Energy-saving and environment-friendly coal-fired cooking heating stove, cooking heating method and application

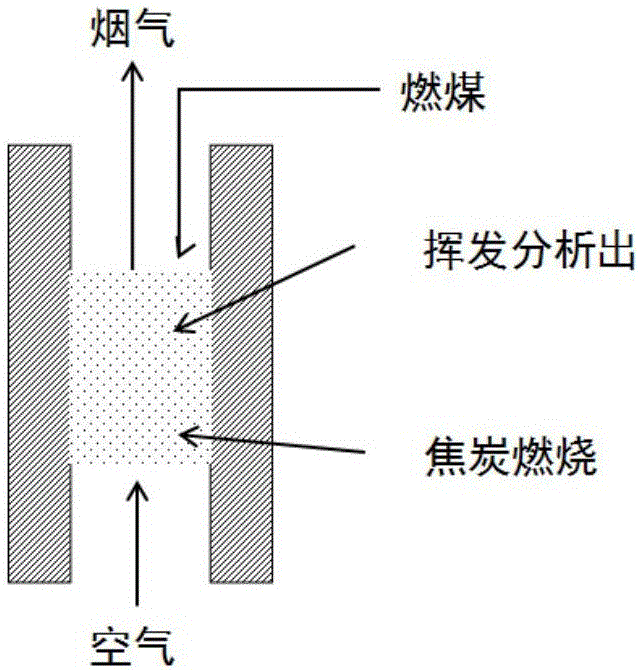

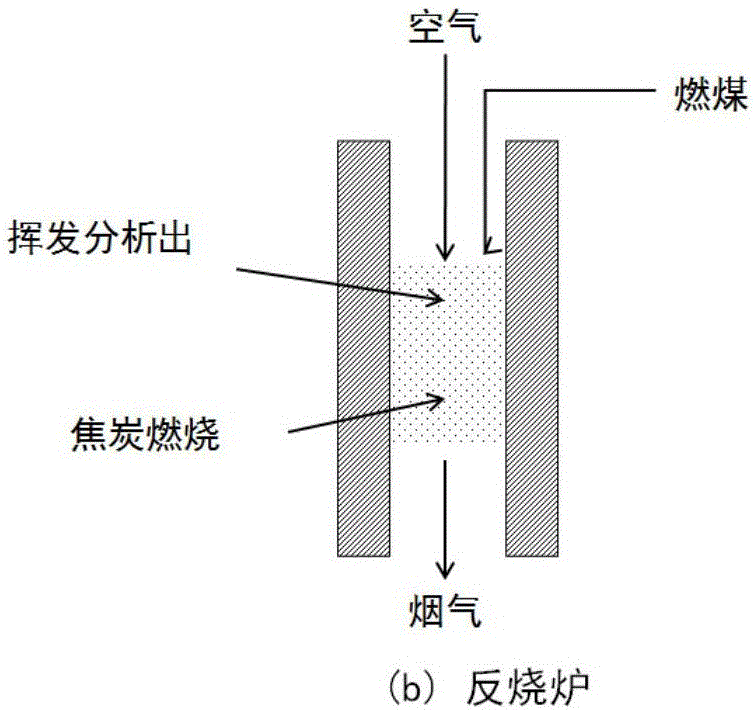

A technology for heating stoves and cooking, which is applied in the fields of energy-saving and environmentally friendly coal-fired cooking heating stoves and cooking heating, which can solve the problems of large void ratio, reduced volatile combustion time, and large primary air volume, so as to reduce generation and emission and enhance burnout Degree, strengthen the effect of staged combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

