Patents

Literature

49results about How to "Large amount of wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

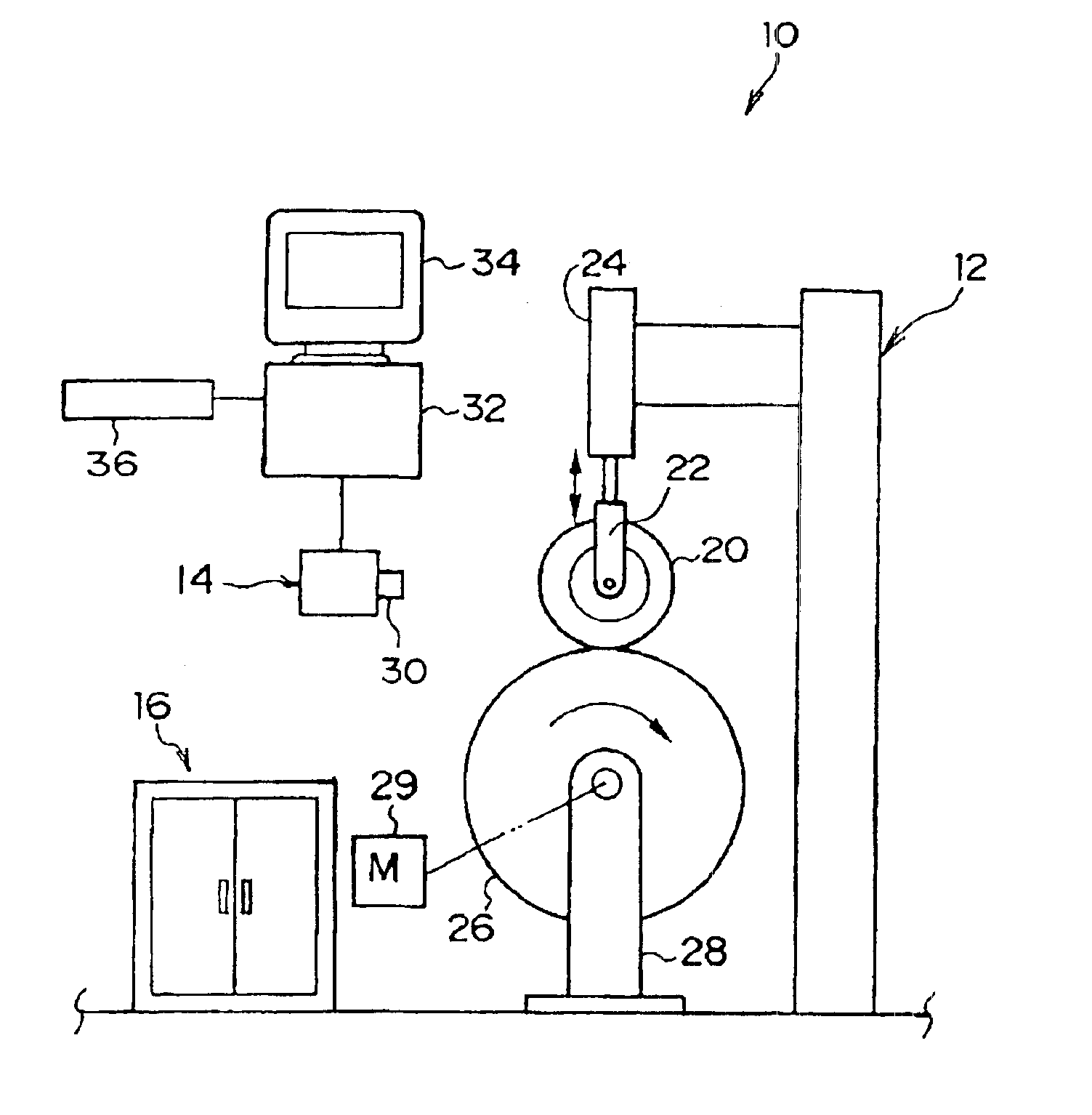

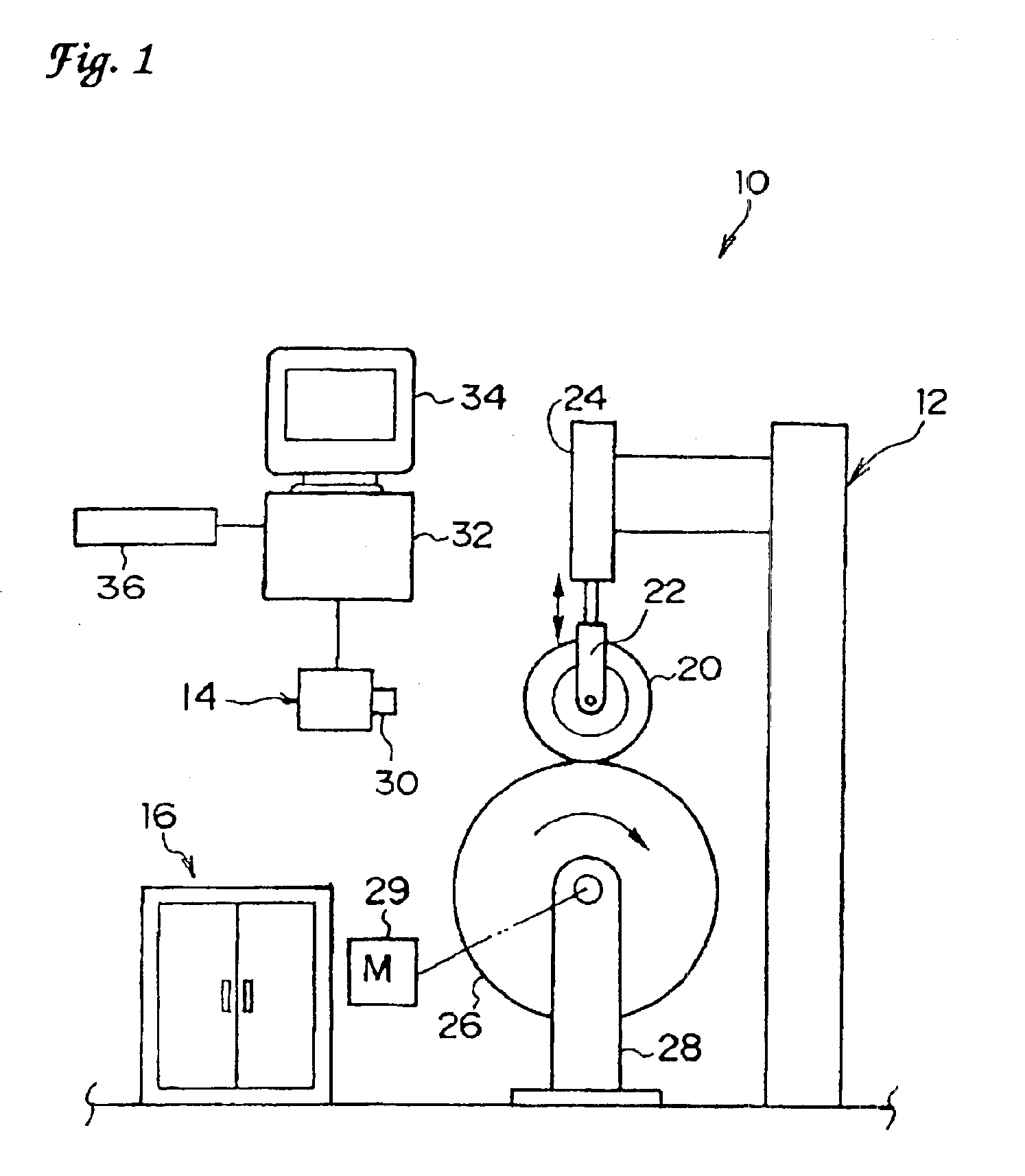

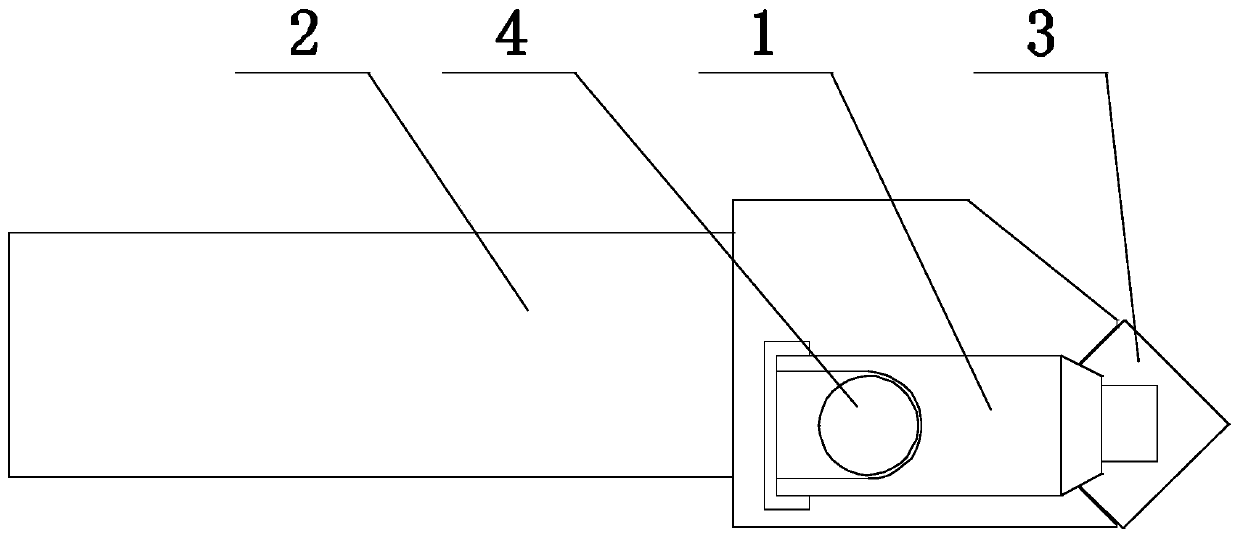

Tire wear forecasting method and apparatus

InactiveUS6883962B2Perform with easeEasily forecast tire wearThermometer detailsWeather/light/corrosion resistanceEngineeringPrediction methods

The temperature of the tread surface part of a tire is increased by running the tire in contact with a drum. The increase in the temperature of the tread surface part is due to the heat of friction between the tread surface part and the drum. Because large increases in temperature indicate that the friction is causing a large amount of wear, it is possible to forecast with ease the amount of wear of the tire from the increase in temperature of the tread surface part. The temperature of the tread surface part can be measured using a thermography machine, and the wear in the tread can be determined by looking at an image that shows the temperature.

