Method for preparing high-wear-resistance self-lubricating composite oxide film on surface of aluminum alloy friction part

A composite oxide film and aluminum alloy surface technology, applied in the field of materials, can solve problems such as limitations, and achieve high wear resistance, improved toughness, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

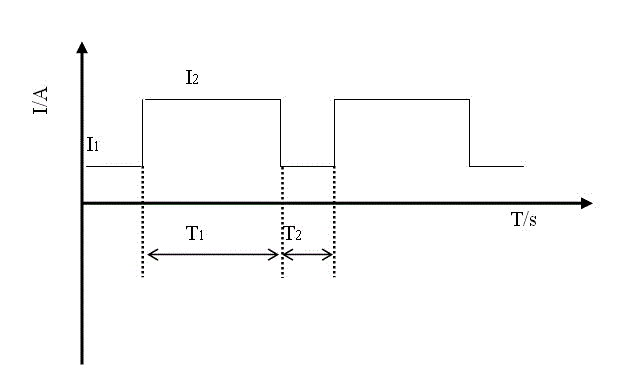

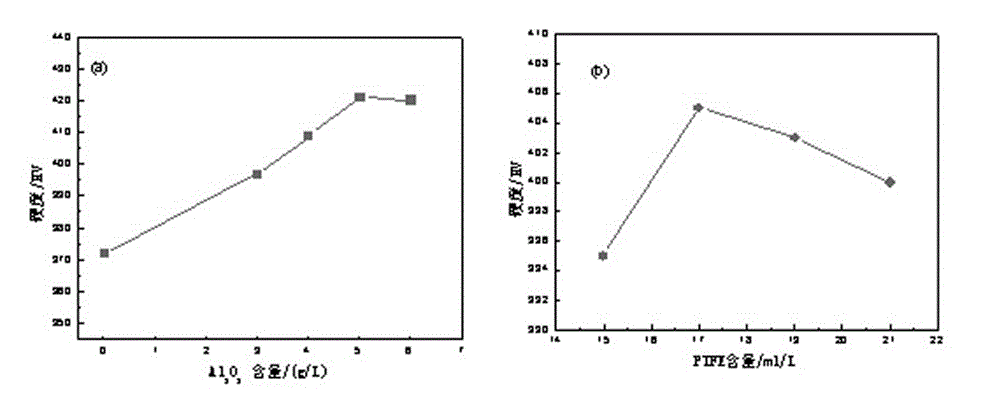

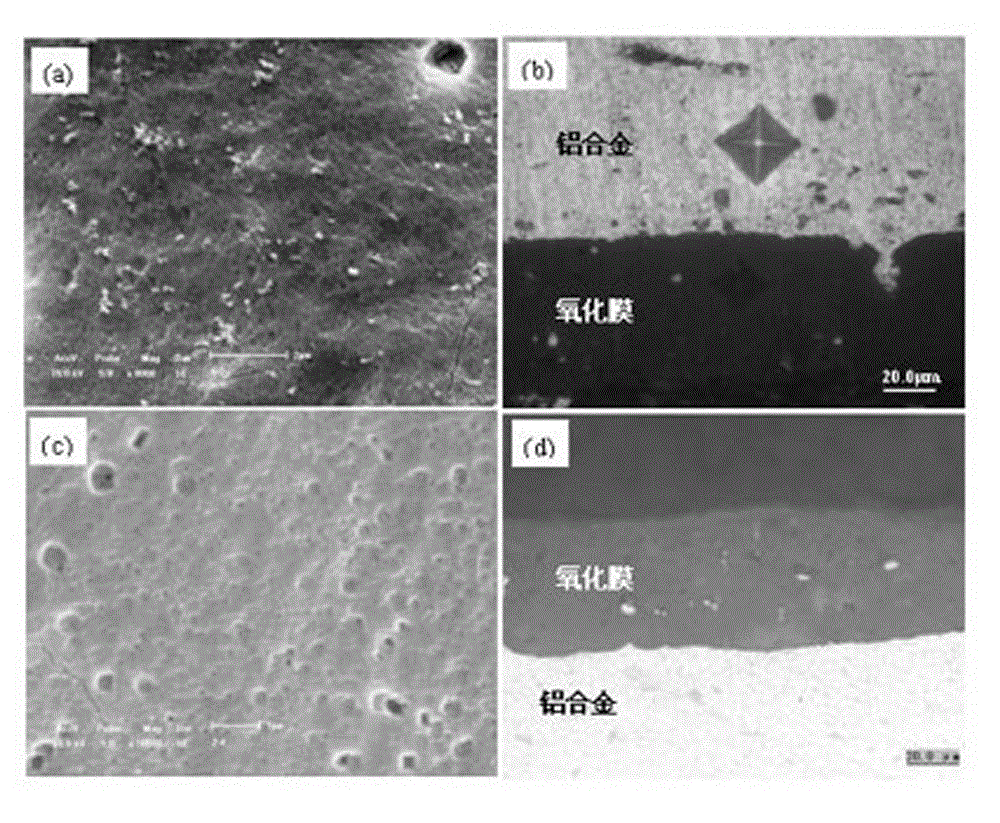

[0035] (1) Pour 3L of deionized water into the oxidation tank, slowly add 900g of sulfuric acid into the water and keep stirring to form a sulfuric acid solution, then add 25g of oxalic acid and 25g of sulfosalicylic acid into the solution and stir to fully dissolve, then add 50g of acetic acid Add sodium and stir, pour 25g of aluminum sulfate into a beaker of 100ml of deionized water, heat and dissolve it, and then add it to the previous electrolyte, add 25ml of glycerin and 2.5g of surfactant into the electrolyte and mechanically stir for 30 minutes; Dilute the volume of ionized water to 5L, mechanically stir for 1h to make it fully mixed; make the concentration of each component equal to that of sulfuric acid H 2 SO 4 180g / L, oxalic acid C 2 h 2 o 4 5g / L, sulfosalicylic acid C 7 h 6 o 6 S·2H 2 O5g / L, glycerol C 3 h 8 o 3 5ml / L, surfactant C 12 h 25 C 6 h 4 NaO 3 S0.5g / L, sodium acetate CH 3 COONa10 g / L, aluminum sulfate Al 2 (SO 4 ) 3 5 g / L; no nano-Al wa...

Embodiment 2

[0039] (1) Prepare 5L electrolyte for composite anodizing:

