Component structure double-gradient functional coating for cutting tool and preparation method of component structure double-gradient functional coating

A cutting tool, dual gradient technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the limited improvement of coating performance, affecting the overall stability of the coating and comprehensive service performance, coating The problem of reducing the adhesion between the layer and the coating is to achieve the effect of service reliability guarantee, good film-base adhesion, and excellent film-film adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Correspondingly, the present invention also provides a method for preparing a composition-structure dual-gradient functional coating for cutting tools, which is characterized in that it comprises the following steps:

[0032] (1) Prepare the tool base and carry out grinding, sandblasting and polishing;

[0033] (2) Pretreatment of the tool substrate, including cleaning and drying, argon ion bombardment etching and activation treatment;

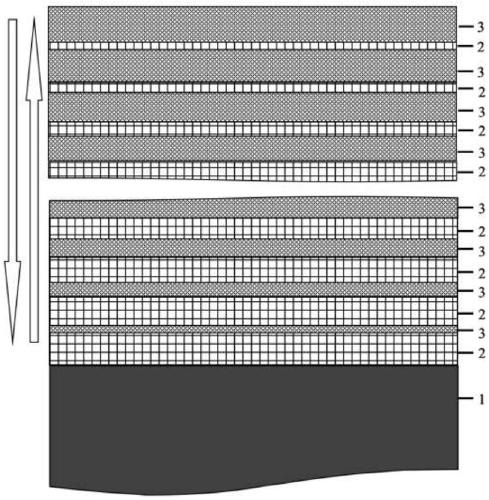

[0034] (3) Using cathodic arc ion plating technology to alternately deposit Ti on the tool substrate in different trends of decreasing and increasing 1-x- y Al x Me' y N layer and Ti 1-x-y Al x Me" y The N layer is naturally cooled to a temperature lower than 200°C under vacuum, and then released from the furnace to obtain a dual-gradient functional coating with composition and structure for cutting.

[0035] Wherein, the substrate bias of the cathodic arc ion plating technology is 30-150V, the target source current is 100-240A, ...