Owner:BRIDGESTONE CORP

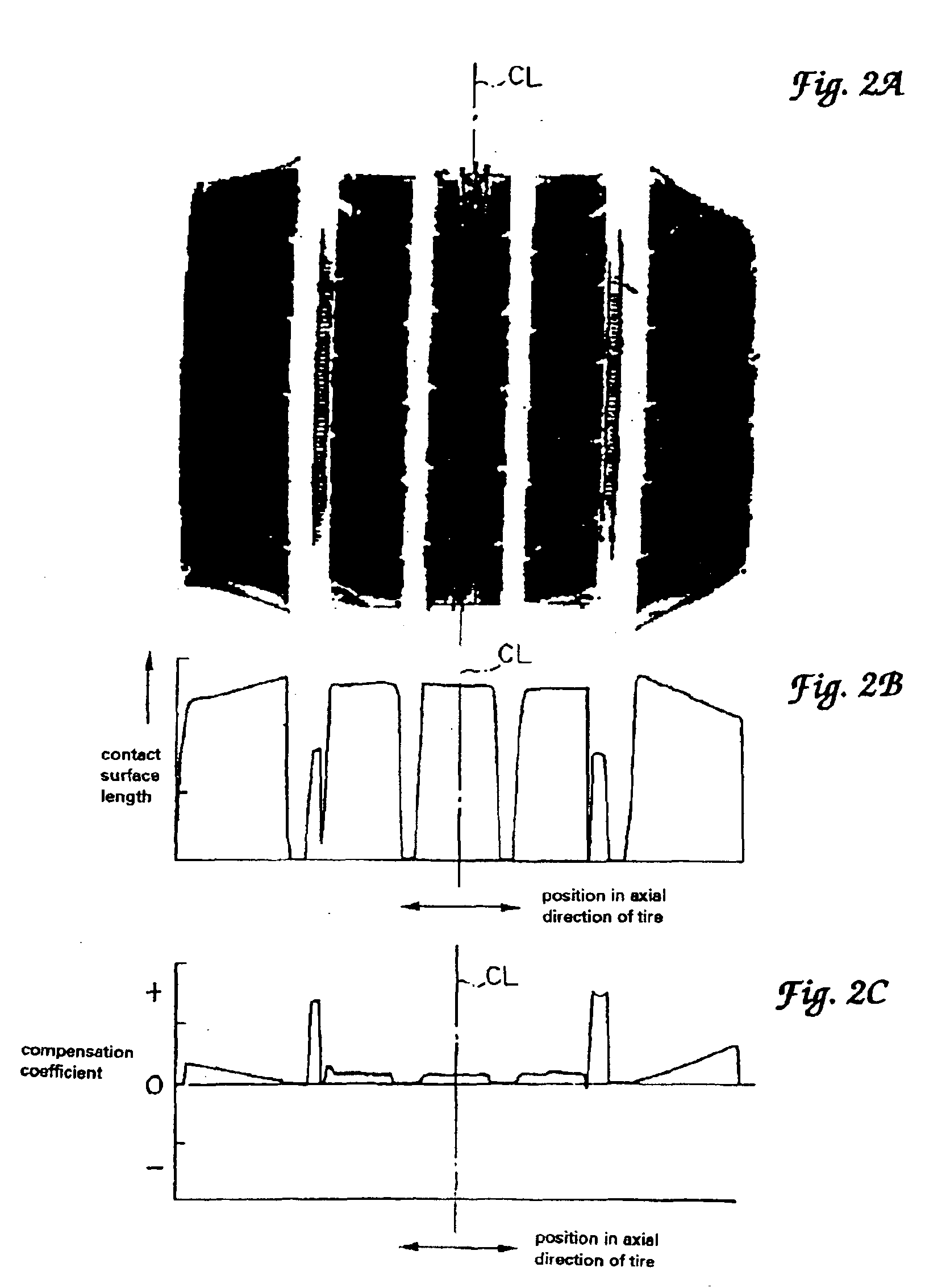

