Patents

Literature

44results about How to "Play a self-lubricating role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear resistant self-lubricating polyformaldehyde and preparation method thereof

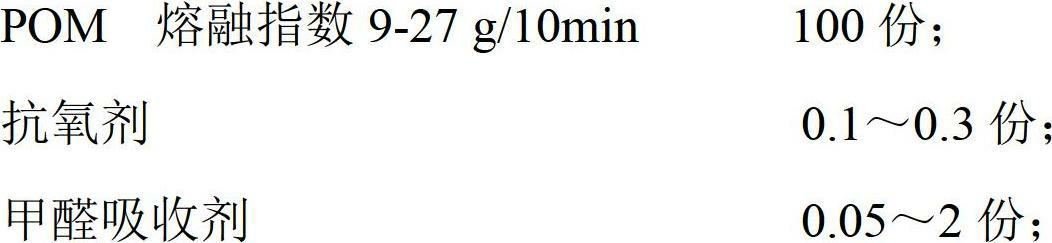

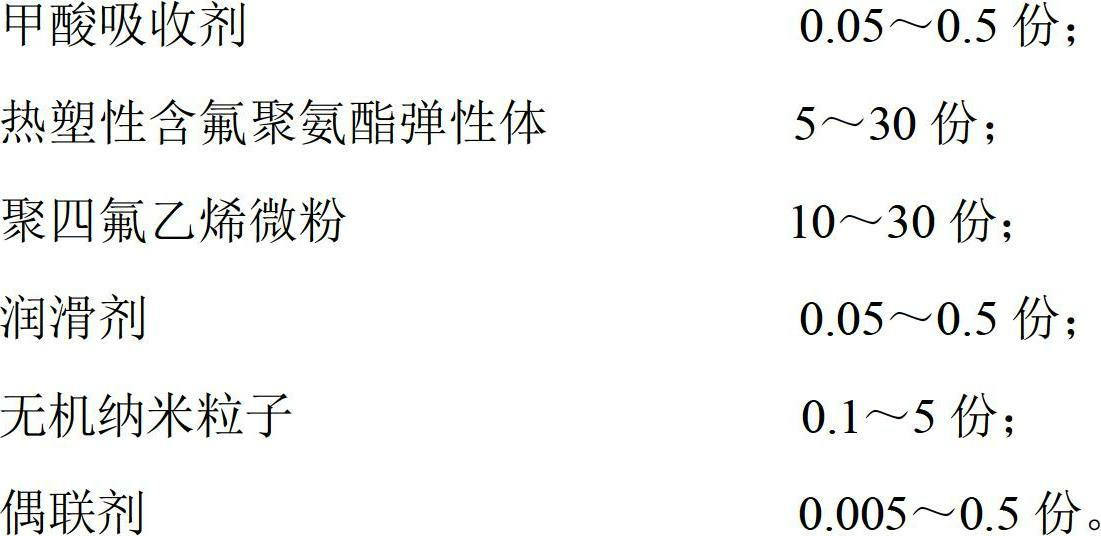

The invention discloses wear resistant self-lubricating polyformaldehyde, which is prepared by the following components through a preparation method comprising the following steps: adding 100 parts of POM (polyoxymethylene) resin, 0.1-0.3 part of antioxidant, 0.05-2 parts of formaldehyde absorber, 0.05-0.5 part of formic acid absorber, 15-30 parts of thermoplastic fluorine-containing polyester elastomer, 10-30 parts of polytetrafluoroethylene micro-powder, 0.1-5 parts of inorganic nano-particles subjected to surface treatment and 0.05-0.5 part of lubricant into a high-speed mixer and mixing, melting and mixing by an exhaust type double-screw extruder, extruding and pelleting to obtain the polyformaldehyde, wherein a rotating speed of screws is 50-200 revolutions per minute, and the temperature of a charging barrel is 140-220 DEG C. According to the invention, the thermoplastic fluorine-containing polyester elastomer with excellent strength and toughness and better compatibility with POM and PTFE (polytetrafluoroethylene) and the inorganic nano-particles are composited with POM and PTFE, so that a tensile strength of the polyformaldehyde reaches 45 MPa, and a notch impact strength reaches about 20 KJ / m<2>.

Owner:YANKUANG GRP CO LTD

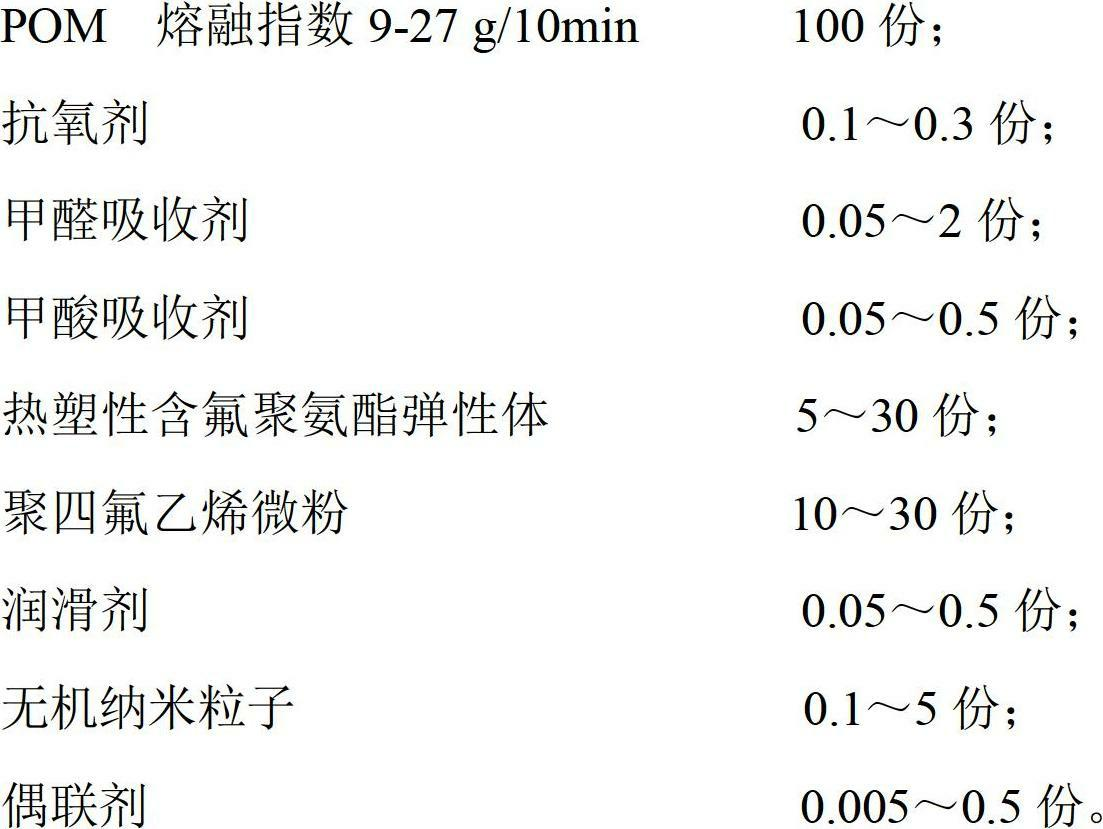

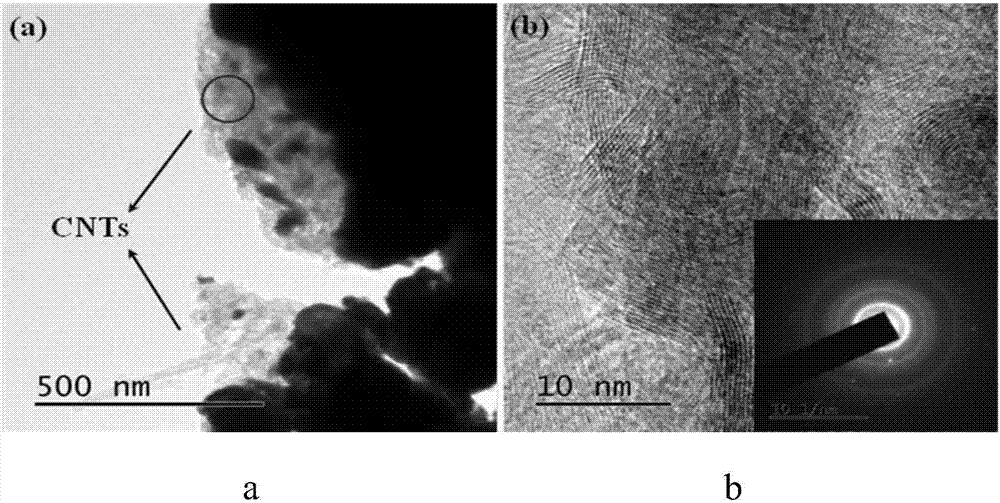

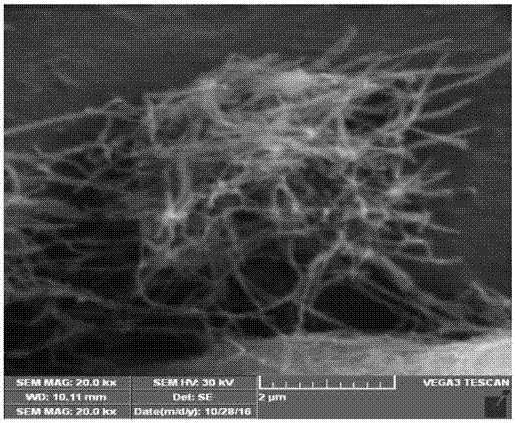

Preparing method of carbon nanometer tube reinforced tungsten copper composite material

ActiveCN107130126APlay a self-lubricating roleImproved arc erosion resistanceHigh energyHydrogen atmosphere

The invention provides a preparing method of a carbon nanometer tube reinforced tungsten copper composite material. The preparing method comprises the specific steps that at first, tungsten powder, copper powder and carbon nanometer tubes are added into a high-energy ball mill according to the proportion to be subjected to ball milling and mixed uniformly, and WCu mixed powder with the CNTs dispersed and distributed is obtained; then the mixed powder is pressed to obtain a composite material green body; and finally, the composite material green body is subjected to liquid phase sintering and infiltration in a high-temperature hydrogen atmosphere sintering furnace, and then the carbon nanometer tubes and the in-situ synthesis tungsten carbide mingled reinforced tungsten copper composite material are obtained. According to the preparing method, by means of the high-energy ball milling technology, the CNTs are dispersed and distributed on the surfaces of tungsten particles and copper particles, by means of high-temperature sintering, carbon sources of the surfaces of the tungsten particles and tungsten are subjected to an in-situ reaction to generate WC phases or W2C phases, the carbon sources of the surfaces of the copper particles will be dispersed and distributed in the copper phases, and then electric arc ablation resistant performance, wear resistance, high-temperature strength and the like of the WCu composite material are improved.

Owner:XIAN UNIV OF TECH

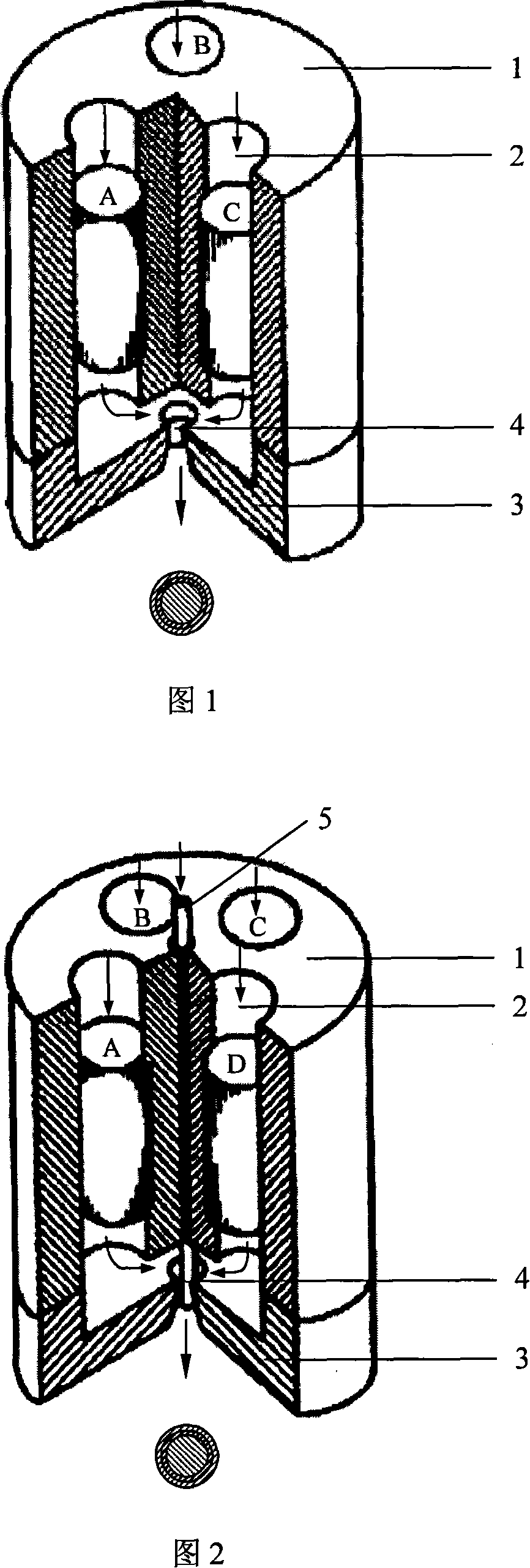

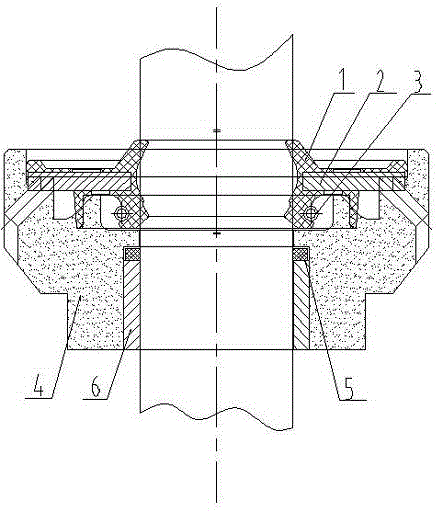

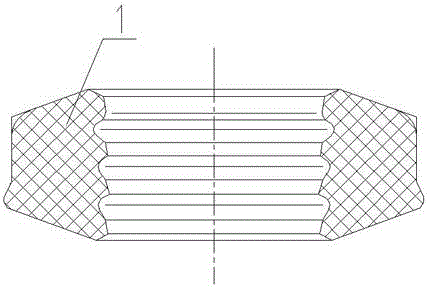

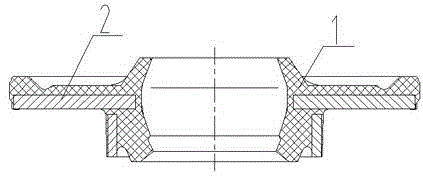

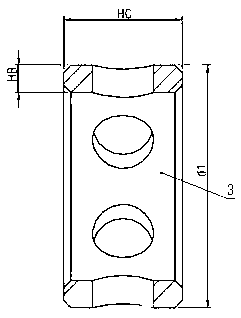

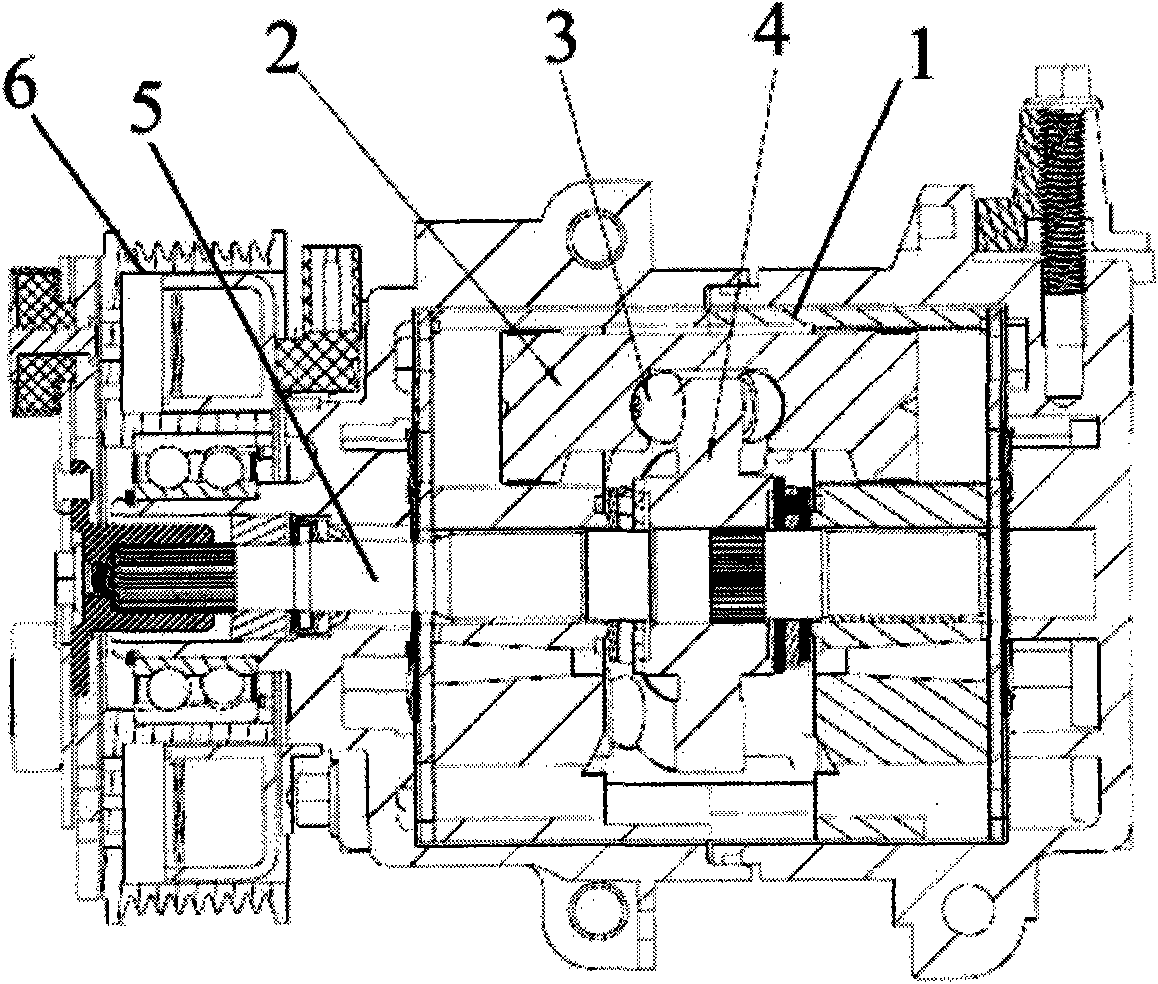

Integral gradient self-lubricating bearing, and fabricating method

This invention relates to an integral grad self-lubricating bearing and its manufacturing method, in which the bearing is composed of a bearing layer, a lubricating layer and a transition layer in the middle, and the bearing layer is made up of carbon steel, stainless steel or bearing steel, the lubricating layer is mixed by a solid lubricating matrix material and a solid lubricant, and the matrix is made of bronze or brass, the solid lubricant is made of MoS2, Sn or graphite, the matrix material is mixed with the solid lubricant to form a solid lubricating layer, the middle transition layer is formed by mixing the bearing material and the solid lubricating material in proportion, which has higher intensity, better rub-reduction and better integration.

