coal particles of the W flame boiler are hard to ignite, hard to burn off, prone to scorification, and high in NOx emission are solved.

Owner:YANTAI LONGYUAN POWER TECH

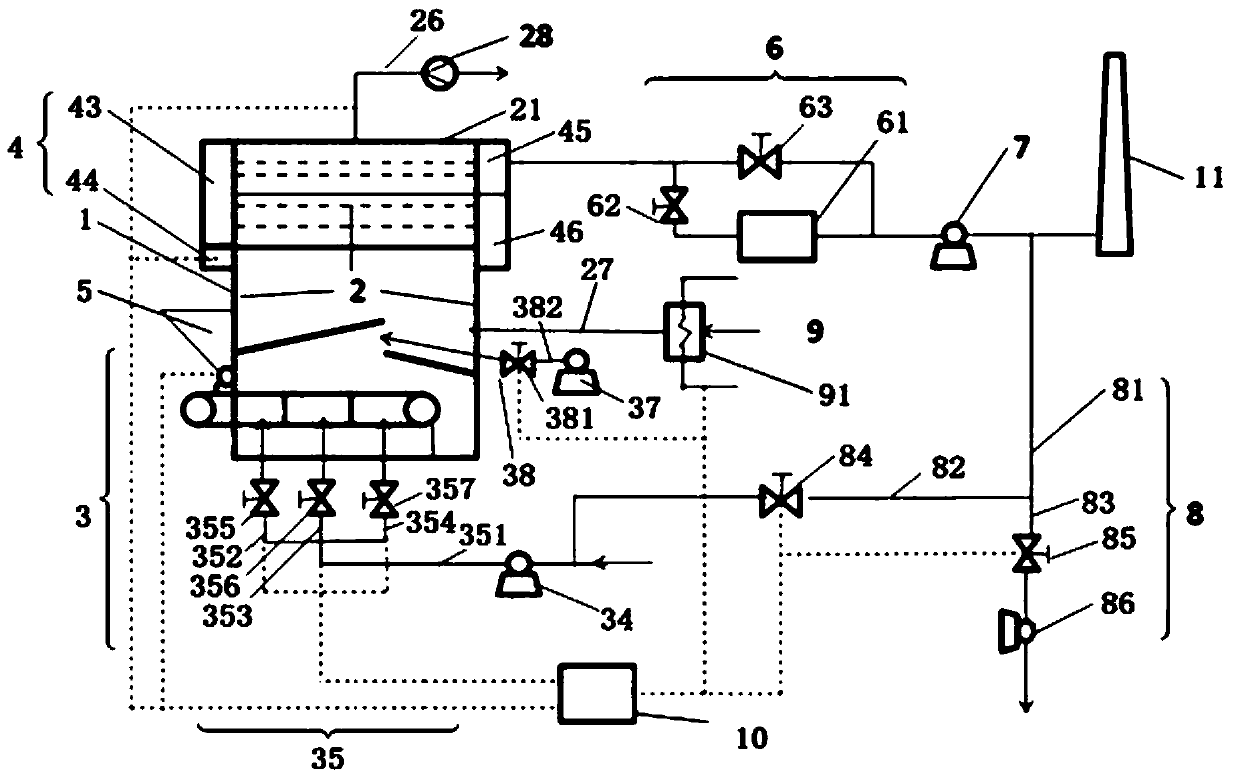

CFB oxygen-enriched combustion smoke near zero emission power generation system

InactiveCN105042610AAchieve integrated removalLow running costCombustion processDirect carbon-dioxide mitigationWater vaporBurn out

The invention provides a CFB oxygen-enriched combustion smoke near zero emission power generation system which is composed of a boiler, a powder feeding system, an air separating device, a chimney, multiple stages of heat exchangers, multiple stages of dust removers, a recirculating fan, an induced draft fan, a dewatering device, an SO2 separating device, a CO2 catching device, an N2 separator, an NOx reaction device and the like. By changing the concentration of oxygen in secondary gas, it is ensured that coal of different types is stably combusted and burnt out, boiler efficiency is improved, and the adaptability of the boiler to loads and coal types is enhanced. Through all the devices, dust, vapor, SO2, NOx, CO2 and the like brought by coal powder combustion smoke are recycled, harmful gas, fine particles and trace elements in the smoke are integrally removed, the smoke exhaust temperature is lowered to be close to the atmosphere temperature, the near zero emission of the combustion smoke is achieved, the environment is protected, and the maximization of resource utilization is achieved.

Owner:SICHUAN CHUANGUO BOILER

Grate-firing boiler with high efficiency and low nitrogen combustion

ActiveCN106989384AGuaranteed burnoutBurn fullySolid fuel combustionCasings/liningsThermodynamicsLow nitrogen

The invention discloses a grate-firing boiler with high efficiency and low nitrogen combustion. The grate-firing boiler comprises a boiler body and a fire grate, wherein the boiler body comprises a front arch, a rear arch, a left side wall, a right side wall, a first partition wall and a second partition wall which are annularly arranged; the fire gate is positioned below the boiler body and is positioned between the front arch and the rear arch; the first partition wall is arranged between the front arch and the rear arch and is positioned above the fire grate; the second partition wall is arranged above the first partition wall and a gap is reserved between the first partition wall and the second partition wall; the second partition wall extends from the front arch to the rear arch and crosses over the first partition wall; a gap is formed between the top end of the second partition wall and the rear arch; and a secondary air inlet is arranged on the boiler body and on a position towering above the front arch. The front arch, the fire grate, the first partition wall and the second partition wall as well as the left side wall and the right side wall are encircled to form a fire volatile area; the fire grate, the first partition wall, the second partition wall and the rear arch as well as the left side wall and the right side wall are encircled to form a main combustion reduction area; and the top end and the rear arch of the second partition wall as well as the left side wall and the right side wall are encircled into a cinder burnout area, thereby reducing pollution.

Owner:YANTAI LONGYUAN POWER TECH

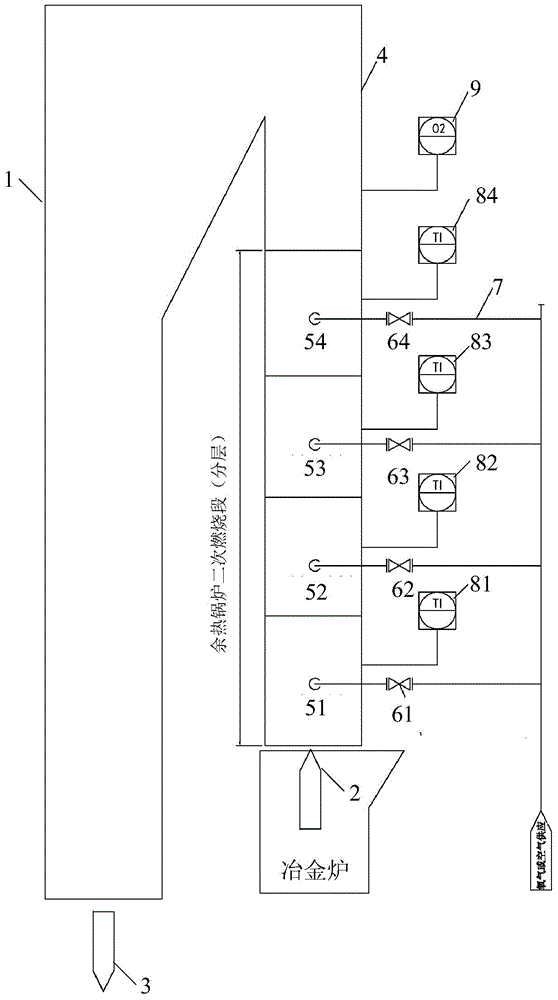

Exhaust-heat boiler

ActiveCN104456497AReduce the degree of high temperature corrosionExtended service lifeAir supply regulationIncreasing energy efficiencyInlet valveEngineering

The invention discloses an exhaust-heat boiler. The exhaust-heat boiler comprises a furnace body, a flue gas inlet, an flue gas outlet, a water-cooling wall arranged in the furnace body, a plurality of nozzles of air supply which are arranged in different height to achieve stratified combustion in the furnace body, a plurality of air inlet valves connected with a plurality of the nozzles of air supply, an air inlet pipeline which is connected with the air inlet valves, a plurality of temperature sensors which are arranged in the furnace body and used for detecting flue gas temperature, an oxygen sensor which is arranged in the furnace body and used for detecting oxygen concentration in the furnace body, and a controller which is used for controlling the air inlet valves according to the flue gas temperature and the oxygen concentration. The exhaust-heat boiler controls the air inlet valves according to the flue gas temperature and the oxygen concentration, thereby achieving secondary combustion of organic matter in the flue gas and achieving control over secondary combustion temperature and deflagration of the organic matter. The exhaust-heat boiler is easy to operate, and the safety and the reliability of the exhaust-heat boiler can be guaranteed.