[0040] (a) Pour 3L of deionized water into the oxidation tank, slowly add 900g of sulfuric acid into the water and keep stirring to form a sulfuric acid solution, then add 25g of oxalic acid and 25g of sulfosalicylic acid into the solution and stir to fully dissolve, then add 50g of acetic acid Add sodium and stir, pour 25g of aluminum sulfate into a beaker of 100ml of deionized water, heat and dissolve, then add to the former electrolyte, add 25ml of glycerin and 2.5g of surfactant into the electrolyte and mechanically stir for 30min;

[0041] (b) Pretreatment of composite particles: prepare 500ml of composite surfactant solution, in which the concentration of sodium dodecylbenzenesulfonate A.B.S is 0.6g / L, and the concentration of alkylphenol polyoxyethylene ether OP-10 is 0.4g / L; then 15g nanometer Al 2 o 3 Powder (Al 2 o 3 The particle size is 500nm) and poured into the prepared composite surfactant solution...

Embodiment 3

[0046] (1) Prepare 5L electrolyte for composite anodizing:

[0047] (a) Pour 3L of deionized water into the oxidation tank, slowly add 900g of sulfuric acid into the water and keep stirring to form a sulfuric acid solution, then add 25g of oxalic acid and 25g of sulfosalicylic acid into the solution and stir to fully dissolve, then add 50g of acetic acid Add sodium and stir, pour 25g of aluminum sulfate into a beaker of 100ml of deionized water, heat and dissolve, then add to the former electrolyte, add 25ml of glycerin and 2.5g of surfactant into the electrolyte and mechanically stir for 30min;

[0048] (b) Pretreatment of composite particles: prepare 500ml of composite surfactant solution, in which the concentration of sodium dodecylbenzenesulfonate A.B.S is 0.6g / L, and the concentration of alkylphenol polyoxyethylene ether OP-10 is 0.4g / L; then 20g nanometer Al 2 o 3 Powder (Al 2 o 3The particle size is 500nm) and poured into the prepared composite surfactant solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com