Owner:UNIV OF SCI & TECH BEIJING

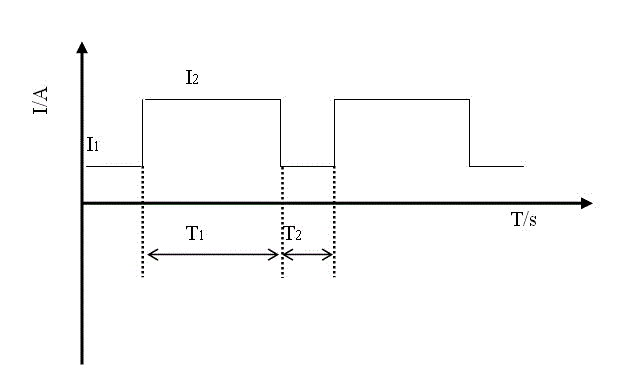

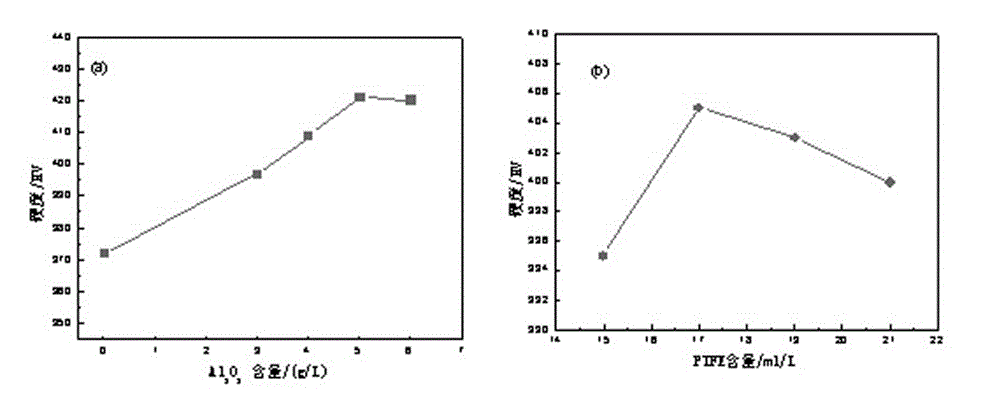

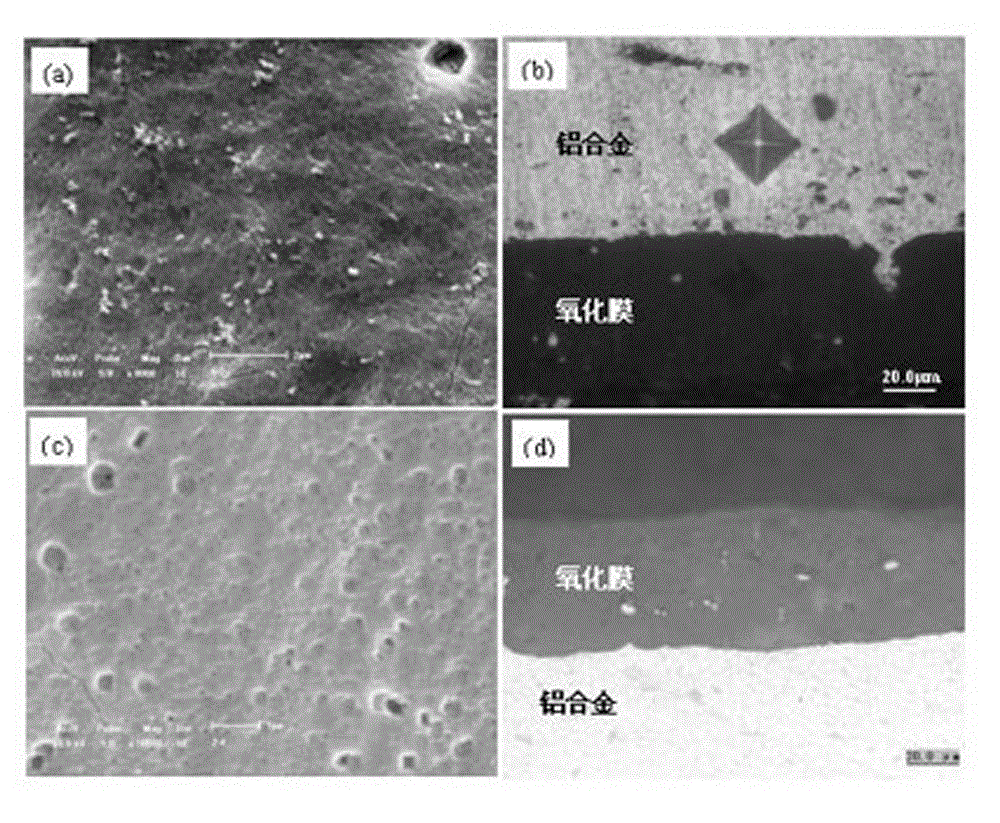

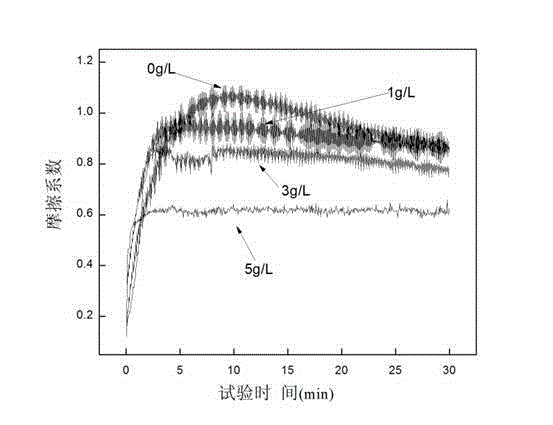

Method for preparing high-wear-resistance self-lubricating composite oxide film on surface of aluminum alloy friction part

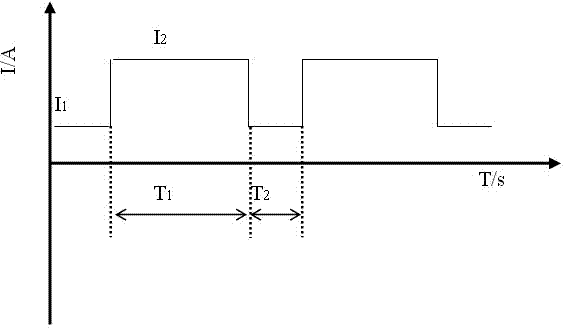

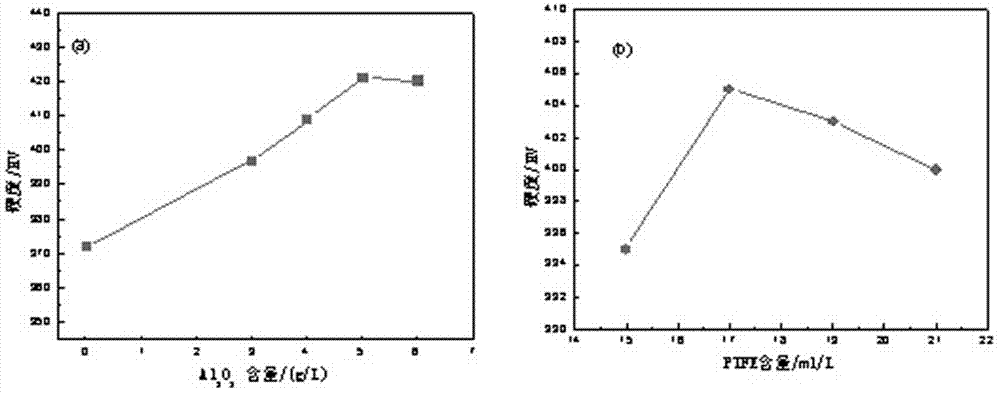

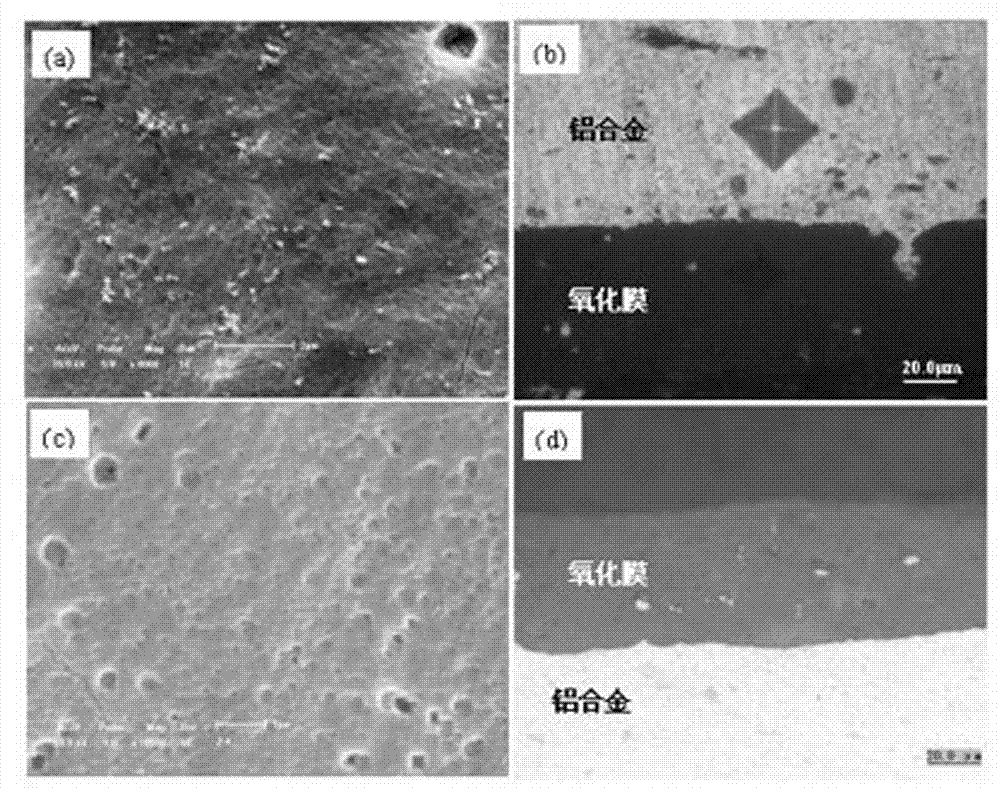

The invention belongs to the technical field of materials, and particularly relates to a method for preparing a high-wear-resistance self-lubricating composite oxide film on the surface of an aluminum alloy friction part. The method comprises the following steps: preparing a composite electrolyte for anodic oxidation; sanding and degreasing the surface of an aluminum alloy, and performing alkaline etching, ash removal and chemical polishing pretreatment; performing composite anodic oxidation treatment to prepare an oxide film, and detecting the hardness; and if the sample does not reach the required hardness, performing heat treatment on the composite oxide film. According to the invention, an oxidization liquid system composed of three acids is designed; the oxide film having high growth speed, high hardness, high wear resistance and high strength and toughness can be grown based on characteristics of pulse current oxidization; and the composite oxide film has higher wear resistance and favorable self-lubricating property through the heat treatment on the oxide film, thereby being applicable to the preparation of oil-free or oil-less lubricating friction parts under different friction conditions (high-speed light load or low-speed heavy load) in the industries of sewing, food, textile, automobiles and the like.

Owner:NORTHEASTERN UNIV

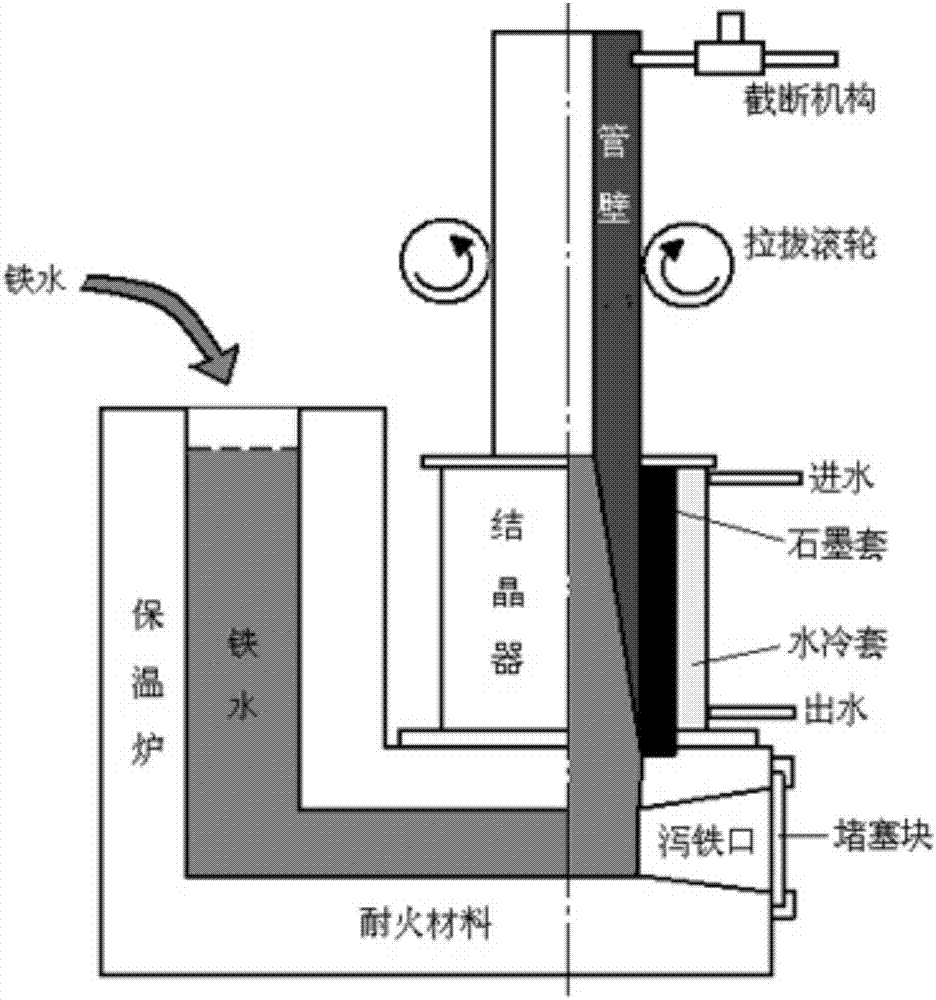

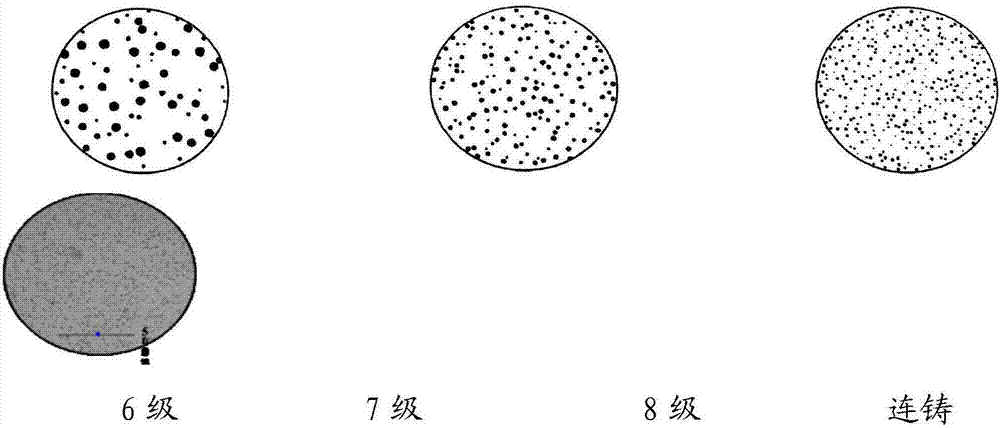

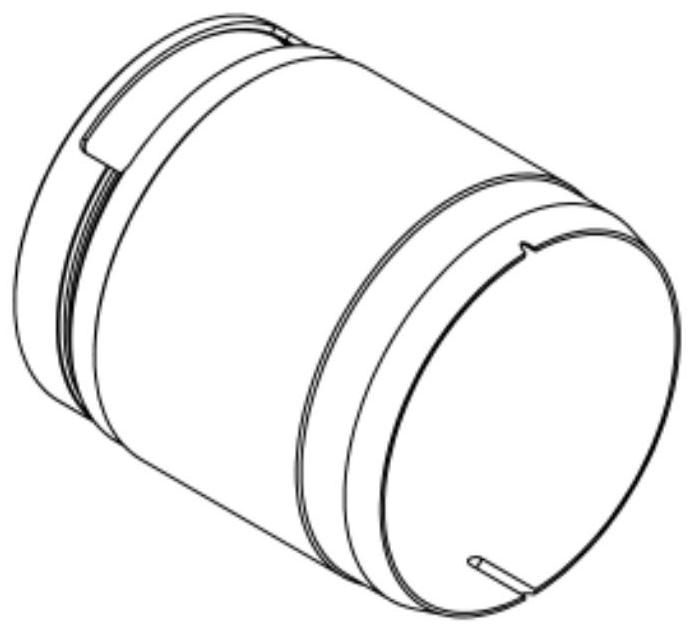

Preparation method of rolling bearing

InactiveCN107504072AAvoid point contact fatigue damageImprove roundnessShaftsBearing componentsCast iron pipeWorking temperature

The invention provides a preparation method of a rolling bearing. Inner and outer rings and a retainer of the rolling bearing are made of a nodular cast iron material instead of bearing steel. A new casting method is provided for preparing nodular cast iron pipe blanks for the rolling bearing. Great change is made for material selection, the hot processing technology and hardness of the inner and outer rings and the retainer of the rolling bearing so as to combine the advantages of the rolling bearing and a self-lubricating sliding bearing. The self-lubricating sliding bearing which can operate under the working conditions of low rotational speed, high working temperature, not frequent injection of lubricating grease and frequent impact is provided for the metallurgical machinery and other equipment manufacturing fields.

Owner:张天贵

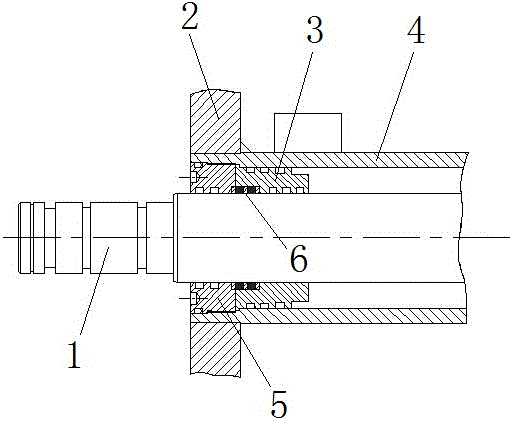

Graphite copper sleeve type piston rod upper assembly capable of replacing guiding belt