Owner:CHINA NERIN ENG

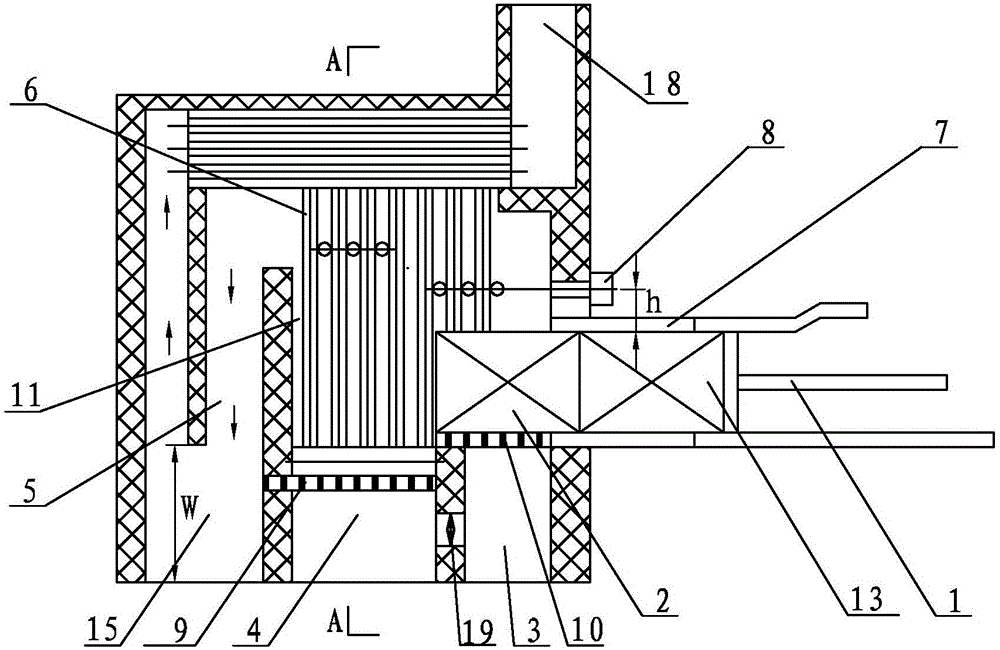

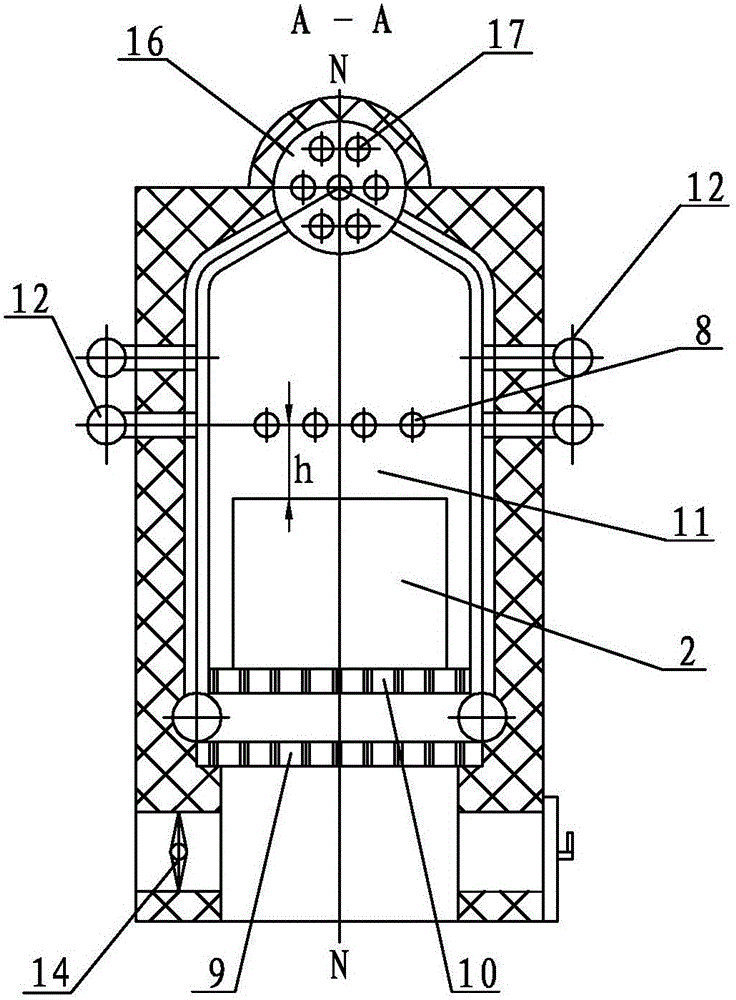

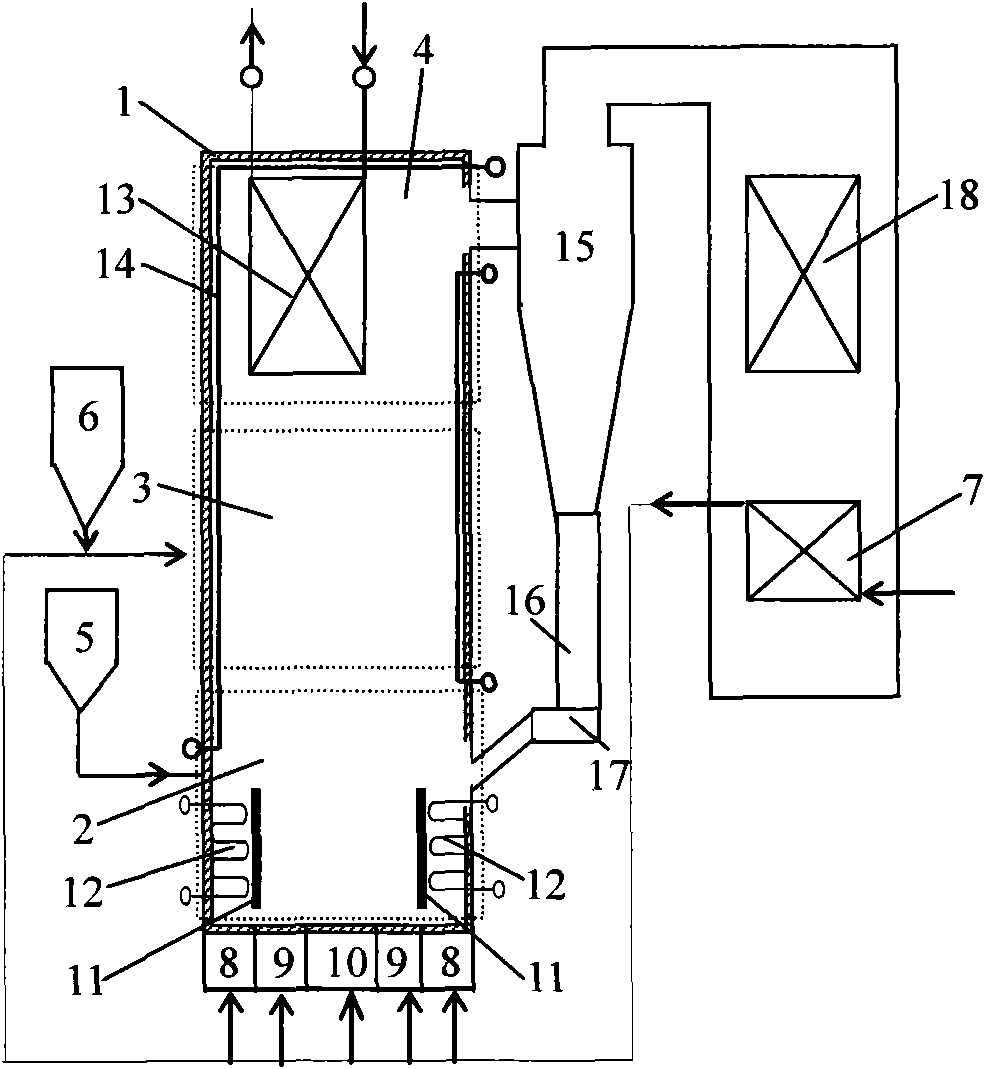

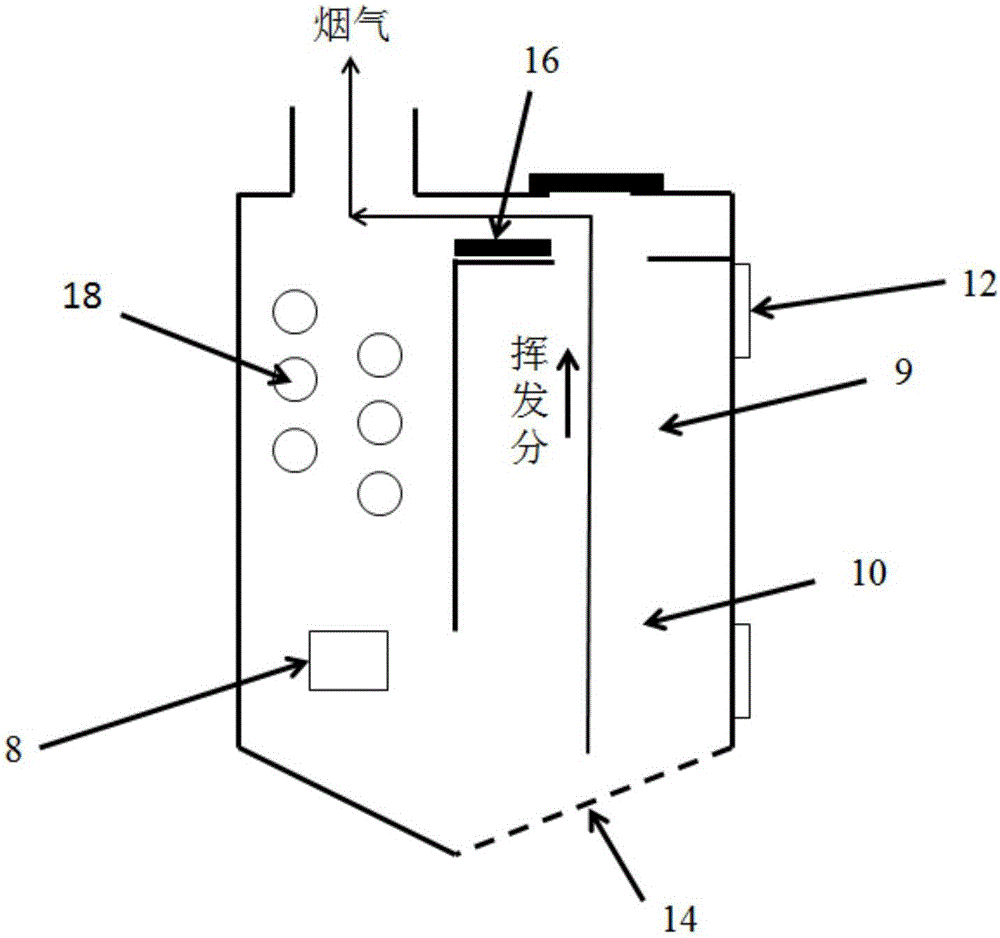

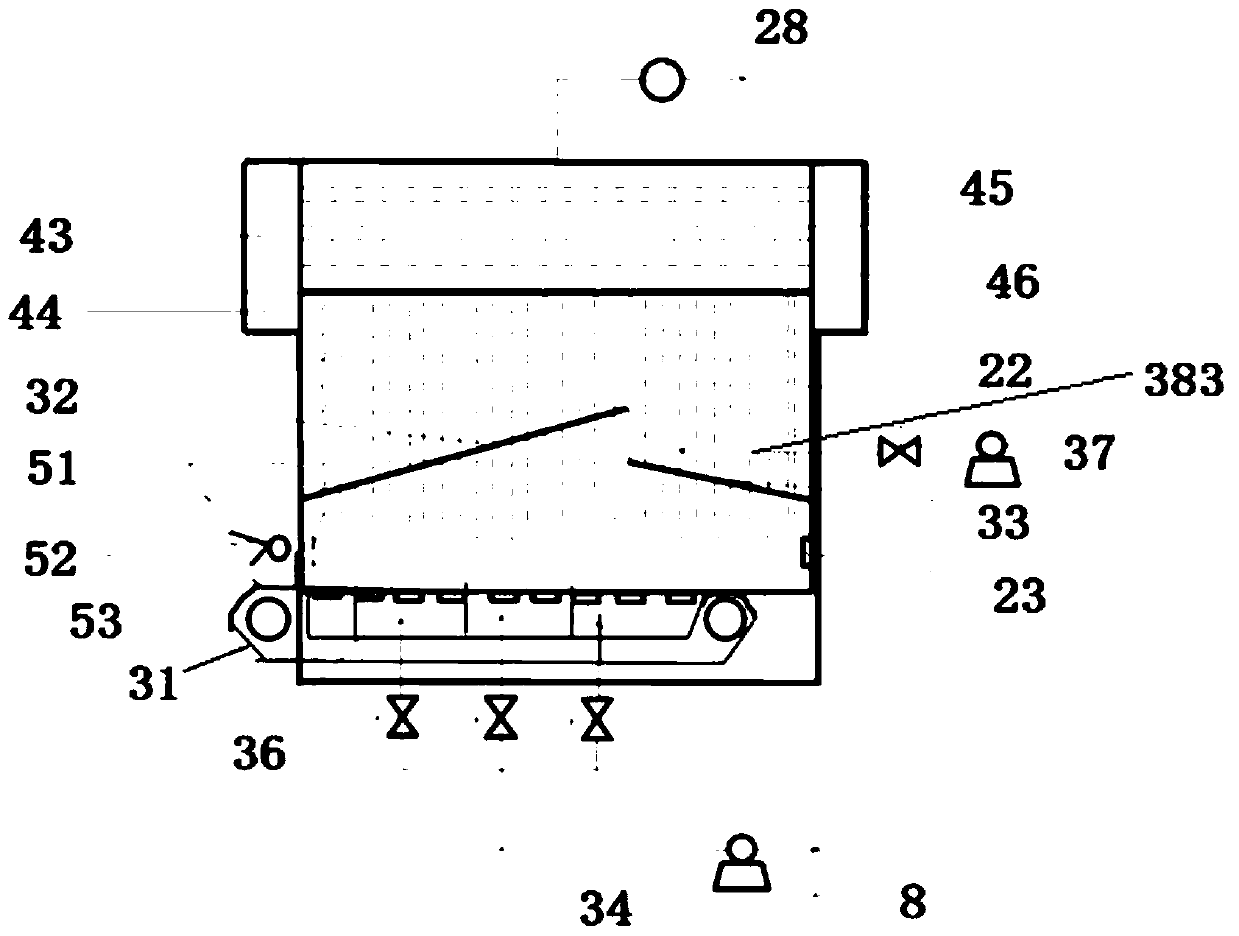

Semi-coke mixed burning system and semi-coke mixed burning method for industrial coal-burning layer burning furnace

ActiveCN109751592APromote fireConducive to stable combustionDirect carbon-dioxide mitigationSolid fuel combustionReducing atmosphereProcess engineering

The invention discloses a semi-coke mixed burning system and a semi-coke mixed burning method for an industrial coal-burning layer burning furnace. The system includes a furnace, a tilt reciprocatingfurnace grate, a chain furnace grate, a coal feeder, a circulating fan, an air blower, a dust remover, an air induced fan, a chimney and a tail flue way and the like. According to the semi-coke mixedburning system, the coal is burned by using the tilt reciprocating furnace grate so as to form the bottom fire in view of the problems of low semi-coke volatile fraction, difficult firing and stable burning, low combustion efficiency in the burning process of the burning furnace, and high NOx generation amount, the semi-coke is paved on the chain furnace grate to form a mixed burning method of lower coal and upper coke so that the two sides of the semi-coke is heated, the proper combustion environment is provided for the semi-coke which has difficult in burning, a re-combustion zone with the reduced atmosphere is formed by carrying the fine powder semi-coke through low-temperature circulating fume in the furnace, meanwhile, the burning exhaust vent spout is formed in the upper portion of the re-combustion zone, and the energy utilization efficiency is improved and the NOx emission is reduced while the semi-coke burning optimization is achieved.

