Fire coal or inferior coal desulfurizer for sulfur fixation in circulating fluidized bed boiler

A circulating fluidized bed and desulfurization agent technology, which is applied in the field of desulfurization agents, can solve the problems of affecting the boiler and failing to reach the allowable upper limit of the concentration, and achieve the effect of low processing cost and low desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

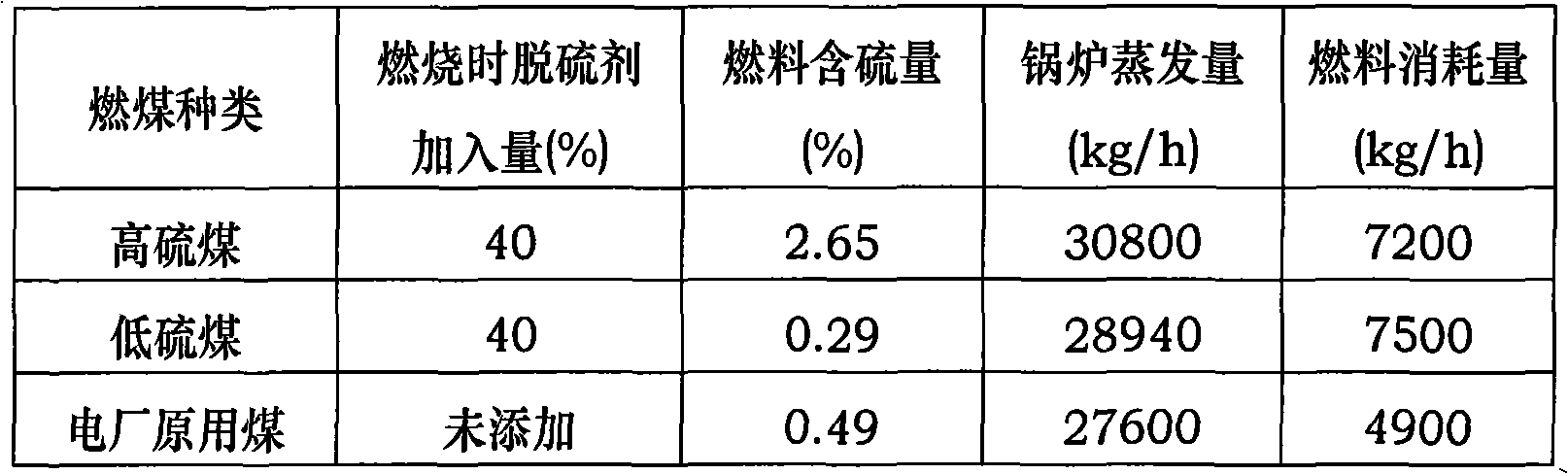

[0025] Add 48 tons of desulfurizer 1# to 120 tons of high-sulfur coal, mix well and set aside;

[0026] Add 48 tons of desulfurizer 1# to 120 tons of low-sulfur coal, mix well and set aside;

