Patents

Literature

41results about How to "Change ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

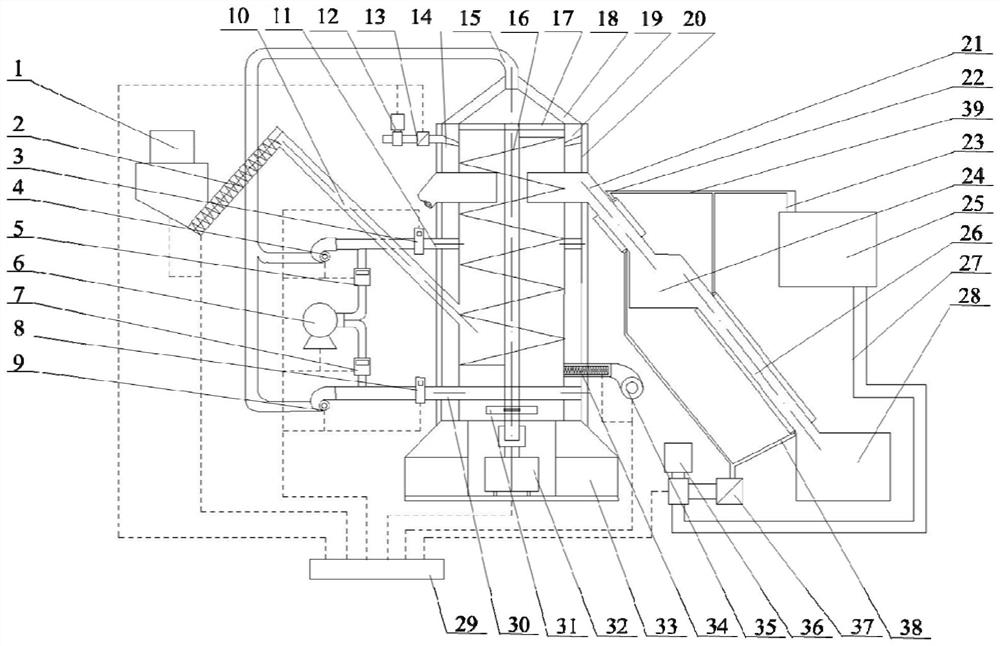

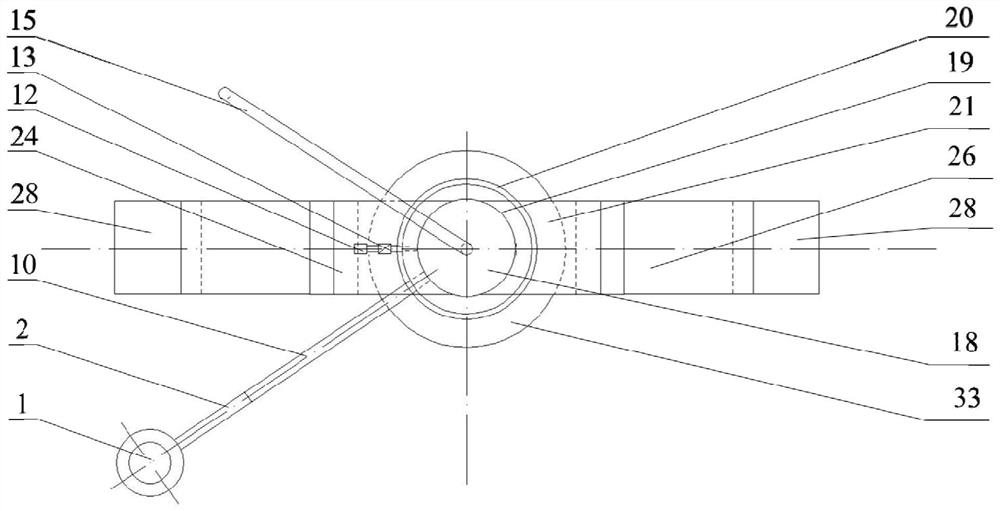

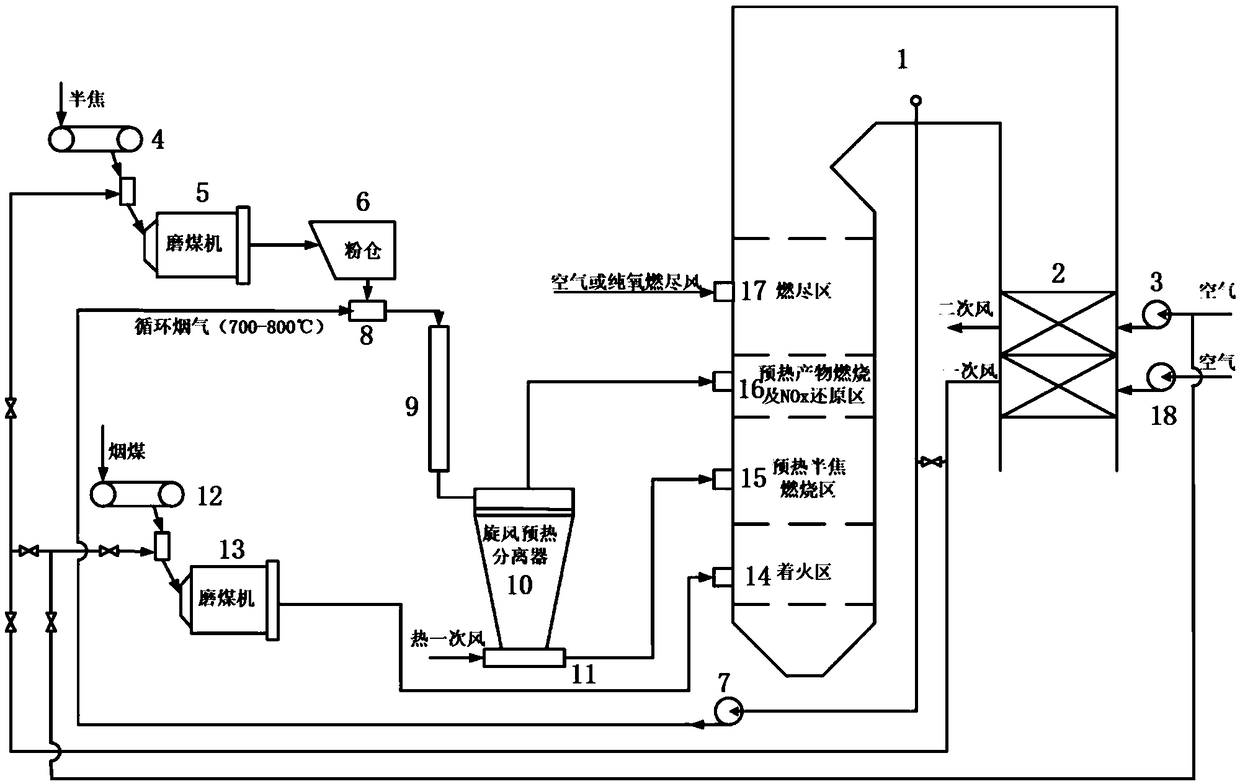

Low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of power station boiler

ActiveCN108151008AIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

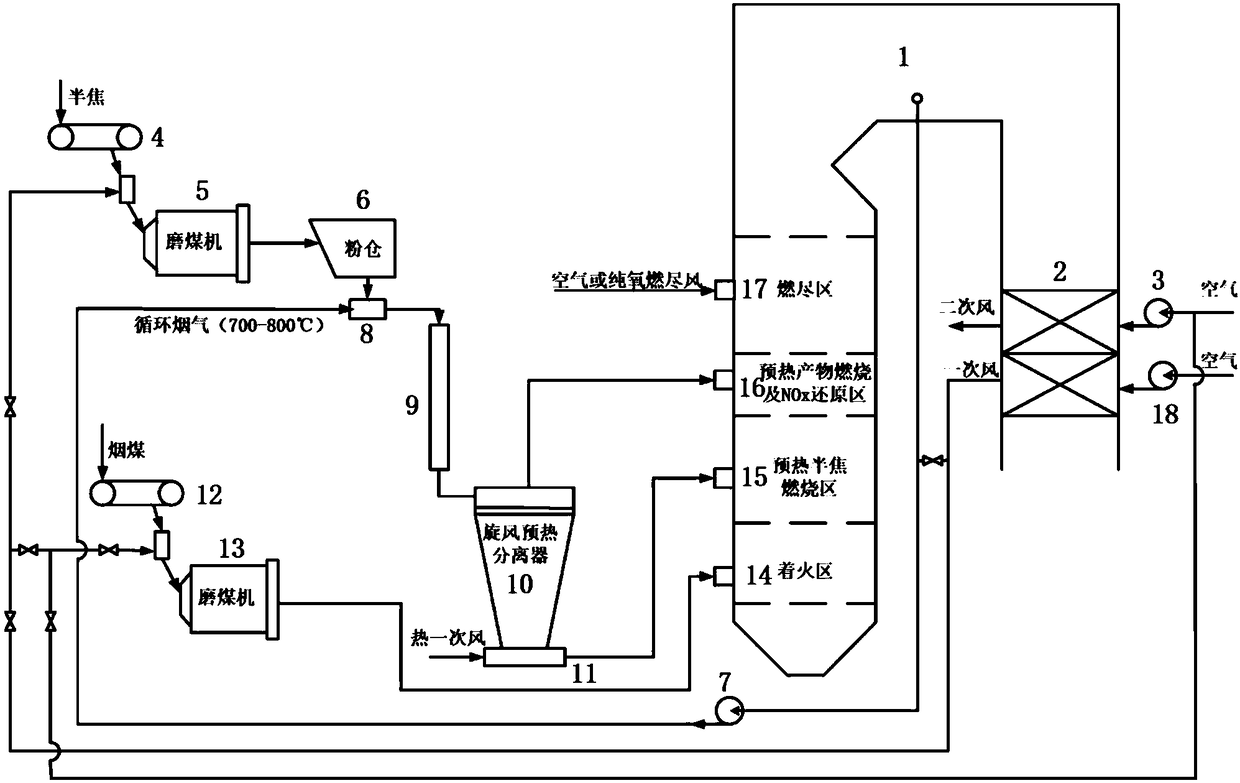

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

Feed raw material rich in energy and protein of omega-3 fatty acid and preparation method thereof

InactiveCN101473889AChange ingredientsChange natureAnimal feeding stuffAdditive ingredientAnti nutritional

The invention discloses a prescription for preparing an energy and protein feeding stuff raw material full of omega-3 fatty acid by using rubber seeds and a method thereof. The weight percentages of the omega-3 energy and protein feeding stuff raw materials are as follows: rubber seeds 20-80%, bean pulp, corn, rapeseed cake (pulp), cottonseed cake (pulp), rice bran and wheat bran or any combination thereof 20-80%. The preparation method is as follows: the exuviated and dried rubber seeds are mixed with various ingredients evenly and puffed, and then finished product is gained. By the invention, the nutrient components such as omega-3 fatty acid, energy and protein and the like contained in the rubber seeds can be used fully, meanwhile, anti-nutritional components such as hydrocyanic acid and the like contained in the rubber seeds are removed, the energy and protein raw materials full of omega-3 fatty acid widely accepted by the feeding stuff industry and applicable to various birds, livestock and fish feeding stuff are processed. The price of the energy and protein raw material is low.