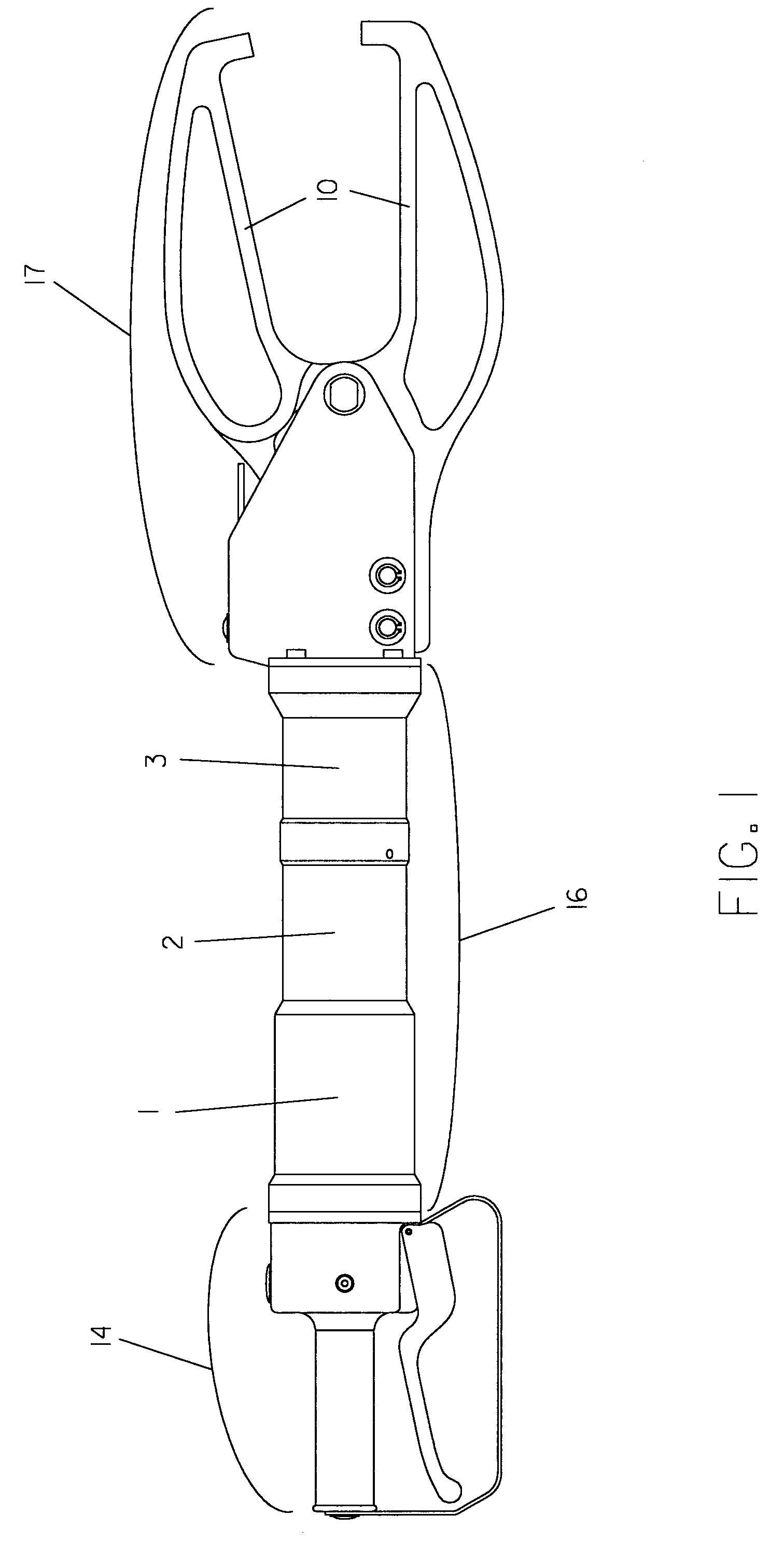