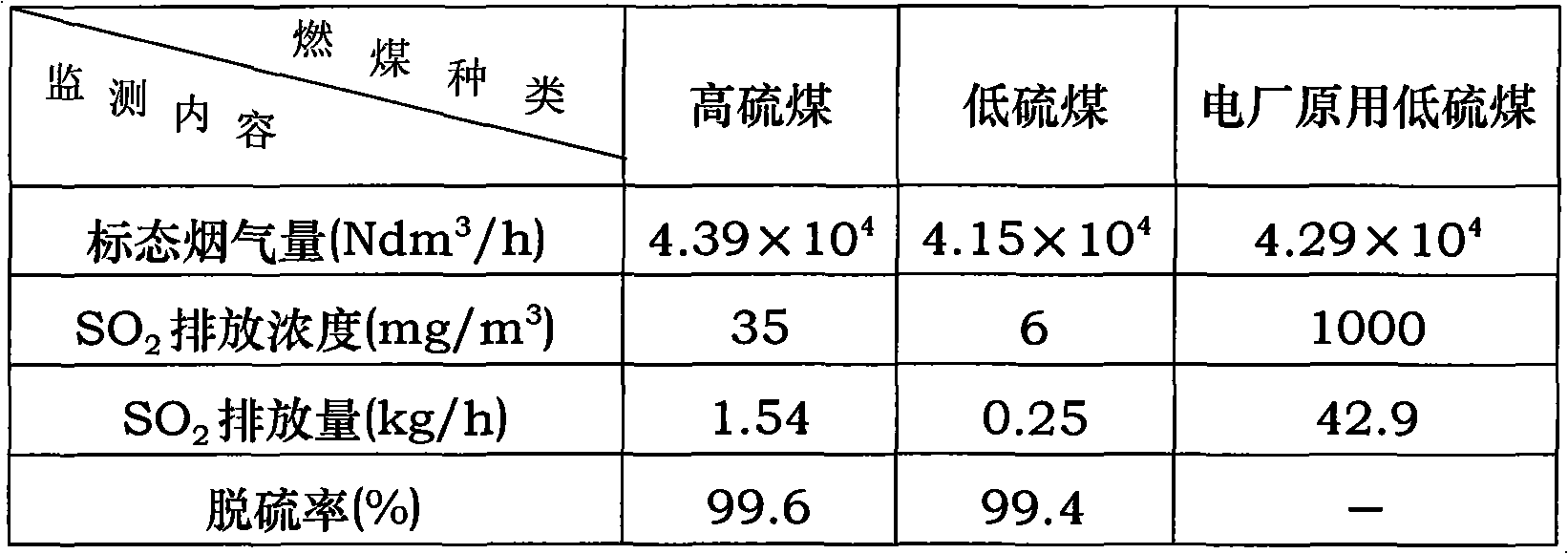

[0027] The high- and low-sulfur coals mixed with the desulfurizer prepared by the present invention are transported to the furnace front warehouse successively through the transportation system of the original fuel, put into the furnace for combustion, and run for 24 hours each. Boiler thermal test and SO 2 Monitoring is performed simultaneously. Thermal testing is done by the Coal Energy Conservation Service Center, SO 2 It is used by the Shandong Provincial Environmental Monitoring Center according to GB / T 16157-1996 "Determination of Particulate Matter in Exhaust from Stationary Pollution Sources and Sampling Methods for Gaseous Pollutants" and HJ / T 57-2000 "Potential Electrolysis Method for Determination of Sulfur Dioxide in Exhaust from Stationary Pollution Sources" Instrument KM...

Embodiment 2

[0037] The power plant has three 35t / h circulating fluidized bed boilers with an annual power generation of 90 million kWh, each boiler consumes 5.20t / h of fuel per hour, and the annual fuel consumption of the three boilers is 105,000 tons.

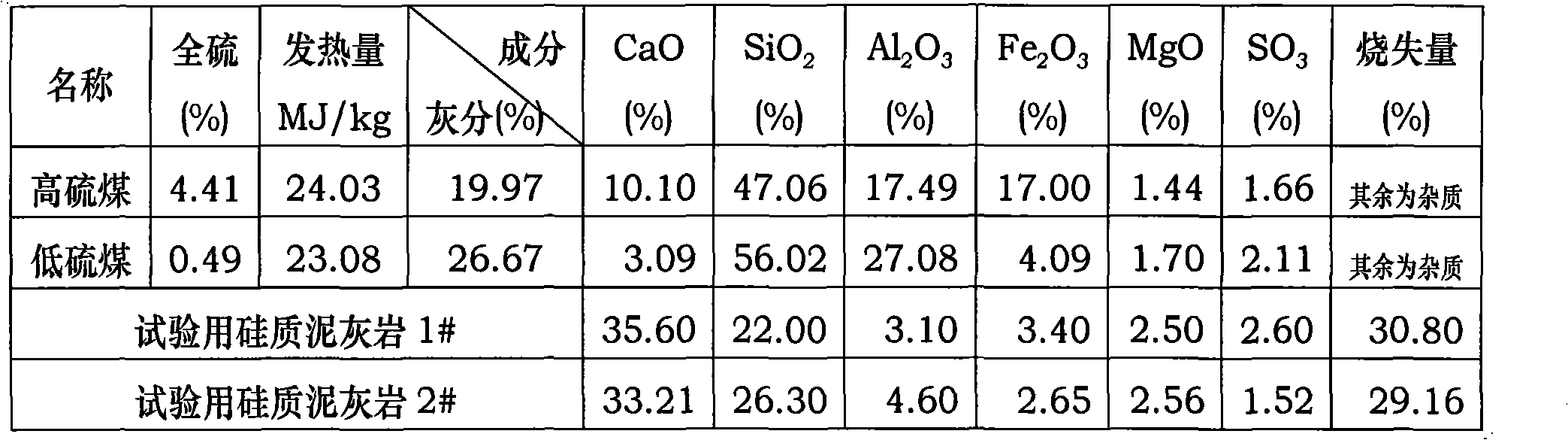

[0038]The industrial analysis of coal combustion is shown in Table 1. Low-sulfur coal, in which total sulfur is 0.49%, boiler SO 2 Emission concentration is 1000mg / m 3 , the emission is 42.9kg / h.

[0039] Add 24 tons of desulfurizer 2# to 120 tons of low-sulfur coal, mix well, and then enter the original fuel transportation system to transport to the furnace front warehouse, burn in the furnace, and run for 24 hours. Boiler thermal test and SO 2 Monitoring is performed simultaneously. Thermal testing is done by the Coal Energy Conservation Service Center, SO 2 According to GB / T16157-1996 "Determination of Particulate Matter in Exhaust from Stationary Pollution Sources and Sampling Method of Gaseous Pollutants" and HJ / T57-2000 "Potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com