Owner:XI AN JIAOTONG UNIV

A medical waste incinerator using oxygen-enriched combustion technology

ActiveCN104006391BAvoid low temperatureBurn completelyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberEngineering

The invention discloses a medical waste incinerator applied with the oxygen-enriched combustion technology, and belongs to the field of environmental-friendly and energy-saving devices. The medical waste incinerator comprises an incinerator body, a second combustion chamber, a combustion air fan, an oxygen-enriched air supply system and a smoke tail processing system. Combustible components of medical waste are decomposed into combustible gas (smoke) in the incinerator body, and combustible gas enters a second combustion chamber body and flows downwards; the combustion air fan delivers combustion air into the incinerator body and the second combustion chamber body; the oxygen-enriched air supply system is used for generating oxygen-enriched gas and leading the oxygen-enriched gas into the second combustion chamber body; the smoke is contacted with the common combustion air and the oxygen-enriched gas which enters into the second combustion chamber respectively, turbulence and perturbation are formed in a main combustion zone by the smoke, and therefore the fact that waste gas burns out is facilitated. According to the medical waste incinerator applied with the oxygen-enriched combustion technology, the burning temperature of the waste gas of the incinerator is guaranteed to the maximum extent through oxygen-enriched equipment and a secondary air system, the second combustion chamber is facilitated to form turbulent flow, the staying time of the smoke in the second combustion chamber is prolonged, and therefore dioxin is decomposed.

Owner:路宁 +1

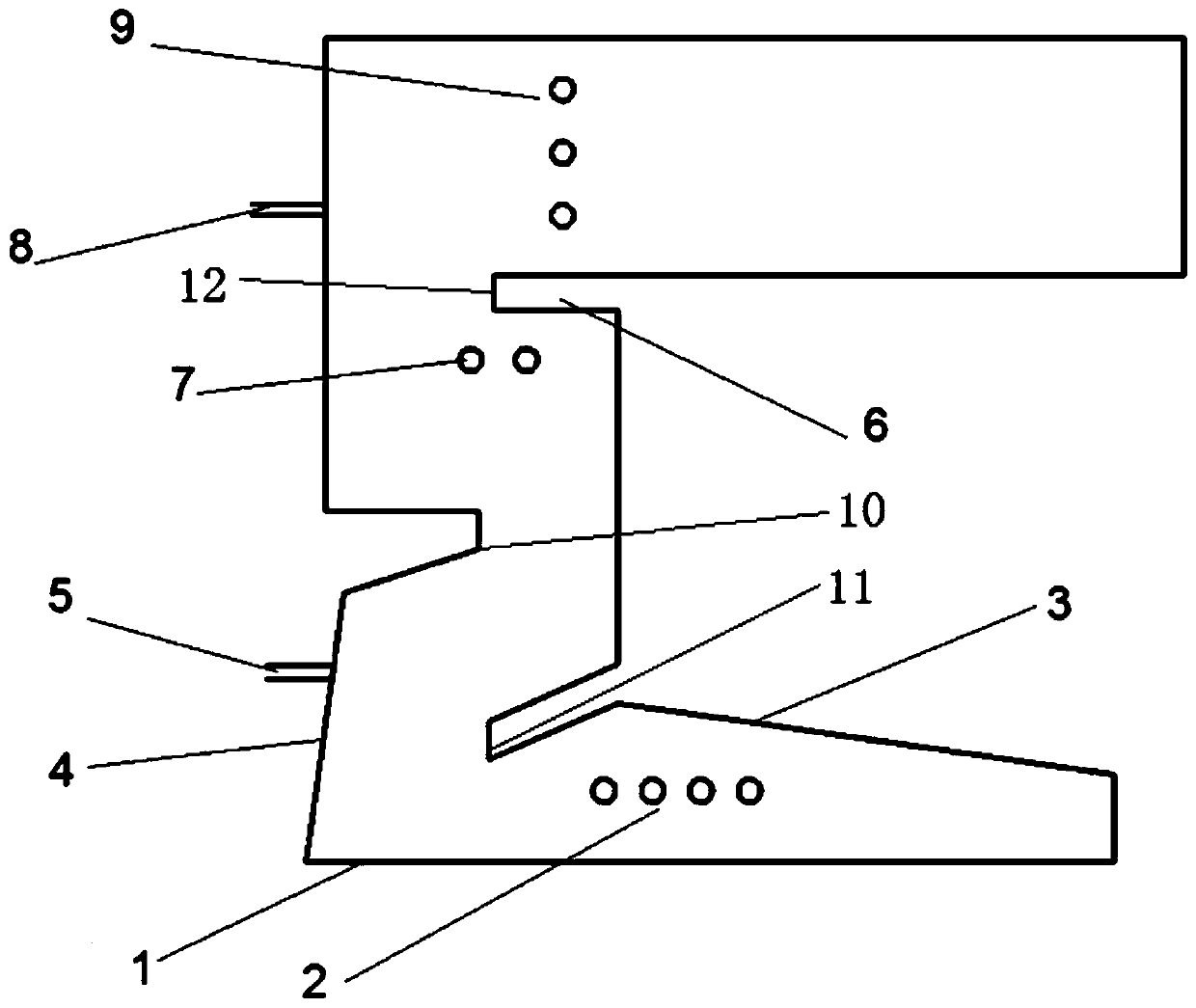

Method and device for gasifying staged combustion of alternative fuel of cement kiln

ActiveCN106495513AUniform temperature distributionReduce generationCombustion chamberFuel gasification

The invention discloses a method and a device for gasifying staged combustion of an alternative fuel of a cement kiln. The device includes a gasified gas outputted from a pyrolysis gasifier and tertiary air of cement kiln fed into a decomposing furnace of the cement kiln, wherein the tertiary air of cement kiln is divided into a first path of air and a second path of air; the two paths of air are respectively fed into the decomposing furnace from upper and lower ends; 10%-30% of total volume of the tertiary air, served as the first path of air, is fed from the bottom of the decomposing furnace; the rest tertiary air, served as the second path of air, is fed from the top of the decomposing furnace; the gasified gas, following the first path of air, is fed from the bottom of the decomposing furnace; the temperature of the flue gas at the outlet of the decomposing furnace is measured for adjusting the air feeding ratio of the first path of air to the total volume of the tertiary air and the feeding volume of the gasified gas. According to the invention, the pyrolytic gasified gas and the decomposing furnace are organically combined, the device has the characteristics of high thermal efficiency and uniform temperature distribution of the decomposing furnace, and the generation of nitric oxide is reduced by forming a reducing atmosphere by feeding coal and air at different ratios into the combustion chamber.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