Owner:云南三环生物技术有限公司

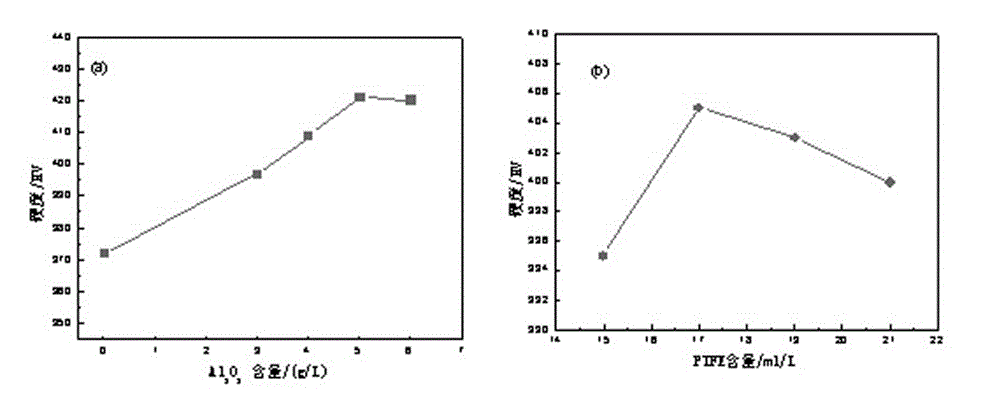

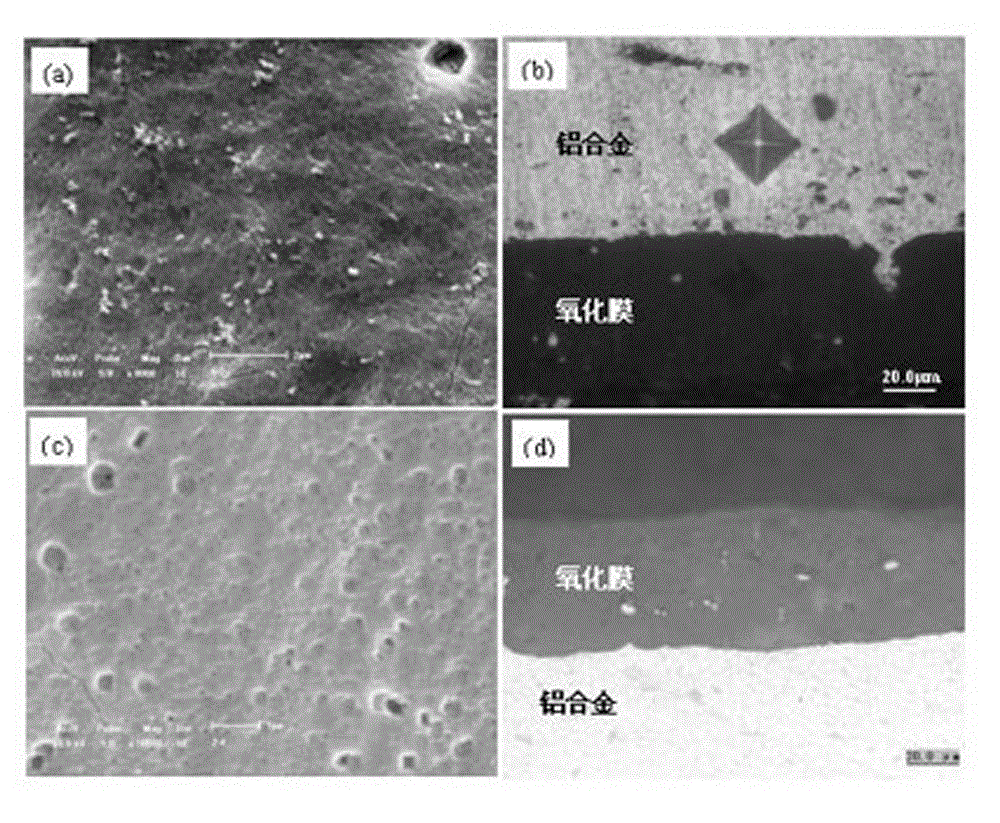

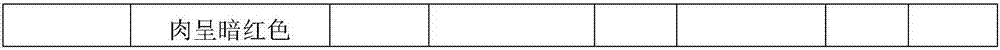

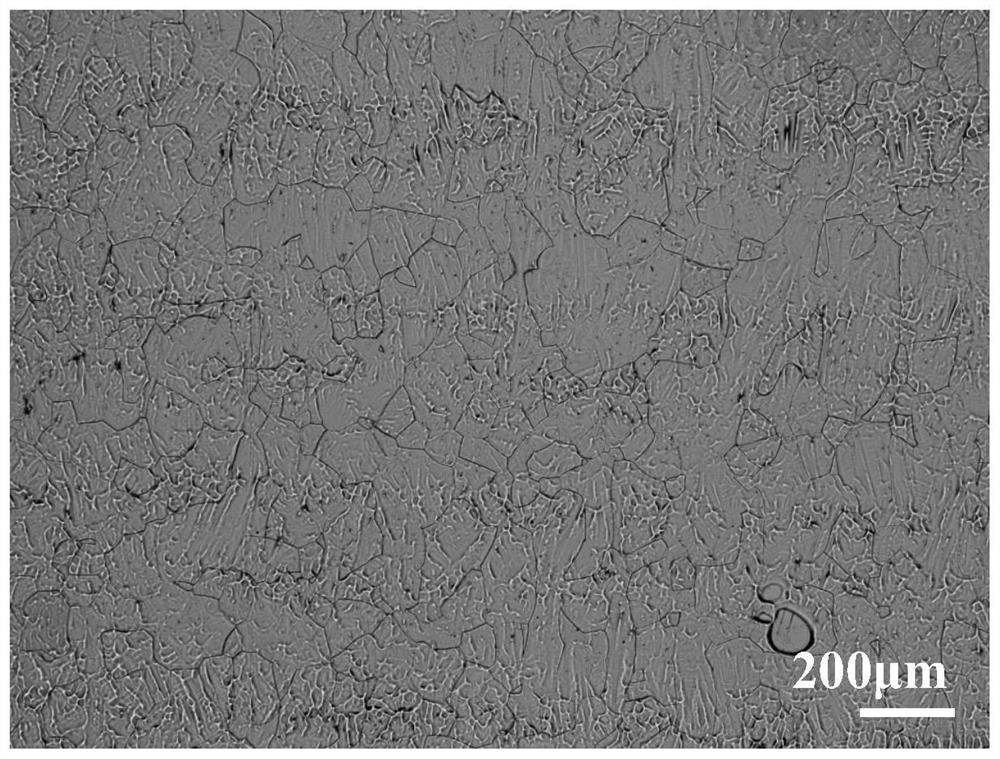

Method for preparing high-wear-resistance self-lubricating composite oxide film on surface of aluminum alloy friction part

The invention belongs to the technical field of materials, and particularly relates to a method for preparing a high-wear-resistance self-lubricating composite oxide film on the surface of an aluminum alloy friction part. The method comprises the following steps: preparing a composite electrolyte for anodic oxidation; sanding and degreasing the surface of an aluminum alloy, and performing alkaline etching, ash removal and chemical polishing pretreatment; performing composite anodic oxidation treatment to prepare an oxide film, and detecting the hardness; and if the sample does not reach the required hardness, performing heat treatment on the composite oxide film. According to the invention, an oxidization liquid system composed of three acids is designed; the oxide film having high growth speed, high hardness, high wear resistance and high strength and toughness can be grown based on characteristics of pulse current oxidization; and the composite oxide film has higher wear resistance and favorable self-lubricating property through the heat treatment on the oxide film, thereby being applicable to the preparation of oil-free or oil-less lubricating friction parts under different friction conditions (high-speed light load or low-speed heavy load) in the industries of sewing, food, textile, automobiles and the like.