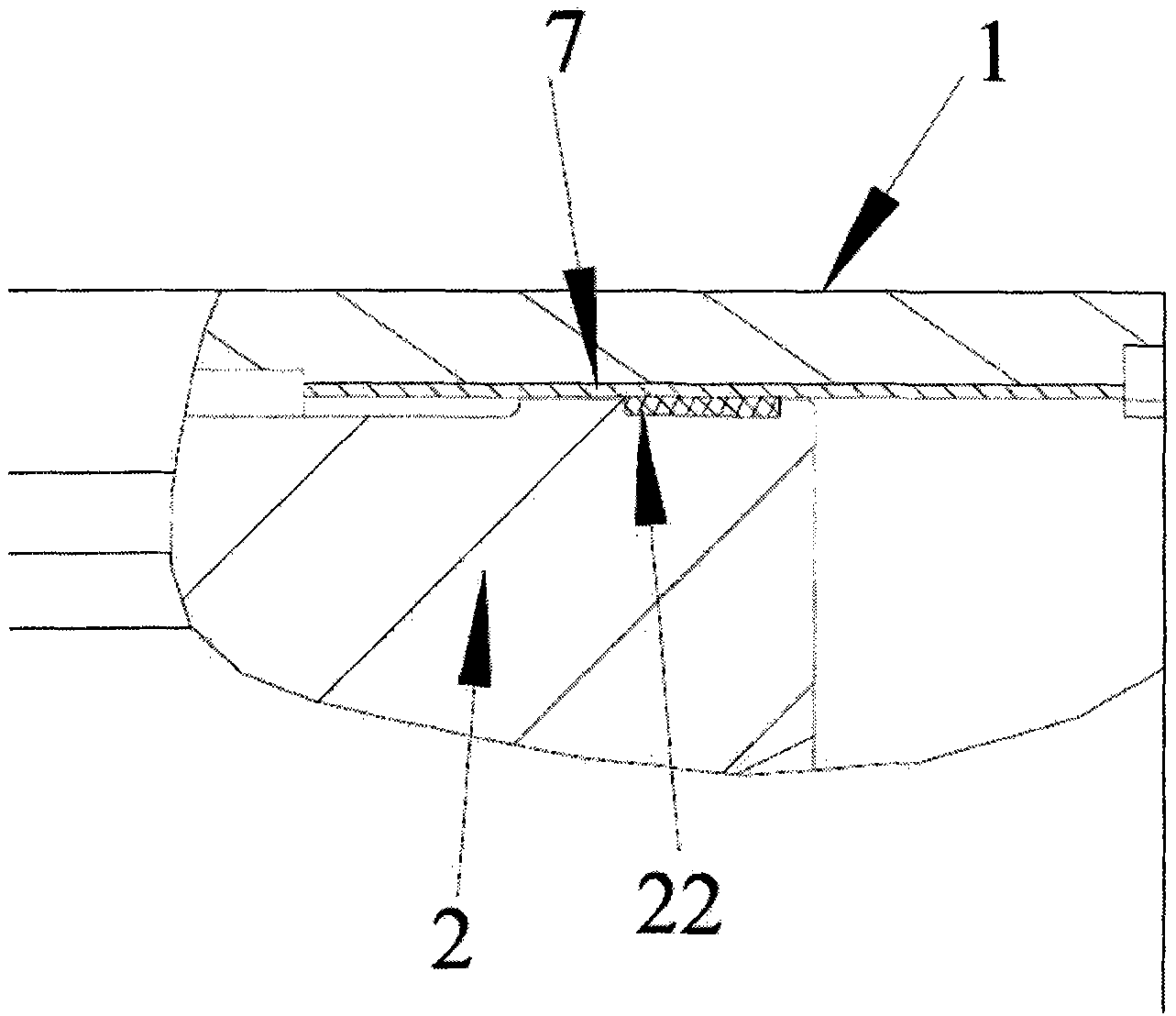

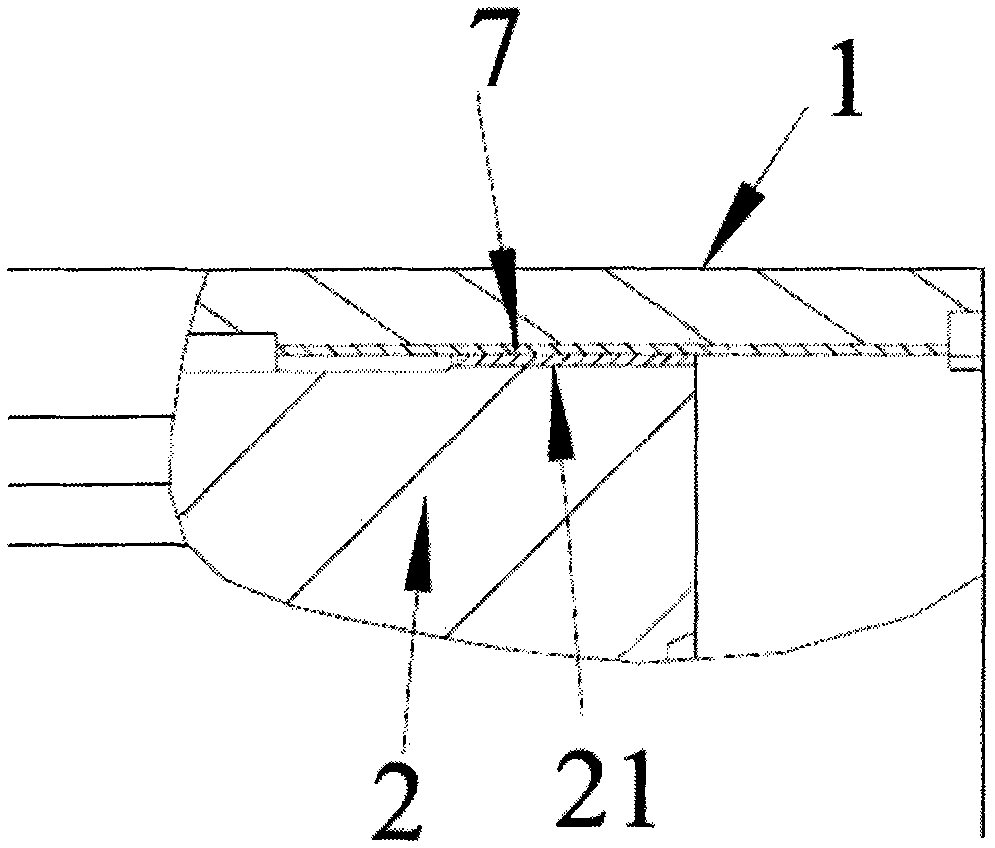

InactiveCN105697444ASimple structureWorking principle is clearFluid-pressure actuatorsHydraulic equipmentEngineering

A graphite copper sleeve piston rod upper assembly that can replace the guide belt belongs to the technical field of hydraulic equipment. The end of the hydraulic cylinder body is provided with an internal seal, a graphite copper sleeve assembly and an external seal in sequence from the inside to the outside. The sleeve assembly is set inside the inner seal, the outer seal is close to the inner seal and the graphite copper sleeve assembly and is tightly connected with the hydraulic cylinder body, and the outer seal, graphite copper sleeve assembly and inner seal are all sleeved on the piston rod and form a sliding fit connection with the piston rod. The structure of the invention is simple and the working principle is clear. The combination of graphite copper sleeve and inner and outer seals is used to replace the traditional resin copper powder guide belt. The graphite plays a self-lubricating role, and the copper sleeve plays a The anti-friction effect reduces the movement resistance of the piston rod, makes the movement of the piston rod more smooth, reduces the eccentric wear of the piston rod, and prolongs the working life of the sealing ring; at the same time, the copper sleeve also increases the radial bearing capacity. Improve the working efficiency of the equipment.

Owner:YANGZHOU SIQI ENVIRONMENTAL PROTECTION EQUIP CO LTD

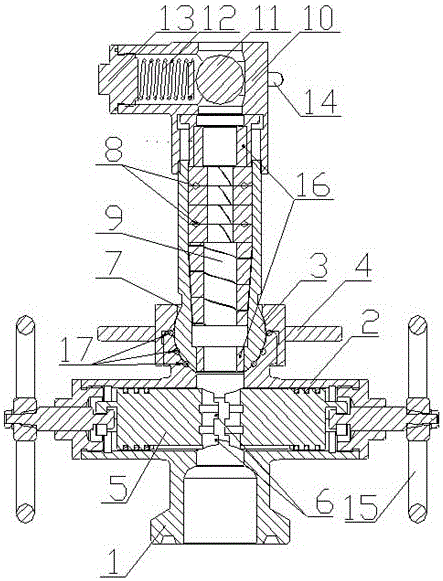

Damper sealing system

InactiveCN105276066AReduce oil seal pressurePrevent oil spillsSpringsShock absorbersAutomotive engineeringSystems design

The invention discloses a damper sealing system, comprising guider assemblies and an oil seal. The guider assemblies at least comprise a guider, a neck bush, and an oil retainer. The oil retainer is arranged on the neck bush. The invention provides design of a sealing system which can satisfy high-low temperature performance of a damper. Through developing sealing performance of each component in the system, on the premise of ensuring high-temperature use of the damper, low-temperature use requirements of the damper can be satisfied, so as to prolong service life of a sealing body and the damper.

Owner:YANTAI RUNFUXIANG OIL SEAL

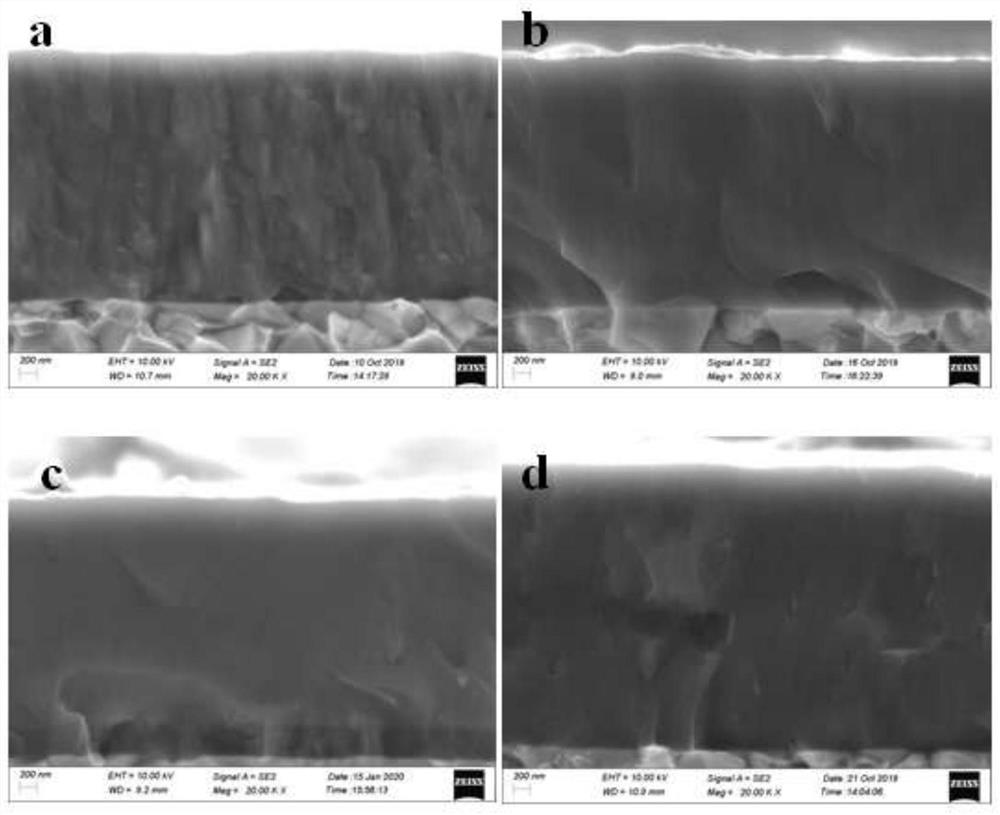

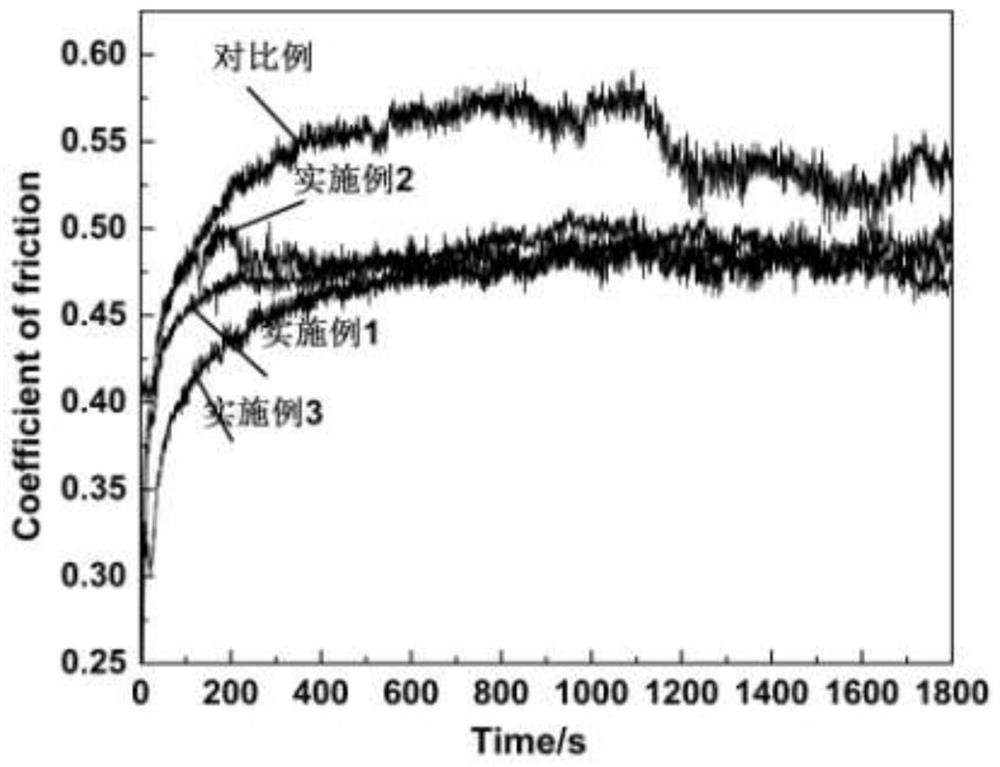

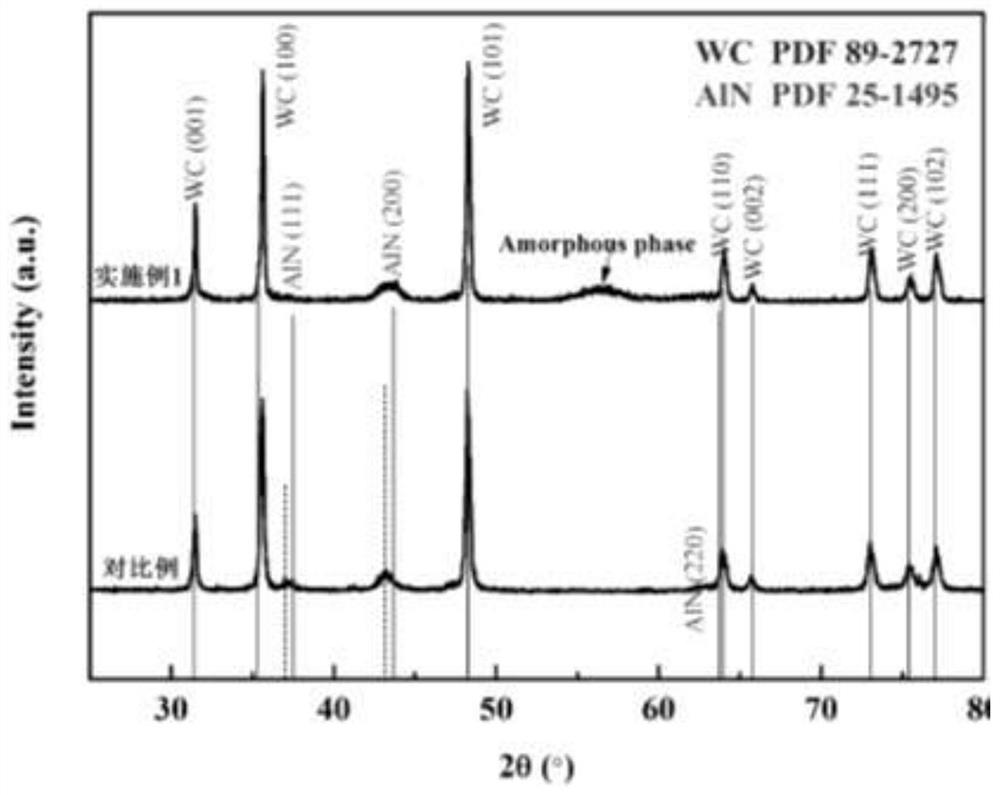

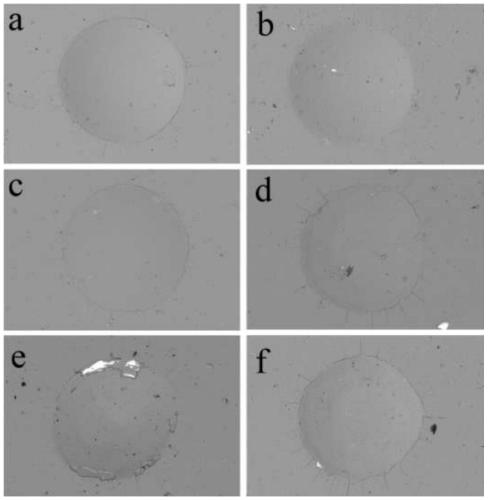

Nanocrystalline amorphous composite coating, preparation method thereof and cutter

ActiveCN111910159ASmall elastic modulus changesLittle changeVacuum evaporation coatingSputtering coatingWear resistanceSi element

The invention provides a TiAl (Nb, Si, C) N-containing nanocrystalline amorphous composite coating, a preparation method thereof and a cutter. The composite coating is a nanocrystalline amorphous TiAl(Nb, Si, C) N coating formed by physical vapor deposition. The TiAlN composite coating with a hardening and wear-resistant Si element, a toughening Nb element and an antifriction C element co-doped in an optimal proportion maintains the characteristics of excellent comprehensive performance and no short plate and good 'wooden barrel effect' of a TiAlN-based coating, meanwhile, the adhesive force,wear resistance and high-temperature stability of the coating can be greatly improved, and the integration of toughness and wear resistance of the coating is realized. The preparation method is simple in process, easy to operate in actual production, low in production cost and suitable for large-scale popularization.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

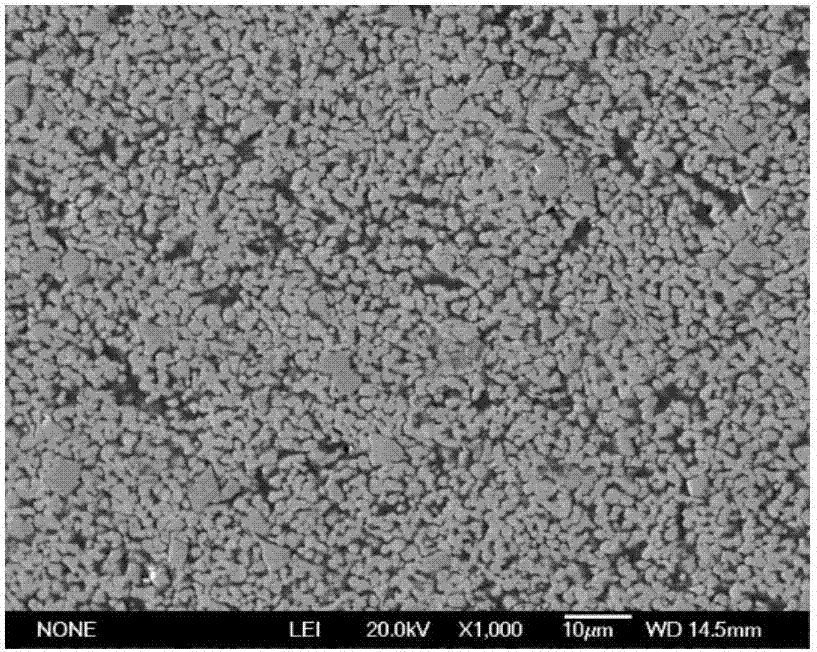

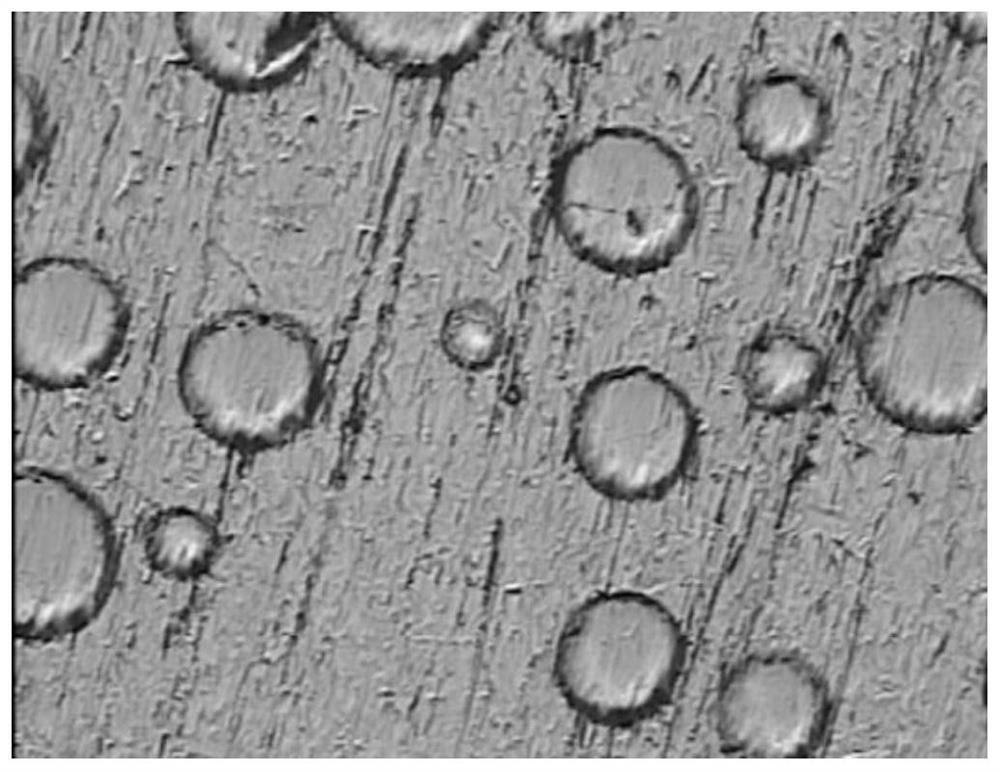

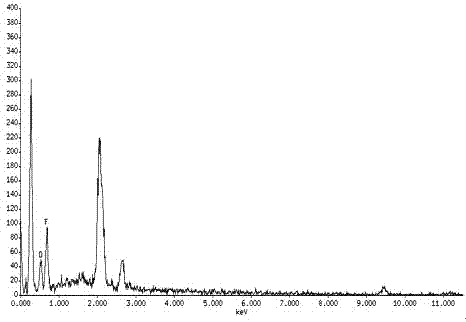

Cast aluminum alloy micro-arc oxidation ceramic membrane layer and preparation method thereof

ActiveCN105624758AUniform film formationReduce roughnessAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides a cast aluminum alloy micro-arc oxidation ceramic membrane layer and a preparation method of the cast aluminum alloy micro-arc oxidation ceramic membrane layer. The adopted bath solution is an aqueous solution of Na2SiO3.9H2O, Na2MnO4.2H2O, NaF, NaOH and Bi2O3. The bath solution adopted by the cast aluminum alloy micro-arc oxidation ceramic membrane layer and the preparation method can form a membrane on the surface of cast aluminum alloy with the high silicon content more easily, and can facilitate uniform membrane formation on the surface of the cast aluminum alloy, and therefore the surface of the formed ceramic membrane layer is smooth, and the roughness is low. In addition, the added Bi2O3 in the bath solution can play a role in self-lubrication, and the wear resistance performance of the micro-arc oxidation ceramic membrane layer is improved.