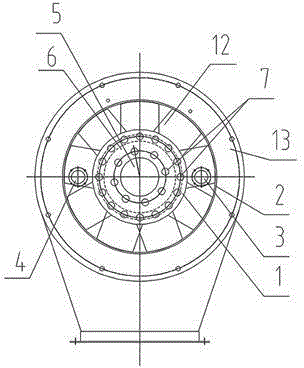

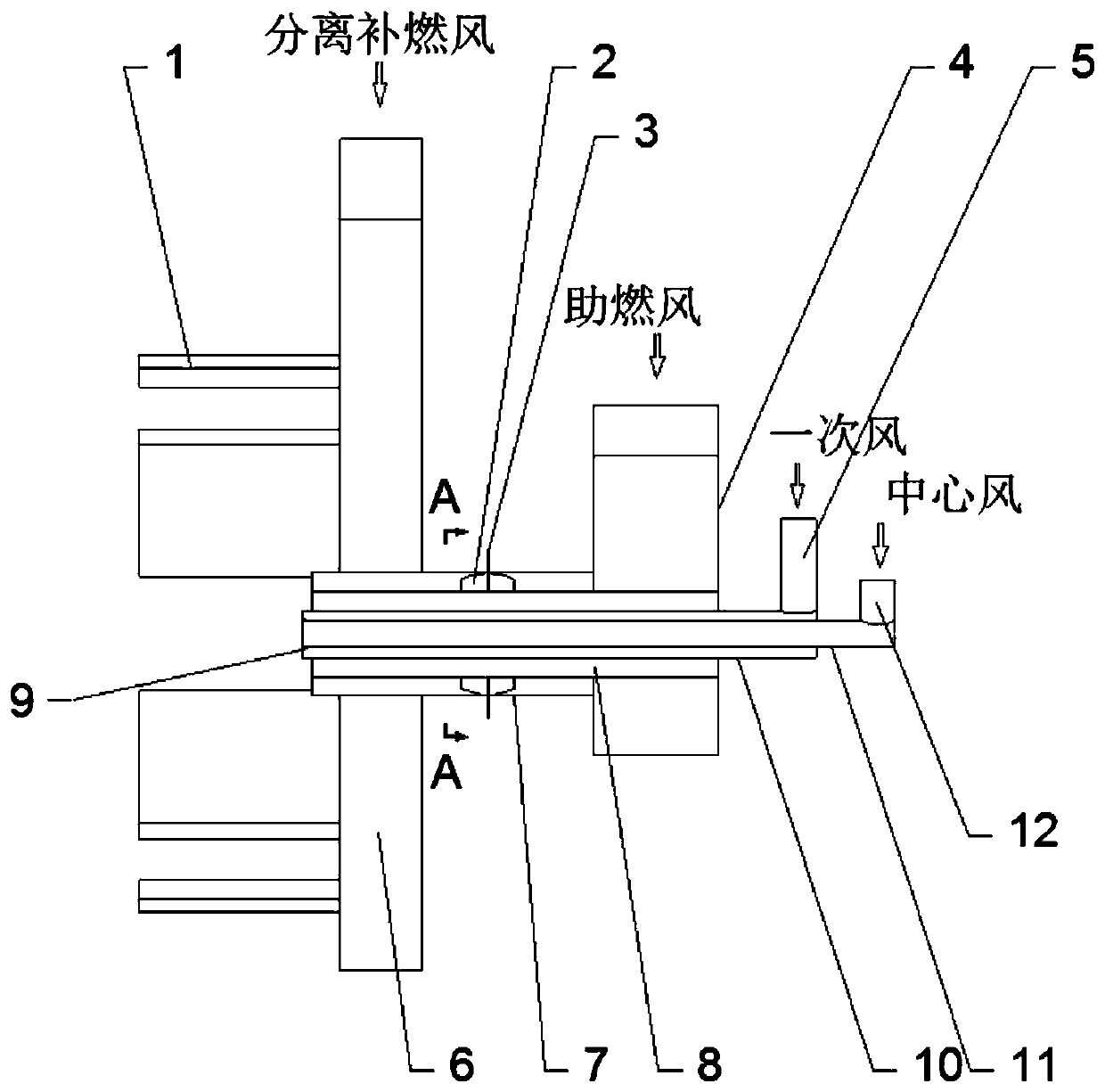

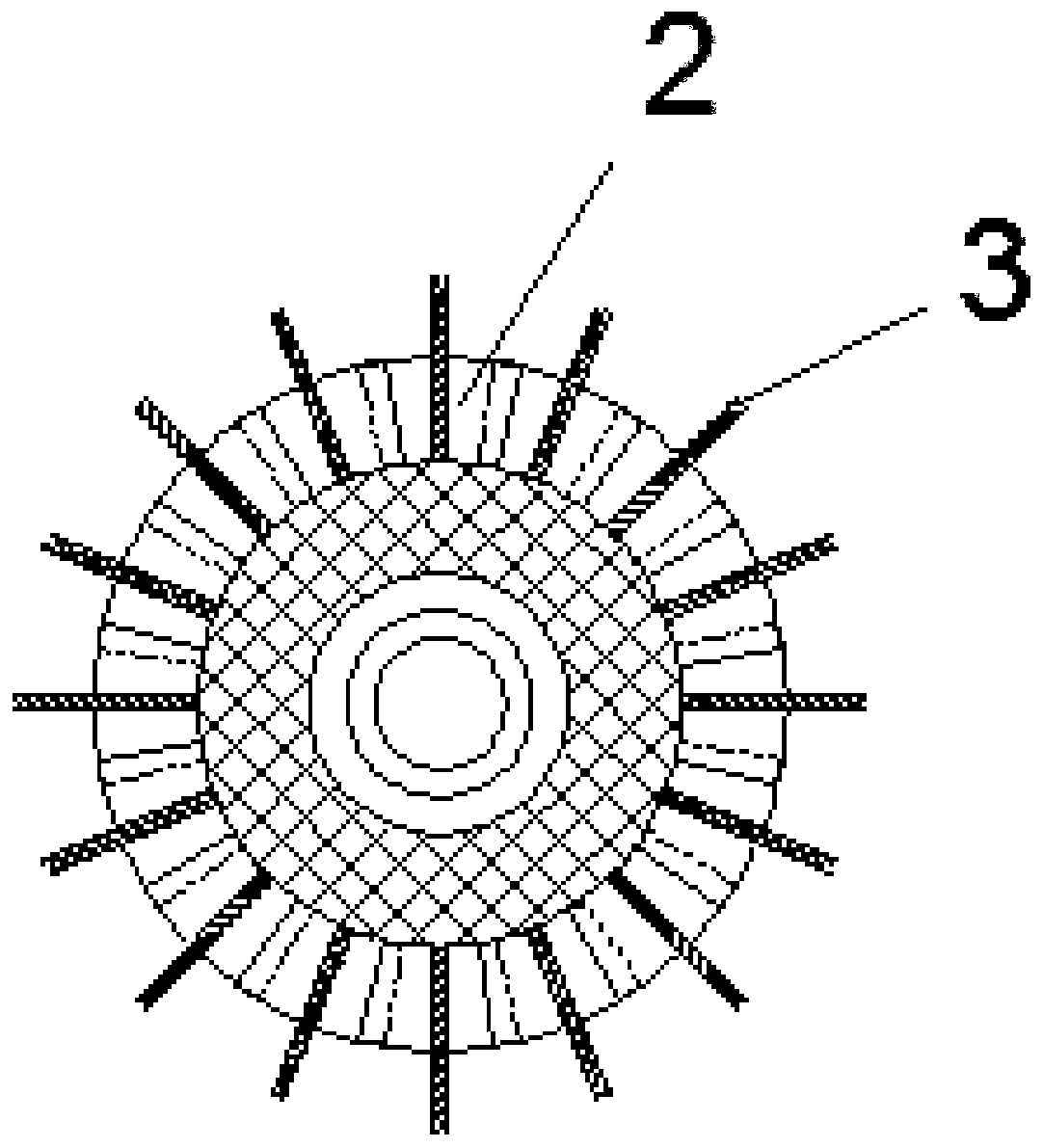

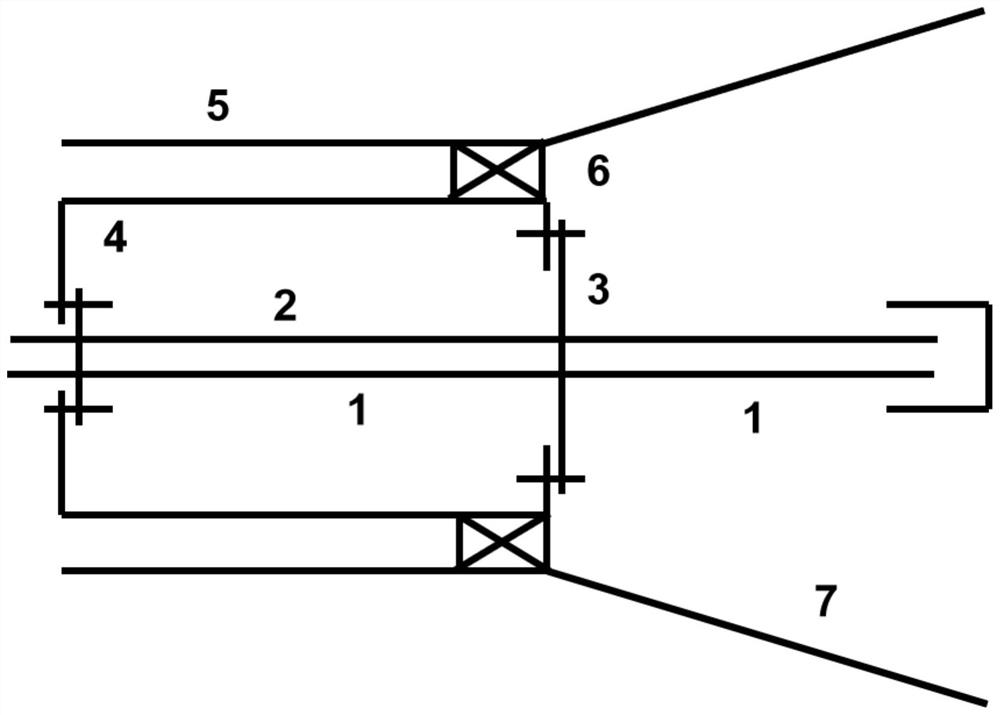

Industrial pulverized coal boiler burner with secondary air axial blade angle capable of being adjusted

PendingCN109973992AStable outputCompact structurePulverulent fuel combustion burnersCycloneCombustion process

The invention discloses an industrial pulverized coal boiler burner with the secondary air axial blade angle capable of being adjusted. The industrial pulverized coal boiler burner includes a centralair pipe, and a primary air casing, a reducing secondary air casing, a separation air casing, a combustion-supporting air casing and a separation afterburning wind volute which successively sleeve thecentral air pipe from inside to outside, the separation air casing for delaying mixing of reducing secondary air and combustion-supporting air is arranged on the outer wall of the reducing secondaryair casing in a clung mode, a combustion-supporting air passage is arranged between the outer wall of the separation air casing and the inner wall of the combustion-supporting air casing and used forintroducing the combustion-supporting air, the combustion-supporting air passage is internally provided with a plurality of axial cyclone blades in the circumferential direction, and a plurality of separation afterburning vanes are arranged along the axis of the central air pipe on the separation afterburning wind volute. A cyclone burner is suitable for powder feeding and combustion of an industrial pulverized coal boiler, the fire stability in a furnace can be improved, and meanwhile, NOx production during combustion can be lowered.