Owner:NORTHEASTERN UNIV

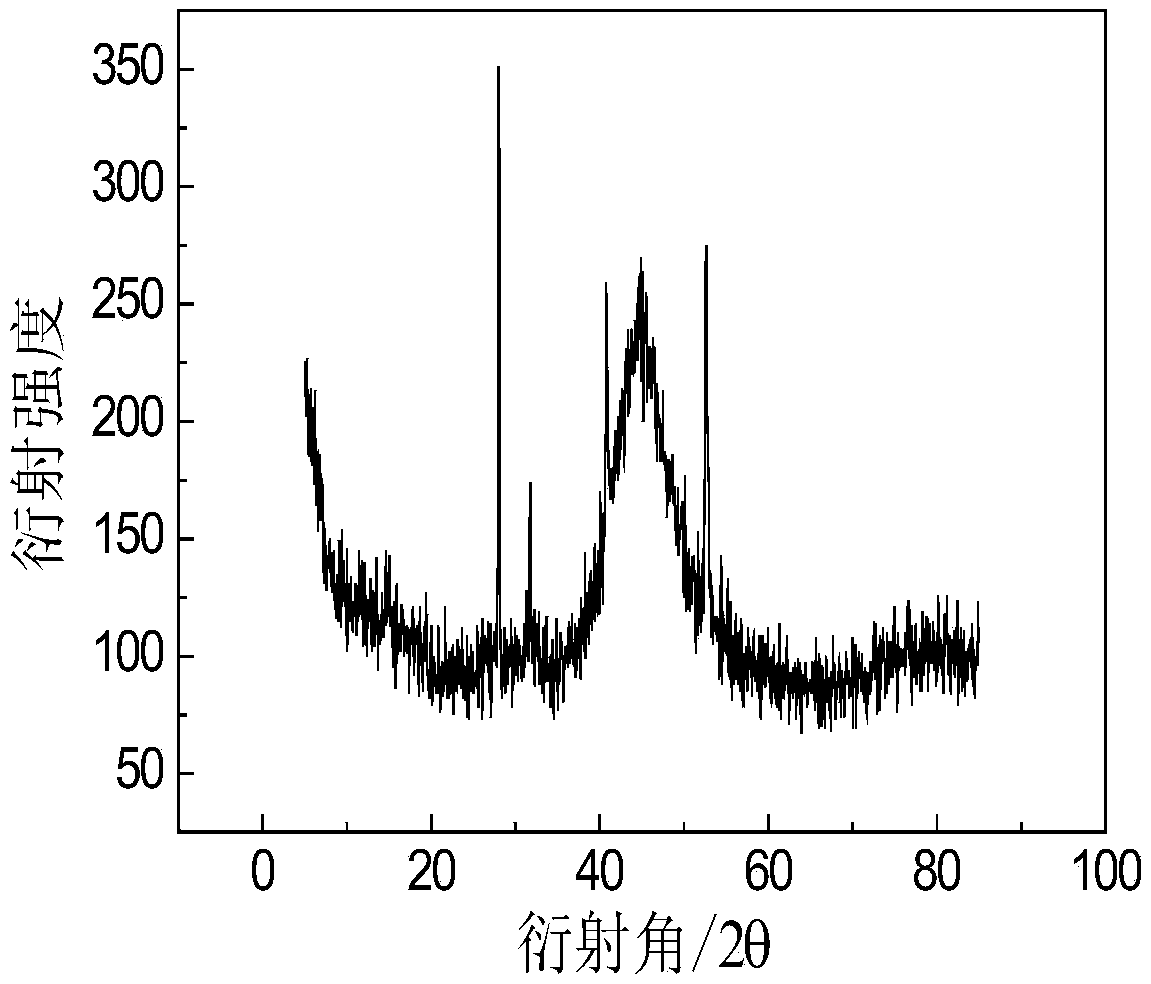

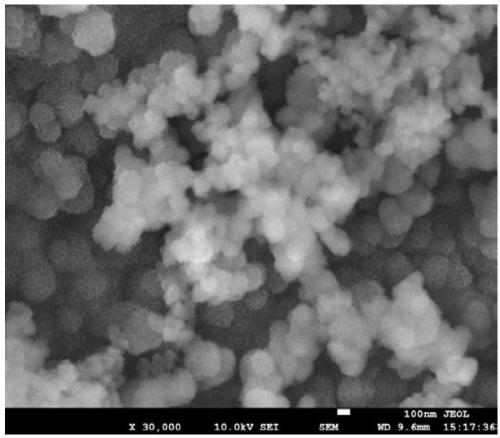

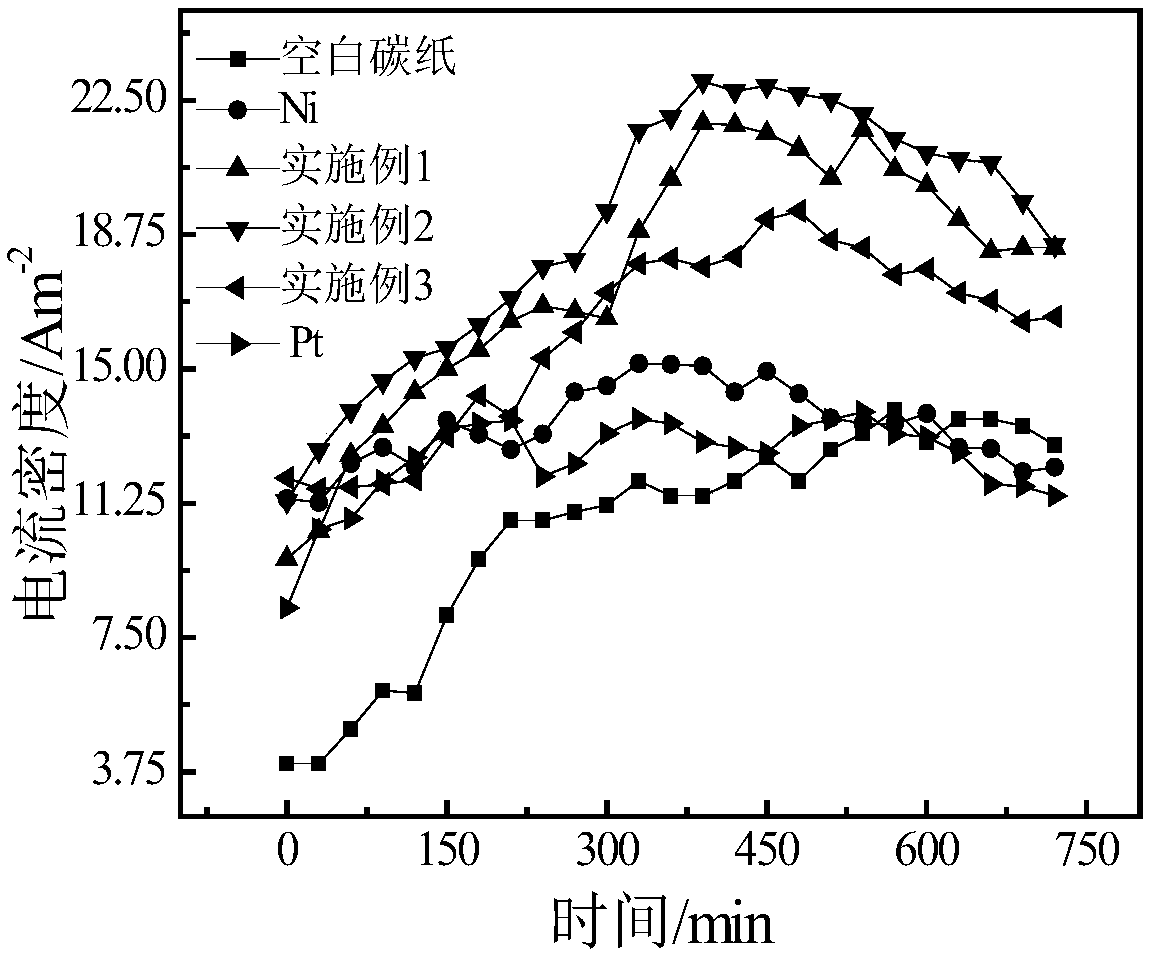

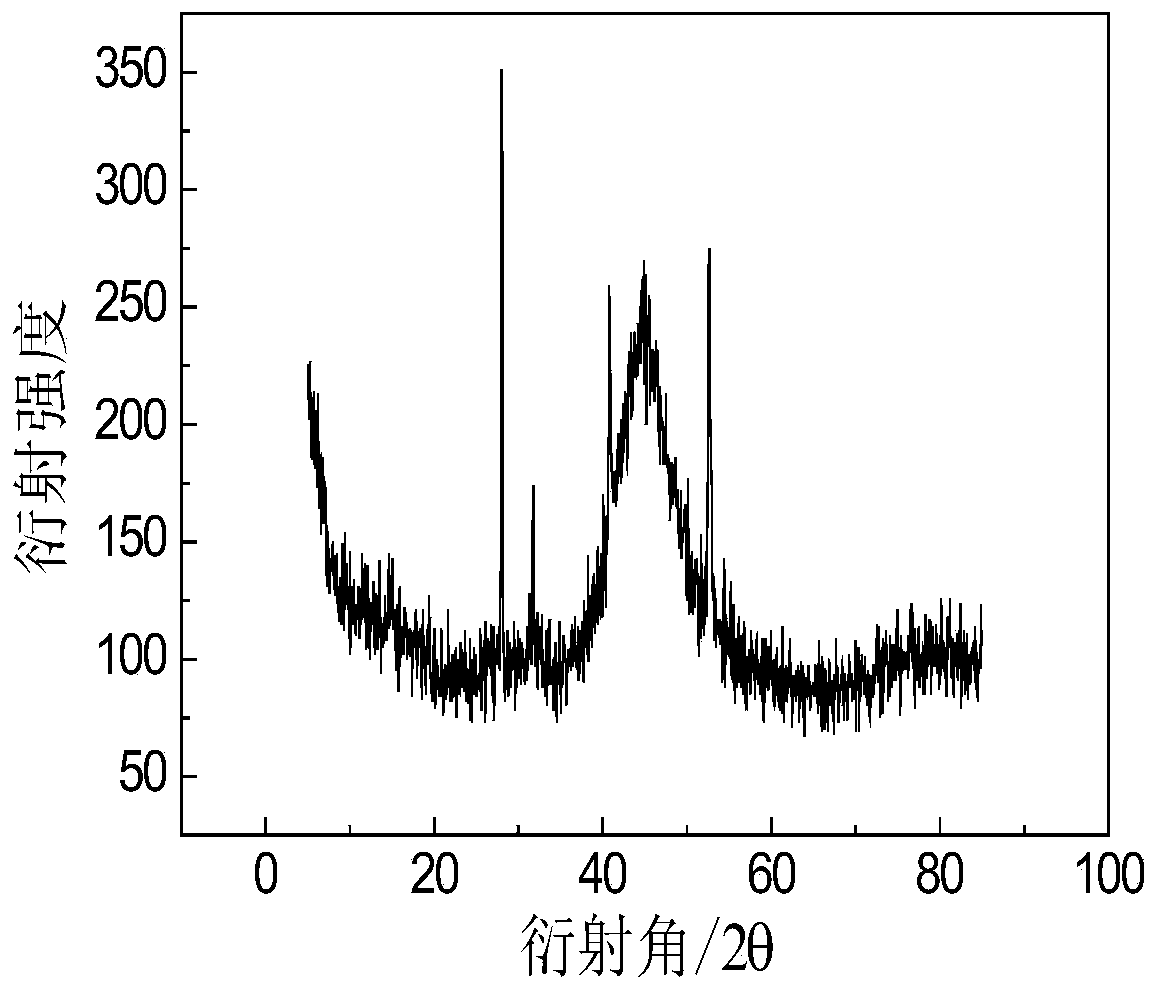

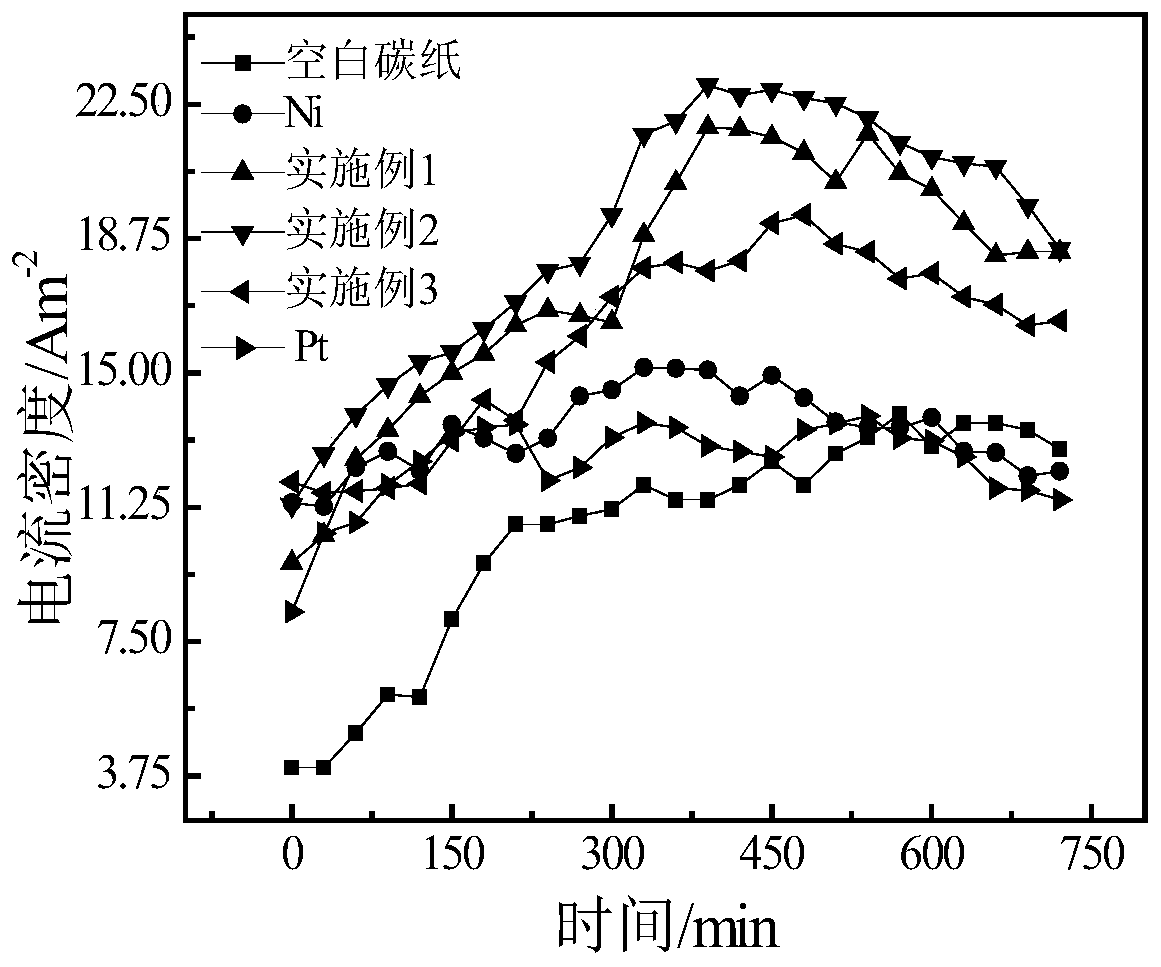

Mo/Ni/Co/P/C composite material as well as preparation method and application thereof

InactiveCN109136983ALow priceLow hydrogen evolution overpotentialTreatment by combined electrochemical biological processesElectrodesAuxiliary electrodeWorkstation

The invention belongs to the technical field of composite materials, and particularly relates to an Mo / Ni / Co / P / C composite material as well as a preparation method and an application thereof. The material is prepared with the following method: in a three-electrode system, a carbon-based substrate taken as a working electrode, a platinum net taken as an auxiliary electrode and Ag / AgCl taken as a reference electrode are connected with an electrochemical workstation, potentiostatic deposition is conducted in a mixed solution of nickel sulfate with concentration of 30-70 g / L, sodium hypophosphitewith concentration of 20-40 g / L, nickel chloride with concentration of 10-20 g / L, boric acid with concentration of 30-35 g / L, cobalt chloride with concentration of 30-50 g / L and sodium molybdate withconcentration of 40-50 g / L, magnetic stirring is conducted throughout the deposition process, initial potential set on the working electrode during electroplating is (-1.5)V-(-1)V, electroplating timeis 5-30 min, electroplating temperature is set to be 25-35 DEG C, a power supply is turned off finally, and the Mo / Ni / Co / P / C composite material is prepared. The Mo / Ni / Co / P / C composite material is taken as a cathode material of a microbial electrolytic cell to treat coking wastewater and produce hydrogen synchronously, waste is changed into treasure, and a new idea and a new perspective are provided for impending coking wastewater treatment.

Owner:TAIYUAN UNIV OF TECH

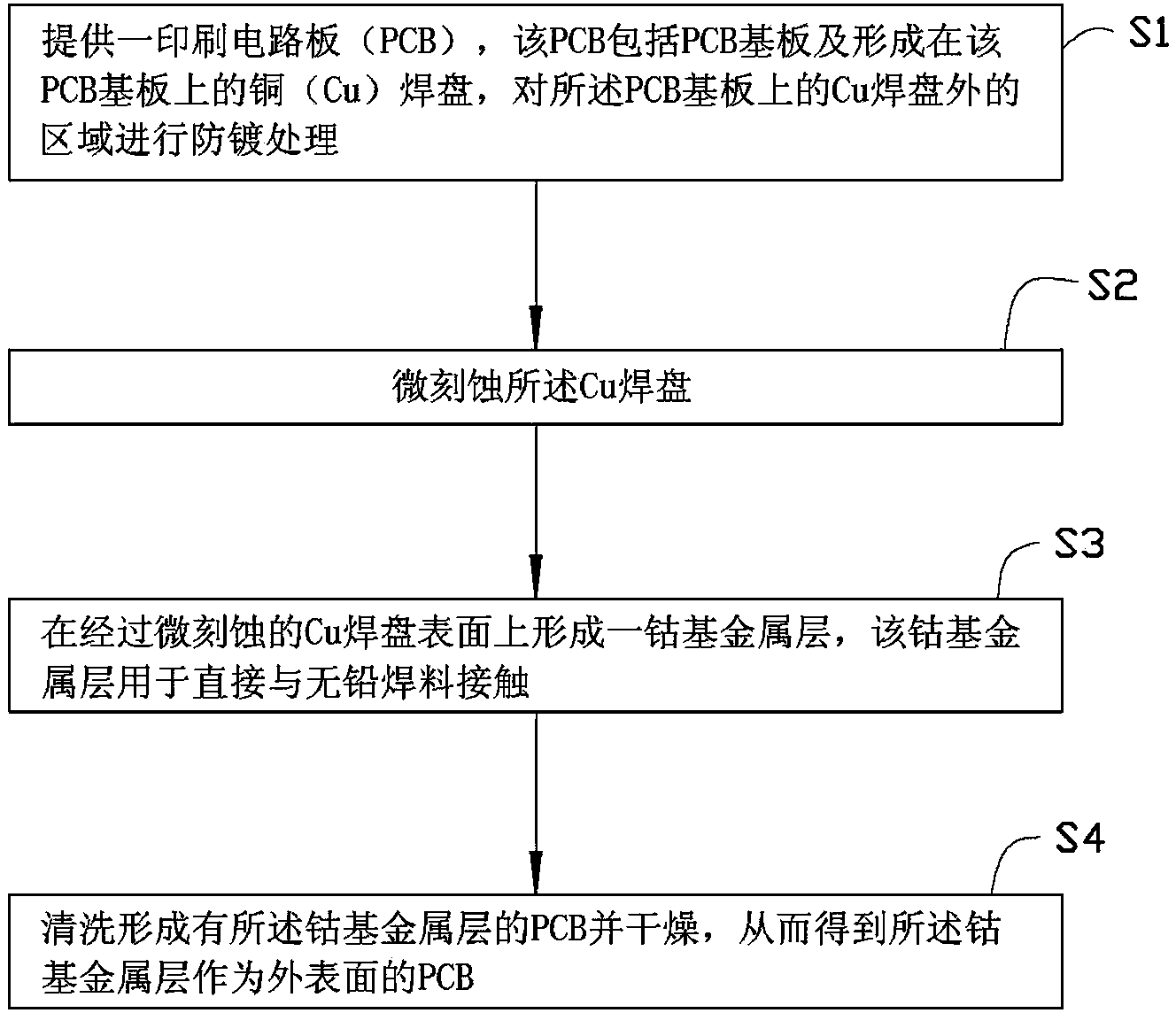

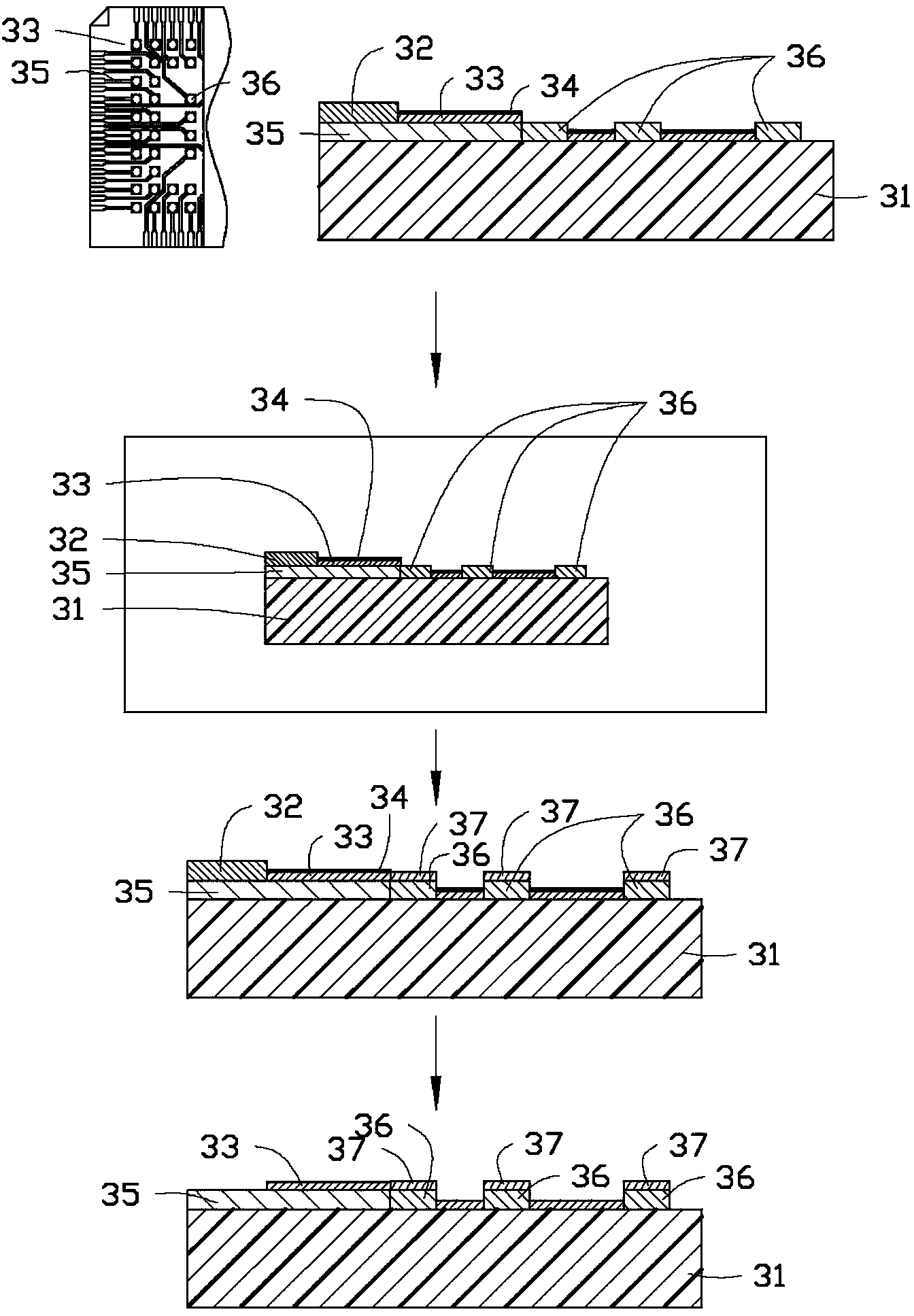

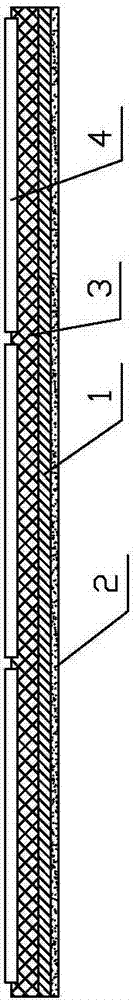

Printed circuit board and method for processing surface of printed circuit board

The invention discloses a method for processing the surface of a printed circuit board. The method comprises the steps that the printed circuit board is provided, the printed circuit board comprises a printed circuit board substrate and a brazing disc formed on the printed circuit board substrate, welding resistance processing and anti-plating processing are conducted on zones outside the brazing disc on the printed circuit board substrate; micro-etching is conducted on the brazing disc; a cobalt-based metal layer is formed on the surface of the brazing disc which undergoes micro-etching and the cobalt-based metal layer is used for directly making contact with lead-free solder, and the printed circuit board with the cobalt-based metal layer is cleaned and dried. The invention further provides the printed circuit board which undergoes the processes.