Owner:山东高密翔宇车桥有限公司

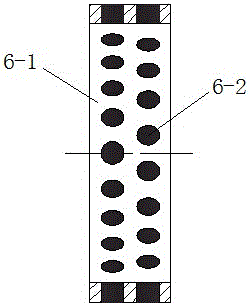

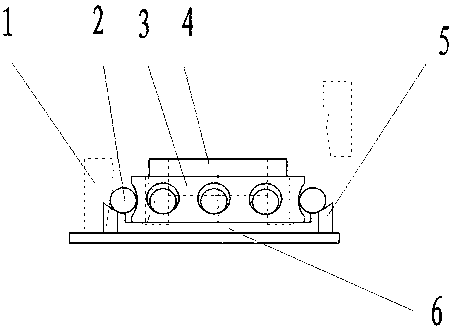

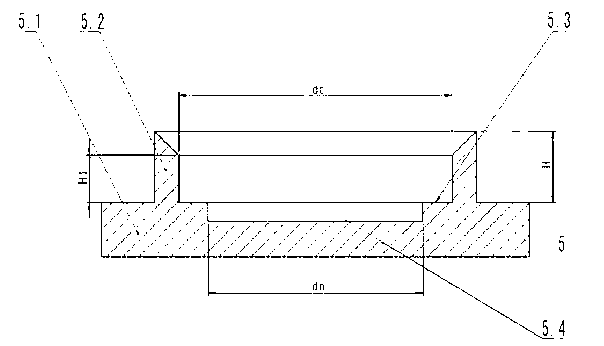

Simple assembly method for miniature ball bearings

Disclosed is a simple assembly method for miniature ball bearings. Firstly, a ball holding ring (5) and a support (6) are manufactured, the support is placed in a positioning ring (5.2) of the ball holding ring, and a cage (3) soaked with lubricant is placed at the bottom of an inner ring of the support. Secondly, an inner ring (4) is mounted in the cage, the inner ring contacts with the bottom of the inner ring of the support, rolling balls (2) soaked with lubricant and having equal amount to that of arranged cage pockets are placed on an assembly support surface, and one of the rolling balls is toggled slightly by a small scoop so that the rolling ball enters one pocket of the cage until all the rolling balls enter the cage pockets. Thirdly, one slope end of an outer ring (1) is aligned with the cage and is pressed down to fully contact with an outer ring, with the height of H, of the positioning rings on the ball holding ring. Finally, the ball holding ring and the support are removed after a miniature ball bearing not assembled, the ball holding ring and the support are turned over, the outer ring continues to be pressed to be parallel to the inner ring, and accordingly simple assembly of the miniature ball bearing is achieved.

Owner:LUOYANG BEARING RES INST CO LTD

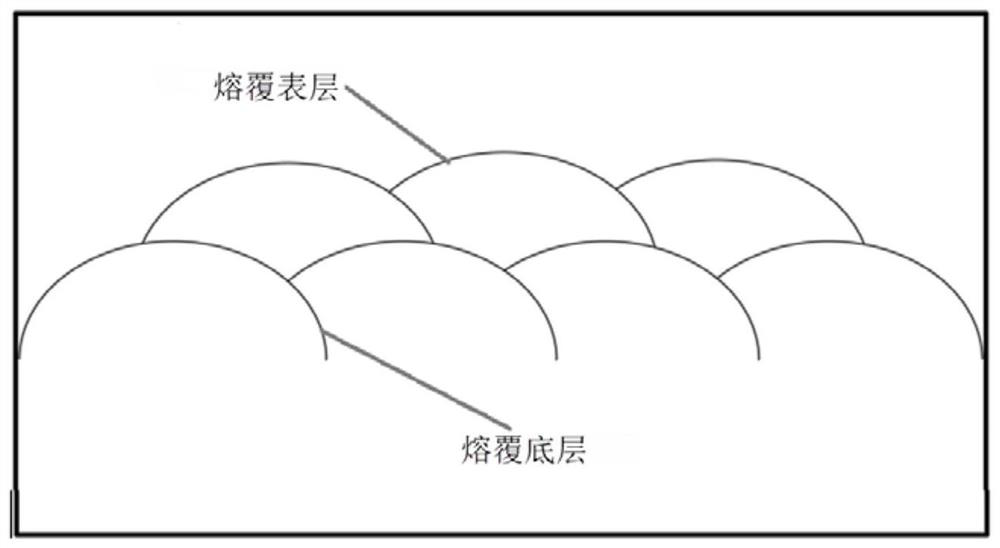

Composite coating for wear-proof casing of petroleum drilling tool and preparation method of composite coating

PendingCN113201734AHigh surface hardnessImprove wear resistanceMetallic material coating processesAlloyGraphite

The invention relates to a composite coating for a wear-proof casing of a petroleum drilling tool. The composite coating comprises a cladding bottom layer and a cladding surface layer, and the cladding surface layer is clad on the surface of the cladding bottom layer. Raw materials of the cladding bottom layer and the cladding surface layer comprise nickel-based alloy powder, tungsten carbide powder and graphene powder, and the mass of the graphene powder accounts for 1%-4% of the total mass of the mixture. A double-formula cladding material is adopted, so that the content of the nickel-based alloy on the inner layer of the cladding coating is high, it is guaranteed that the cladding layers have enough toughness, the impact resistance of the coating is improved, the content of tungsten carbide on the surface layer of the cladding coating is high, it is guaranteed that the cladding layer has enough hardness, the wear resistance of the coating is improved, and the nickel-based alloy, the tungsten carbide, and the graphene are mixed for use in the composite coating. The microstructure can be improved, the strengthening phase distribution is more uniform, and the self-lubricating effect also can be achieved.

Owner:天津市汇利通金属表面技术有限公司

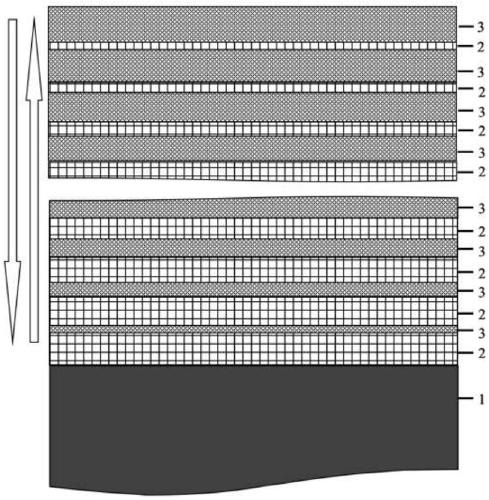

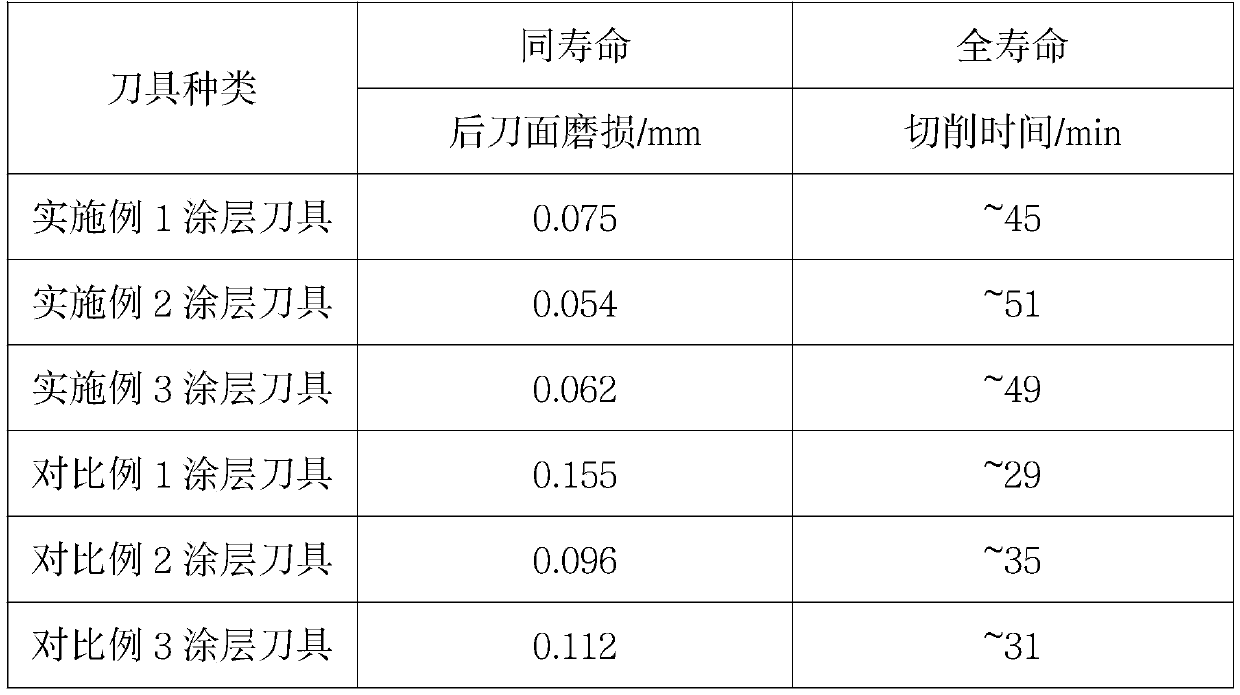

Component structure double-gradient functional coating for cutting tool and preparation method of component structure double-gradient functional coating

ActiveCN111270202AImprove performanceObvious performance advantageVacuum evaporation coatingSputtering coatingComposite effectHeat stability

The invention provides a component structure double-gradient functional coating for a cutting tool and a preparation method of the component structure double-gradient functional coating. The coating is formed by alternately depositing two performance variation layers, namely a Ti<1-x-y>Al<x>Me'<y>N layer and a Ti <1-x-y>Al<x>Me"<y>N layer, on the surface of a tool base body in thickness progressive decreasing and processing increasing trends. The preparation method comprises the following steps that the tool base body is prepared; the tool base body is pretreated; and the Ti<1-x-y>Al<x>Me'<y>Nlayer and the Ti <1-x-y>Al<x>Me"<y>N layer are alternatively deposited on the tool base body in the different progressively decreasing and progressively increasing trends by adopting a cathodic arc ion plating technology to obtain the component structure double-gradient functional coating for cutting. Compared with a common-structure multi-element coating, the component structure double-gradientfunctional coating for the cutting tool has the advantages that the multi-element composite effect is maximized, the gradient structure design is optimized, the stress of the coating is reduced, the good film-base and film-film binding force is guaranteed, meanwhile, the wear resistance, the impact resistance and the thermal stability of the coating are further improved, the machining life of a correspondingly coated tool is also greatly prolonged, and the service reliability of the corresponding coated tool is also greatly improved.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Method for lubricating air cylinder of automobile air-conditioning compressor

InactiveCN101892974AAvoid damageReduce the initial running torquePositive displacement pump componentsPositive-displacement liquid enginesPiston ringAutomobile air conditioning

The invention relates to a method for lubricating an air cylinder of an automobile air-conditioning compressor. The method for lubricating the air cylinder of the automobile air-conditioning compressor comprises one step of arranging a lubricating layer between a piston hole of a cylinder body and a piston, wherein the surface of the piston is provided with a coating or a piston ring; a tin layer with the thickness of 0.5 to 10 mu m is arranged on the inner wall of the piston hole by a chemical immersion plating method; and the chemical immersion plating method comprises the processes of preparing and cleaning, degreasing and cleaning, rinsing, plating a bath, neutralizing, rinsing again and blowing. In the method for lubricating the air cylinder of the automobile air-conditioning compressor, the tin layer is arranged on the inner wall of the piston hole of the air cylinder of the automobile air-conditioning compressor by the chemical immersion plating method, so that a self-lubricating effect is achieved when the compressor is started by utilizing the lubricating property of the tin, the damage to the piston coating and the piston ring and the sliding of an automobile clutch are avoided, and the service life of the compressor is prolonged.

Owner:上海双桦机械制造有限公司

Alloy material for ring gear for automobile synchronizer

The invention discloses an alloy material for a ring gear for an automobile synchronizer. The alloy material comprises, by mass, 51.0% to 63.0% of Cu, 0.1% to 0.9% of Sn, 0.5% to 1.2% of Ti, 0.01% to 0.08% of Zr, 0.05% to 0.08% of B, 0.02% to 0.06% of Sb, 0.2% to 4.3% of Ni, 1.0% to 5.0% of Mn, 0.5% to 1.5% of Fe, 0.3% to 1.6% of Si, 1.3% to 6.0% of Al, 0.1% to 1.0% of Pb, 0.05% to 0.20% of rare earth, impurities which are not larger than 0.05%, and the balance Zn. According to the alloy material for the ring gear for the automobile synchronizer, multi-phase and multi-scale toughness of the ring gear can be achieved through multicomponent alloying-multistage heat treatment and a high temperature solid solution-twin-stage aging process to enable rigidity of particles to optimally match with toughness of matrixes; and the ring gear can maintain good using performance and long service life under extremely severe impact conditions.

Owner:JINCHUAN GROUP LIMITED

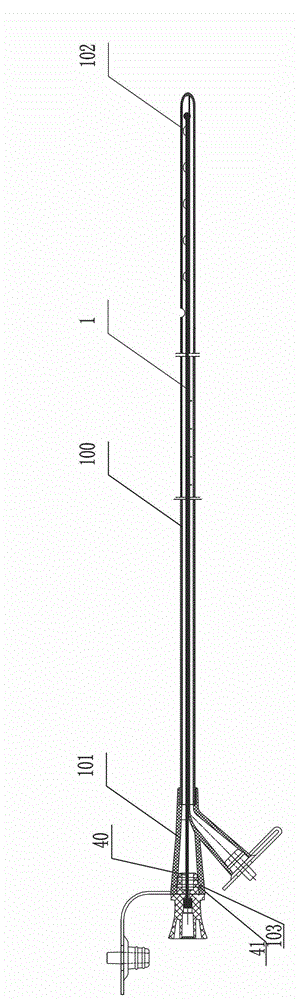

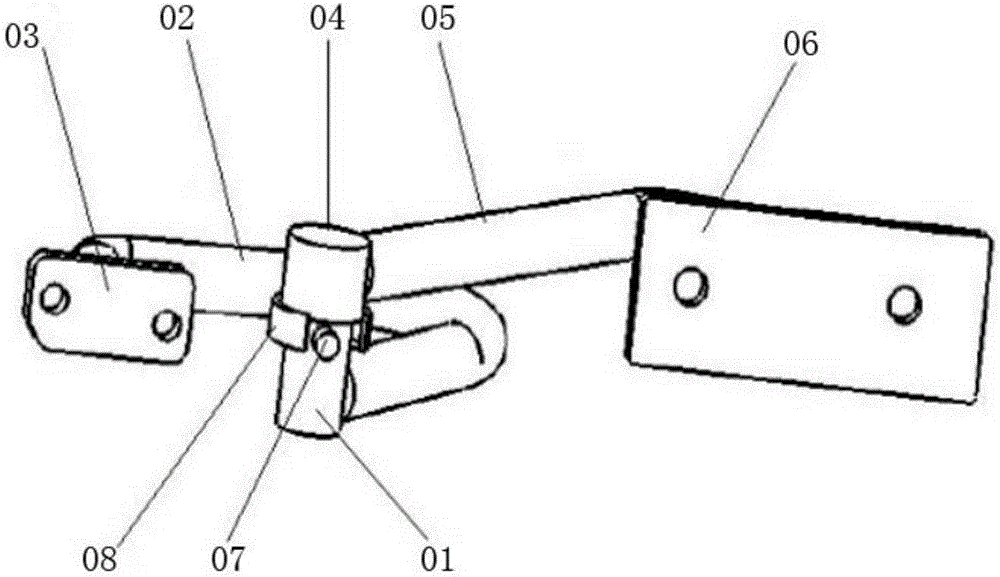

High-wear-resistant blowout-control deviation adjustment polished rod sealer

InactiveCN105863547APrevent sprayingAvoid churnSealing/packingWear resistantElectrical energy consumption

The invention provides a highly wear-resistant anti-blowout adjustable polarizing rod sealer, which belongs to the field of oil pumping equipment. There is a vent-free assembly between them; there is a deflection adjustment gap between the universal sphere and the first locking handle, and the deflection adjustment gap enables the sealer to swing 10°-20° in any direction of 360°, realizing The automatic radial adjustment and centering of the polished rod solves the problem of increased eccentric load wear, greatly reduces the load of the pumping unit, and saves about 20% of electricity consumption; the inner cavity of the middle and upper part of the universal sphere is sequentially arranged from top to bottom The wear-resistant V-cylindrical packing with openings and the wear-resistant tapered packing with openings are provided, which have good sealing performance and long service life; the top of the universal sphere is provided with a blowout prevention device to prevent downhole liquid from ejecting, avoiding Problems such as crude oil loss and environmental pollution caused by breaking off.

