Stationary bed boiler preheated vertically and burnt sectionally at low temperature

A technology of low-temperature combustion and fixed bed, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc. It can solve the problems of easy coking, difficult burning of residual carbon, and difficult combustion efficiency, etc., and achieves the improvement of coal utilization rate, The effect of improving combustion heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

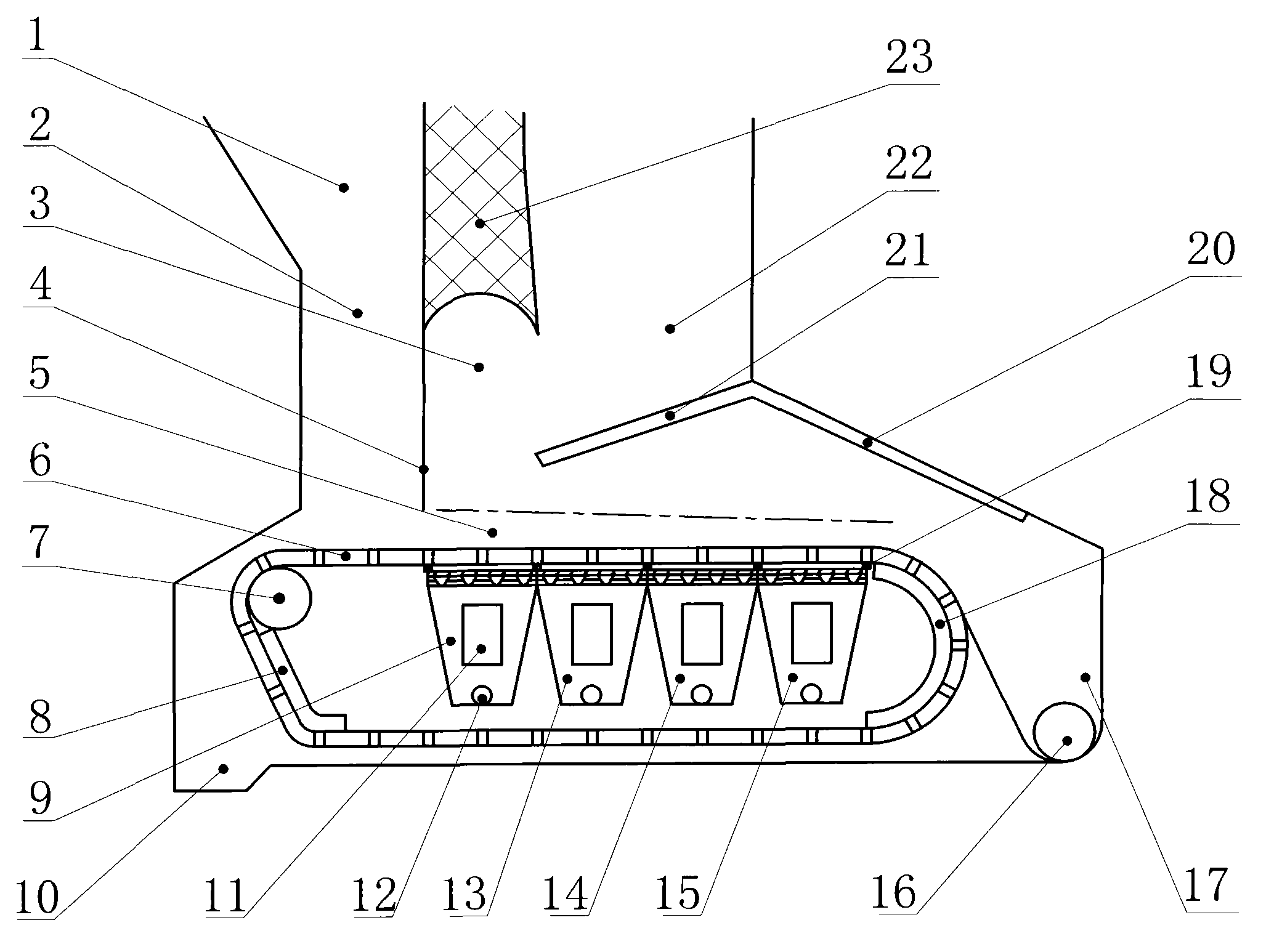

[0027] When the coal passes through the vertical falling section 2 of the coal bunker 1 and passes through the vertical preheating plate 4, the temperature has been preheated by the high temperature of the furnace to above 400 degrees, which is close to the ignition temperature of the coal, and the heated coal falls onto the beam grate 6 After passing through the first air chamber 9, a proper amount of oxygen is obtained, and the coal seam 5 starts anoxic combustion, and the temperature of the coal seam continues to rise, and combustible gas is produced by high-temperature dry distillation to provide combustible gas for the gas combustion zone 3. The fourth air chamber 15 is used for slag cooling, and all the waste heat in the slag is recovered to the furnace. The high-temperature wind generated by the cold slag provides oxygen for combustible gas combustion; the second air chamber 13 and the third air chamber 14 are the main combustion areas, and the combustion The coal is bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com