Owner:TSINGHUA UNIV

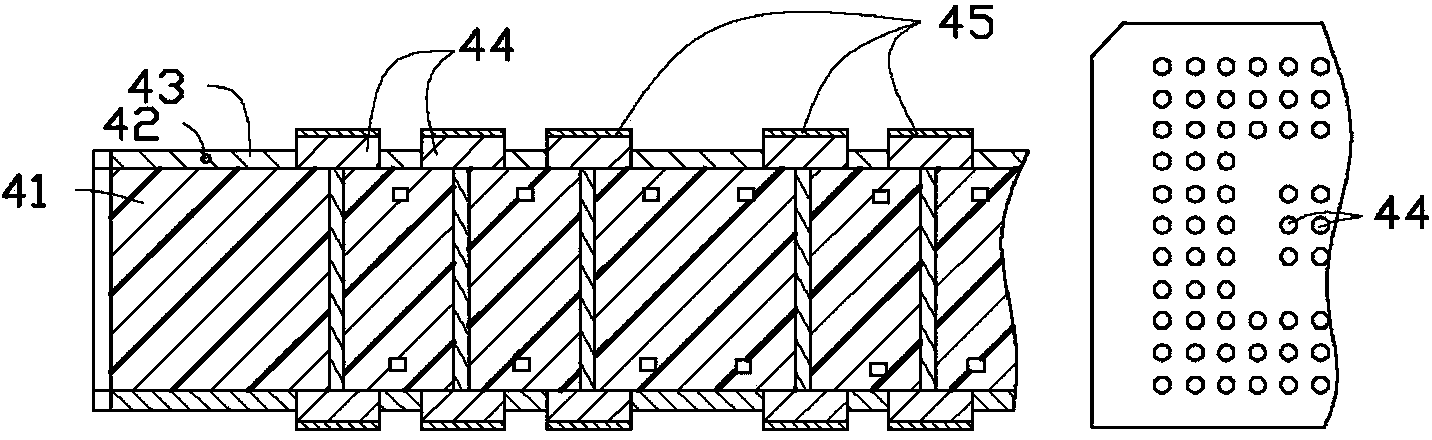

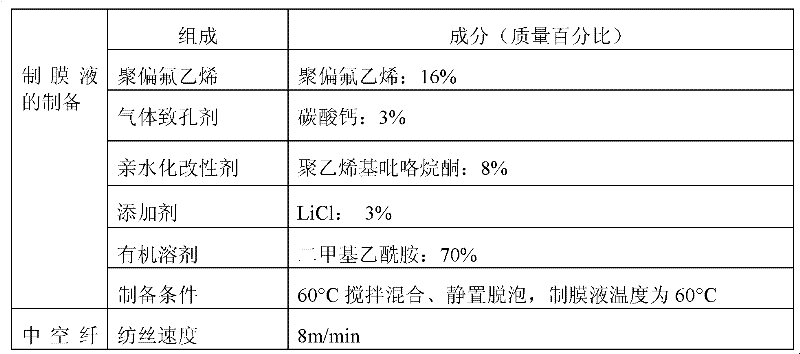

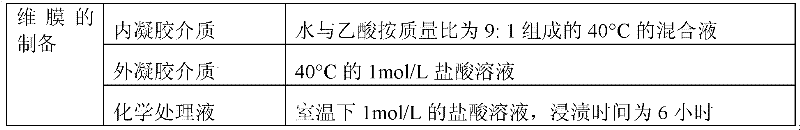

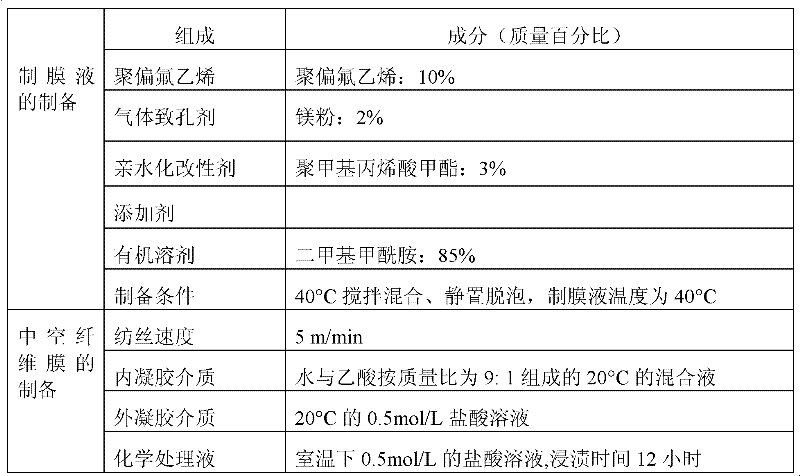

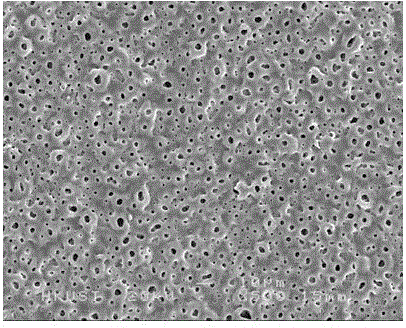

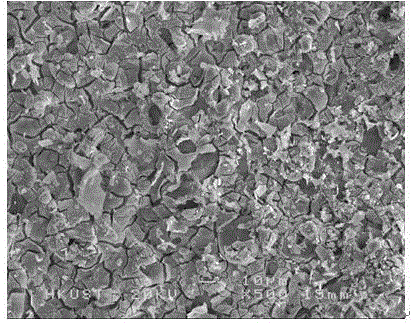

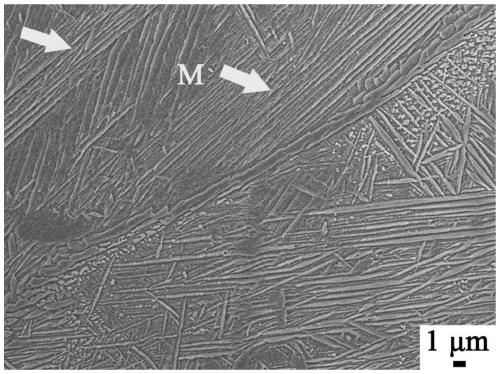

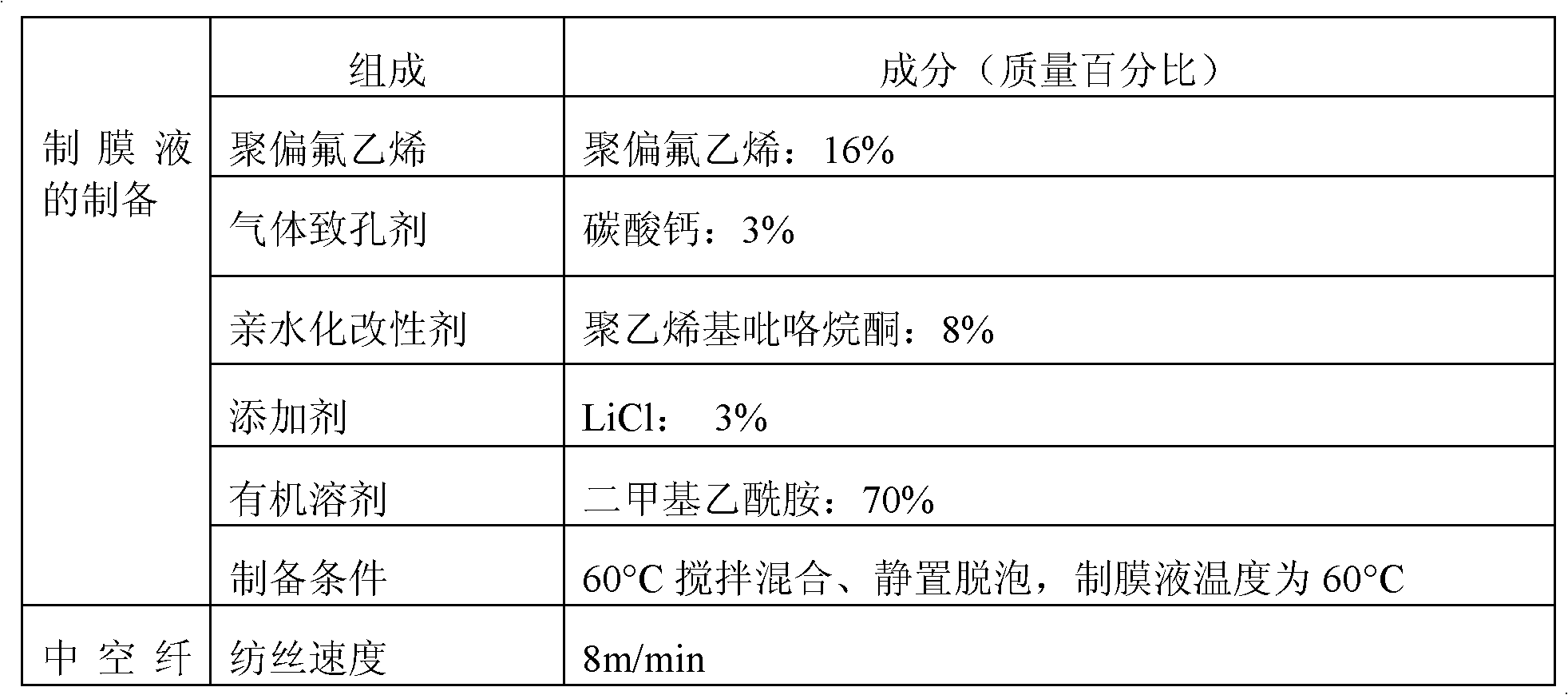

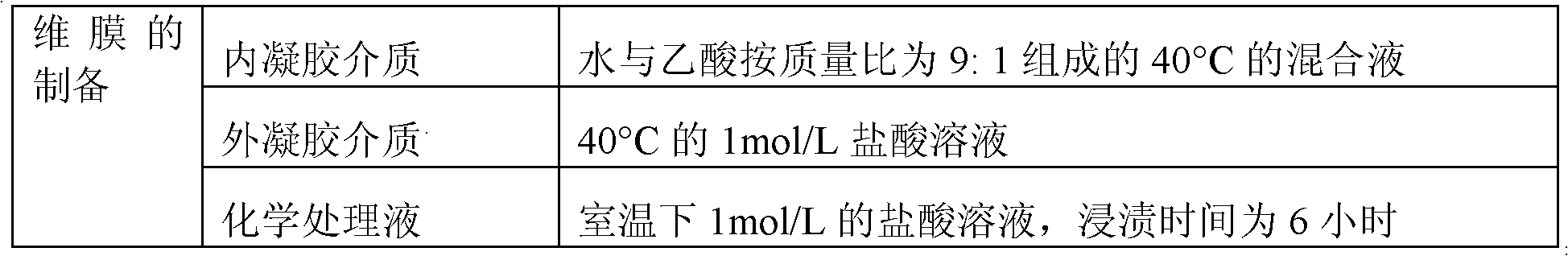

Method for preparing high-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN102512987AImprove throughputFlux does not destroySemi-permeable membranesChemical treatmentChemical reaction

The invention discloses a method for preparing a high-flux polyvinylidene fluoride hollow fiber membrane. The method comprises the following steps of: mixing polyvinylidene fluoride, a gaseous pore-forming agent, a hydrophilic modifier, additives and organic solvents and making a membrane-making solution; allowing an internal gelling medium and the membrane-making solution to pass through spinning nozzles on dry / wet spinning equipment at the same time, injecting into an external gelling medium, and performing phase-splitting treatment to make a primary membrane; and performing special chemical treatment on the primary membrane with a chemical treatment liquid to obtain a high-flux polyvinylidene fluoride hollow fiber membrane. The invention is characterized in that the membrane is reinforced with the pores by chemical reactions between the internal gelling medium, external gelling medium and chemical treatment liquid and the gaseous pore-forming agent; and the polyvinylidene fluoride hollow fiber membrane has a high flux, a high strength, a high entrapment rate and good hydrophilicity.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

Polishing process for stainless steel base tape for coated conductor

InactiveCN102703937AChange ingredientsImprove adsorption capacityElectrical conductorPhosphoric acid

The invention relates to a polishing process for a stainless steel base tape for a coated conductor, which belongs to the technical field of surface polishing for base tapes of high-temperature coated superconductors and mainly provides a stainless steel polishing process integrating acid cleaning, chemical polishing and electrochemical polishing. According to the invention, toxic chromic acid and hydroflouric acid and volatile hydrochloric acid solution in the traditional polishing solution are removed, pollution to environmental, harm to human body and corrosion to equipment of the used materials are reduced, the raw materials of the polishing solution, including common phosphoric acid and sulfuric acid solutions, hydrogen peroxide used as an oxidant, dimethylglyoxime used as a complexing agent and ZP-1 corrosion inhibitor, are easily obtained, the cost is low, the operability of the preparation process is strong, the prepared solution can be used at normal temperature, the energy consumption of equipment is reduced, the electricity is saved, the production cost is saved by the optimized polishing process, and the polishing finish is enhanced.

Owner:BEIJING UNIV OF TECH

Micro-arc oxidation ceramic membrane and preparation method thereof

InactiveCN106119926AChange ingredientsImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides a micro-arc oxidation ceramic membrane and a preparation method thereof. The preparation method comprises the steps of micro-arc oxidation treatment and hole sealing treatment. After a magnesium alloy is subjected to micro-arc oxidation treatment, the ceramic membrane with high corrosion resistance and heat radiation performance is generated on the surface, hole sealing treatment is carried out through hole sealing liquid, the compactness of the ceramic membrane is enhanced, and the corrosion resistance of the ceramic membrane is further enhanced. The micro-arc oxidation ceramic membrane and the preparation method have the following beneficial effects that after the magnesium alloy is subjected to micro-arc oxidation treatment, and the ceramic membrane with high heat radiation performance is formed on the surface, so that the heat radiation efficiency of the magnesium alloy is improved; an additive containing glycerine and tungstate is added into a micro-arc oxidation electrolyte, components of the ceramic membrane are changed, the corrosion resistance of the ceramic membrane is enhanced, and therefore the corrosion resistance of the magnesium alloy is increased, and the service life is prolonged; and hole sealing treatment is carried out through the hole sealing liquid, the compactness of the ceramic membrane is improved, the corrosion resistance of the magnesium alloy is further improved, and meanwhile the problem that the colors of micro-arc oxidation ceramic membranes in the current market are not abundant is solved.