Owner:史志升

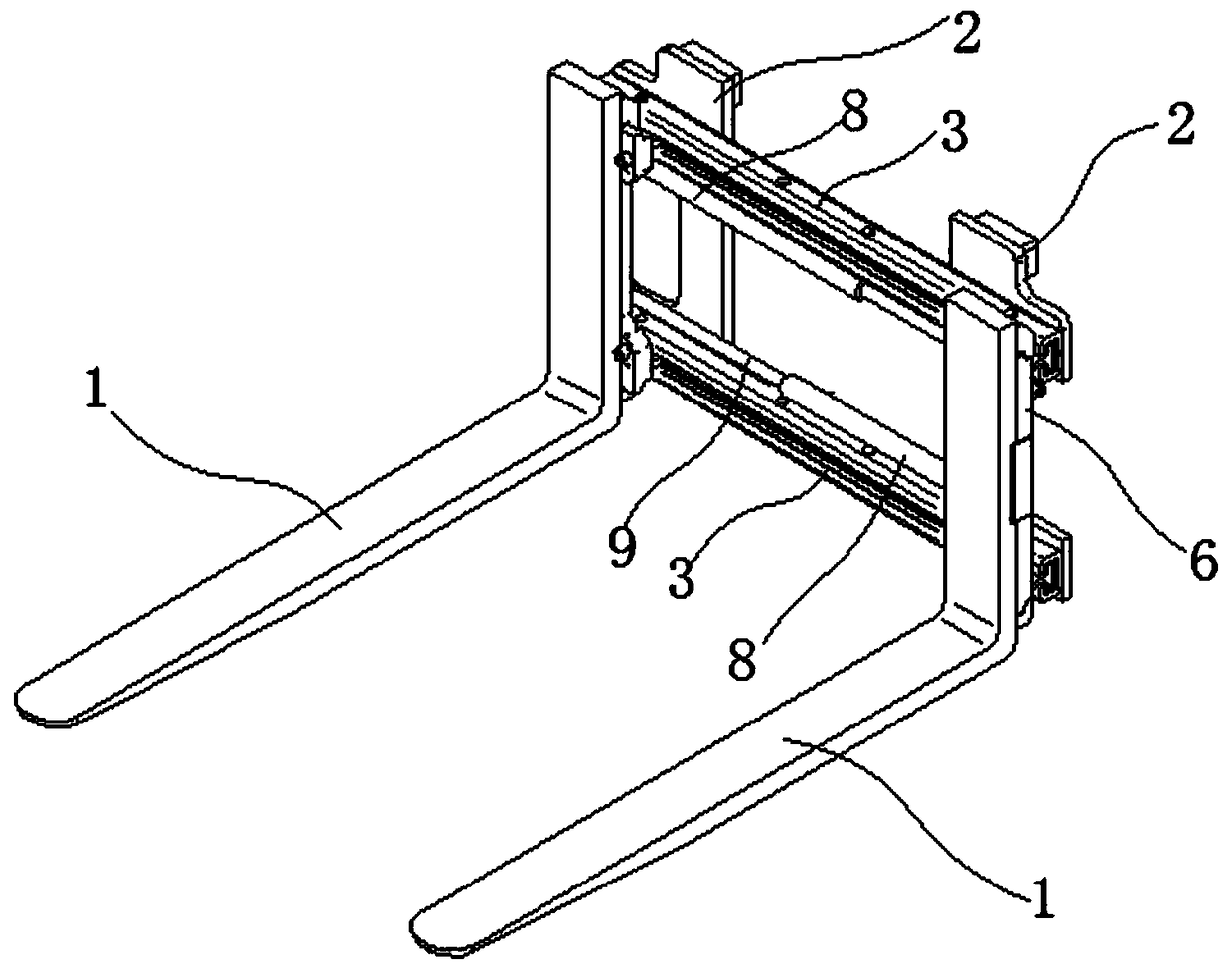

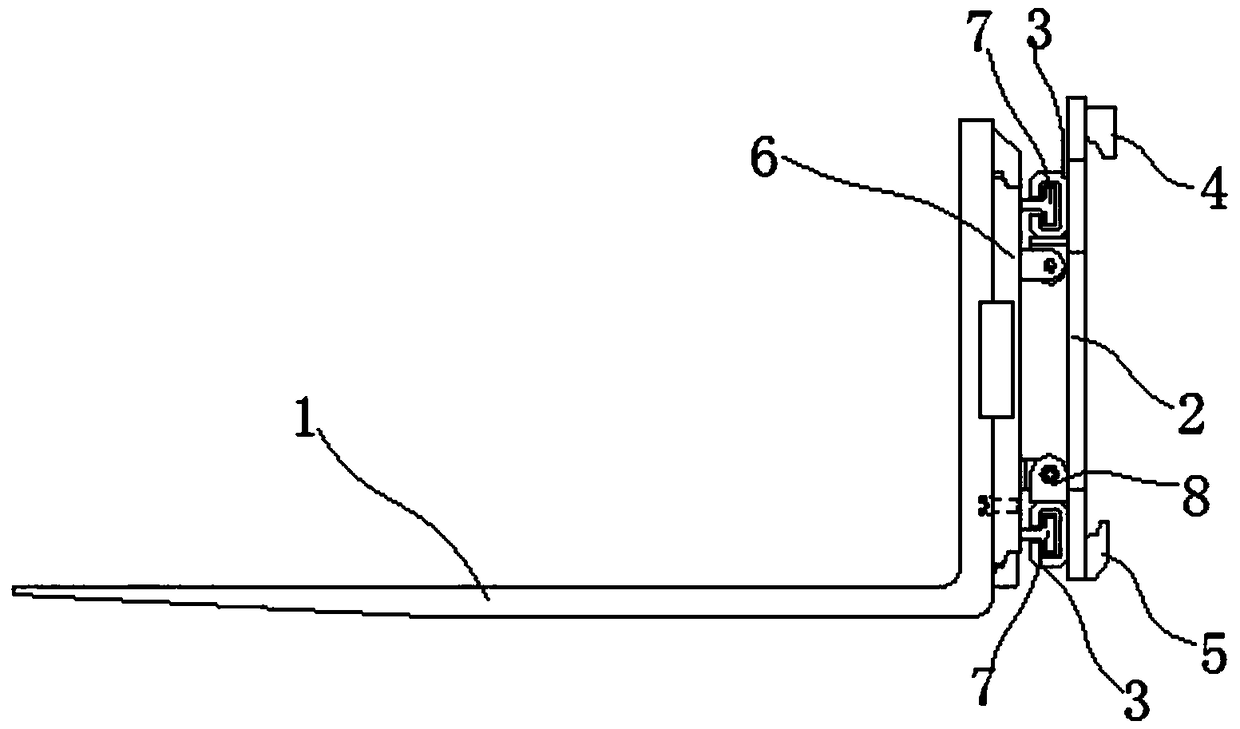

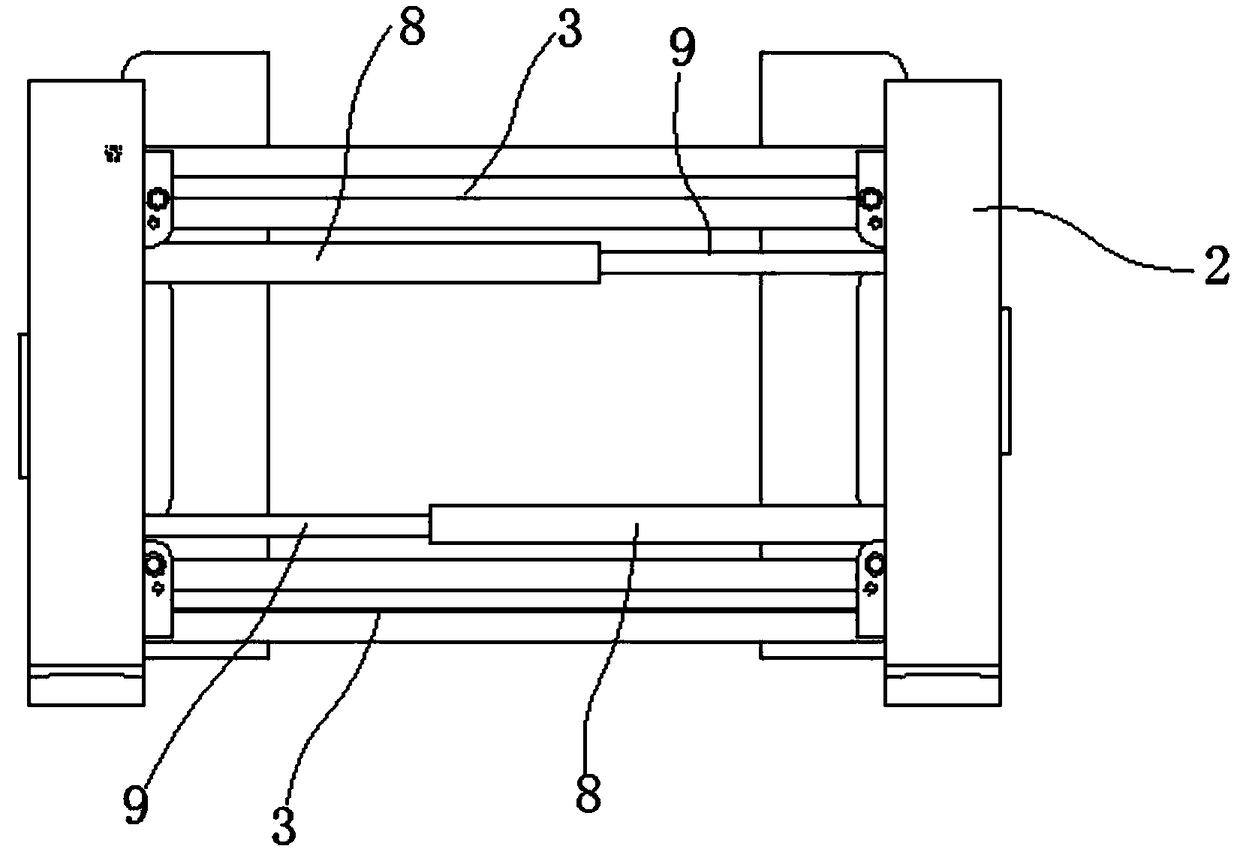

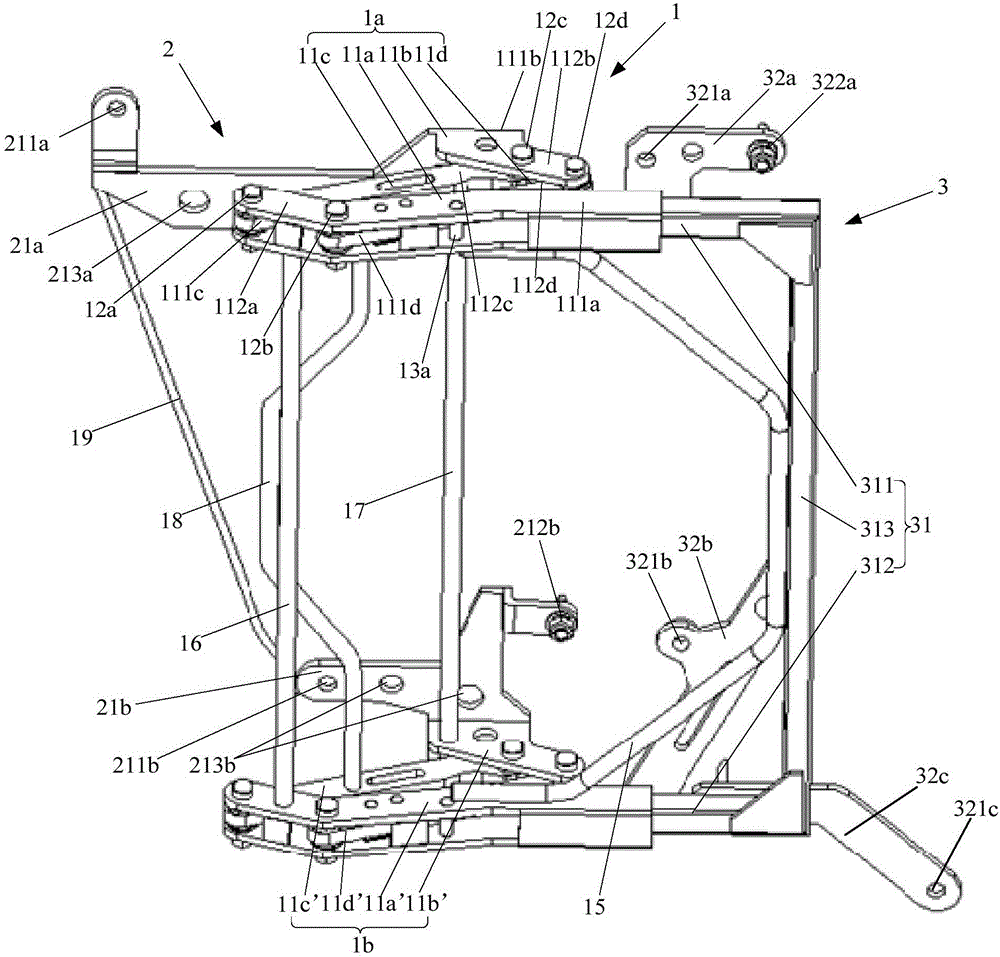

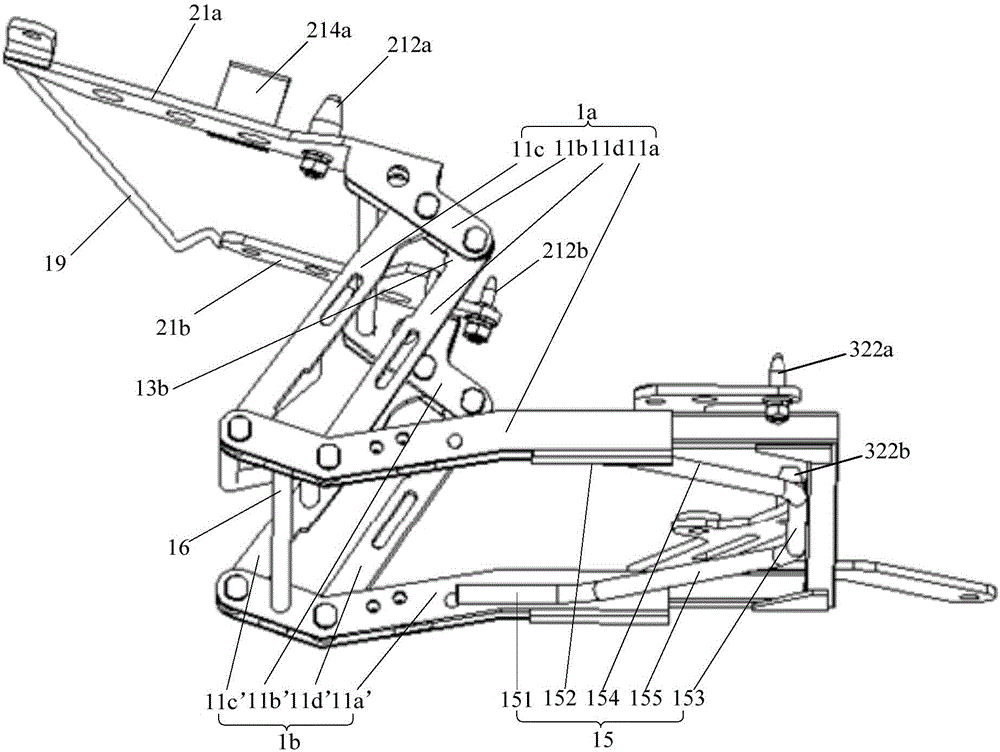

Wide-field hanging type distance adjusting device

Owner:瑞格尔特(厦门)叉车属具有限公司

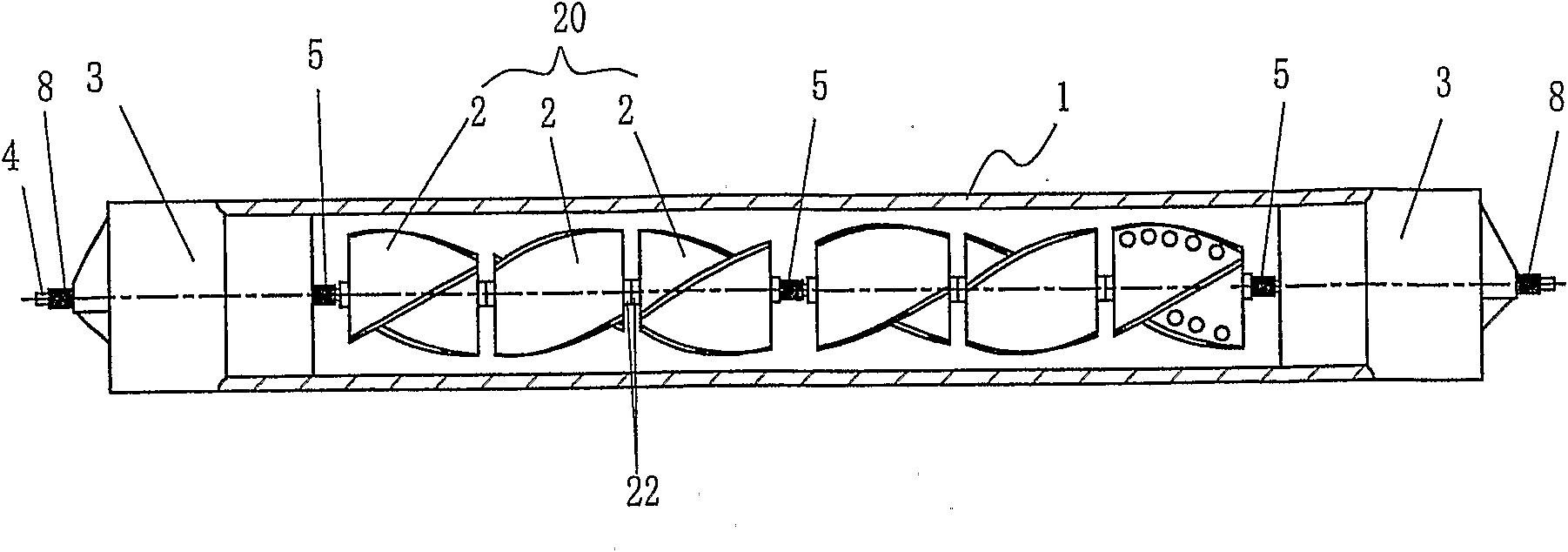

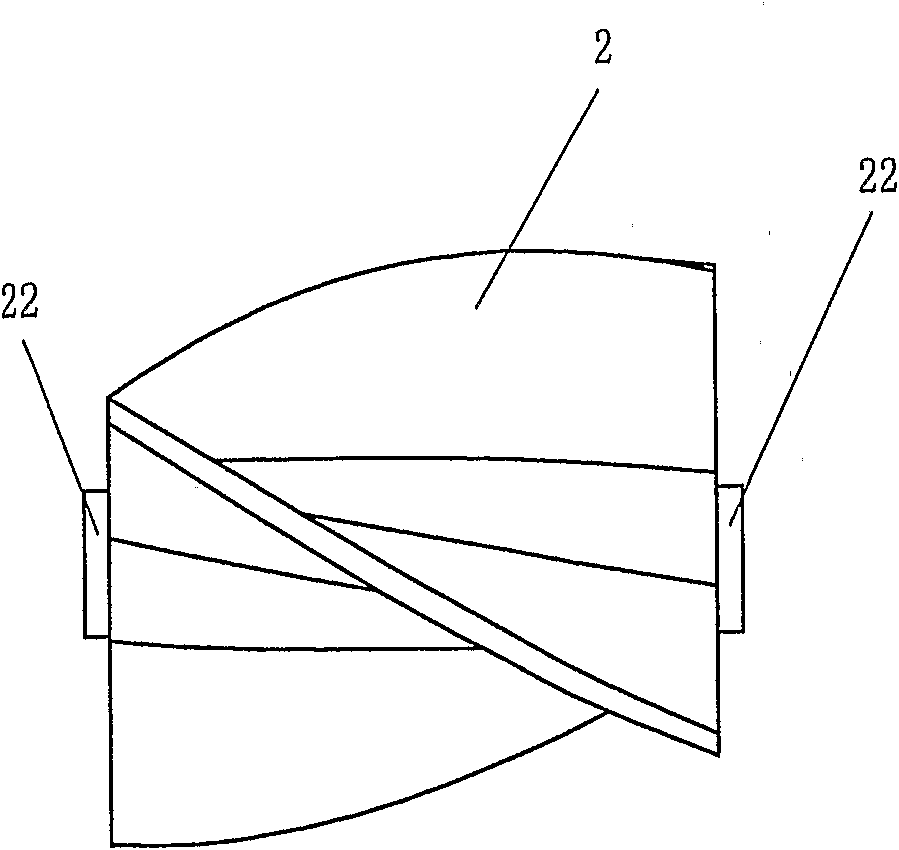

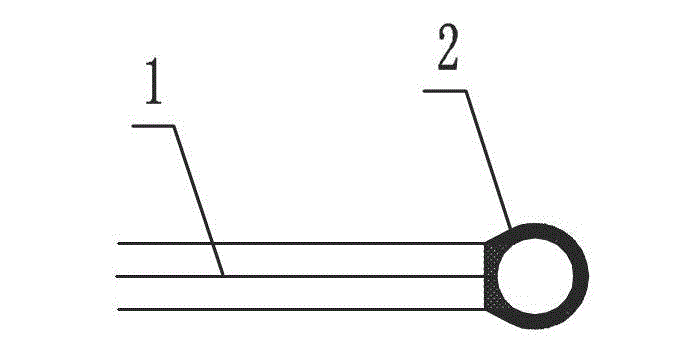

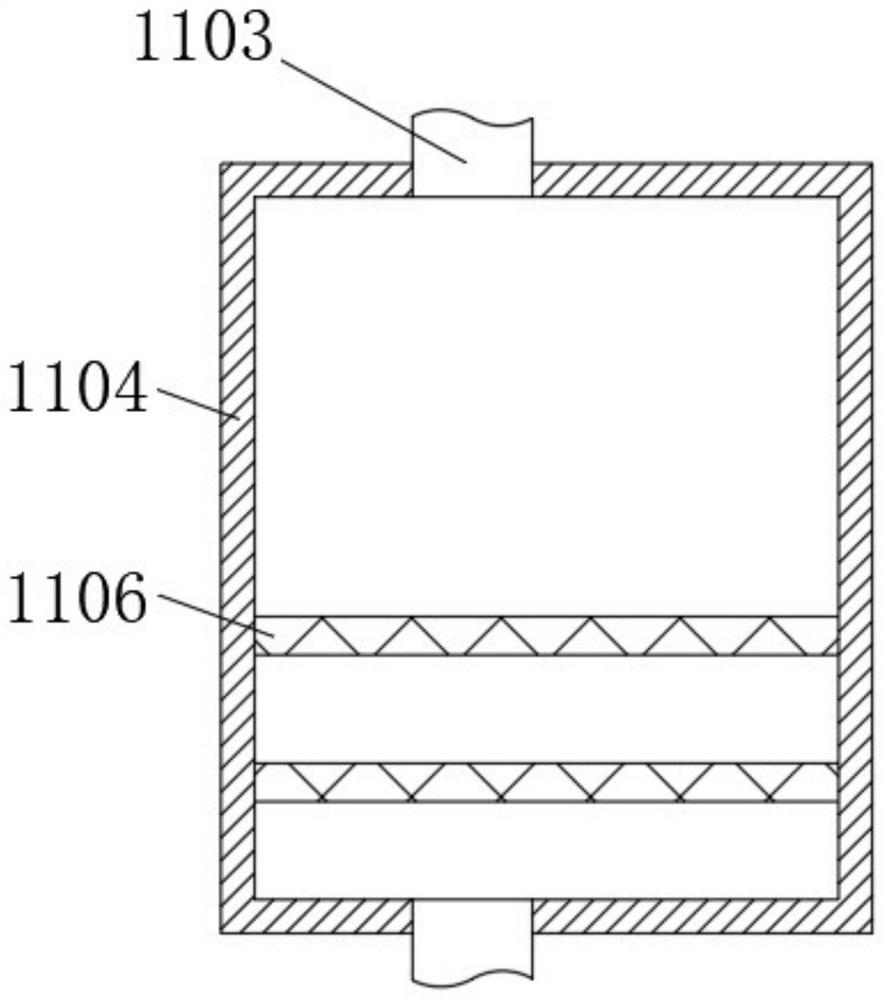

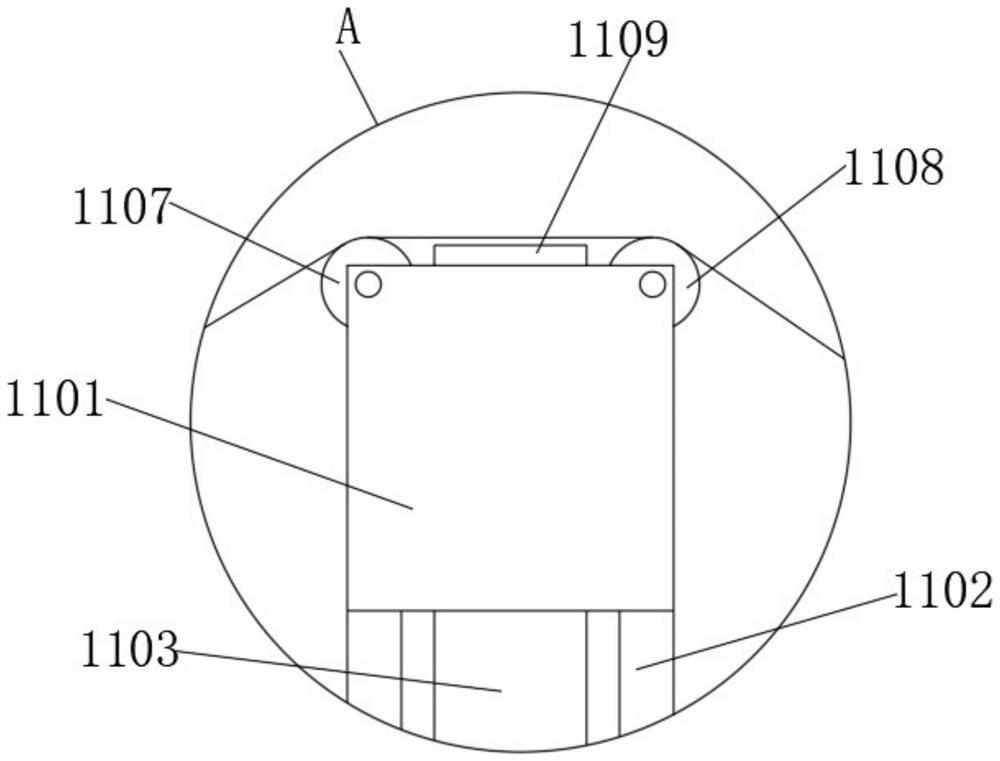

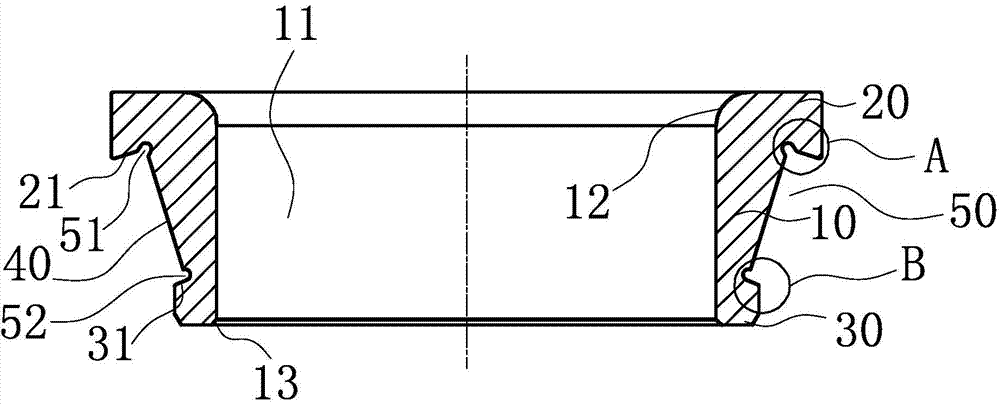

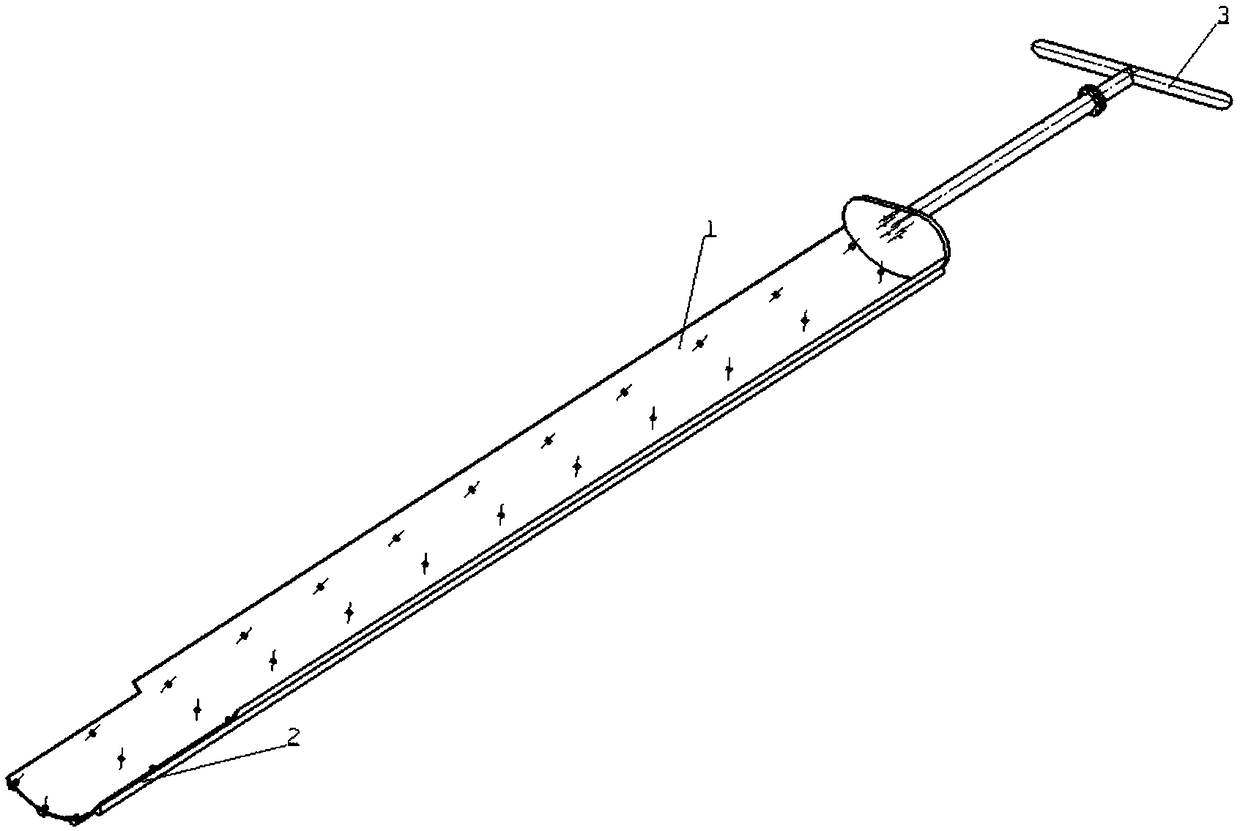

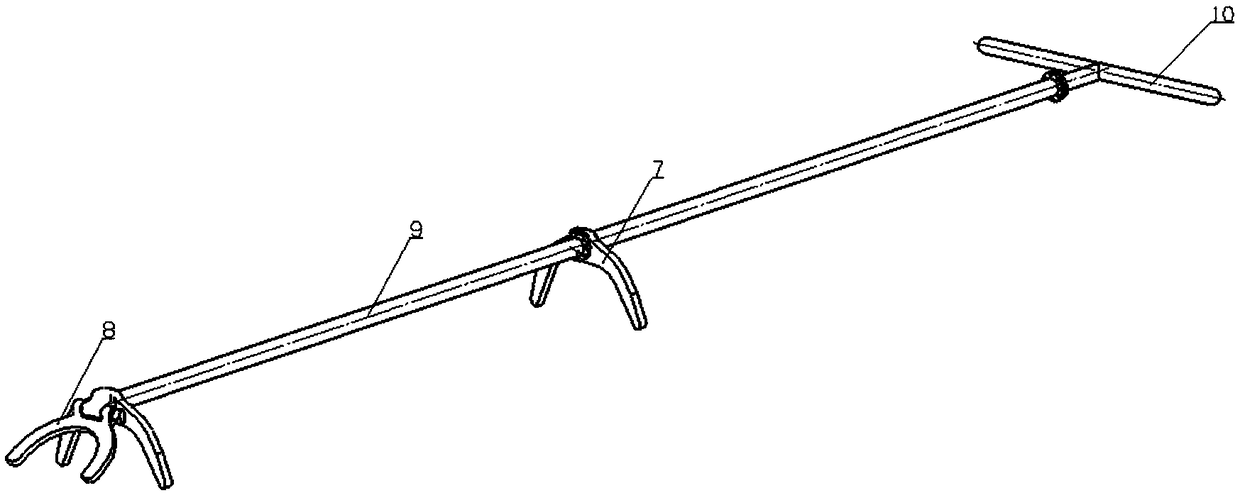

A self-cleaning enhanced heat transfer device inside a tube

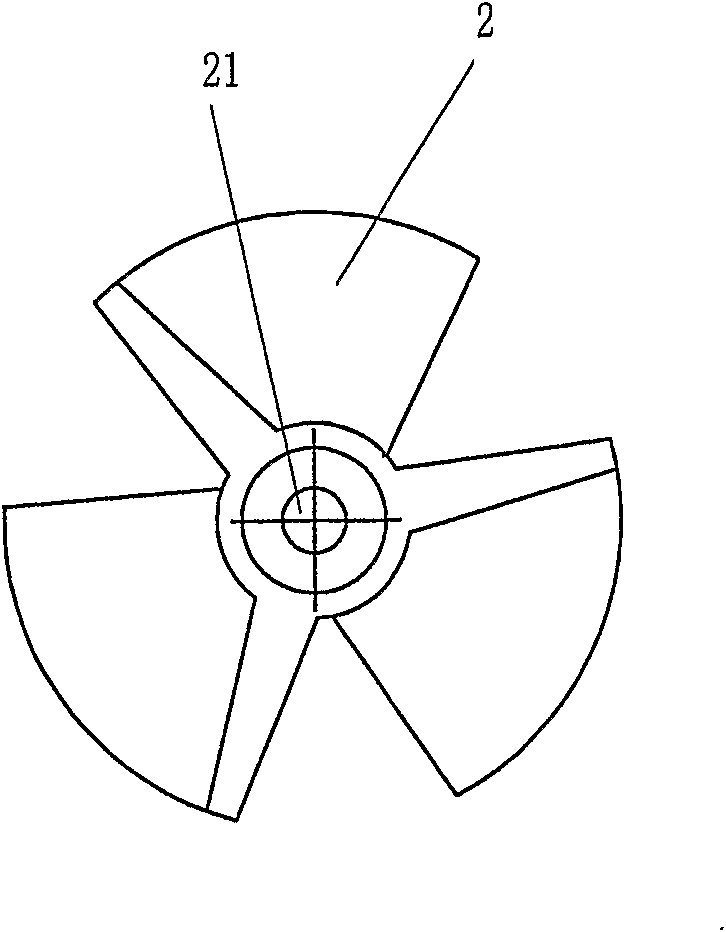