Owner:XI AN JIAOTONG UNIV

Energy-saving and environment-friendly coal-fired cooking heating stove, cooking heating method and application

PendingCN107435952AIncrease burnoutEnhanced Staged CombustionStoves/ranges with convection heatingInclined grateFlueProcess engineering

The invention provides an energy-saving and environment-friendly coal-fired cooking heating stove, a cooking heating method and application. The coal-fired cooking heating stove is characterized in that a volatile component return pipeline is longitudinally arranged in a pyrolysis gasification zone, the top of the volatile component return pipeline is higher than a coal adding opening, and the bottom of the volatile component return pipeline extends into a semi-coke combustion area; a heating flue and a cooking flue are combined into a heating and cooking flue, and a cooking-heating switching rod and a movable cover plate are used to regulate the operation state of the coal-fired cooking heating stove. The coal-fired cooking heating stove has the advantages that on the basis of the staged combustion theory, the volatile component return pipeline is arranged in the pyrolysis gasification zone, and accordingly smoke reversing when the coal adding opening is opened can be avoided; in addition, the heating flue and the cooking flue are combined into one flue, the flue is provided with tertiary air orifice to form a secondary complete combustion area, flue gas complete combustion degree is enhanced greatly, and stable smoke-free combustion under full work conditions (coal adding, slagging, cooking, heating, stove sealing and the like) is achieved.

Owner:YANKUANG GRP CO LTD +1

Long front arch and secondary air composite structure of lignite-fired traveling grate boiler

InactiveCN102954485AImprove combustion efficiencyGuaranteed burnoutCasings/liningsNon-combustible gases/liquids supplyOxygen deficiencyBrown coal

The invention discloses a long front arch and secondary air composite structure of a lignite-fired traveling grate boiler. The structure comprises a traveling grate stoker, a lignite hopper, a single long front arch, composite secondary air exhaust pipes and a smoke guide arch, wherein the single long front arch is arranged inside a hearth from front to back, the composite secondary air exhaust pipes are arranged on a side wall of the hearth and positioned below the long front arch, and the smoke guide arch is used for guiding high-temperature smoke to an upper hearth. Lignite can be quickly ignited under the action of thermal radiation of the long front arch after being fed into the hearth along with the traveling grate stoker, and flame generated by combustion of the lignite and the high-temperature smoke skim through along an integral lignite bed of the traveling grate stoker from front to back and are discharged from a long front arch outlet positioned at the rear of the hearth, so that the integral lignite bed which is positioned below the long front arch and arranged on the traveling grate stoker is in a high-temperature state, and high combustion efficiency can be realized. Besides, air delivered by an air blower is sprayed into the upper side of the lignite bed positioned below the long front arch via the composite secondary air exhaust pipes, so that high-volatility matters in the lignite are guaranteed against generating black smoke due to oxygen deficiency during combustion.

Owner:哈尔滨工大格瑞环保能源科技有限公司

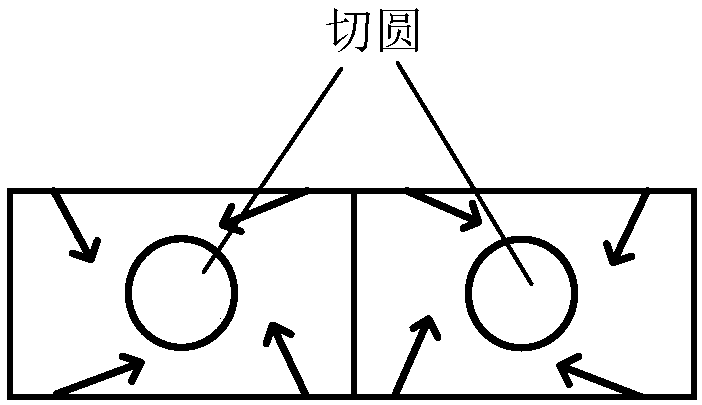

Air distribution device for smoke and garbage incinerator

The invention provides an air distribution device for smoke and a garbage incinerator. The air distribution device comprises at least two layers of spraying openings formed in a throat outlet of the incinerator, so that the smoke can be sprayed into the incinerator, wherein each layer is provided with multiple spraying openings. According to each two layers of vertically adjacent spraying openings, the spraying direction of the multiple spraying openings of one layer rotates clockwise in a hearth to form a tangent circle, the spraying direction of the multiple spraying openings of the other layer rotates anticlockwise in the hearth to form a tangent circle, and thus perturbation of the smoke near the throat of the incinerator is increased. According to the scheme, the low level of the oxygen content of the incinerator throat can be ensured while complete burning of CO is ensured, thus generation of NOx is restrained, uniformity of the section temperature field of the throat outlet of the incinerator can also be facilitated, and the possibility that high-temperature smoke gets close to a rear wall, and a large scale of coking is produced on the rear wall is avoided.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +2

Chain grate boiler with full-coverage front arch

InactiveCN102798117ASmoky GuaranteeGuaranteed burnoutSolid fuel combustionCasings/liningsEngineeringHearth

The invention relates to a chain grate boiler with a full-coverage front arch. The boiler comprises a chain grate, a coal hopper, a full-coverage front arch arranged in a hearth from front to back, a combinational secondary air spray pipe arranged on the side wall of the hearth at the lower part of the full-coverage front arch and a smoke guide arch for guiding the high-temperature smoke gas to the upper hearth. After entering the hearth along with the grate, raw coal is on fire rapidly under heat radiation of the full-coverage front arch, flame and high-temperature smoke gas generated during combustion of raw coal crosses over from front to back along the coal bed of the whole chain grate and flows out from an outlet at the rear part of the hearth so that the coal bed on the whole chain grate at the lower part of the full-coverage front arch is in a high-temperature state, and high combustion efficiency is realized. At the same time, air fed from a blower is sprayed over the coal bed at the lower part of the long front arch through the combinational secondary air spray pipe, so that the situation that the volatile matter of raw coal generates black smoke due to oxygen deficiency in the combustion process can be avoided.

Owner:哈尔滨工大格瑞环保能源科技有限公司

Turbulent burner capable of rapidly switching pulverized coal feeding modes and using method

ActiveCN113237057AShorten the disassembly and installation periodLarge load adjustment rangePulverulent fuel combustion burnersCombustion apparatusCoalEngineering

The invention discloses a turbulent burner capable of rapidly switching pulverized coal feeding modes and a using method of the turbulent burner. The burner comprises a pulverized coal reverse supply mechanism, a pulverized coal forward supply mechanism, a transition channel inner sleeve, a transition channel outer sleeve, a secondary air guide cylinder and a stable combustion cavity. The secondary air guide cylinder and the stable combustion cavity are connected to form a burner body, the transition channel outer sleeve is arranged in the secondary air guide cylinder, the pulverized coal reverse supply mechanism penetrates through the central axis in the burner body, and the transition channel inner sleeve is arranged outside the inlet end of the pulverized coal reverse supply mechanism. A secondary air channel is formed between the secondary air guide cylinder and the transition channel outer sleeve, and the transition channel inner sleeve and the transition channel outer sleeve are connected to form a closed transition channel. The pulverized coal reverse supply mechanism is replaced with the pulverized coal forward supply mechanism, so that quick switching of pulverized coal feeding modes is realized.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Gasification coupling low-NOx combustion system and method and design method