Owner:KA SHUI TECH HUIZHOU CO LTD

Medicine for treating calculus in hepatobiliary system

InactiveCN102579980AEasy to shrinkPromote secretionDigestive systemPlant ingredientsSalvia miltiorrhizaDisease

The invention discloses a medicine for treating calculus in a hepatobiliary system and enables the problems that conventional medicines can not remove calculus and dissolve calculus at the same time to be overcome. The medicine is prepared from the following bulk drugs by weight: 20 to 30 of Guangdong desmodium, 20 to 25 of Artemisia capillaris, 15 to 20 of Fructus Gardeniae, 15 to 20 of gentrin knotweed, 15 to 20 of curcuma tuber, 4 to 8 of rheum officinale, 15 to 20 of bitter organe, 15 to 20 of betel nuts, 9 to 12 of toosendan fruit, 6 to 9 of banksia rose, 9 to 12 of chicken's gizzard membrane, 20 to 25 of haw, 9 to 12 of Chinese angelica, 20 to 25 of red sage root, 9 to 12 of radix paeoniae rubrathe, 3 to 6 of mirabilite, 15 to 20 of green tangerine peel and 20 to 25 of dark plum. The medicine provided in the invention is obtained through refined extraction of pure Chinese herbal medicines, has the effects of removing calculus, dissolving calculus and preventing formation of calculus, has a complete calculus removal rate of 43% and a total effective rate of 95.6%, costs little, provides a safe and effective treatment way for old people who are not willing to or cannot have surgery and for patients suffering from cardiovascular and cerebrovascular diseases and is easily accepted by patients.

Owner:张国栋

Process for producing health fruit and vegetable vermicelli

InactiveCN1451299AChange ingredientsIncrease health functionFood preparationFruits and vegetablesFruits vegetables

A health-care long-thread fruit-vegetable vermicelli is prepared from starch and fruit-vegetable juice (1-10%).

Owner:陈利民

Ternary alloy sealing-in material and preparation method thereof

The invention provides a ternary alloy sealing-in material and a preparation method thereof. The ternary alloy sealing-in material is prepared from, by mass percent, 35%-45% of Ag, 45%-55% of Cu and 5%-15% of Ga. The preparation method of the ternary alloy sealing-in material comprises the steps of smelting, casting, solid solution, ageing, turning, cold rolling, tempering, annealing and finish machining. The prepared sealing-in material has the beneficial effects of being high in cleanliness, resistant to corrosion, good in oxidation resistance, low in cost and the like.

Owner:WUXI RIYUE ALLOY MATERIALS

Method for cultivating ginseng and American ginseng on ginseng rear land and flat land

A method for cultivating ginseng or American ginseng in the field after previous ginseng has been harvested or flat field features that solution of chloropicrin is proportionally injected in said field at 30-cm intervals by 15-20 cm in depth for changing the components in soil.

Owner:殷国生 +1

Fish balls with pumpkin sauce stuffing

InactiveCN107616438AChange ingredientsRefreshing and deliciousFood coatingMonosodium glutamateCuttlefish

The invention discloses fish balls with pumpkin sauce stuffing. The fish balls with the pumpkin sauce stuffing is composed of the following raw materials in parts by weight: 15-20 parts of chicken meat, 30-35 parts of fish meat, 15-20 parts of corn starch, 2-4 parts of seasonings, and 3-6 parts of pumpkin sauce; and the seasonings comprise crystal sugar, edible salt, monosodium glutamate, and sesame oil. According to the fish balls with the pumpkin sauce stuffing, the fish balls and the pumpkins are combined by adopting a rational raw material ratio and reasonable processing steps, and thus, ingredients of cuttlefish balls can be effectively changed; moreover, asparagus is added so that taste of the cuttlefish balls becomes more refreshing and delicious, and the functions of clearing awayheat and so on of the asparagus are added.

Owner:DONGSHAN QICHANG FREEZING PROCESS CO LTD

Externally-used medicine for treating ankylosing spondylitis and preparation method

InactiveCN102755618AImprove defense and disease resistanceChange ingredientsAnthropod material medical ingredientsAntipyreticOral medicineSpondarthritis

The invention relates to traditional Chinese medicine and a preparation method thereof, in particular to externally-used medicine for treating ankylosing spondylitis and the preparation method of the medicine. The medicine includes the following components: syzygium aromaticum, cinnamon, radix angelicae, fennel, asarum, musk and cantharides. The preparation method includes grinding the componentsinto fine powder, breaking and filtering ginger powder to obtain ginger mud and ginger juice, scattering medicine powder on one face of strip mulberry paper immersed in the ginger juice, laying the ginger mud on the other face of the strip mulberry paper and embedding moxa cone into the ginger mud to obtain the externally-used medicine for treating ankylosing spondylitis. The medicine organicallycombines the components, gives full play to pharmacologic action of the components, directly acts on sicken parts through skin absorption and osmosis, is quick in medicine effect, avoids inconvenience caused by oral medicine, is easy to accept by patients and is good in treatment effect.

Owner:周健

Manufacturing formula of momordica grosvenori cake

InactiveCN107927094ASweet but not greasyEnhance immune functionDough treatmentBakery productsFruit juiceSucrose

The invention discloses a manufacturing formula of a momordica grosvenori cake. The manufacturing method comprises the following steps of preparing materials, conducting cleaning, squeezing, baking, grinding, fermenting, mixing stirring and secondary baking, and obtaining a finished product. Momordica grosvenori is squeezed, water is replaced with the juice, the juice is mixed with flour and the like, and fruit dregs after squeezing are dried and grinded into powder, and are put in the flour to be fermented together with the flour, so that the finished product of the cake has the flavor of momordica grosvenori; honey and momordica grosvenori are adopted as main raw materials of sugar, and thus the cake has the advantage of being sweet while not greasy; selenium tablets are added to facilitate strengthening of the immunity of the human body and have the effect of protecting and restoring the organism of the heart, preventing pancreatic beta cells from being oxidized and destroyed and lowering blood glucose and urine glucose; L-arabinose is added during cake making, can inhibit rising of blood sugar when an eater absorbs saccharose and the increase of fat, prevent constipation, and change the functions of components of skeletal muscle fiber, and thus the momordica grosvenori cake has the effect of improving diabetes.

Owner:贺州市星辉科技有限公司

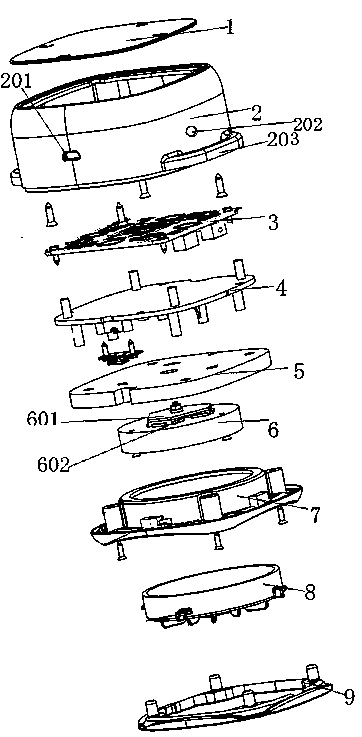

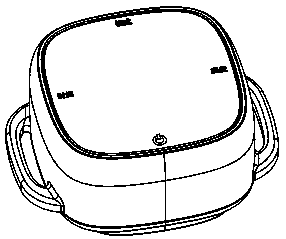

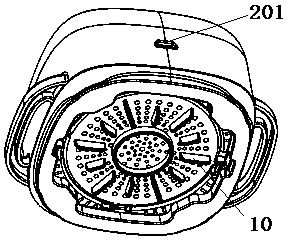

Low-medium frequency therapeutic instrument with moxibustion function

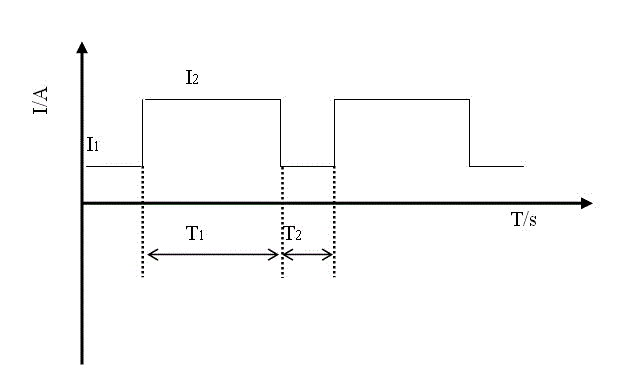

PendingCN109395247AChange ingredientsIncrease the number ofDevices for heating/cooling reflex pointsElectrotherapyModern medicineMedicine

The invention relates to a low-medium frequency therapeutic instrument with moxibustion function. The therapeutic instrument combines the moxibustion of traditional Chinese medicine with low-medium frequency treatment of modern medicine for mutual catalysis and reinforcement of the health care physiotherapy effect. In order to solve the technical problems, according to a technical scheme adopted by the invention, the low-medium frequency therapeutic instrument with moxibustion function includes a therapeutic instrument shell, and is characterized in that: a touch display panel is disposed on the shell, the shell is internally equipped with a main circuit board, a support part, a heat insulation protective layer and a heating plate in order, a heating module is mounted on the heating plate,the bottom is equipped with a base, a rubber mat is mounted around the base, and a rotatably buckled bottom cap is disposed at the middle part of the base.

Owner:ZUODIAN IND (HUBEI) CO LTD

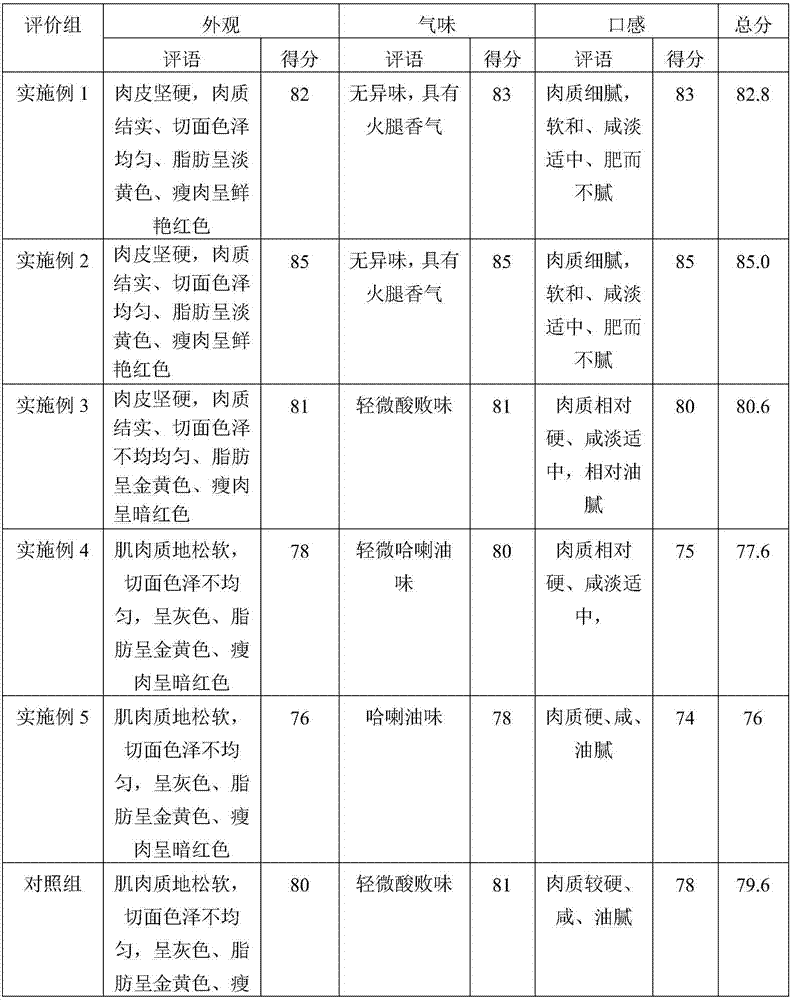

Processing method of ham

InactiveCN107509965AChange ingredientsFirm fleshFood ingredient as colourClimate change adaptationFood processingChemistry

The invention relates to the field of food processing and particularly relates to a processing method of ham. The processing method comprises the steps of material selecting and trimming, soaking, pickling, ham washing and airing and fermenting. By using a specially-made solution 1 and mixture, the ham processed by the processing method provided by the invention has good color, delicate meat and excellent taste, nutritional values of the ham are increased, and the demand of consumers for the quality of the ham is met.