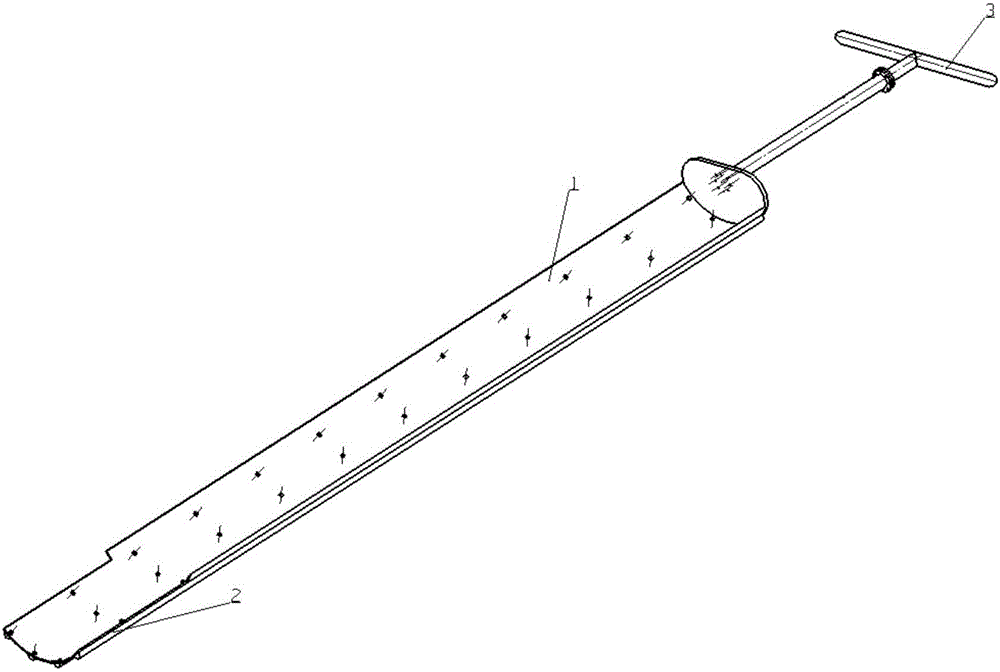

InactiveCN101506611BExtended service lifeReduce mutual frictionHollow article cleaningHeat transfer modificationEnhanced heat transferEngineering

A self-cleaning enhanced heat transfer device inside a tube comprises multiple rotary members (2) mounted inside a heat transfer tube (1). A fixing frame (3) is mounted at each end of the heat transfer tube (1). A supporting shaft (4) passes through the heat transfer tube (1) and the two ends of the supporting shaft (4) are fixed at the fixing frames (3). The rotary members (2) are pivotally mounted at the supporting shaft (4). A limiting member (5) is mounted between at least a pair of adjacent rotary members (2) for separating the ends of the adjacent rotary members (2).