Embodiment 1

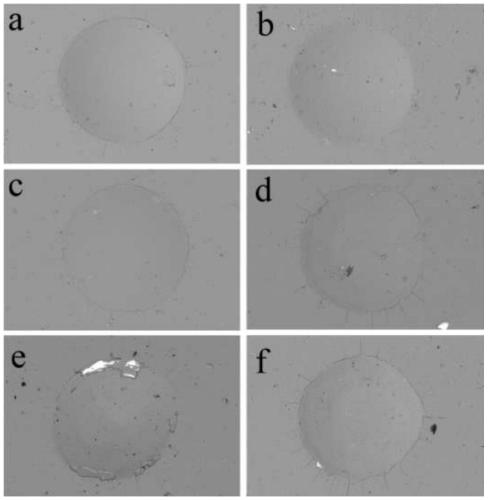

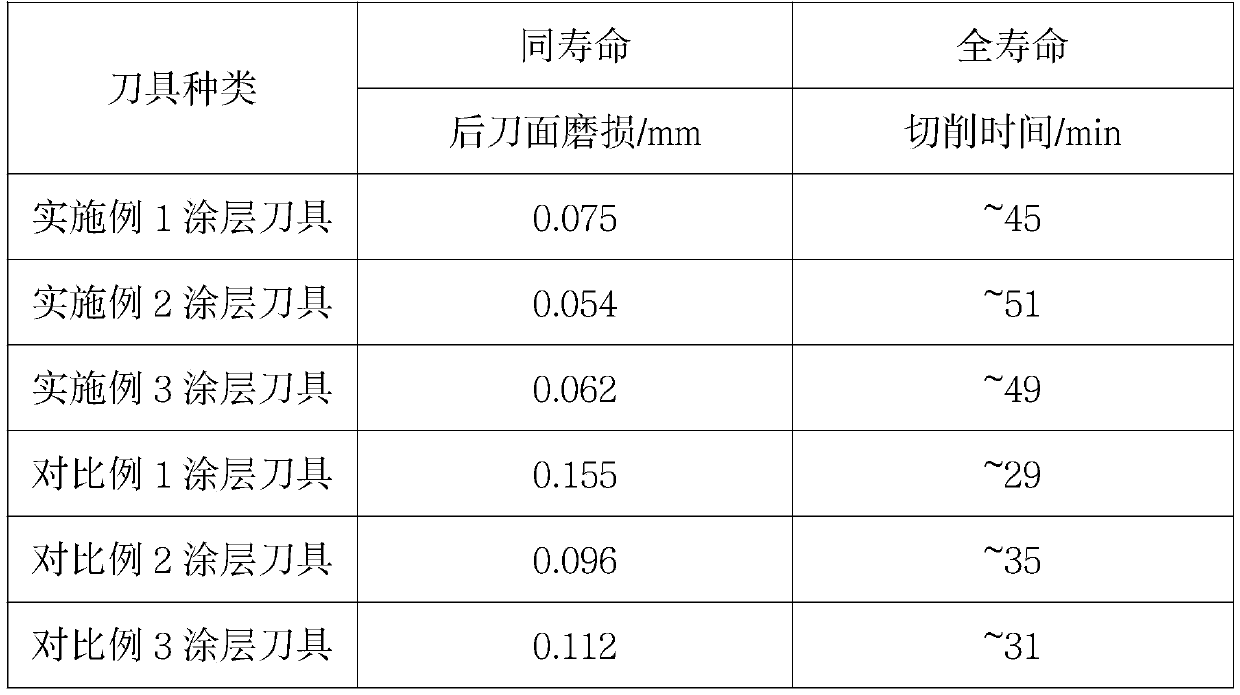

[0041] Deposition of Ti on Tool Substrate by Cathodic Arc Ion Plating Technology 0.3 Al 0.6 (BC) 0.1 N / Ti 0.3 Al 0.6 Si 0.1 N (B:C atomic ratio is 1:1, atomic composition is the theoretical design value) composition structure double-gradient functional coating, each adjacent Ti from the surface of the tool substrate 0.3 Al 0.6 (BC) 0.1 N layer and Ti 0.3 Al 0.6 Si 0.1 The N layer constitutes a period, and the total thickness of each period is m (m value is 0.6 μm), Ti 0.3 Al 0.6 (BC) 0.1 N layer and Ti 0.3 Al 0.6 Si 0.1 The variation of the thickness of the N layer by alkali and incremental deposition is n (the n value is 0.1 μm), and the fluctuation of the n value of each layer is ±10%. In this embodiment, by turning on and off different targets, the deposition time of different targets is controlled, and then the coating thickness of different components is gradually increased and decreased. The specific deposition process is as follows: the working gas N 2 A...

Embodiment 2

[0043] Deposition of Ti on Tool Substrate by Cathodic Arc Ion Plating Technology 0.3 Al 0.6 (BC) 0.1 N / Ti 0.3 Al 0.6 Si 0.1 N (B:C atomic ratio is 8:2, the atomic composition is the theoretical design value) composition structure double-gradient functional coating, starting from the surface of the tool substrate, every adjacent Ti 0.3 Al 0.6 (BC) 0.1 N layer and Ti 0.3 Al 0.6 Si 0.1 The N layer constitutes a period, and the total thickness of each period is m (m value is 0.02μm), Ti 0.3 Al 0.6 (BC) 0.1 N layer and Ti 0.3 Al 0.6 Si 0.1 The variation of the thickness of the N layer by alkali and incremental deposition is n (the n value is 0.005 μm), and the fluctuation of the n value of each layer is ±10%. In this embodiment, the evaporation ionization rate of different targets is controlled by the gradient change of the target source current, and then the coating thickness of different components is gradually increased and decreased. The specific deposition proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com