Owner:贵州秀水旅游资源开发有限责任公司

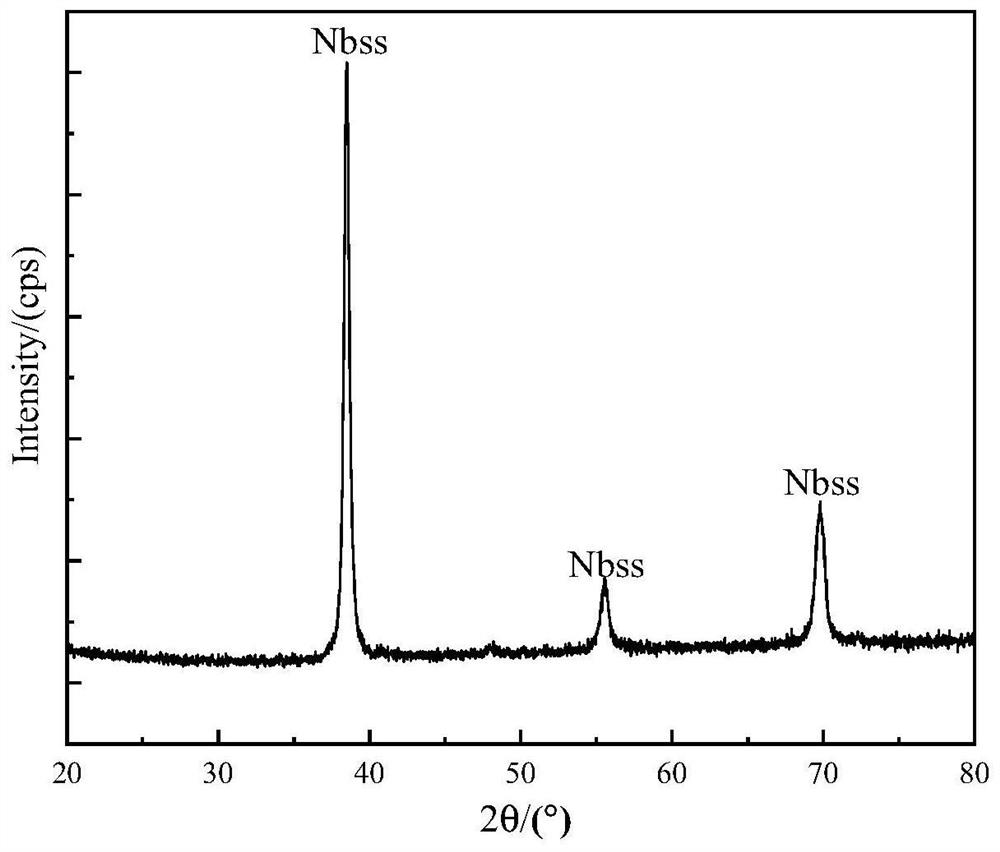

TiC reinforced low-density niobium alloy and structure-controllable laser three-dimensional forming method thereof

PendingCN113652585AReduce productionIncrease productivityAdditive manufacturing apparatusIncreasing energy efficiencyIngotNiobium alloy

The invention belongs to the technical field of metal additive manufacturing, and discloses a TiC reinforced low-density niobium alloy and a structure-controllable laser three-dimensional forming method thereof. The niobium alloy comprises the following components of, in atomic percent, 30%-45% of Ti, 0-15% of Al, 0-10% of TiC and the balance Nb. The laser additive manufacturing technology is adopted, the production efficiency can be improved, the machining period can be shortened, and the niobium alloy ingot blank preparation processes of smelting, powder metallurgy and the like can be omitted; and meanwhile, parts with complex shapes can be directly prepared through the laser three-dimensional forming technology, and the alloy microstructure can be regulated and controlled by adjusting technological parameters.

Owner:CHANGAN UNIV

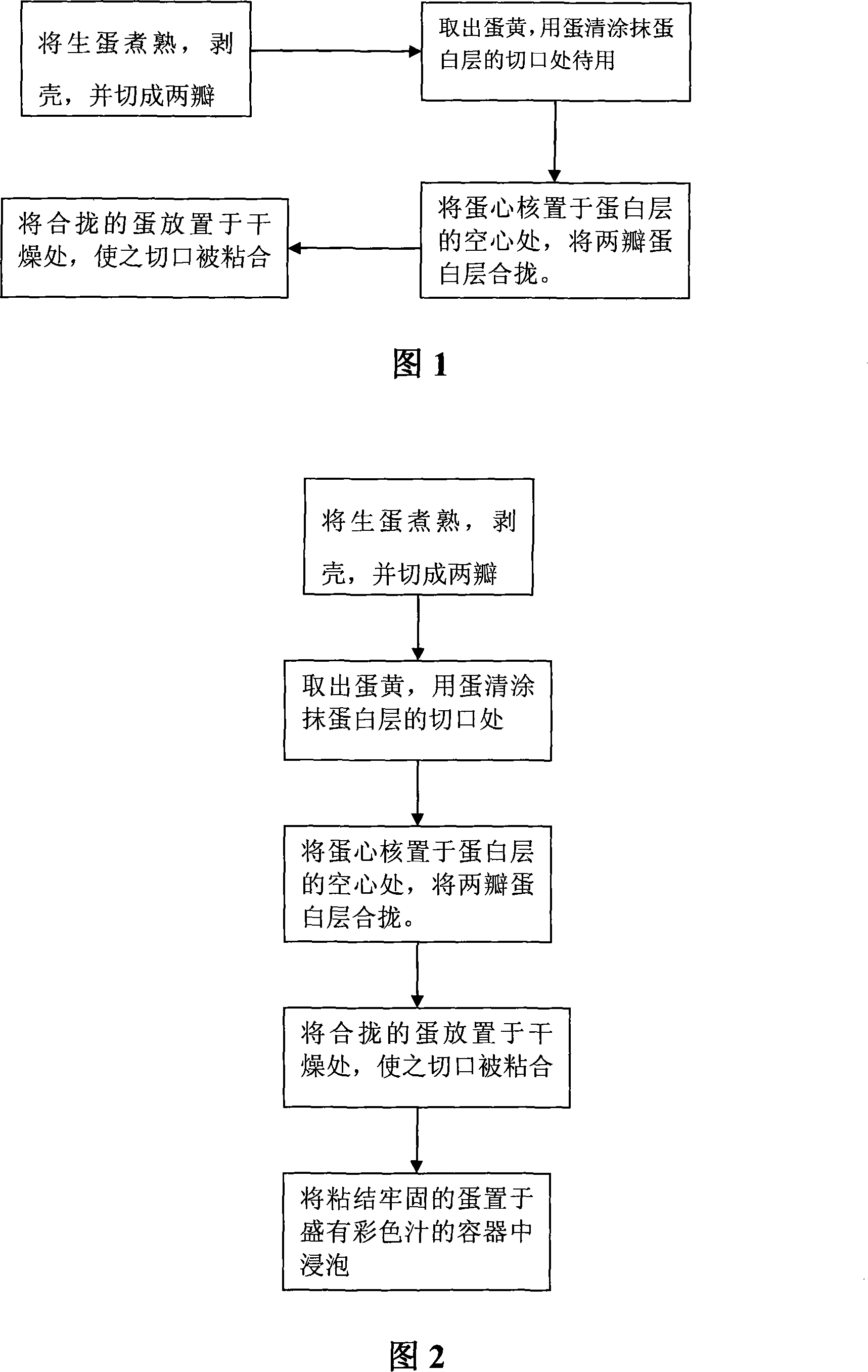

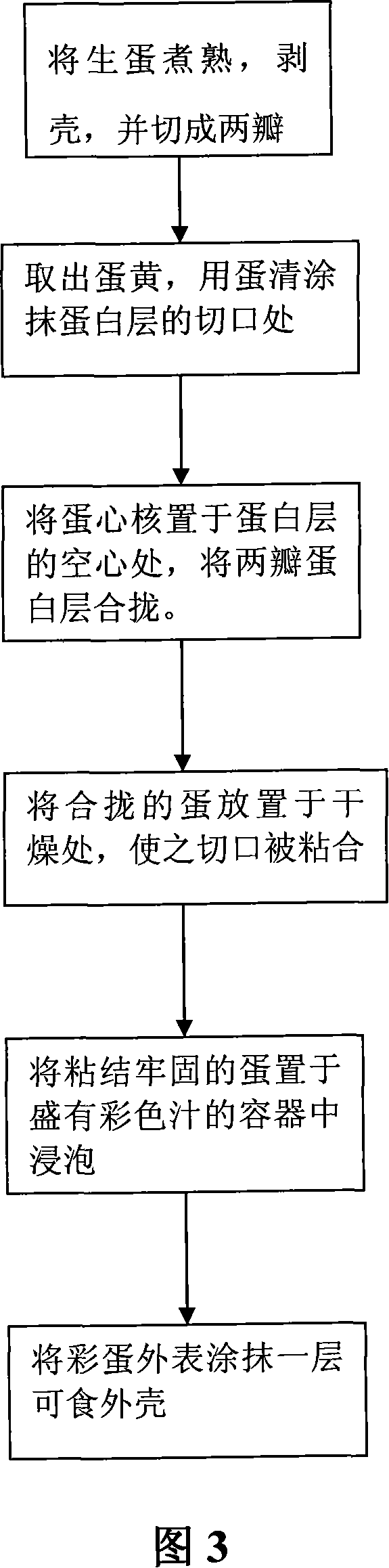

Center replaced easter egg and method of manufacturing the same

The invention discloses a heart changing color egg and its preparation method, which comprises an egg white layer and an egg kernel inside the egg white layer. The egg kernel refers to replaced yolk. The preparation method of the invention is as follows: 1. boil raw egg into cooked one, peel off the shell and cut it into two parts; 2. take out the yolk and daub the cutting section of the egg white layer with egg white; 3. place the yolk to be replaced at the hollow cavity inside the egg white layer, join the two parts of egg white layer at the cutting section, so that the egg kernel is enclosed in the egg white layer; 4. heat the joined egg to ensure fast bonding. The invention has the advantages that: the egg kernel can be replaced; the component for the egg kernel can be changed to make egg of different flavor; the appearance of the egg identifies with naturally laid egg; vivid appearance and favorable taste.