ActiveCN112503521AAvoid depositionEfficient burnoutGaseous fuel burnerNitrogen oxidesProcess engineering

The invention discloses a gasification coupling low-NOx combustion system and method and a design method. The system comprises a semi-collision semi-tangent-circle gasification furnace, a rich-lean separator and a flow-down combustion chamber; the semi-collision semi-tangent-circle gasification furnace is sequentially provided with a semispherical top cover, an airflow guide table, burners, a cylindrical main body and a conical barrel from top to bottom, and a gasification furnace product outlet is formed in the bottom of the conical barrel; the whole rich-lean separator is arranged in the horizontal direction, and an inlet of the rich-lean separator is communicated with the gasification furnace product outlet; a rich-phase product outlet and a lean-phase product outlet of the rich-lean separator are communicated with the flow-down combustion chamber; and the number of the burners is four, two burners are only arranged in a 180-degree collision manner, and the other two burners are offset by a set angle in the diameter direction of a circle where the burners are located. Based on the idea of decoupling combustion, the technical idea of entrained-flow bed gasification is introducedinto a solid fuel preheating combustion technology, a gasification reaction is promoted, and after gasification, reducing gas in a gas phase can reduce nitrogen oxide generated by combustion of a rich-phase product.

Owner:XI AN JIAOTONG UNIV

A cement kiln alternative fuel gasification staged combustion method and device

ActiveCN106495513BUniform temperature distributionReduce generationCombustion chamberNitrogen oxides

The invention discloses a method and a device for gasifying staged combustion of an alternative fuel of a cement kiln. The device includes a gasified gas outputted from a pyrolysis gasifier and tertiary air of cement kiln fed into a decomposing furnace of the cement kiln, wherein the tertiary air of cement kiln is divided into a first path of air and a second path of air; the two paths of air are respectively fed into the decomposing furnace from upper and lower ends; 10%-30% of total volume of the tertiary air, served as the first path of air, is fed from the bottom of the decomposing furnace; the rest tertiary air, served as the second path of air, is fed from the top of the decomposing furnace; the gasified gas, following the first path of air, is fed from the bottom of the decomposing furnace; the temperature of the flue gas at the outlet of the decomposing furnace is measured for adjusting the air feeding ratio of the first path of air to the total volume of the tertiary air and the feeding volume of the gasified gas. According to the invention, the pyrolytic gasified gas and the decomposing furnace are organically combined, the device has the characteristics of high thermal efficiency and uniform temperature distribution of the decomposing furnace, and the generation of nitric oxide is reduced by forming a reducing atmosphere by feeding coal and air at different ratios into the combustion chamber.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

A Composite Biomass Clean and Efficient Combustion System

ActiveCN106765242BImprove the mixing effectReduce generationCasings/liningsNon-combustible gases/liquids supplyCombustion systemCombustion