Owner:BEIJING UNIV OF CHEM TECH

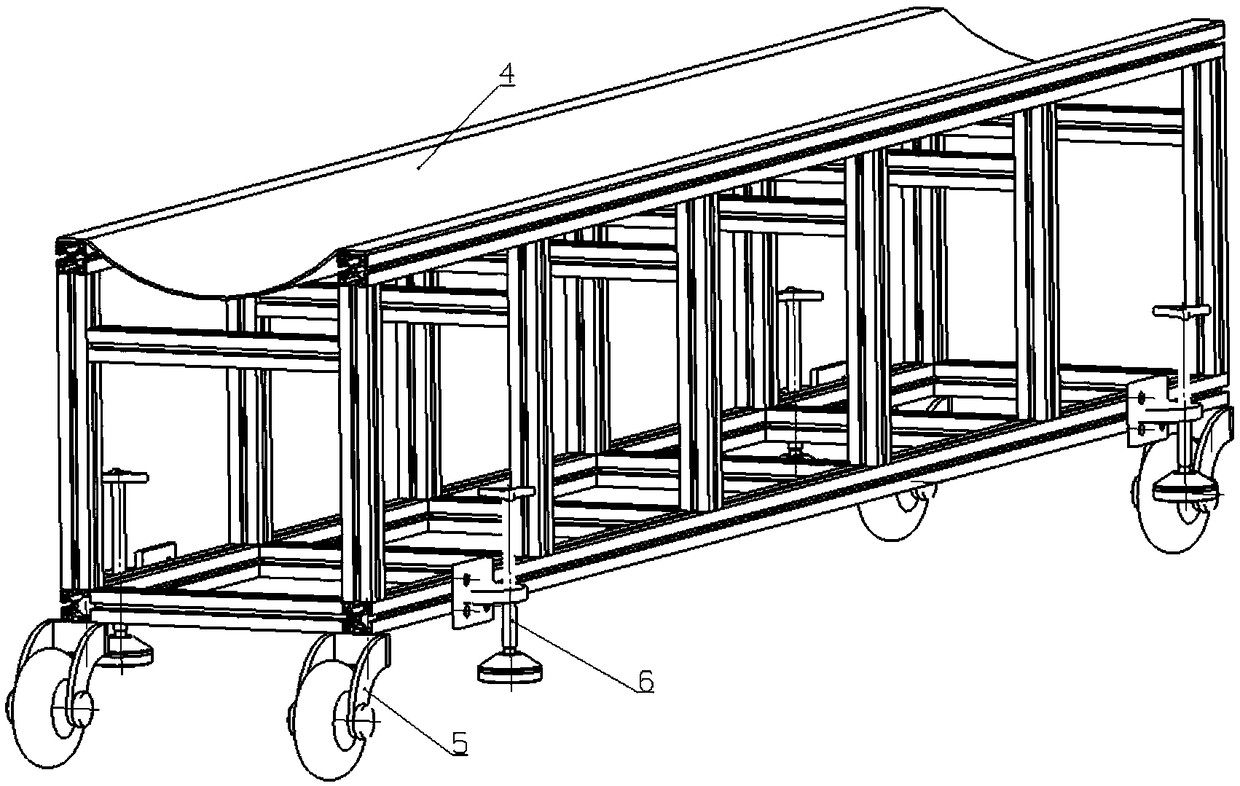

Launching method of pipeline leakage flux inner detector

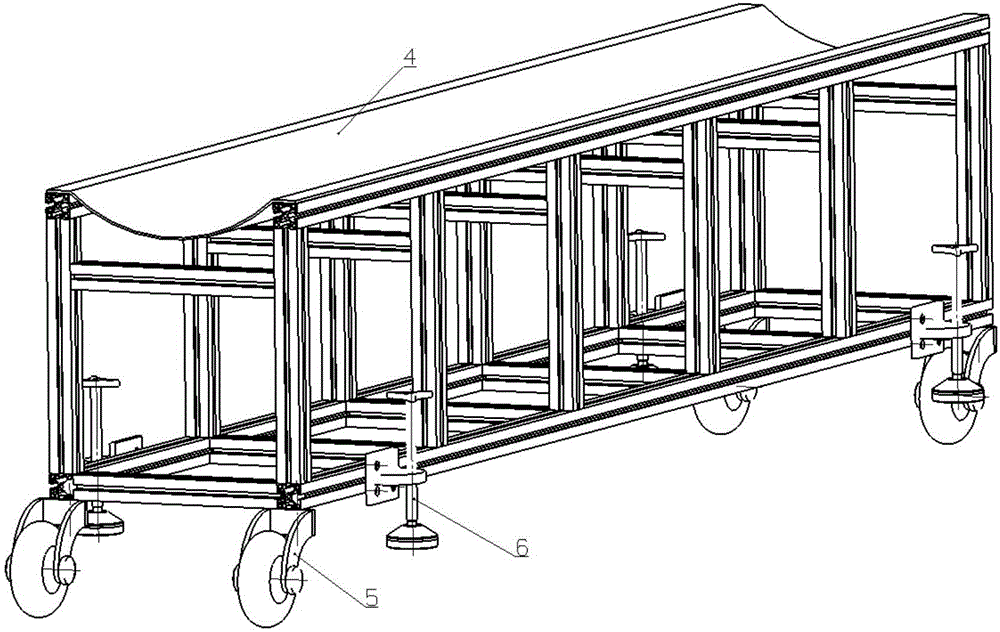

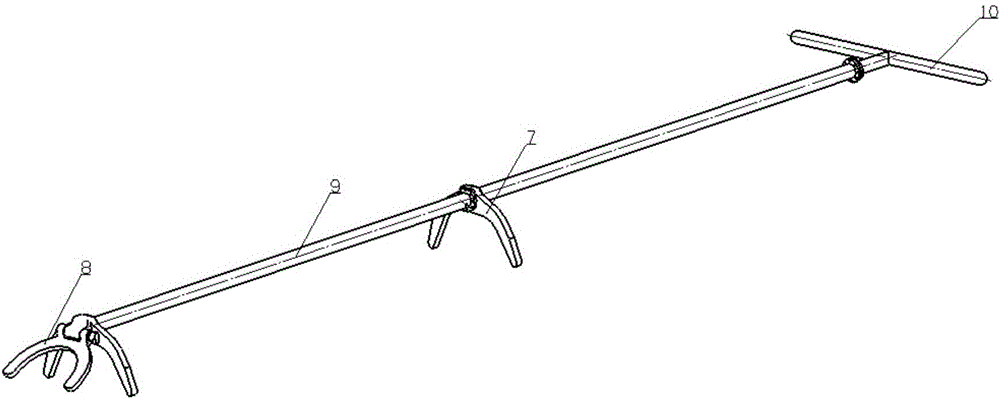

ActiveCN106764457AGenerate magnetic forceReduce frictionPipeline systemsNon magneticElectrical and Electronics engineering

The invention provides a launching method of a pipeline leakage flux inner detector. According to the method, the pipeline leakage flux inner detector is placed on a tray and then placed on a cart through the tray, the pipeline leakage flux inner detector is put into a launching barrel through the tray, and the situation that the pipeline leakage flux inner detector is pulled out together when the tray is pulled out is prevented through a shifting fork push rod; the tray, the cart and the shifting fork push rod are all made of non-magnetic stainless steel; the height and the position can be adjusted through the cart so that the tray can be aligned to the launching barrel; and the shifting fork push rod is used for preventing the pipeline leakage flux inner detector from being pulled out together with the tray. According to the launching method, the launching work of the pipeline leakage flux inner detector can be completed, the launching process is convenient, fast and reliable, and the launching requirement of the pipeline leakage flux inner detector can be met.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

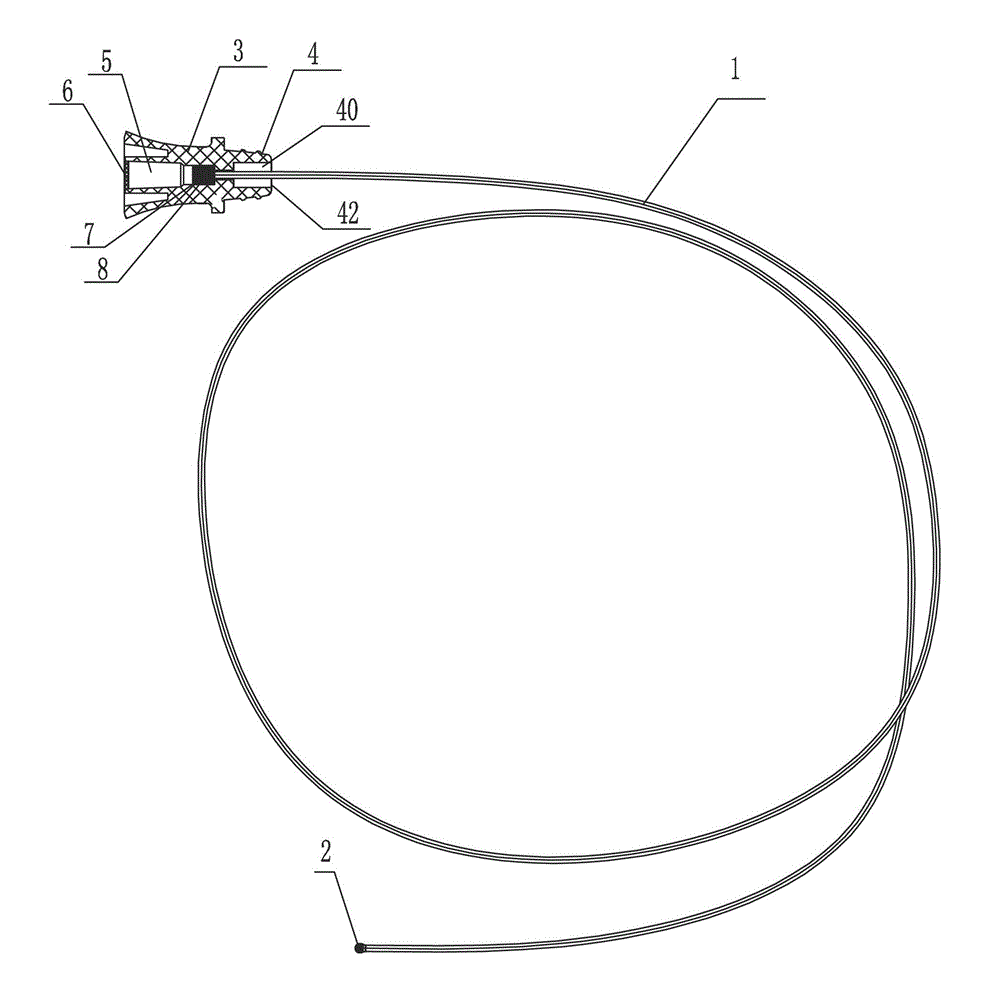

Novel guide wire of gastric tube

The invention provides a novel guide wire of a gastric tube. The novel guide wire comprises a guide wire strip. A plastic reinforcement head is further wrapped on the outside of a head of the guide wire strip, the guide wire is further provided with a handle, and the tail of the guide wire strip is connected with the handle; the lower portion of the handle is a hollow and downwardly open plug, and the plug is matched with a gastric tube joint and is used for being plugged in the gastric tube joint and connecting the handle with the gastric tube joint; and the upper portion of the inside of the handle is an injection cavity, an opening of the injection cavity is sealed by a sealing film, and the injection cavity is communicated with a hollow portion of the plug. The novel guide wire is good in lubricating effect, the plastic reinforcement head has a suspension effect, and friction between the guide wire strip and the wall of the gastric tube is reduced, so that the guide wire strip can be drawn easily; the head of the guide wire strip is effectively prevented from penetrating through an outward open hole at the front end of the gastric tube to destroy gastric and intestinal tissues; and the novel guide wire is doubly sealed under the action of the plug and the action of the sealing film of the injection cavity, and the phenomenon of reverse ejection of contents of the stomach of a patient is stopped.

Owner:边俊杰

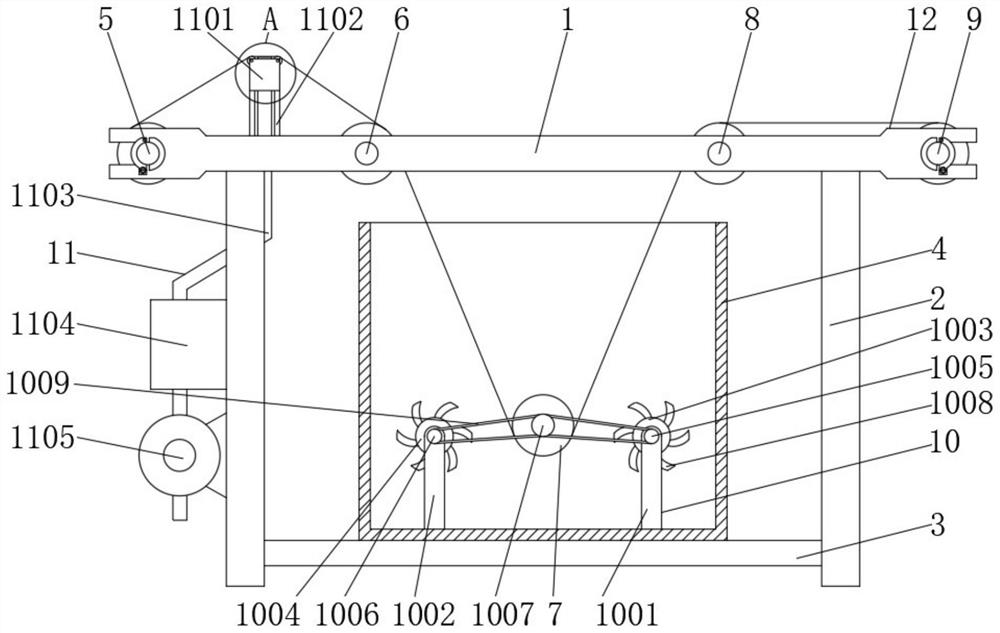

Dyeing device for sun umbrella cloth processing and application method thereof

InactiveCN112095251AAvoid loosenessIncrease rotational resistanceMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a dyeing device for sun umbrella cloth processing and an application method thereof. The dyeing device comprises a supporting frame, supporting legs are fixedly mounted at thebottom of the supporting frame, the number of the supporting legs is two, a connecting frame is fixedly connected between the two supporting legs, and a pigment barrel is placed on the upper portion of the connecting frame; and a discharging roller is movably mounted at one end of the supporting frame, a first steering roller is movably mounted at the position, located on one side of the discharging roller, of the inner side of the supporting frame, and a dyeing roller is movably mounted at the position, close to the lower portion, of the center of the interior of the pigment barrel. Accordingto the dyeing device for sun umbrella cloth processing, pigment can be stirred, the precipitation phenomenon is avoided, supporting of a power device is not needed, the discharging roller and a winding roller can be conveniently disassembled and assembled, the use convenience is improved, in addition, the impurity removal function is achieved, dust and impurities on the surface of umbrella clothand in holes of the umbrella cloth are prevented from polluting pigment, and the device is more beneficial to using.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

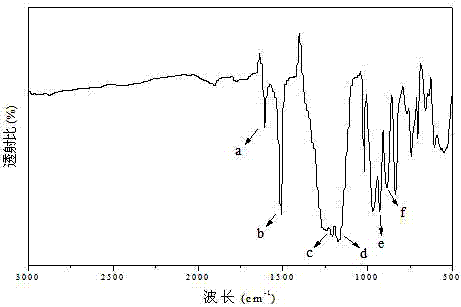

Preparation method of aqueous polyurethane/fluorinated phosphazene nano fiber composite material

InactiveCN107057331AImprove anti-friction and anti-wear propertiesEvenly dispersedMonocomponent synthetic polymer artificial filamentIn situ polymerizationIsophorone diisocyanate

The invention discloses a preparation method of an aqueous polyurethane / fluorinated phosphazene nano fiber composite material. The method comprises the following steps: dissolving hexachlorocyclotriphosphazene and 4,4'-(hexafluoro isopropyl fork) bisphenol into a toluene / acetone composite solution; dropwise adding triethylamine and carrying out nucleophilic substitution reaction under a magnetic power stirring condition, and carrying out post-treatment to obtain fluorinated phosphazene nano fibers; adding the nano fibers into polypropylene glycol; then adding isophorone diisocyanate, a catalyst and 2,2-dimethylolpropionic acid until the reaction is completed; reducing the temperature and adding triethylamine to be neutralized; dispersing into the deionized water to obtain an aqueous polyurethane solution; and casting the aqueous polyurethane solution into an extensible sample strip mould to be naturally solidified to obtain the aqueous polyurethane / fluorinated phosphazene nano fiber composite material. According to the preparation method disclosed by the invention, by adopting a chemical in-situ polymerization method, the reaction is added into an aqueous polyurethane basal body, and the successfully obtained aqueous polyurethane composite material has excellent heat stability, extension performance and friction and abrasion performance.

Owner:ZHEJIANG UNIV OF TECH

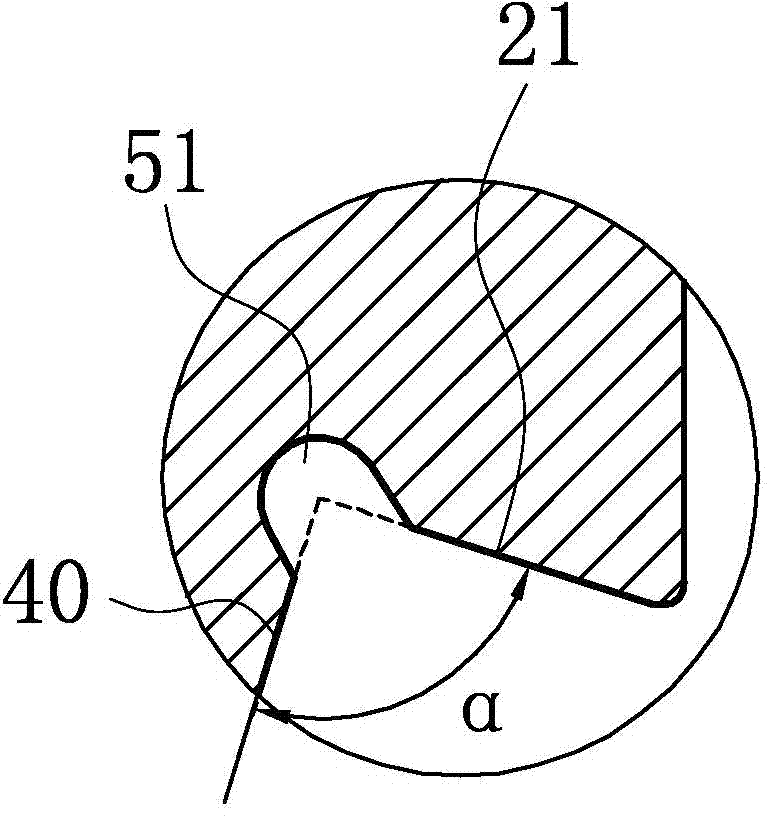

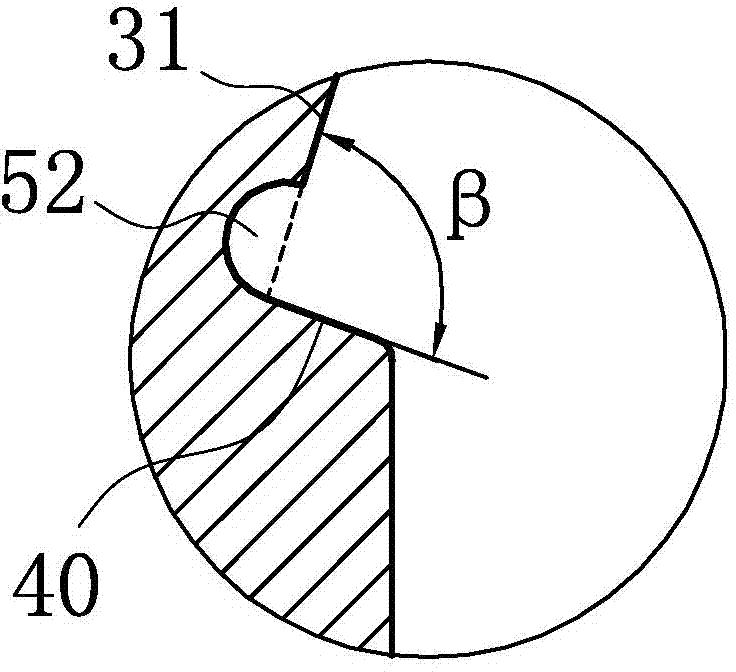

Vehicle special-shaped bearing narrow inner ring

The invention belongs to the technical field of automobile parts and relates to a vehicle special-shaped bearing narrow inner ring. The invention aims at solving the technical problem of unstable operation in the prior art. The vehicle special-shaped bearing narrow inner ring comprises an inner ring body, wherein a shaft hole is formed in the inner ring body, a first retaining ring is arranged at one end of the inner ring body, a second retaining ring is arranged at the other end of the inner ring body, the outer diameter of the first retaining ring is larger than that of the second retaining ring, the outer wall of the inner ring body between the first retaining ring and the second retaining ring forms a tapered outer inclined plane, the outer inclined plane, the first retaining ring and the second retaining ring encircle to form a ball groove for accommodating a ball, the surface of the first retaining ring, which is positioned in the ball groove, has a tapered first retaining ring inclined plane, the surface of the second retaining ring, which is positioned in the ball groove, has a tapered second retaining ring inclined plane, the included angle alpha between the first retaining ring inclined plane and the outer inclined plane is more than 89 degrees and less than 90 degrees, and the included angle beta between the second retaining ring inclined plane and the outer inclined plane is more than 90 degrees and less than 91 degrees. The vehicle special-shaped bearing narrow inner ring provided by the invention is reasonable in design, stable in operation and good in loading performance.

Owner:德清德曼汽车零部件有限公司

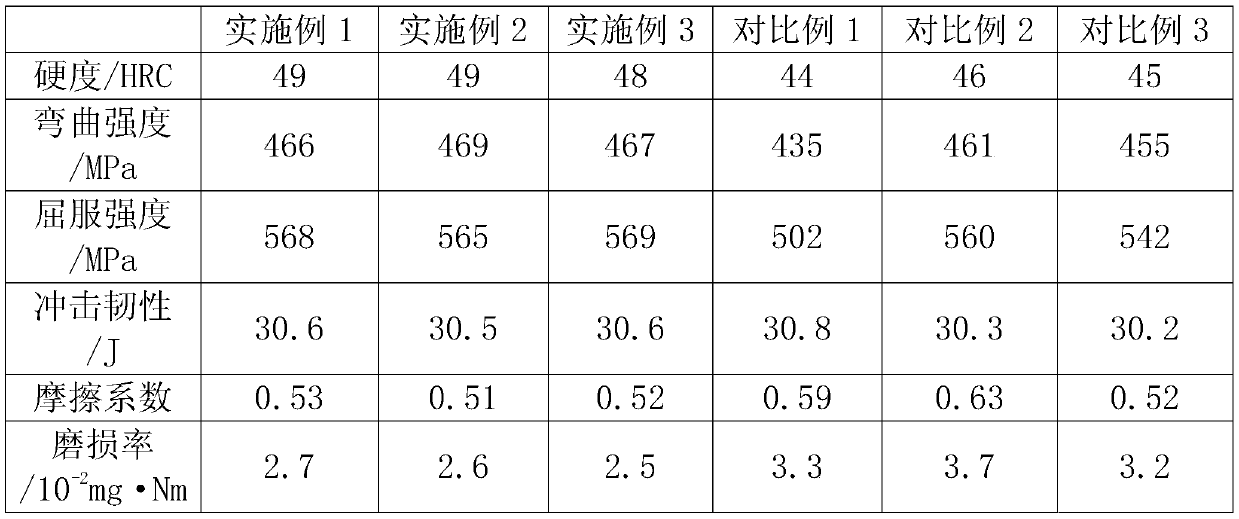

Alloy material for bearing rolling body and preparation method thereof

ActiveCN110066934AUniform stressHigh strengthTransportation and packagingMetal-working apparatusAlloyHardness

The invention discloses an alloy material for a bearing rolling body. The alloy material is prepared from the following raw materials in parts by weight: 80-100 parts of a base material, 9-11 parts ofa lubricant and 6-7 parts of modified graphene oxide, wherein the base material comprises Ti powder, Al powder, Cr powder, Nb powder and Al2O3 powder. The invention also discloses a preparation method of the alloy material. The preparation method comprises the following steps: two-step grinding, plasma sintering and the like. By taking the Ti powder, Al powder, Cr powder, Nb powder and Al2O3 powder as the base material of the alloy, the alloy material is prepared by means of two-step grinding and plasma sintering by adding the lubricant and the modified graphene oxide. By adding the stretchedlaminar graphene oxide, the mechanical properties of hardness, strength and the like of the alloy material can be improved. The self-lubricating effect of the alloy material can be improved by meansof a synergistic effect of the lubricant and a graphene lubricating film. The alloy material is prepared into the bearing rolling body which is excellent in comprehensive performance.