Owner:强坚华

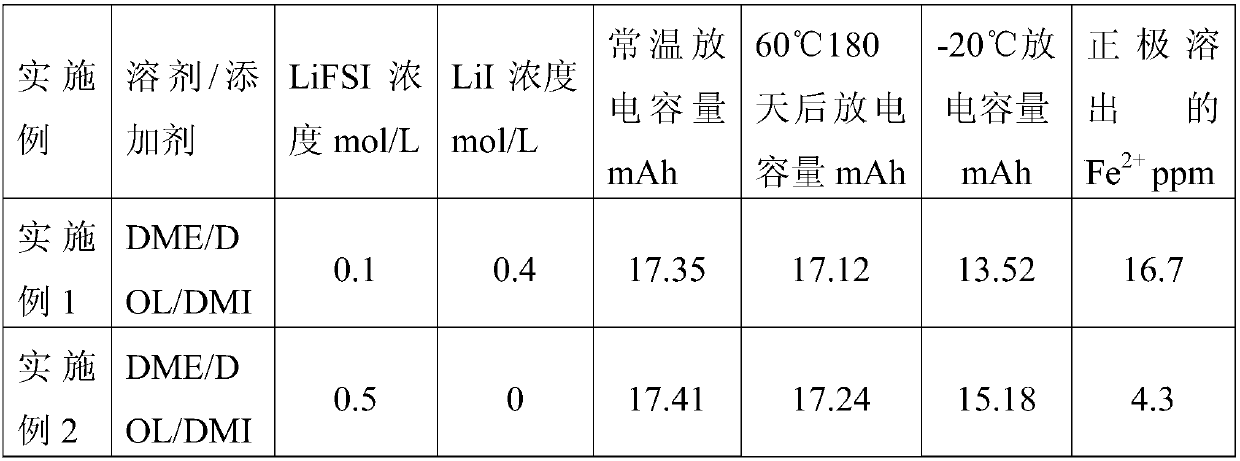

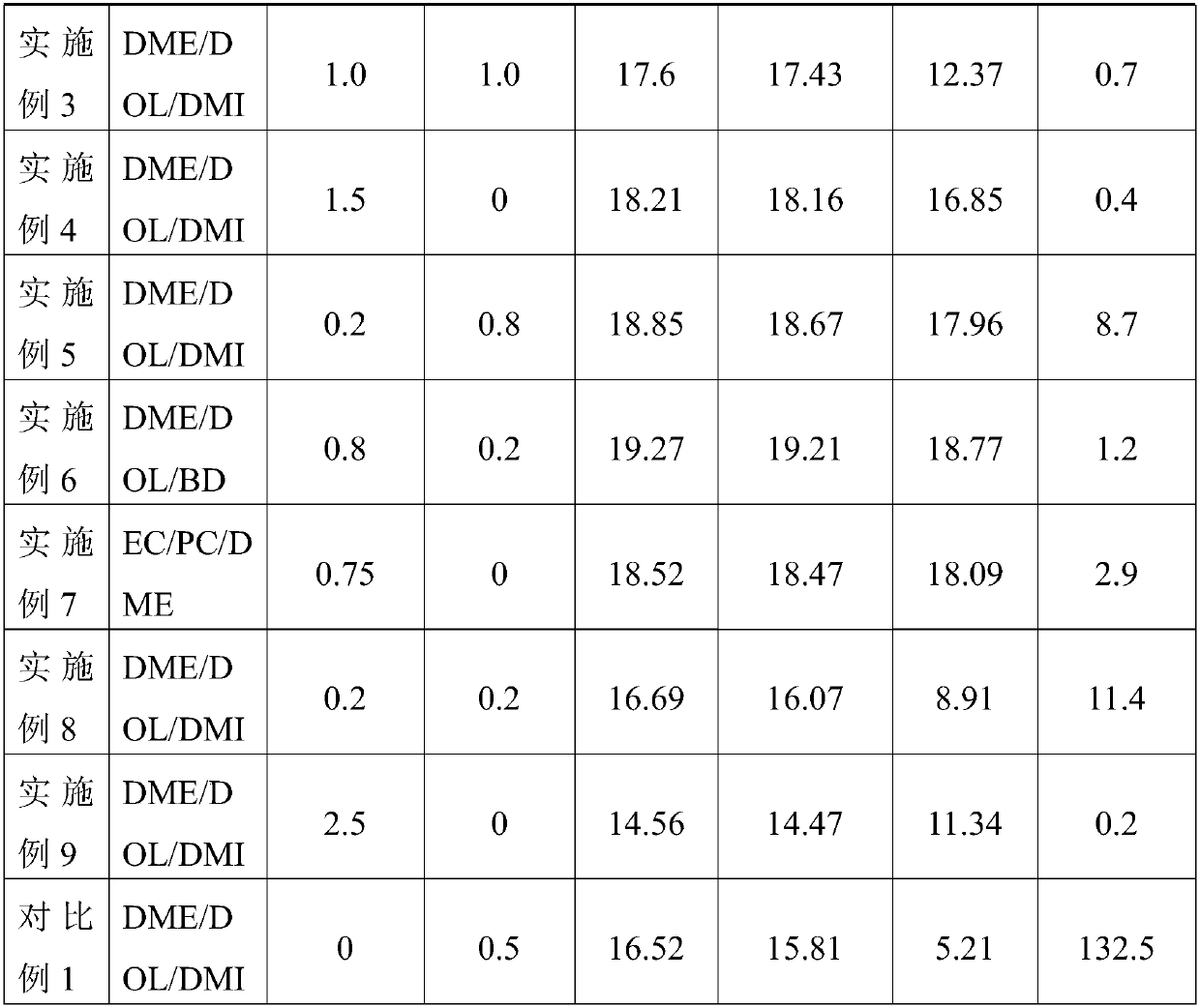

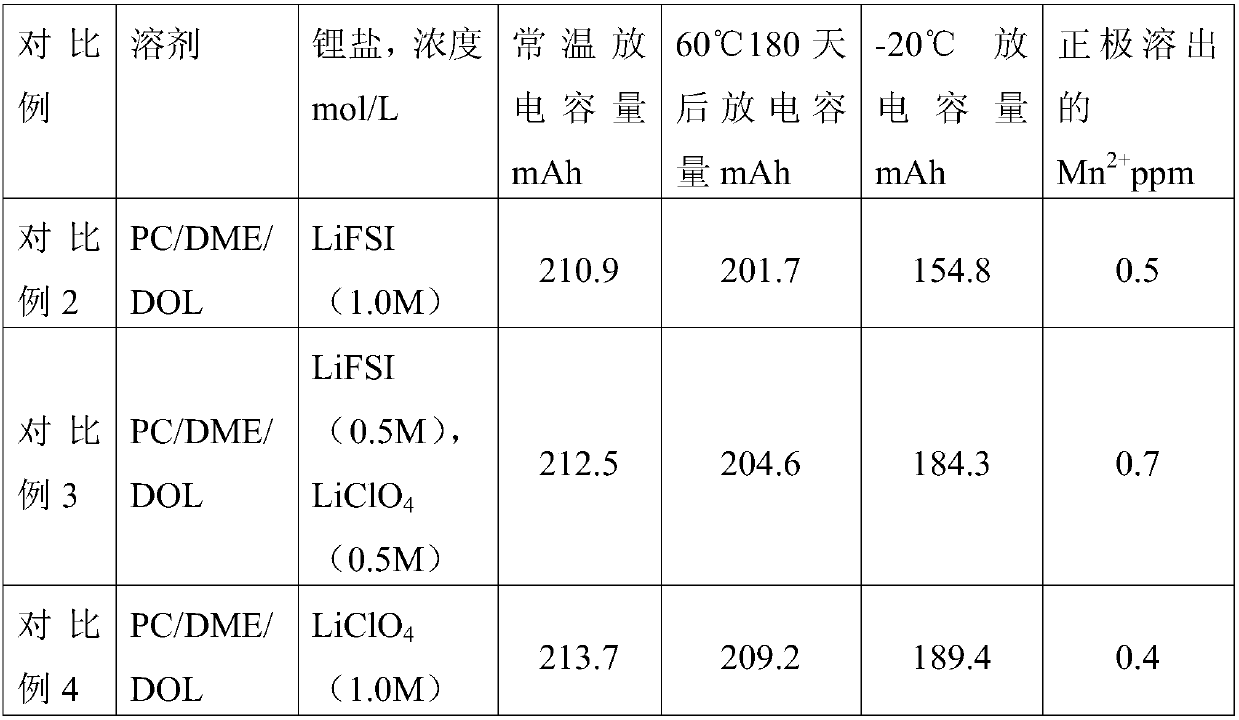

Lithium-iron disulfide battery

InactiveCN107565144ASuppresses internal micro-short circuitsExtended shelf lifeOrganic electrolyte cellsOrganic solventDissolution

The invention discloses a lithium-iron disulfide battery, which comprises iron disulfide (FeS2) as an anode, lithium or lithium alloy as a cathode and a partition board between the anode and the cathode, and further comprises non-aqueous electrolyte, wherein the non-aqueous electrolyte comprises a non-aqueous organic solvent and electrolyte salt; and the electrolyte salt at least includes lithiumbis(fluorosulfonyl)imide (LiFSI). The lithium-iron disulfide battery utilizes LiFSI to form a layer of protective film on the anode of a lithium iron battery, so that the dissolution of Fe2+ on the anode is effectively inhibited, and the components of a passive film at the cathode is changed, so that the stability of the passive film at the cathode is improved, and thus the occurrence of micro short circuit of the lithium iron battery in a storage process is inhibited, and the storage life and the discharge capacity of the battery are improved.

Owner:SHENZHEN CAPCHEM TECH CO LTD

A kind of mo/ni/co/p/c composite material and its preparation method and application

InactiveCN109136983BLow priceLow hydrogen evolution overpotentialTreatment by combined electrochemical biological processesElectrodesSodium phosphatesWater chlorination

The invention belongs to the technical field of composite materials, and particularly relates to an Mo / Ni / Co / P / C composite material as well as a preparation method and an application thereof. The material is prepared with the following method: in a three-electrode system, a carbon-based substrate taken as a working electrode, a platinum net taken as an auxiliary electrode and Ag / AgCl taken as a reference electrode are connected with an electrochemical workstation, potentiostatic deposition is conducted in a mixed solution of nickel sulfate with concentration of 30-70 g / L, sodium hypophosphitewith concentration of 20-40 g / L, nickel chloride with concentration of 10-20 g / L, boric acid with concentration of 30-35 g / L, cobalt chloride with concentration of 30-50 g / L and sodium molybdate withconcentration of 40-50 g / L, magnetic stirring is conducted throughout the deposition process, initial potential set on the working electrode during electroplating is (-1.5)V-(-1)V, electroplating timeis 5-30 min, electroplating temperature is set to be 25-35 DEG C, a power supply is turned off finally, and the Mo / Ni / Co / P / C composite material is prepared. The Mo / Ni / Co / P / C composite material is taken as a cathode material of a microbial electrolytic cell to treat coking wastewater and produce hydrogen synchronously, waste is changed into treasure, and a new idea and a new perspective are provided for impending coking wastewater treatment.

Owner:TAIYUAN UNIV OF TECH

Caustic sludge drying accelerating method

InactiveCN1099507CChange alkalineIncrease alkalinitySolid waste managementEmbankmentsSludgePollution

The said method is that the solidifying and drying agent in the amount of 0.1-10% of the caustic sludge weight is added into caustic sludge; and the solidifying and drying agent consists of acid in 20-60 wt%, salt in 10-40 wt%, and flocculant in 10-40 wt%. It can shorten caustic sludge drying period, so that the present invention provides one way for reasonable utilization of caustic sludge and reduction of environment pollution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Organic-inorganic fertilizer

InactiveCN111087267AImprove absorption rateChange ingredientsSuperphosphatesFertilizer mixturesSoil scienceBiology

The invention discloses an organic-inorganic fertilizer. The organic-inorganic fertilizer is prepared from the following components in parts by weight: 6 to 10 parts of potassium chloride, 4.7 to 11 parts of calcium superphosphate, 7 to 11 parts of ammonium bicarbonate, 5 to 13 parts of an organic fertilizer, 2.5 to 6 parts of amino acids, 3.2 to 5.8 parts of bentonite, 1.3 to 3.8 parts of artemisia dubia, 4 to 8 parts of bone meal, 1.3 to 3.4 parts of bacterial sludge and 3.2 to 4.6 parts of plant residues. The fertilizer has the beneficial effects that the fertilizer can improve the soil structure and the fertilizer absorption rate of soil, meanwhile, organic substances and inorganic substances are matched, the components of the fertilizer are changed, and the yield of crops can be increased.

Owner:刘小春

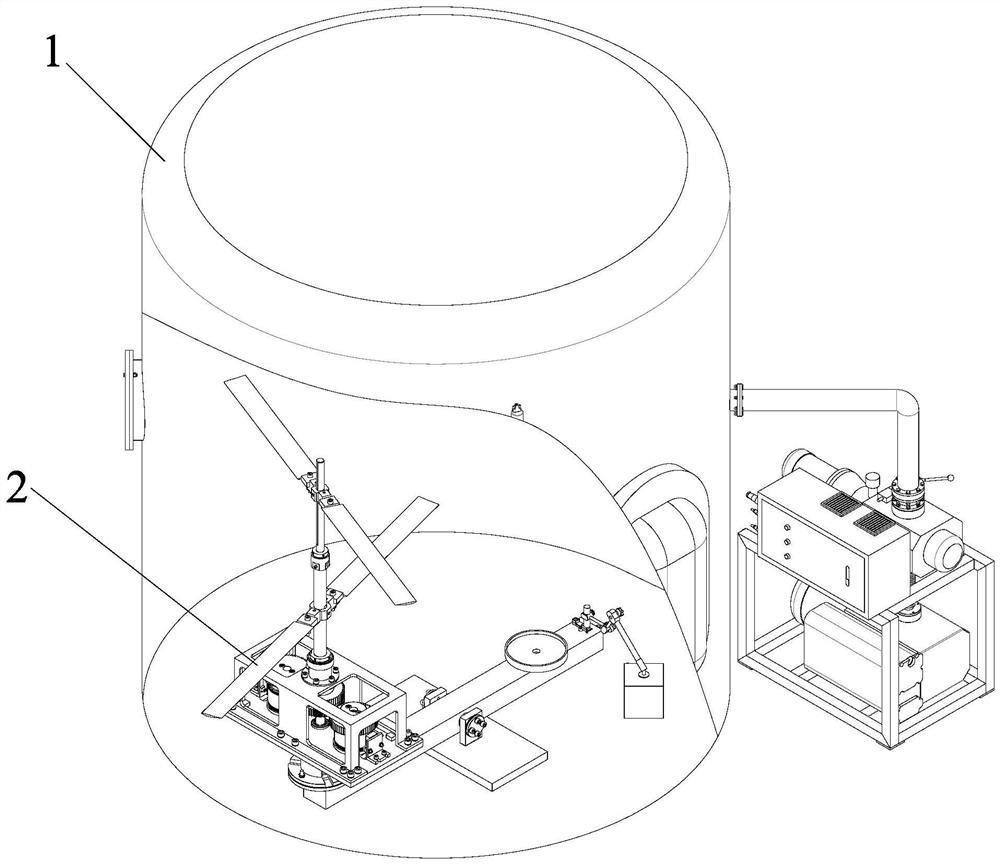

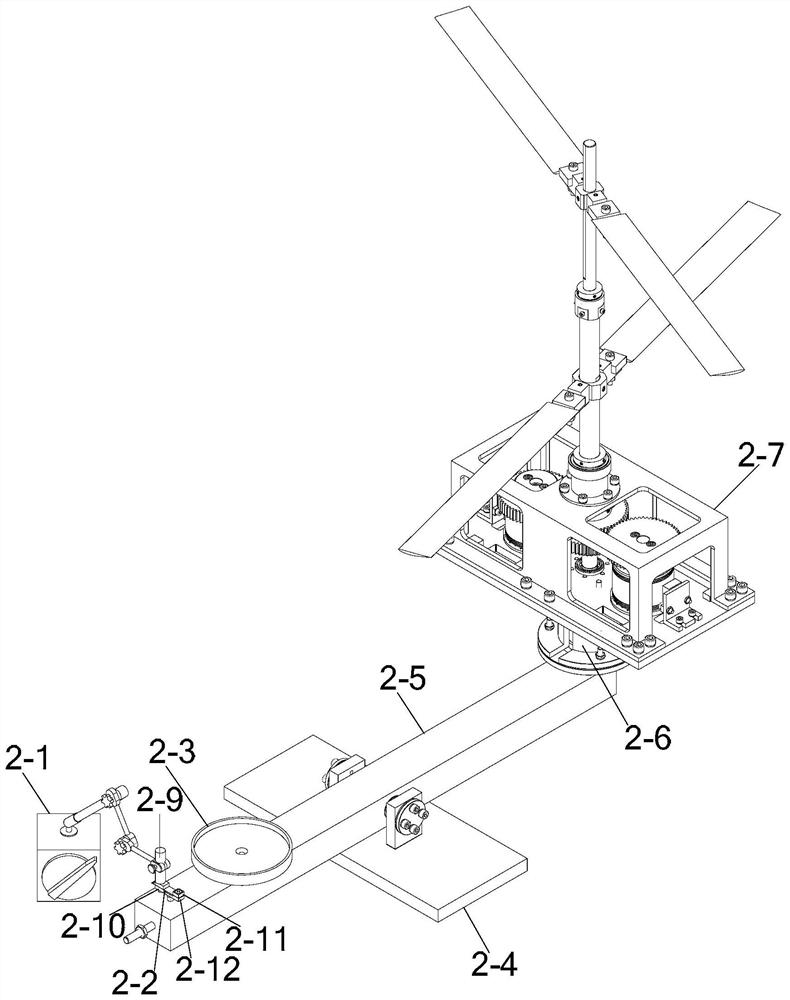

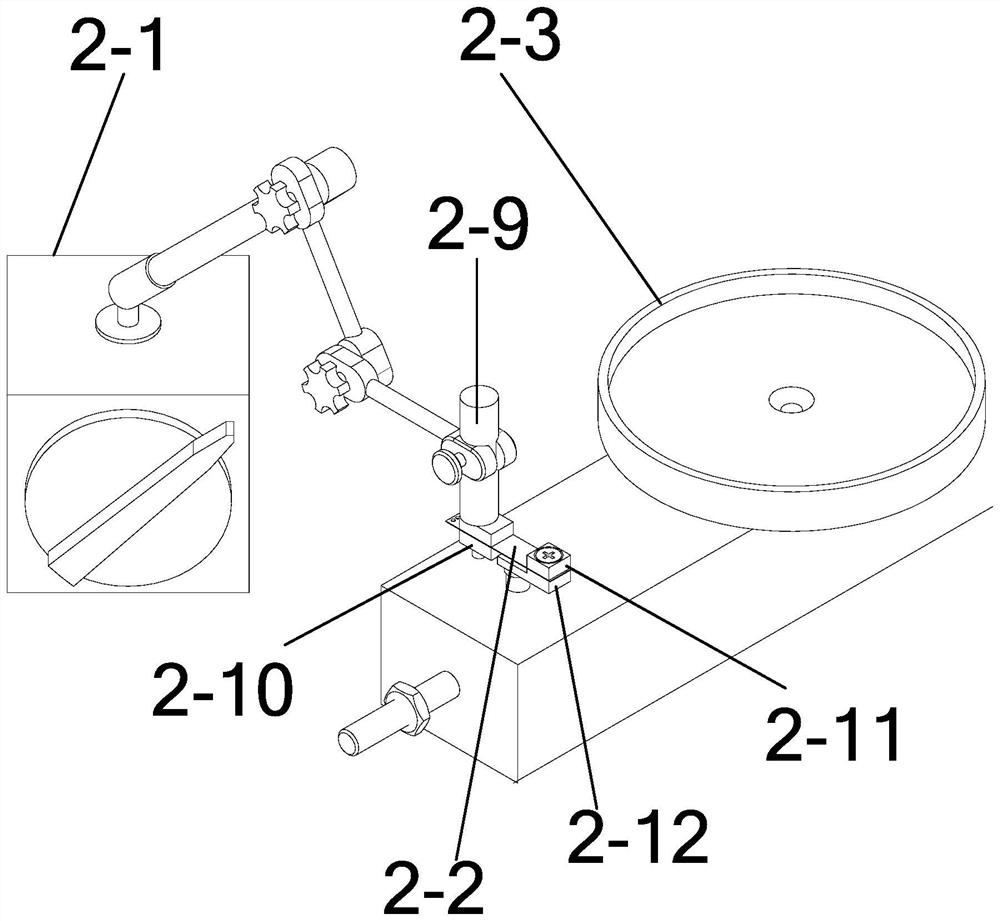

A hovering characteristic test simulation device and method of a lever-type Mars UAV rotor system

ActiveCN107933979BGet hover featureImprove measurement accuracyCosmonautic condition simulationsAircraft components testingClassical mechanicsUncrewed vehicle

The invention provides a lever type hovering characteristic test simulating device and method of a Mars unmanned aerial vehicle rotor wing system, and relates to the field of hovering characteristic test of unmanned aerial vehicle rotor wing systems. The lever type hovering characteristic test simulating device aims to solve the problems that an existing hovering characteristic test device can only be used for evaluating the hovering performance of an Earth unmanned aerial vehicle rotor wing system, simulation of the Mars environment cannot be achieved, the applicability is poor, and the measuring errors are large. A hovering experiment device is located on the inner bottom face of a Mars atmosphere environment simulating device, and the Mars atmosphere environment simulating device is used for simulating a low-vacuum carbon dioxide gas environment. A base serves as the fulcrum of a balancing plate, a rotor wing of the rotor wing system is mounted reversely, so that the lifting force direction goes downwards vertically, a torque sensor is used for measuring a torque generated in the rotating process of the rotor wing of the rotor wing system, a weight is placed in a weight disk soas to balance the weights of the two ends of the balancing plate, thus the balancing plate can be in a balanced state, and a force cell is used for measuring the lifting force generated in the rotating process of the rotor wing of the rotor wing system. The lever type hovering characteristic test simulating device is used for testing the hovering characteristic of the Mars unmanned aerial vehiclerotor wing system.

