Micro-arc oxidation ceramic membrane and preparation method thereof

A micro-arc oxidation and ceramic film technology, applied in anodizing and other directions, can solve the problem of single color of ceramic film, and achieve the effect of increased density, good heat dissipation performance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

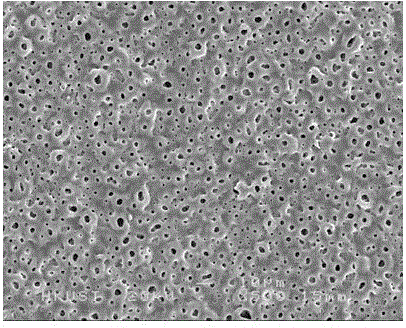

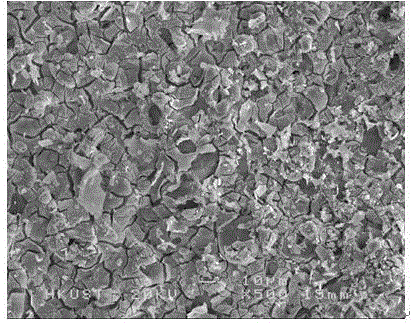

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of Micro-arc Oxidation Ceramic Film with Strong Heat Dissipation and Corrosion Resistance

[0028] Step 1, preparation of micro-arc oxidation electrolyte

[0029] First, add 30g / L sodium silicate, 8g / L sodium phosphate and 5g / L sodium hydroxide into a stainless steel container and dissolve with deionized water. Then add 6g / L glycerin and 1g / L sodium tungstate as additives.

[0030] Step 2, micro-arc oxidation treatment

[0031] The sample used in the test is a commercial grade magnesium alloy AZ31B, and other magnesium alloys (such as AZ91D) with a magnesium content of more than 88% are also suitable for the present invention. The sample size is 30 mm × 30 mm × 1 mm. The samples were immersed in the solution described above for micro-arc oxidation treatment at a current density of 0.15 A / cm 2 , the pulse frequency is 1500Hz, and the duration is 720 seconds. After treatment, a ceramic layer with chemical and mechanical protection properties i...

Embodiment 2

[0038] Example 2: Preparation of a micro-arc oxidation ceramic film with a color number of PANTONE P 4-15U

[0039] Step 1, preparation of micro-arc oxidation electrolyte

[0040] First, add 25g / L sodium silicate, 10g / L sodium phosphate and 3g / L sodium hydroxide into a stainless steel container and dissolve with deionized water. Then add 5g / L glycerin and 1g / L sodium tungstate as additives.

[0041] Step 2, micro-arc oxidation treatment

[0042] The sample used in the test is a commercial grade magnesium alloy AZ31B, and other magnesium alloys (such as AZ91D) with a magnesium content of more than 88% are also suitable for the present invention. The sample size is 30 mm × 30 mm × 1 mm. The samples were immersed in the solution described above for micro-arc oxidation treatment at a current density of 0.1 A / cm 2 , the pulse frequency is 600Hz, and the duration is 240 seconds. After treatment, a ceramic layer with chemical and mechanical protection properties is formed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com