Method for preparing high-flux polyvinylidene fluoride hollow fiber membrane

A polyvinylidene fluoride, fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low pore size and pore density, pressure resistance, low flux, etc. Membrane flux and rejection, increased phase separation speed, improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

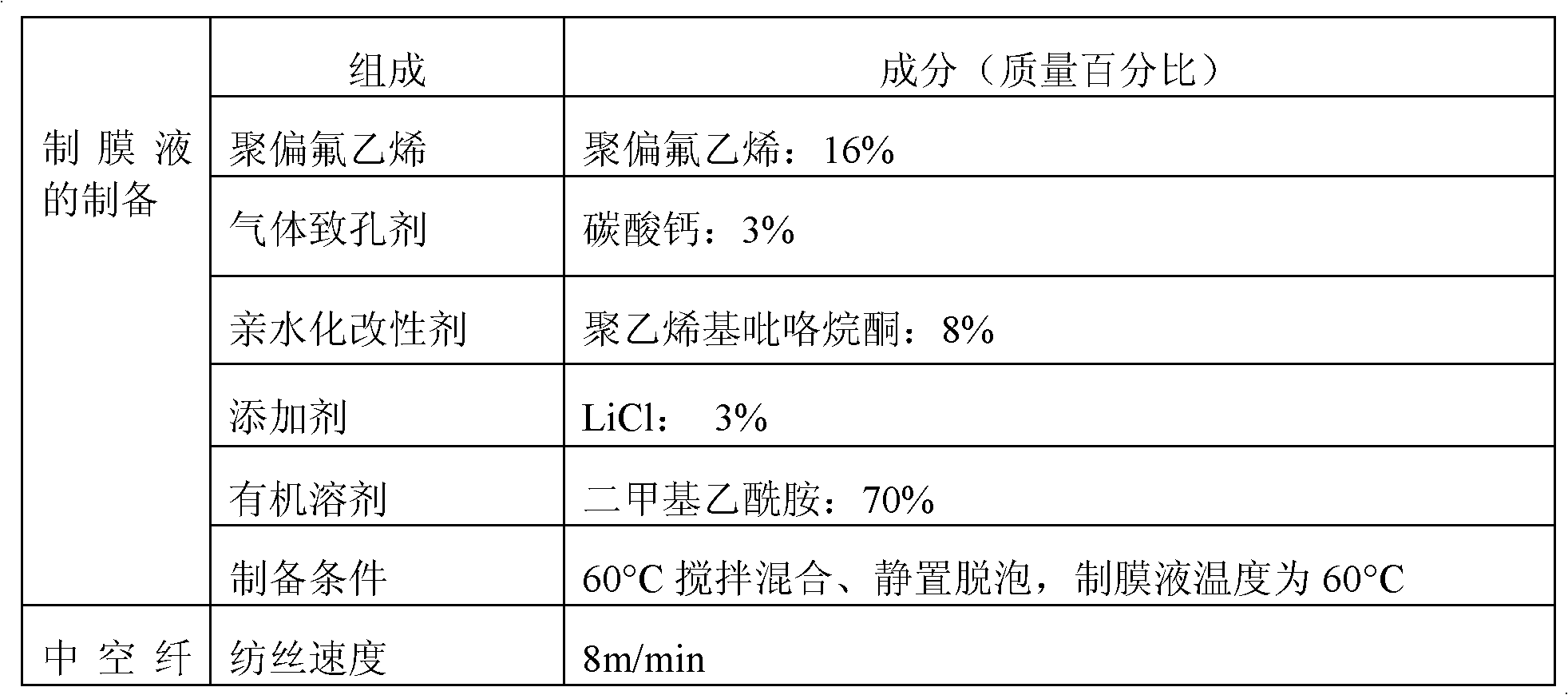

[0025] The preparation steps are as follows:

[0026] 1) Preparation of film-forming solution: 10-20% by mass of polyvinylidene fluoride, 2-8% of gas porogen, 3-8% of hydrophilic modifier, 0-10% of additives, 65- Stir and mix 85% of the organic solvent at a temperature of 40-80°C, let it stand for defoaming, and obtain a film-forming solution at a temperature of 40-80°C;

[0027] 2) Preparation of hollow fiber membrane: using dry and wet spinning equipment at a set spinning speed (5-10m / min), the inner gel medium (water or water and one of acetic acid, hydrochloric acid, glycerin) according to The mass ratio is 4-9: 1 ratio composition) and the film-making liquid pass through the spinning nozzle on the dry-wet spinning equipment at the same time, and inject the outer gel medium (a kind of hydrochloric acid or acetic acid and water composition 0.1 -1mol / L solution) to obtain the primary hollow fiber membrane by phase separation; the primary hollow fiber membrane is placed in a...

Embodiment 2

[0033] The preparation steps are the same as in Example 1, and the preparation conditions are as follows:

[0034]

[0035] The outer diameter of the obtained hollow fiber ultrafiltration membrane is about 1.48mm, the wall thickness is about 0.24mm, and the pure water flux under 0.1MPa reaches 463L / (m 2 h), the rejection rate of BSA is basically maintained above 95%, and the tensile strength is about 3.70MPa.

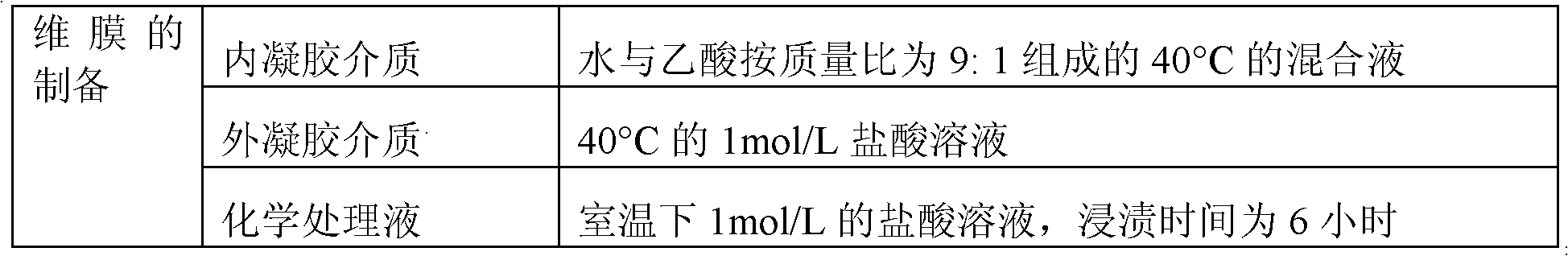

Embodiment 3

[0037] The preparation steps are the same as in Example 1, and the preparation conditions are as follows:

[0038]

[0039]

[0040] The outer diameter of the obtained hollow fiber ultrafiltration membrane is about 1.61mm, the wall thickness is about 0.30mm, and the pure water flux under 0.1MPa reaches 580L / (m 2 h), the rejection rate of BSA is basically maintained above 90%, and the tensile strength is about 3.21MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com