Owner:SHANGHAI JIAOTONG UNIV

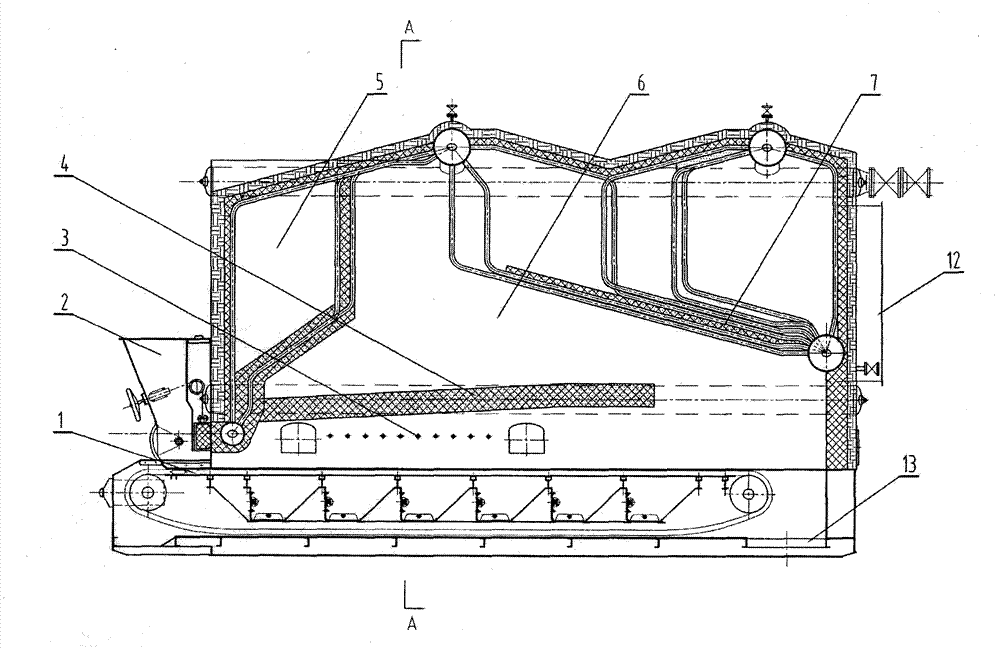

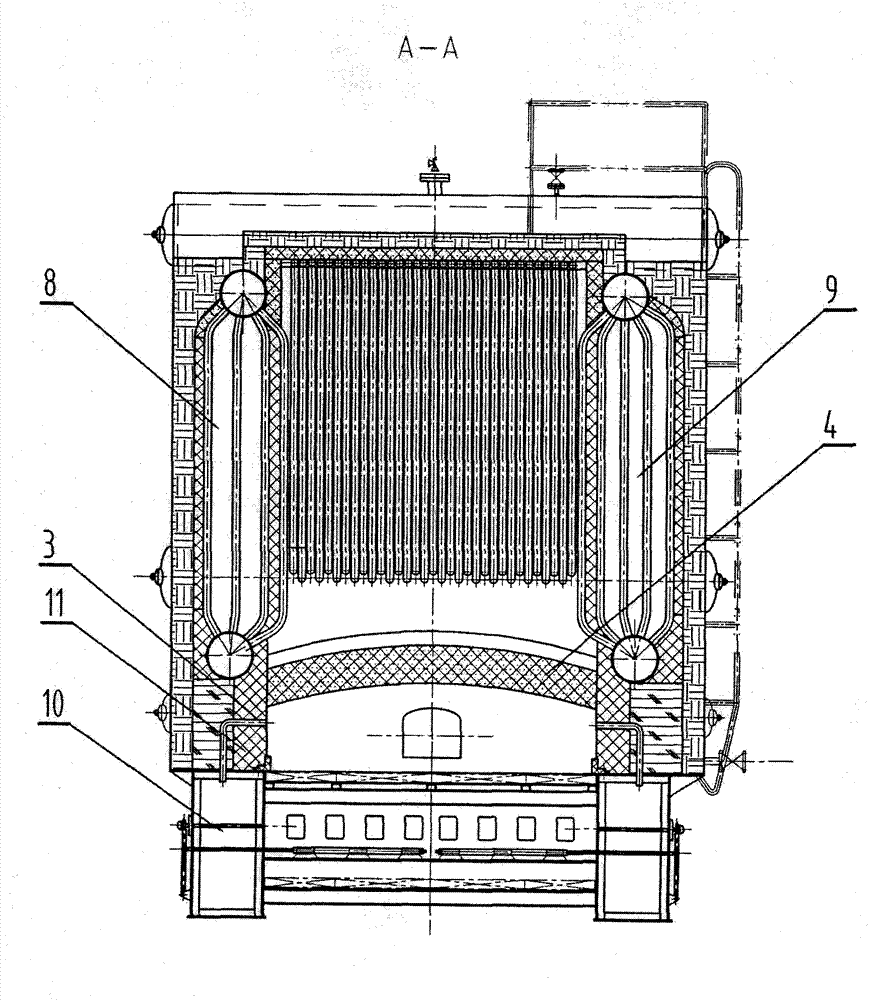

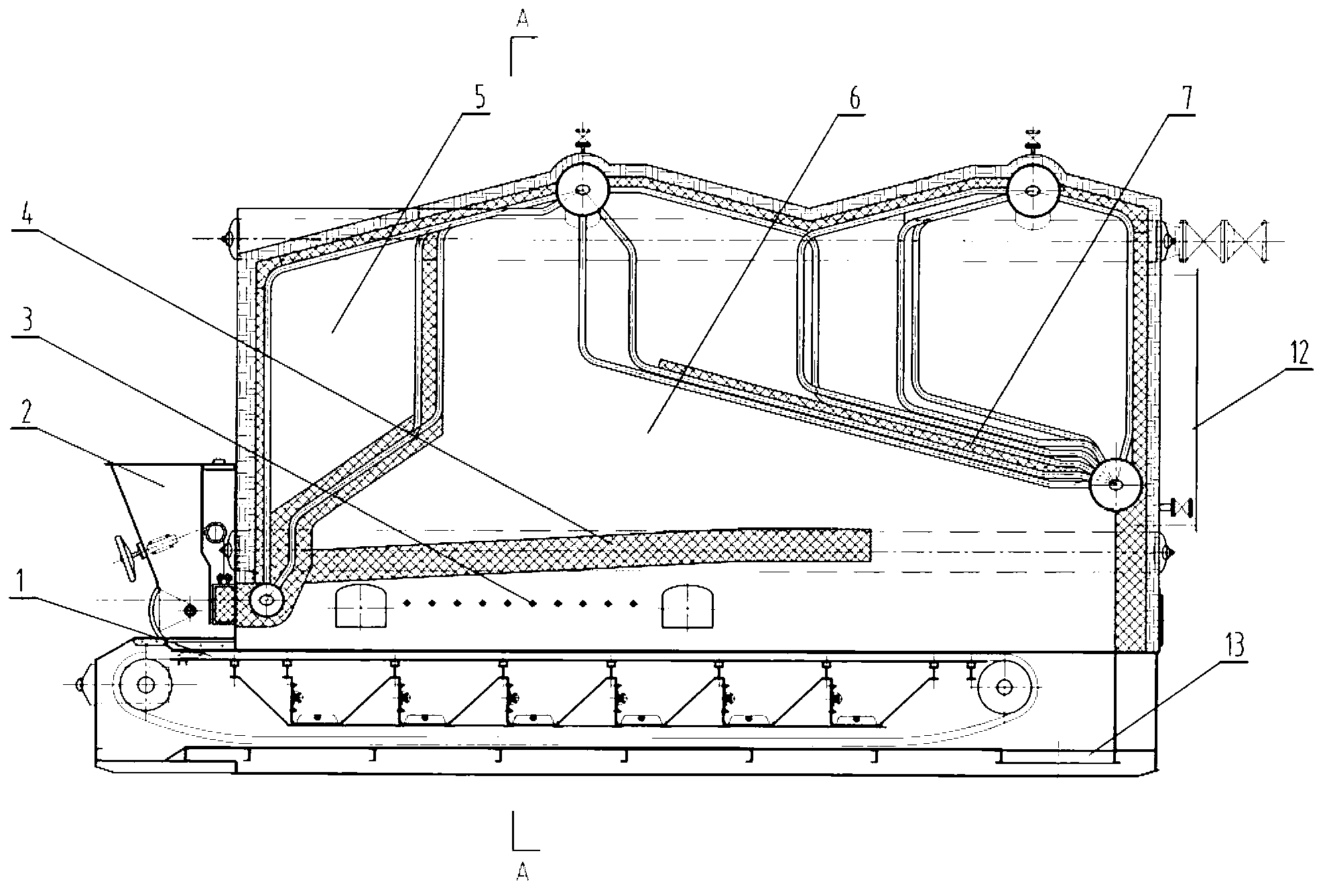

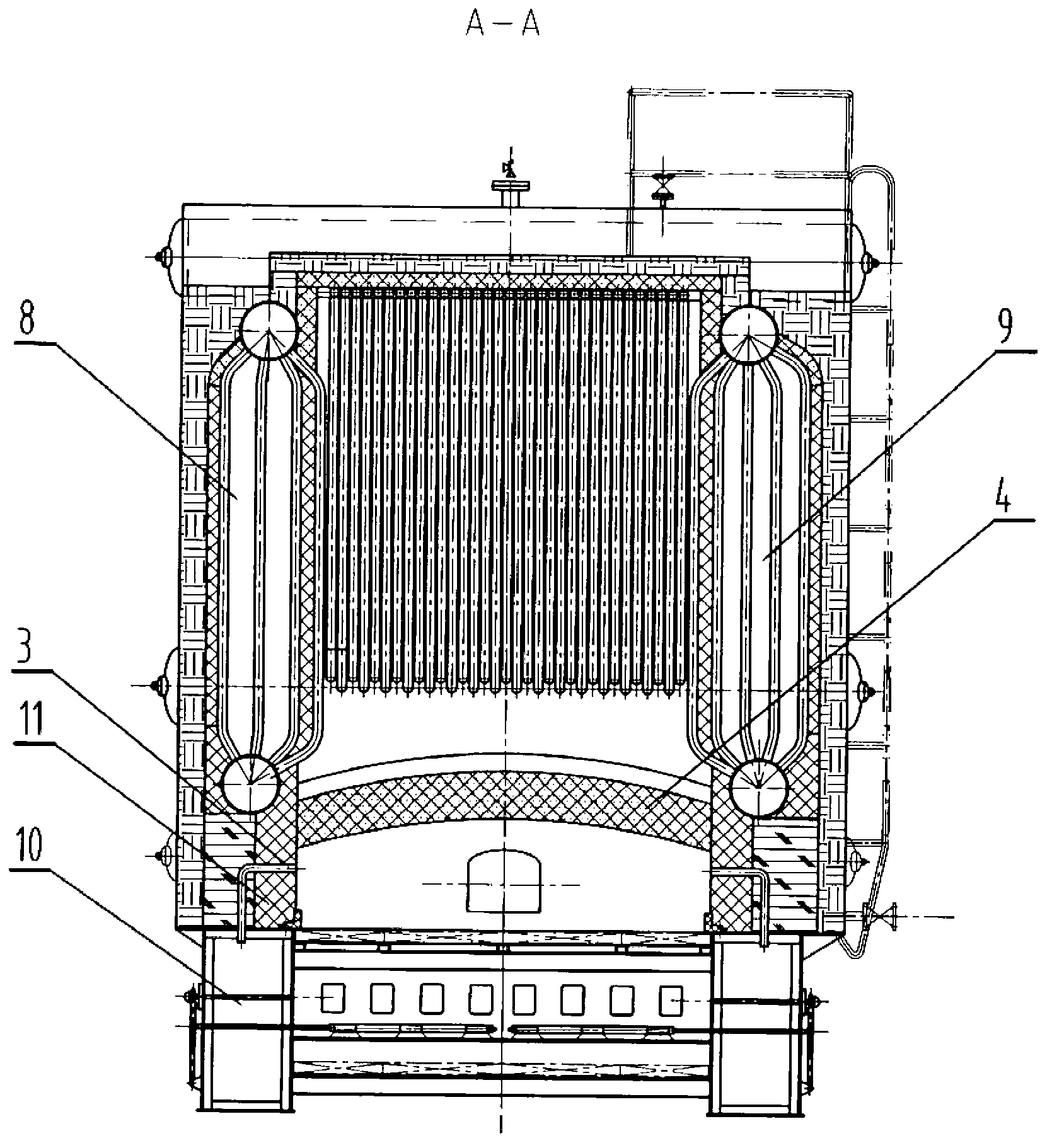

A biomass briquette fuel hot water boiler system

ActiveCN107120824BEnhance the intensity of radiation heat transferHigh thermal efficiencySolid fuel combustionWater heatersWater circulationBiomass briquettes

The invention relates to a biomass briquette hot water boiler system. The biomass briquette hot water boiler system is characterized by comprising a boiler, a water circulation system, a fire grate and combustion system, a heat transfer system, a briquette fuel feeding system, a dust removal system, an induced draught system, a flue gas recirculation system, a solar photovoltaic power system and a control system; fuel in the briquette fuel feeding system enters the fire grate and combustion system through a feeding opening in the lower end of the boiler and is used for combustion, high-temperature flue gas generated during combustion heats low-temperature water in the water circulation system through the heat transfer system, the heated high-temperature water is conveyed to a glasshouse, the low-temperature flue gas enters the dust removal system through a smoke outlet of the heat transfer system, the flue gas obtained after dust removal is conducted through the dust removal system is extracted by the induced draught system, part of the flue gas is exhausted through a chimney, the other part of the flue gas enters the fire gate and combustion system through the flue gas recirculation system, and furthermore a small part of flue gas is extracted and used for supplementing carbon dioxide required by the photosynthesis of crops to the glasshouse. The biomass briquette hot water boiler system can be widely applied to a renewable energy source heating system.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com