Owner:HARBIN INST OF TECH

Composite potash fertilizer

InactiveCN112174734ARaise the ratioHigh activityExcrement fertilisersBioloigcal waste fertilisersMicroorganismSoil science

The invention relates to the technical field of agricultural fertilizers, in particular to a composite potash fertilizer which is prepared from the following raw materials in percentage by weight: 10to 20 percent of livestock and poultry manure, 10 to 20 percent of furfural residue, 6 to 8 percent of nitrogenous fertilizer, 10 to 30 percent of potash fertilizer, 5 to 15 percent of turf, 10 to 15percent of rice hull powder, 0.3 to 1 percent of soil activator, 0.1 to 3 percent of complexing agent and 0.1 to 0.3 percent of bioactive strain. The potash fertilizer disclosed by the invention is simple in raw material proportioning, and the activity of bacteria in the fertilizer is improved by adding bioactive bacteria and utilizing microbial activity so that the absorption and utilization rateof soil on the fertilizer is improved, soil components can be effectively changed, and the soil structure is improved.

Owner:菏泽市艾农生态肥有限公司

Biomass granular fuel gasification carbon-making device

PendingCN111978968ARealize real-time monitoringIncrease reaction spaceSpecial form destructive distillationCombustion chamberCarbon storage

The invention provides a biomass granular fuel gasification carbon-making device. The biomass granular fuel gasification carbon-making device comprises a feeding system, a combustion system, an air supply system, an ignition system, a spraying system, a carbon storage system, a cooling system and a control system. The combustion system comprises a combustion chamber communicating with the feedingsystem, a combustion auger, a limiting flow guide cover plate and a motor; the air supply system comprises air blowers communicating with the bottom and the middle of the combustion chamber through air pipes respectively and an air compressor communicating with two stages of air pipes, the two stages of air pipes are connected in parallel and then communicate with an air collecting hood fixed to the top of the combustion chamber, and a primary air loop and a secondary air loop are formed by the two stages of air pipes and the combustion chamber. The carbon storage system comprises an upper coke channel, a middle coke channel, a lower coke channel and a bottom carbon storage chamber which sequentially communicate with one another. The water flow direction of cooling water in the cooling system is opposite to the sliding direction of coke. A structure of feeding from bottom and carbon discharging from top is adopted, the strong reducibility of a high-temperature carbon layer is used forreducing the emission of nitrogen oxides, and diversified gas distribution and control measures can adapt to different types of biomass granular fuels.

Owner:TSINGHUA UNIV

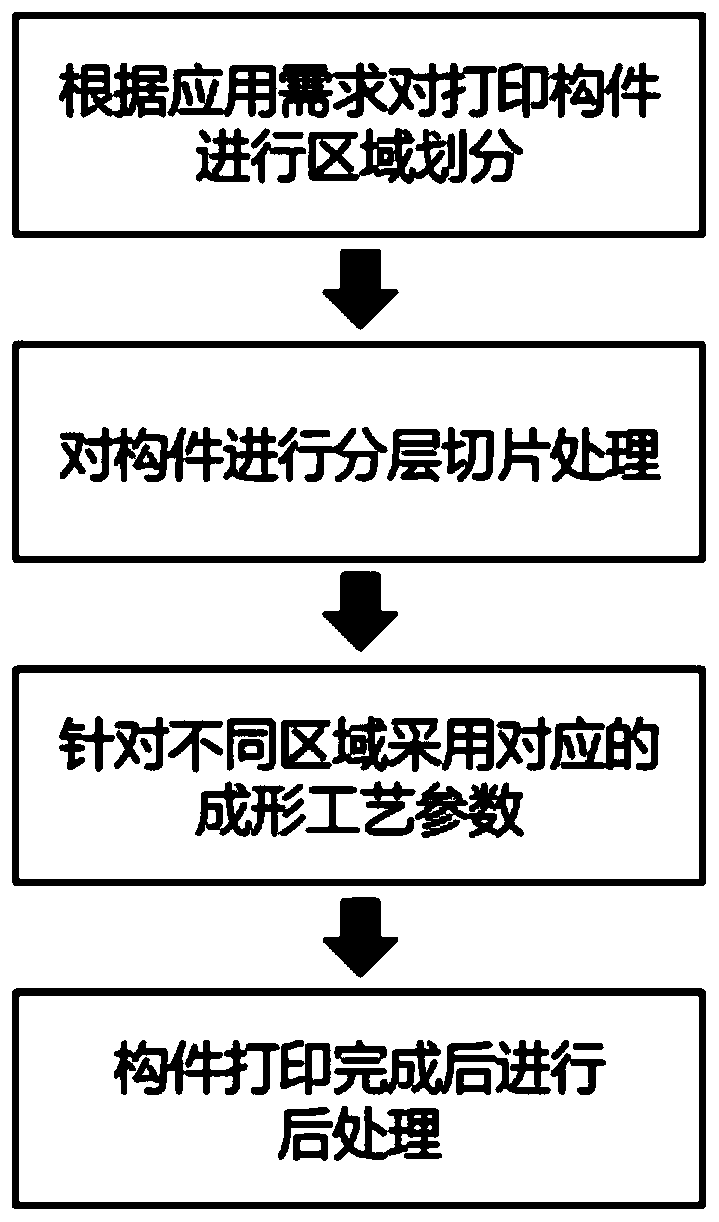

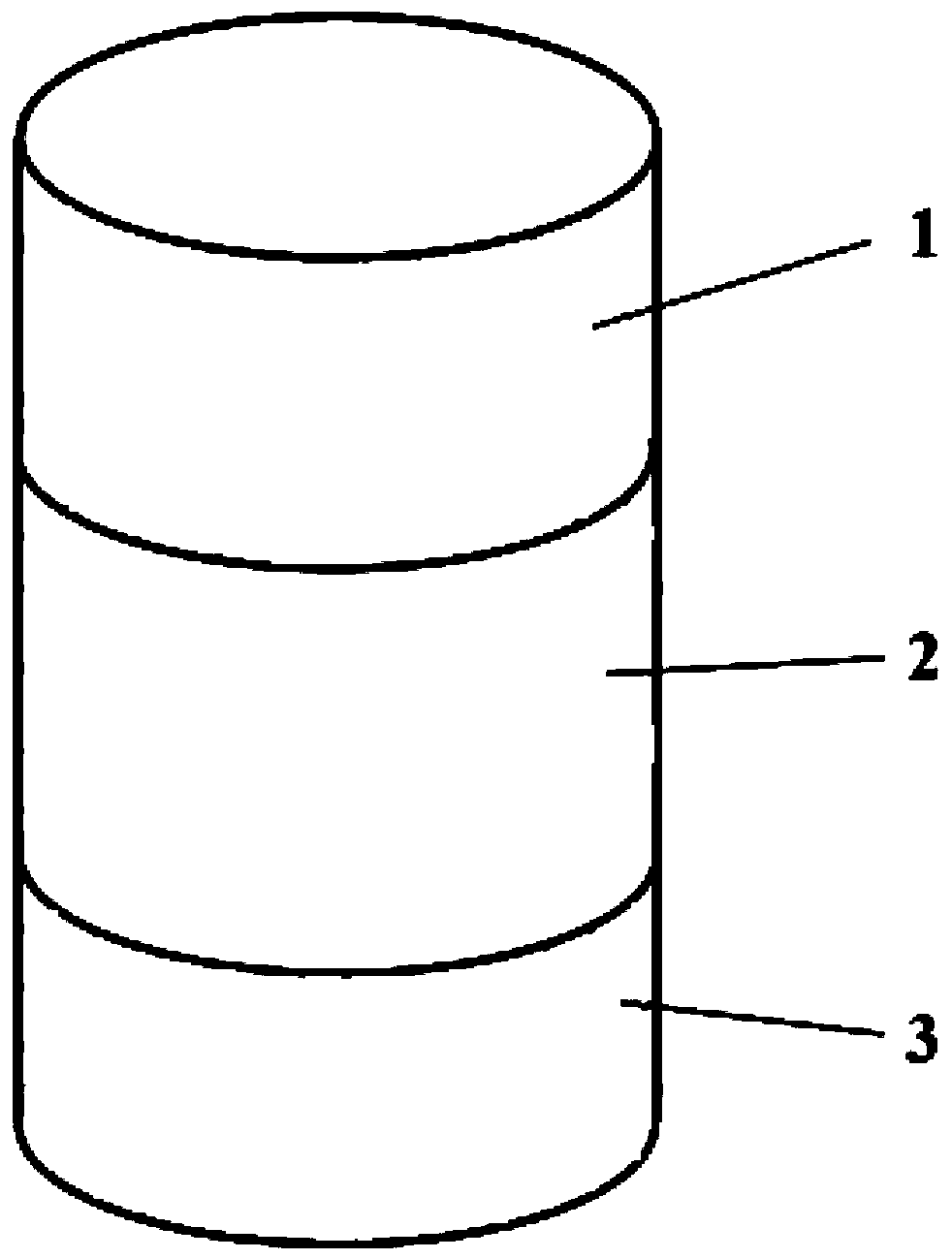

4D printing method and product of functionally graded copper-based shape memory alloy smart components

ActiveCN110434331BAchieve continuous changeSimple preparation processAdditive manufacturing apparatusIncreasing energy efficiencyShape-memory alloyManufactured material

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing high-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN102512987BImprove hydrophilicityFast phase separationSemi-permeable membranesFiberChemical treatment

The invention discloses a method for preparing a high-flux polyvinylidene fluoride hollow fiber membrane. The method comprises the following steps of: mixing polyvinylidene fluoride, a gaseous pore-forming agent, a hydrophilic modifier, additives and organic solvents and making a membrane-making solution; allowing an internal gelling medium and the membrane-making solution to pass through spinning nozzles on dry / wet spinning equipment at the same time, injecting into an external gelling medium, and performing phase-splitting treatment to make a primary membrane; and performing special chemical treatment on the primary membrane with a chemical treatment liquid to obtain a high-flux polyvinylidene fluoride hollow fiber membrane. The invention is characterized in that the membrane is reinforced with the pores by chemical reactions between the internal gelling medium, external gelling medium and chemical treatment liquid and the gaseous pore-forming agent; and the polyvinylidene fluoride hollow fiber membrane has a high flux, a high strength, a high entrapment rate and good hydrophilicity.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

Aluminum alloy and aluminum shell machining process

The invention relates to the technical field of metal processing, in particular to an aluminum alloy and an aluminum shell machining process. The aluminum alloy is included and is characterized by comprising the following components in parts by weight: 0.30-0.50 parts of Fe, 0.10-0.30 parts of Si, 0.05-0.20 parts of Cu, 0.05-0.25 parts of Mn, less than or equal to 0.05 parts of Mg, not more than 0.05 parts of Zn, 0.010-0.035 part of Ti, and the balance is aluminum Al, wherein the ratio of Fe to Si ranges from 1: 1 to 5: 1. The aluminum shell machining process is also included and comprises the steps that the aluminum alloy is blended and melted; after refining, deslagging and online degassing are carried out on the blended and melted aluminum alloy, cast rolling is carried out on the aluminum alloy to form a blank; after cold rolling, high-temperature annealing and cooling are carried out on the blank, the blank is rolled to form an aluminum shell finished product; low-temperature annealing is carried out on the aluminum shell finished product, and then slitting is carried out. According to the aluminum alloy and the aluminum shell machining process, aiming at the technical problem of insufficient performance of the aluminum shell, the aluminum alloy components and the manufacturing process thereof are changed, the tensile property of the aluminum alloy is improved, the surface quality is improved, the strength of the aluminum alloy is improved, and the cost is reduced.

Owner:杭州奥星实业有限公司

A low-NOx co-combustion system and method for power plant boilers with high-temperature flue gas preheating semi-coke

ActiveCN108151008BIncrease temperatureFire guaranteeGas treatmentDispersed particle separationCycloneCombustion system

The invention relates to a low NOx hybrid combustion system and method for preheating semi-coke by high-temperature flue gas of a power station boiler. According to the hybrid combustion system and method, a preheating pipeline and a cyclone preheating separator are adopted, the semi-coke is directly preheated through the high-temperature flue gas, so that the temperature of the semi-coke sprayedinto a hearth is remarkably improved; meanwhile, a stable ignition region for combustion of bituminous coal is arranged at the lower part of the hearth, so that ignition and flame stabilization of combustion of ultra-low volatile semi-coke fuel are facilitated, and the large proportion (larger than or equal to 45%) blending combustion of the semi-coke fuel of the power station boiler is achieved;a preheating product with the relatively strong reducibility is produced while the semi-coke is preheated, the preheating product is directly sprayed into the middle part of the hearth through a combustor, a NOx reduction zone is formed on the upper part of a preheating semi-coke combustion zone, so that emission of NOx is greatly reduced, and low NOx combustion of ultra-low volatile carbon-basedfuel is effectively realized; and air or pure oxygen over fire air is injected into the upper part of a combustion region of the hearth so that the fuel can be completely combusted, and the carbon content of the fly ash and the NOx emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com