Owner:NINGBO DAER MACHINERY TECH CO LTD

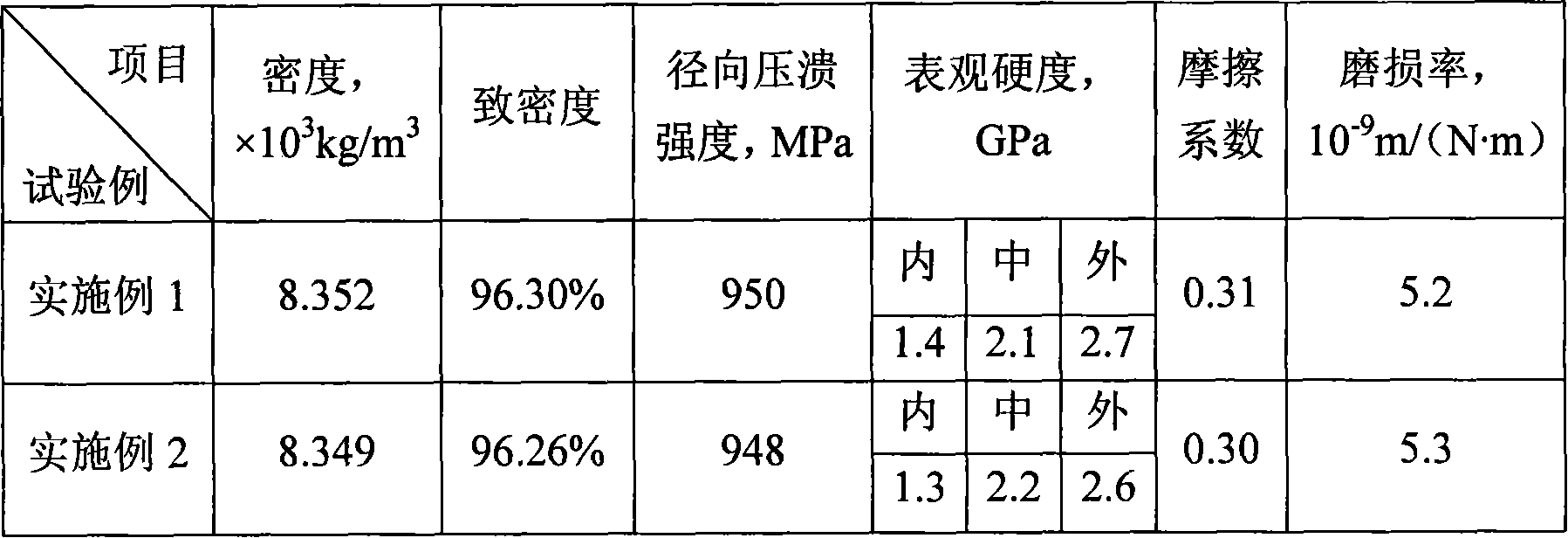

Preparation method of CuSnNiP-based copper alloy lubricating friction-resistant material by liquid-phase sintering method

The embodiment of the invention discloses a preparation method of a CuSnNiP-based copper alloy lubricating friction-resistant material by a liquid-phase sintering method, and particularly relates to the field of powder metallurgy. The preparation method comprises the following steps that firstly, CuSn8NiP copper powder atomized by water flow or air flow is selected; and secondly, 0.02-4 wt% of low-melting-point metal such as tin powder Sn or low-melting-point metal alloy powder is added into the copper alloy powder CuSn8NiP alloy, and the copper alloy powder in which the low-melting-point metal is added is fully mixed and stirred evenly in a mixer for 0.5-3 h. According to the preparation method of the CuSnNiP-based copper alloy lubricating wear-resistant material by the liquid-phase sintering method, a copper alloy layer of a copper-steel alloy lubricating wear-resistant material prepared by the method has the advantages of good contractibility, a low void ratio, relatively good compactness, high strength and good mechanical fatigue resistance; and the copper-steel alloy lubricating wear-resistant material prepared by the liquid-phase sintering method has specific metallurgical metallographic characteristics.

Owner:WUHAN UNIV OF SCI & TECH

Sliding door tool

InactiveCN106076702AMeet width requirementsMeet passability size requirementsSpraying apparatusFixed frameEmbedded system

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Method for preparing high-wear-resistance self-lubricating composite oxide film on surface of aluminum alloy friction part

Owner:NORTHEASTERN UNIV LIAONING

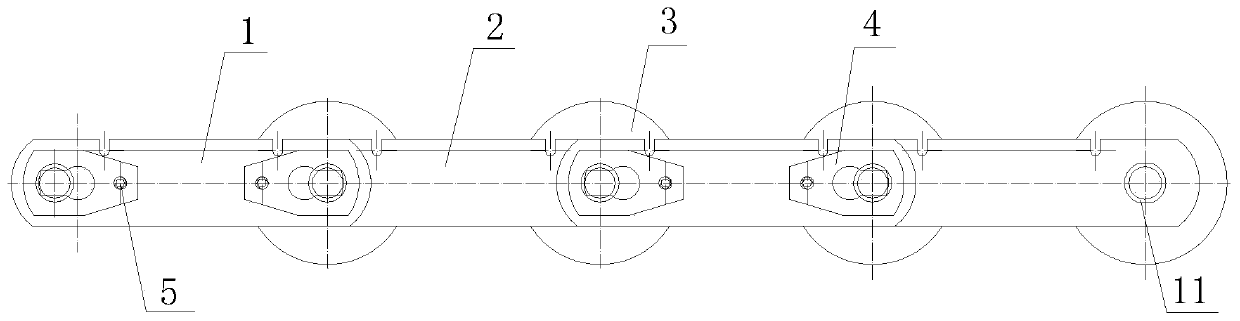

Self-lubricating structure of double-row heavy-load cement conveying chain

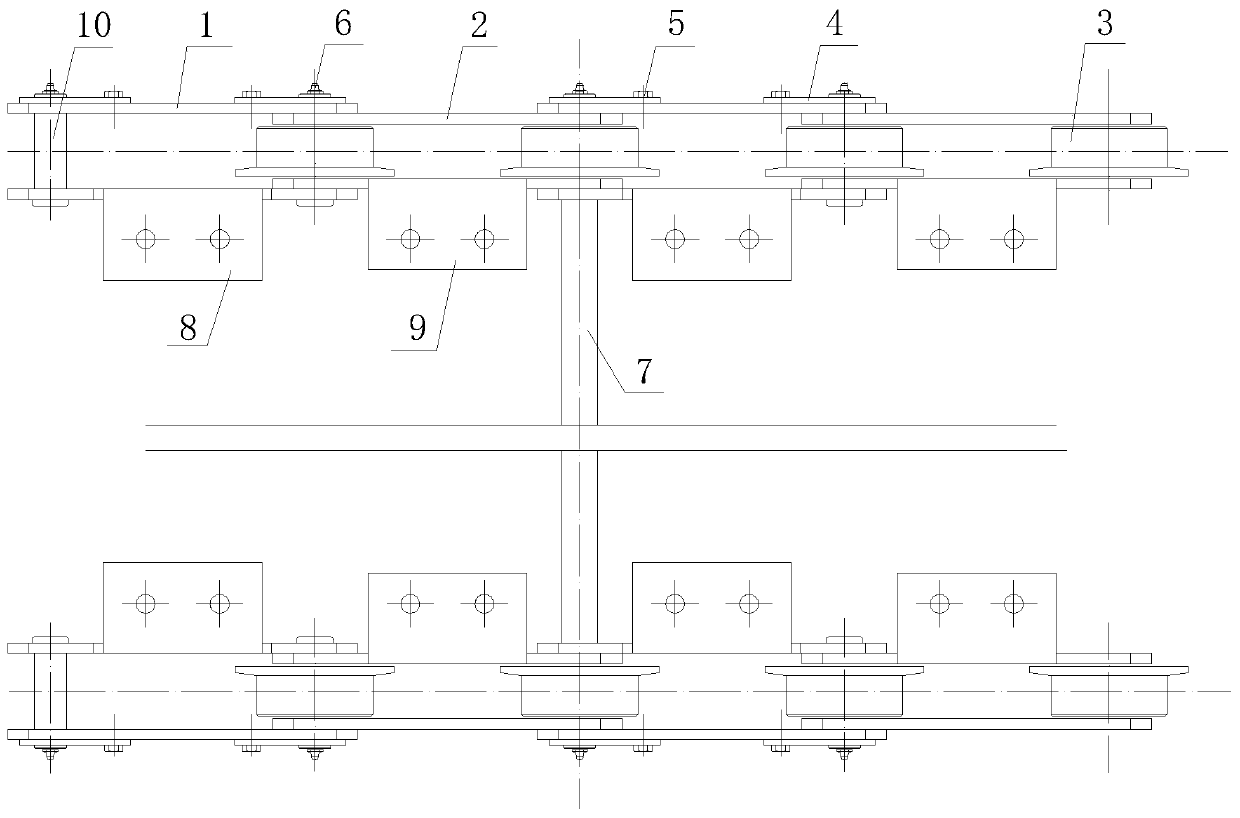

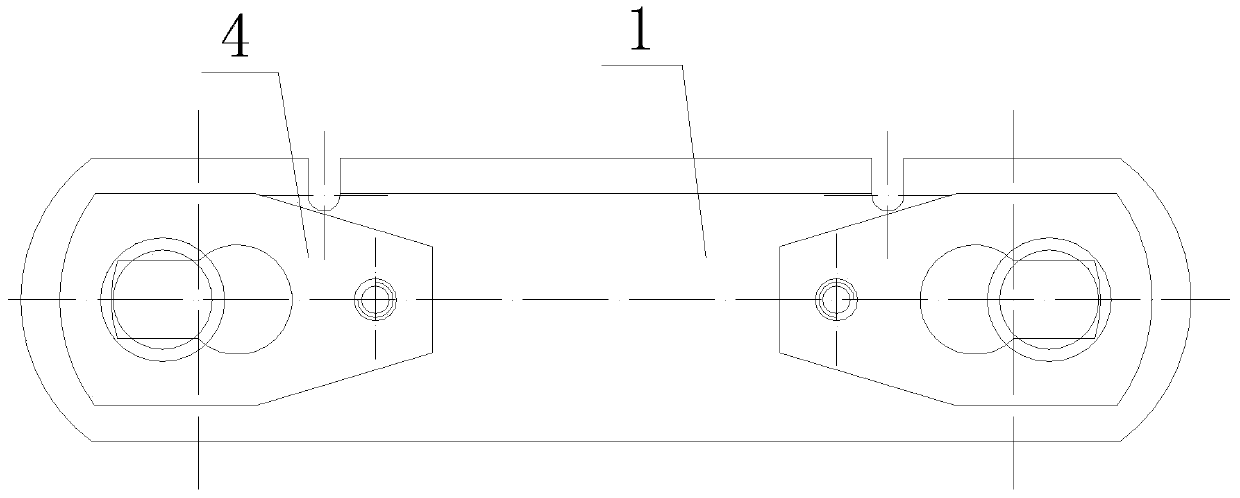

The invention relates to the technical field of self-lubricating conveying chains, and provides a self-lubricating structure of a double-row heavy-load cement conveying chain. The self-lubricating structure effectively improves the lubrication sufficiency of the conveying chain, enhances the high temperature resistance, wear resistance, impact fatigue resistance and the like of the chain, and prolongs the service life of the chain. The self-lubricating structure comprises two closed structures defined by a plurality of chain links, and the two closed structures are arranged in parallel. The self-lubricating structure is characterized in that each chain link comprises an inner chain plate, an outer chain plate and a pin shaft, wherein the outer chain plates and the inner chain plates are oppositely and alternately connected through the pin shafts, a roller is arranged between every two inner chain plates, a sleeve is inserted in the middle of each roller, each sleeve is arranged on thecorresponding pin shaft in a sleeving mode, the pin shafts are in large clearance fit with the sleeves, the inner end of each pin shaft is provided with an end step, the other end of each pin shaft isprovided with an oil groove, and an oil cup is installed at a port of each oil groove in a threaded manner. The self-lubricating structure is particularly suitable for self-lubricating of the heavy-load conveying chain, and has high social use value and application prospects.

Owner:安徽黄山中友链条制造有限公司

A kind of pipeline magnetic flux leakage inner detector launching method

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

A kind of alloy material for bearing rolling body and preparation method thereof

ActiveCN110066934BIncrease room temperature shapingHigh strengthTransportation and packagingMetal-working apparatusAl powderUltimate tensile strength

The invention discloses an alloy material for a bearing rolling body, which is made of the following raw materials in parts by weight: 80-100 parts of base material, 9-11 parts of lubricant, 6-7 parts of modified graphene oxide, and the base material includes Ti powder, Al powder, Cr powder, Nb powder, Al 2 o 3 powder; the invention also discloses the preparation method of the alloy material, including two steps of ball milling and plasma sintering. The present invention adopts Ti powder, Al powder, Cr powder, Nb powder, Al 2 o 3 The powder is used as the matrix material of the alloy, and lubricant and modified graphene oxide are added, and the alloy material is prepared by two-step ball milling method and plasma sintering method. The addition of stretched lamellar graphene oxide can improve the hardness and strength of the alloy material And other mechanical properties, the synergistic effect of the lubricant and the graphene lubricating film can improve the self-lubricating effect of the alloy material, and the alloy material can be made into a bearing rolling body with excellent comprehensive performance.

Owner:NINGBO DAER MACHINERY TECH CO LTD

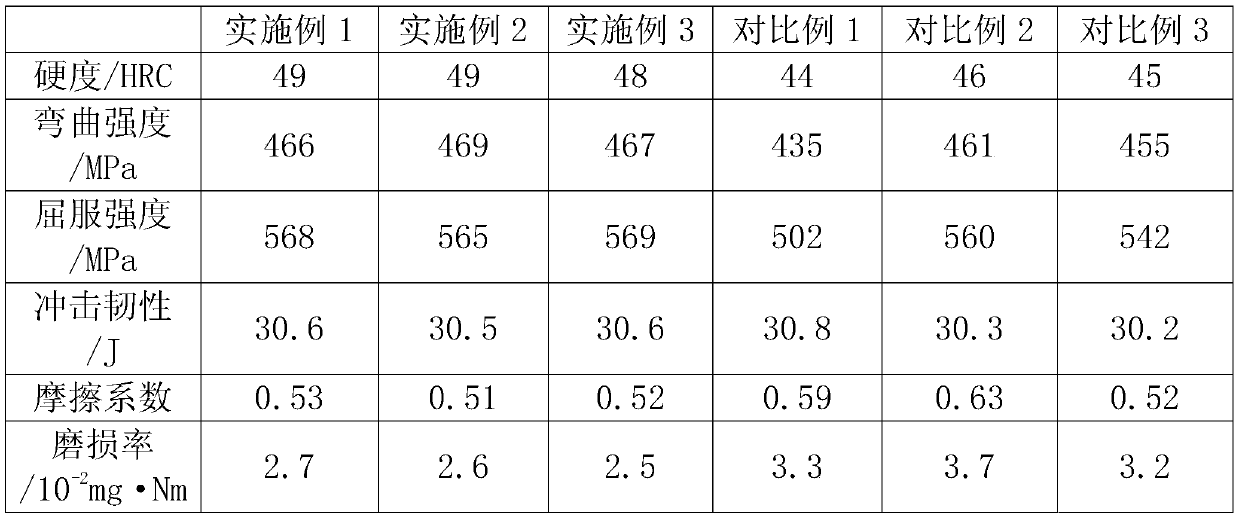

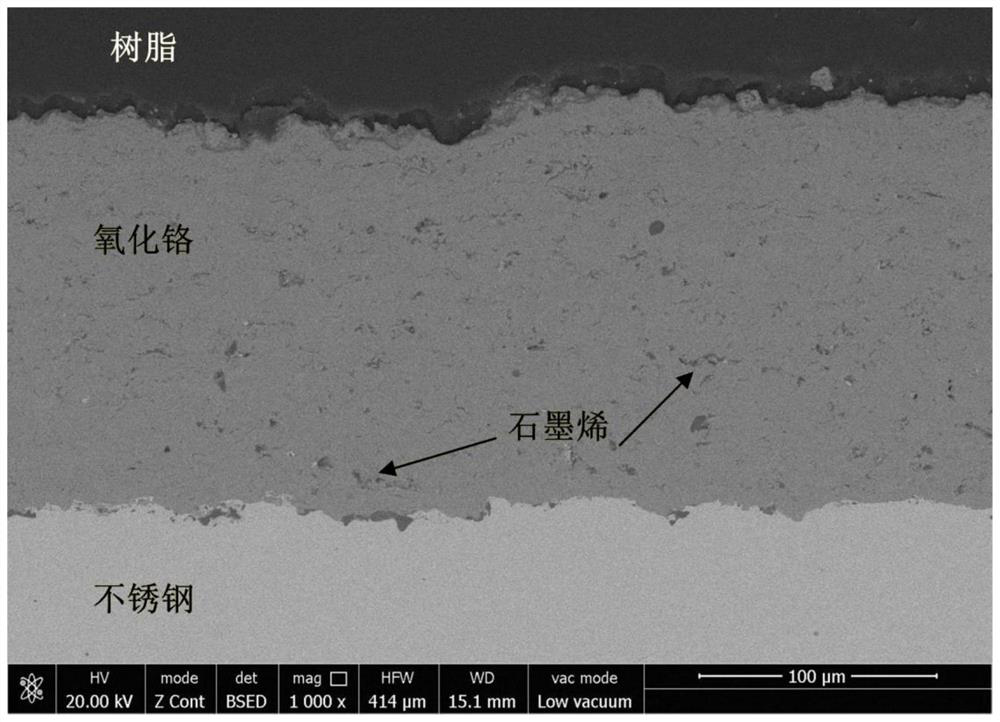

Preparation method of composite powder, dynamic friction sealing coating and preparation method

PendingCN113774309AImprove liquidityImprove spraying effectMolten spray coatingCarbon compoundsChemical compositionGraphite

The invention provides a preparation method of chromium oxide / graphene composite powder. Cr2O3 and graphene are respectively granulated, the proportion of Cr2O3 to graphene spherical powder is designed, so that the Cr2O3 and the graphene in the composite powder are spherical, the particle size distribution is 40-120 microns, compared with graphene powder directly added into Cr2O3 thermal spraying powder, the chromium oxide / graphene composite powder has better flowability and spraying performance, the chromium oxide / graphene composite powder for the dynamic friction sealing coating is obtained, according to the preparation method, the novel chromium oxide / graphene dynamic friction sealing coating is obtained by utilizing the composite powder through plasma spraying, and the coating has a dual-phase chemical composition, and is compact / loose in structure and multi-element coordinated in structure. The problem of cracking caused by overlarge stress in the preparation process of an existing chromium oxide coating is solved, meanwhile, the abrasion rate is reduced through the self-lubricating effect of the coating, and the requirement for dynamic sealing of the surface of a high-speed friction moving ring can be met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com