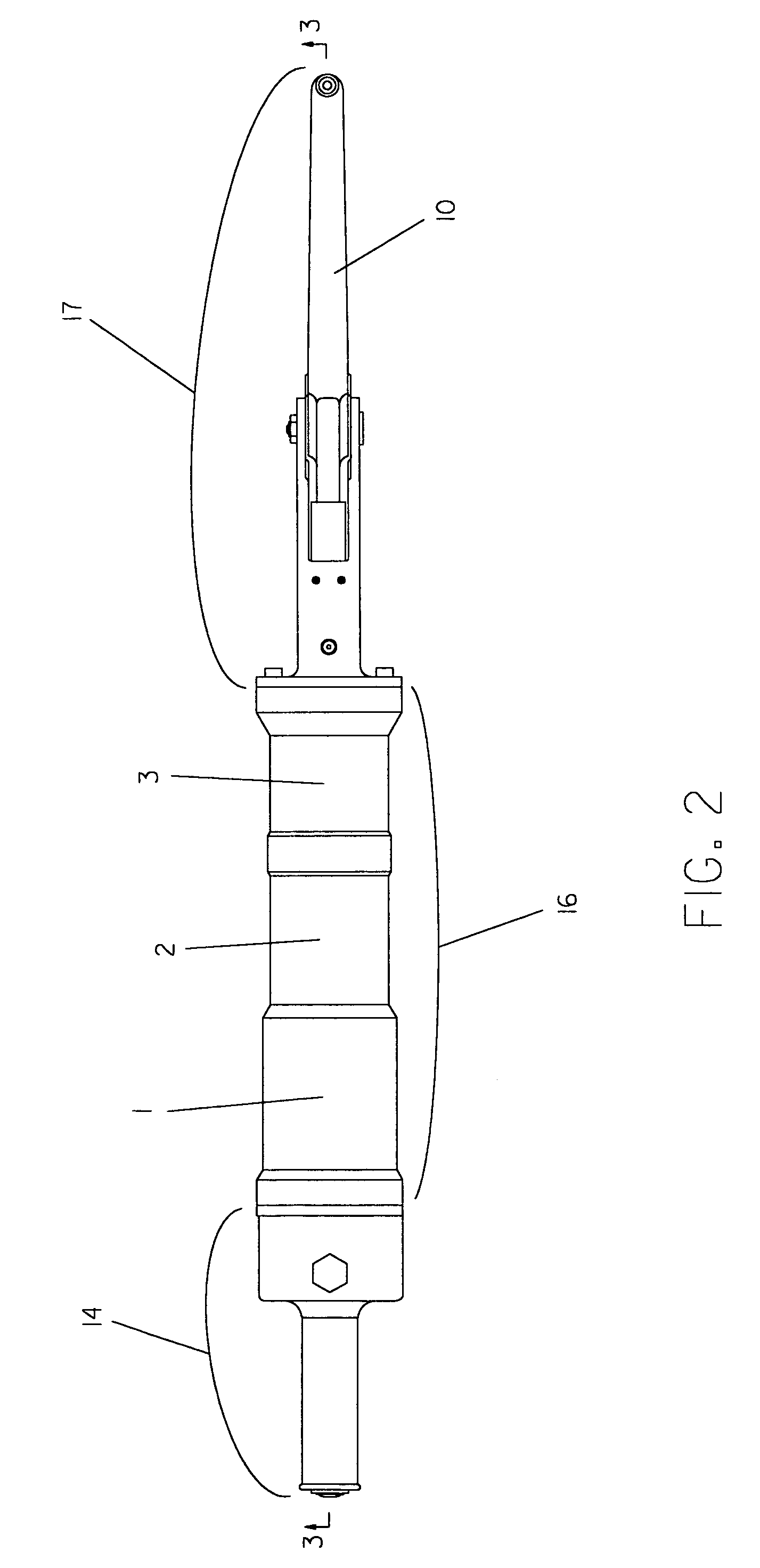

