Method for lubricating air cylinder of automobile air-conditioning compressor

A technology of automotive air conditioners and compressors, applied in the mechanical field, can solve problems such as reduced clutch life, large resistance, and increased starting torque, and achieve the effects of prolonging service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

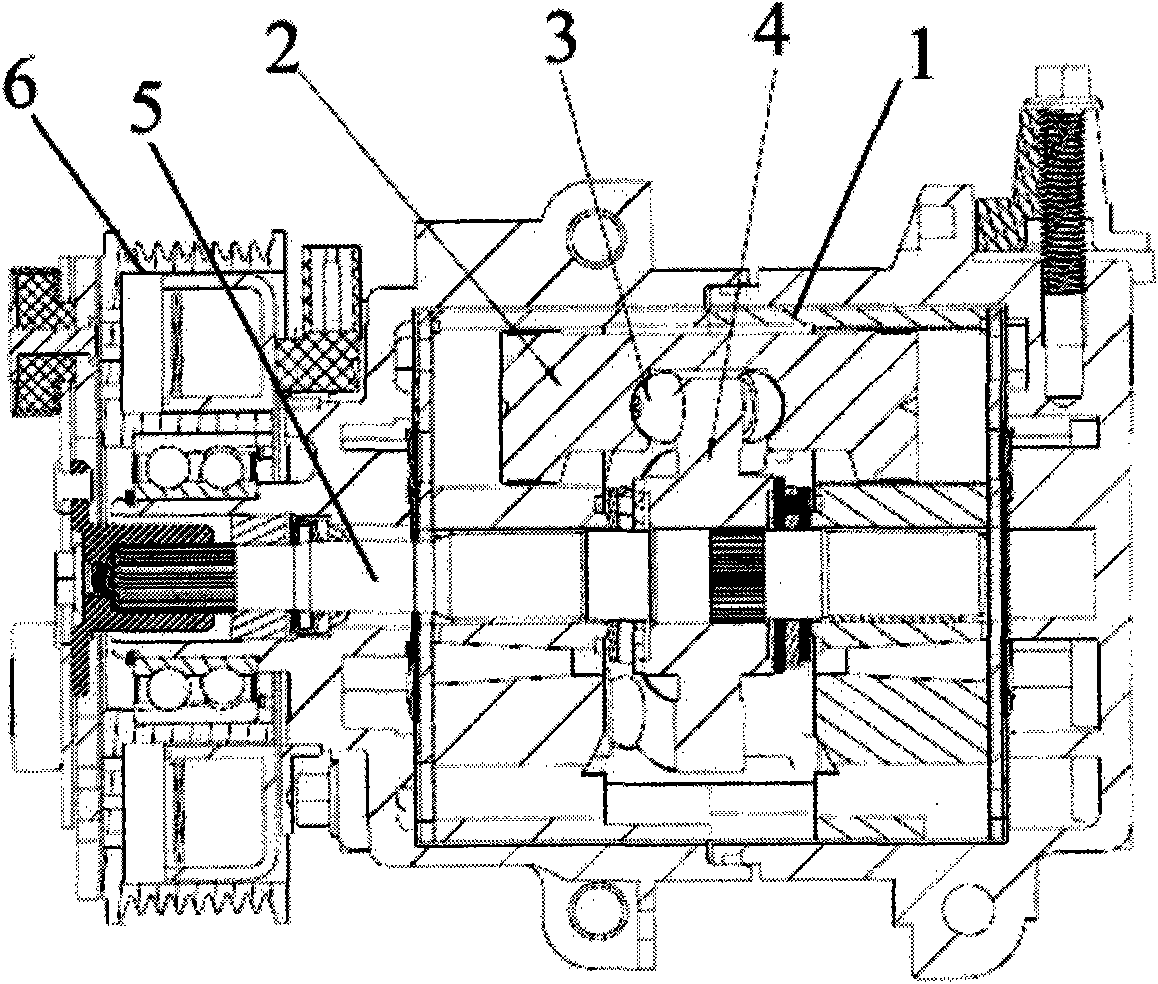

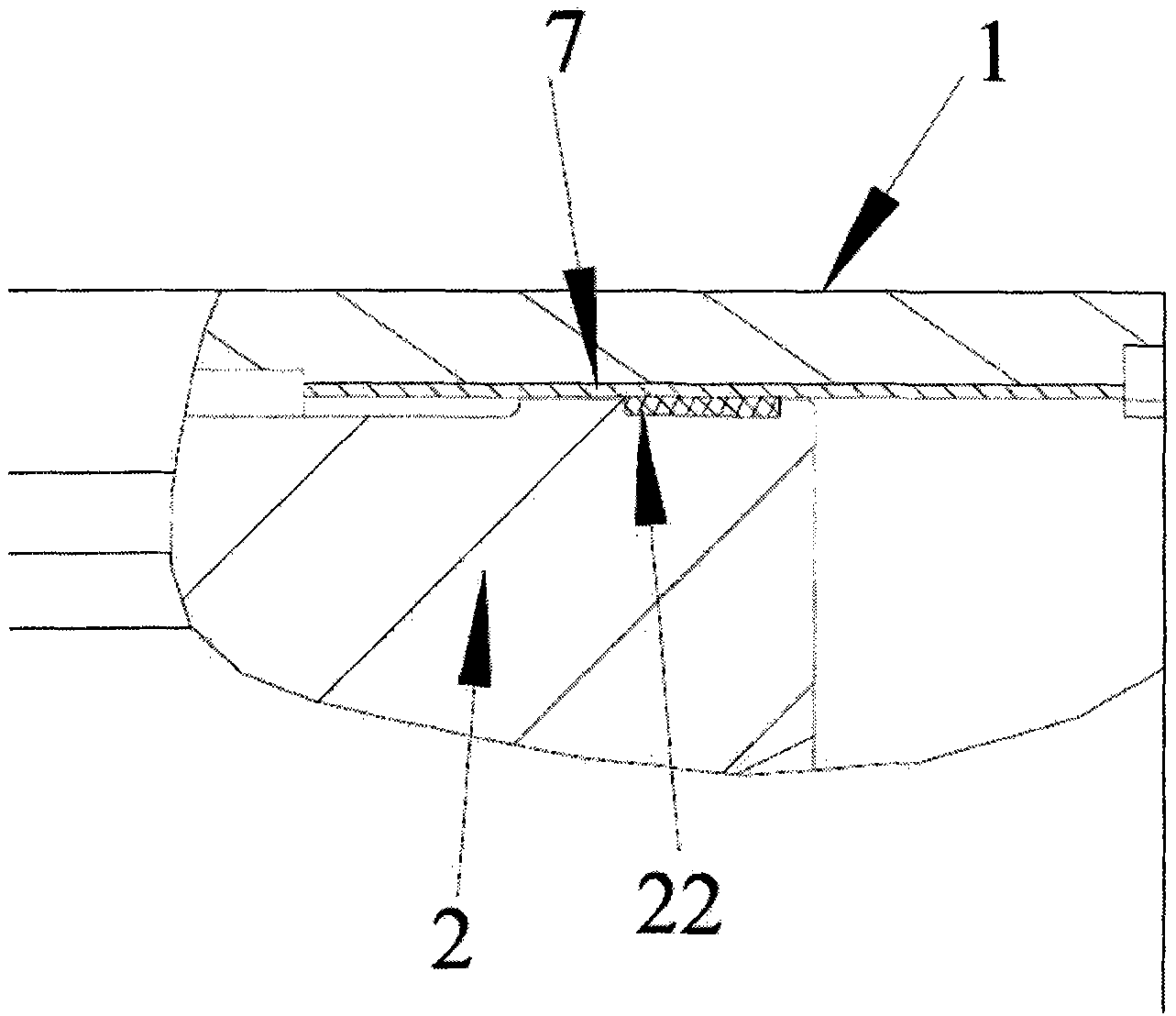

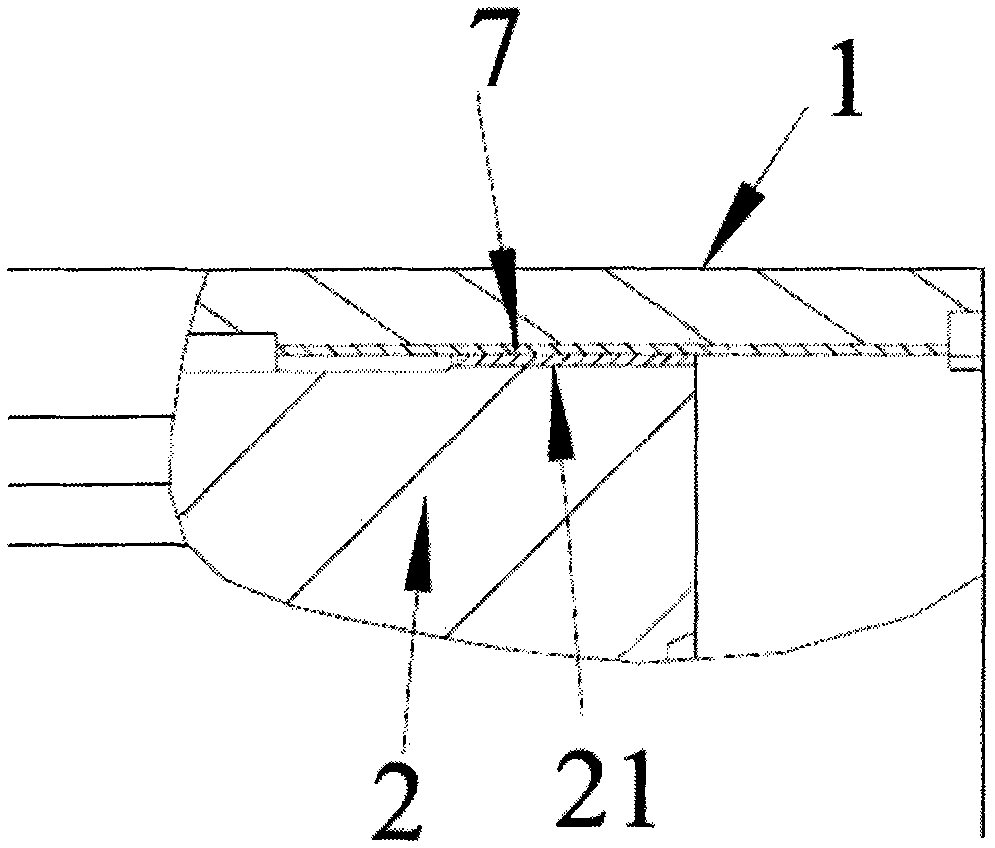

[0013] Such as figure 1 , figure 2 and image 3 As shown, in one embodiment of the lubrication method of the automobile air-conditioning compressor cylinder of the present invention, the automobile air-conditioning compressor cylinder is composed of a cylinder block 1, a sliding shoe 3 and a swash plate 4, and the cylinder block 1 is provided with a piston hole , the piston hole is provided with a piston 2, the piston 2 is connected to the swash plate 4 through the sliding shoe 3, the surface of the piston 2 is provided with a coating 21 or a piston ring 22, wherein, in A tin layer 7 is provided on the inner wall of the piston hole.

[0014] Further, the thickness of the tin layer 7 is 0.5 micron to 10 micron.

[0015] Specifically, the tin layer 7 is formed by chemical immersion plating.

[0016] The method for lubricating the cylinder of the automobile air-conditioning compressor of the present invention includes a step of setting a lubricating layer between the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com