Long front arch and secondary air composite structure of lignite-fired traveling grate boiler

A combination structure and chain grate technology, applied in the boiler field, can solve the problems of low combustion efficiency, inability to adapt to the combustion characteristics of lignite, and easy generation of black smoke, etc., and achieve the effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

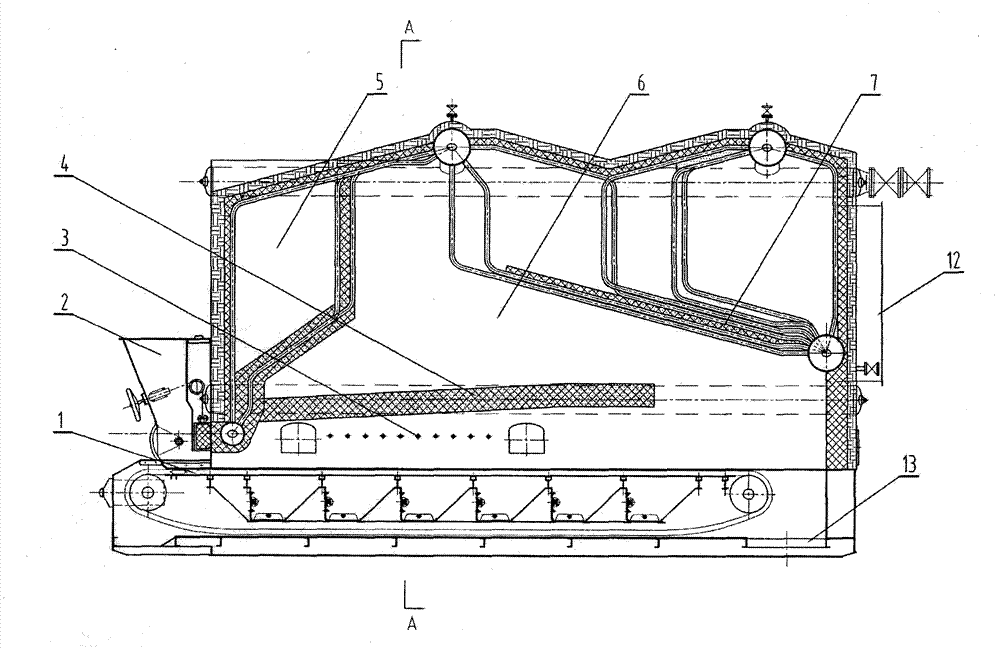

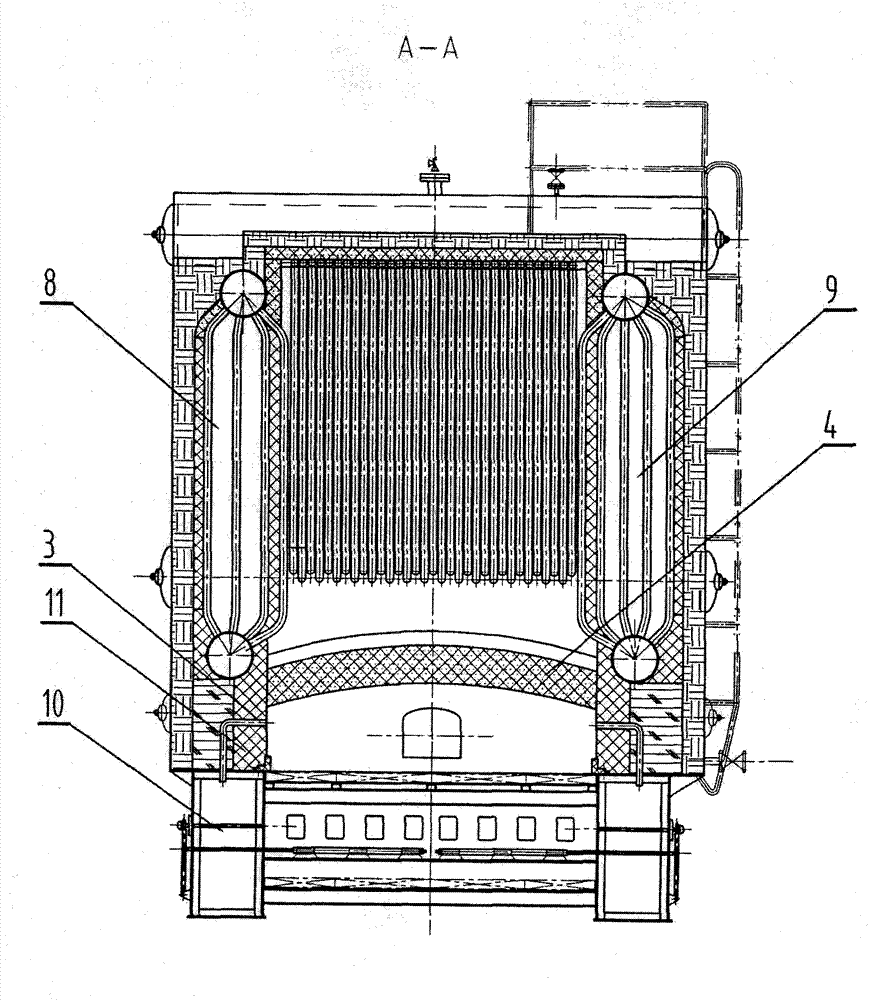

[0009] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The long front arch and secondary air combination structure of the lignite chain grate boiler includes chain grate 1, coal hopper 2, secondary air pipe 3 connected with air supply duct 10, long front arch 4, and smoke guide arch 7 . On the upper part of the air duct 10 is provided a boiler body including a left convection tube bundle flue 8 and a right convection tube bundle flue 9 for transferring the heat generated by fuel combustion to the working medium in the boiler.

[0010] When the boiler is running, the lignite in the coal hopper 2 falls on the chain grate 1, and enters the lower part of the long front arch 4 with the chain grate 1 moving from front to back. Due to the high volatile content and low ignition point of lignite , under the thermal radiation of the long front arch 4 with a relatively high temperature, the surface of the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com