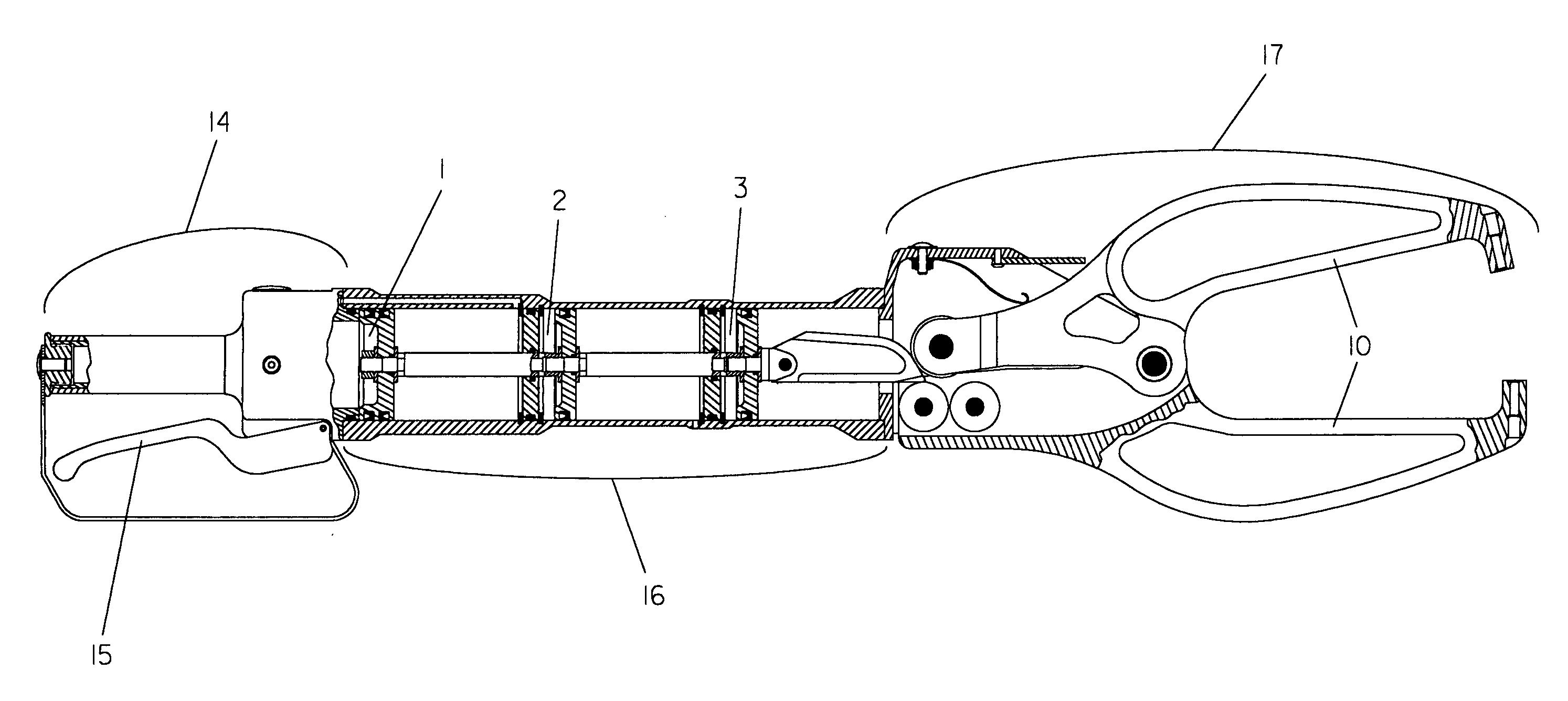