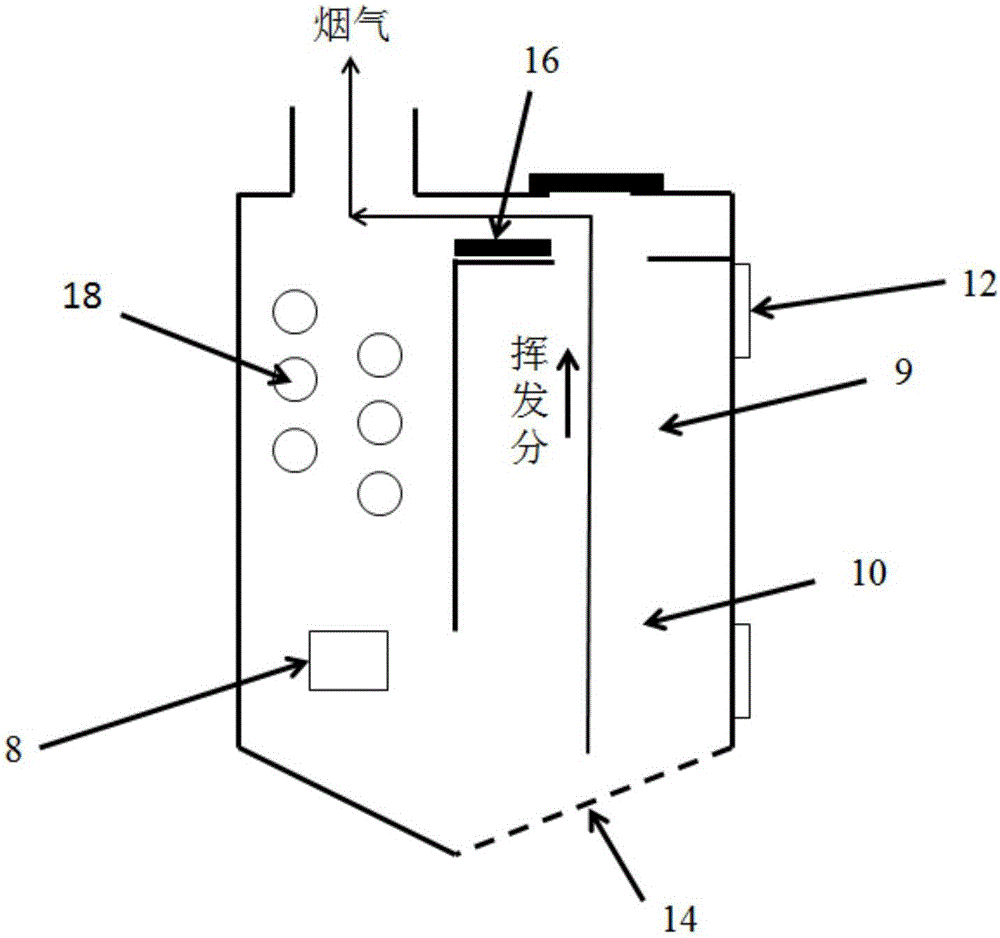

Embodiment 1

[0077] This embodiment provides a coal-fired cooking and heating furnace and its treatment method. A chimney 1 is provided on the top side of the main body of the coal-fired cooking and heating furnace, and a chimney 1 is provided on the top of the main body of the coal-fired cooking and heating furnace. Cooking port 2; the first horizontal partition 3 is arranged below the cooking port 2 inside the main body of the coal-fired cooking and heating furnace, and one side of the first transverse partition 3 is connected to the furnace wall on the side of the cooking port 2 of the main body of the coal-fired cooking and heating furnace. Connecting; the bottom of the chimney 1 inside the main body of the coal-fired cooking and heating furnace is provided with a second transverse partition 4, and one side of the second transverse partition 4 is connected to the furnace wall on one side of the main chimney 1 of the coal-fired cooking and heating furnace, The height of the second transv...

Embodiment 2

[0092] This embodiment provides a coal-fired cooking and heating stove and its treatment method. The structure of the coal-fired cooking and heating stove refers to Example 1, the difference is that: the grate 9 is movable, and the Venturi throat The diameter of the pipe at the pipe is 1 / 3 of the diameter at the flue gas inlet, and the number of tertiary air outlets 6 is 6.

[0093] The heating and cooking method of the coal-fired heating furnace described in this embodiment refers to the processing method in Example 1, the difference is that: the air introduced from the primary tuyere 14 in step (b) accounts for 40% of the total air volume content; The air introduced from the secondary air outlet 8 accounts for 30% of the total air volume content; the air introduced from the tertiary air outlet 6 accounts for 30% of the total air volume content in step (c).

[0094] Since the system of this embodiment is provided with a volatile matter return pipe in the pyrolysis gasificatio...

Embodiment 3

[0096] This embodiment provides a coal-fired cooking and heating stove and its treatment method. The structure of the coal-fired cooking and heating stove refers to Example 1, the difference is that the diameter of the pipe at the throat of the Venturi pipe is the same as that at the entrance of the flue gas 1 / 2.5 of the diameter, and the number of tertiary air outlets 6 is 8.

[0097] The heating and cooking method of the coal-fired heating furnace described in this embodiment refers to the treatment method in Example 1, the difference is that: the air introduced from the primary tuyere 14 in step (b) accounts for 50% of the total air volume content; The air introduced from the secondary air outlet 8 accounts for 30% of the total air volume content; the air introduced from the tertiary air outlet 6 accounts for 20% of the total air volume content in step (c).

[0098] Since the system of this embodiment is provided with a volatile matter return pipe in the pyrolysis gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com