High-wear-resistant blowout-control deviation adjustment polished rod sealer

A polished rod sealer, high wear-resistant technology, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc. The root sealing performance is not ideal, so as to avoid the wear of the polished rod, the performance is reliable, and the sealing performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

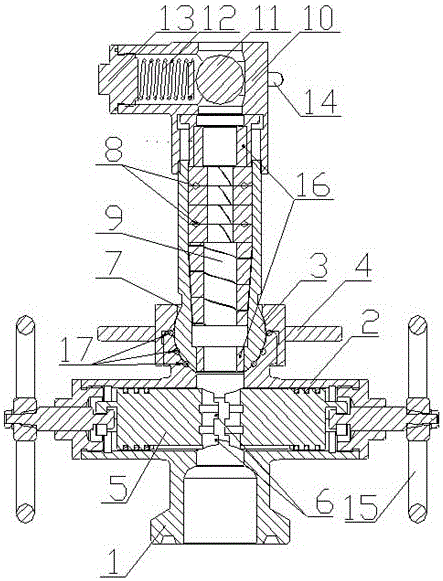

[0025] Attached below figure 1 The highly wear-resistant anti-spray polarizing rod sealer of the present invention will be described in detail below.

[0026] as attached figure 1 As shown, the high wear-resistant anti-blowout adjustable polarizing rod sealer of the present invention has a structure comprising a base 1 connected to the wellhead, a translation base 2, and a universal sphere 3, and the bottom of the universal sphere 3 is arranged in the translation base 2 and used A locking handle 4 is locked, a spherical seal 17 is provided between the universal sphere 3 and the translation base 2, and a vent-free assembly is provided between the translation base 2 and the base 1. The vent-free assembly includes two oppositely arranged lateral translation Type piston 5, the two transverse translation pistons 5 are respectively provided with sealing bodies and cooperate to form a cross-displacement sealing body 6, and the translation position of the lateral translation piston 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com