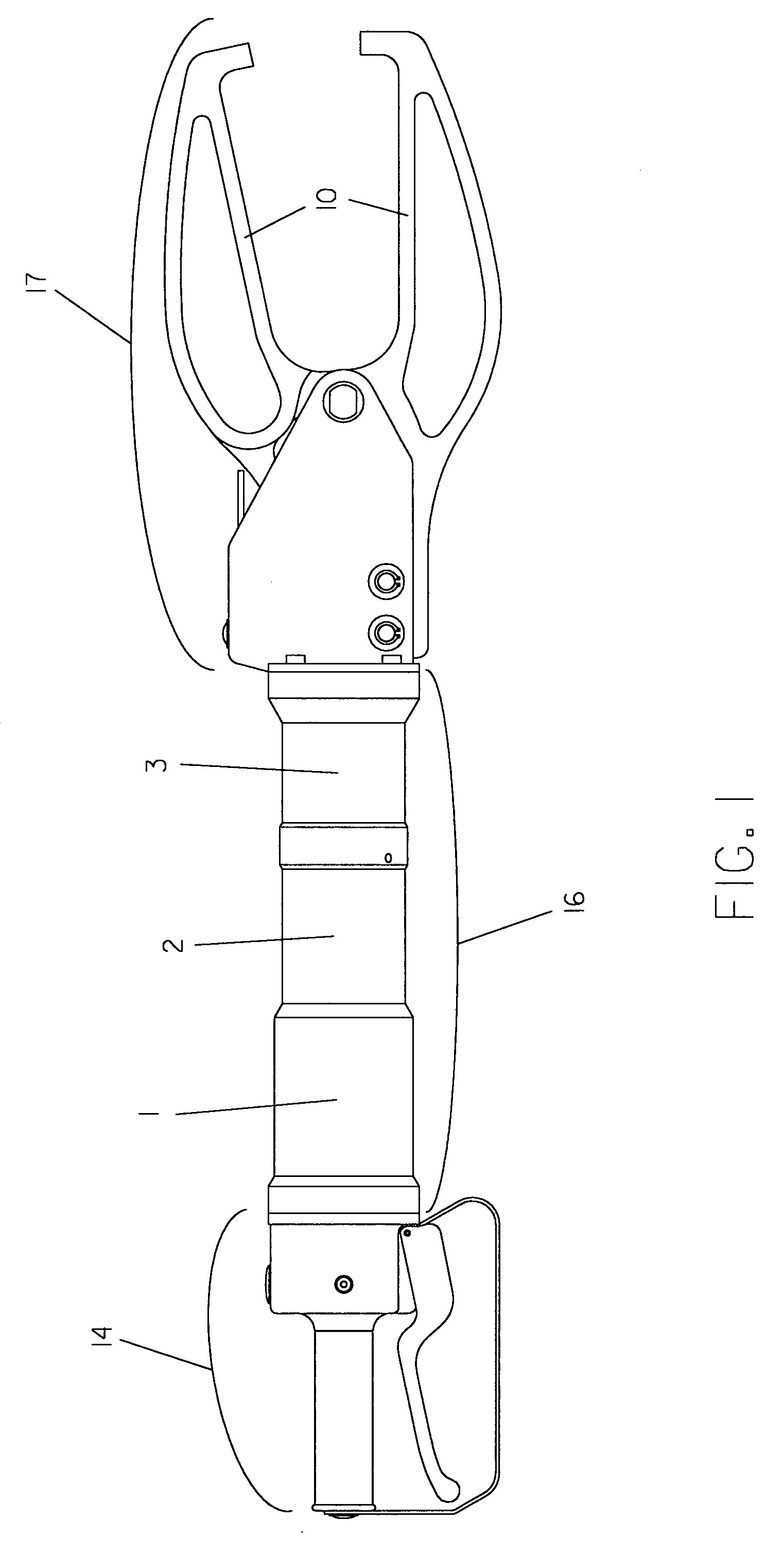

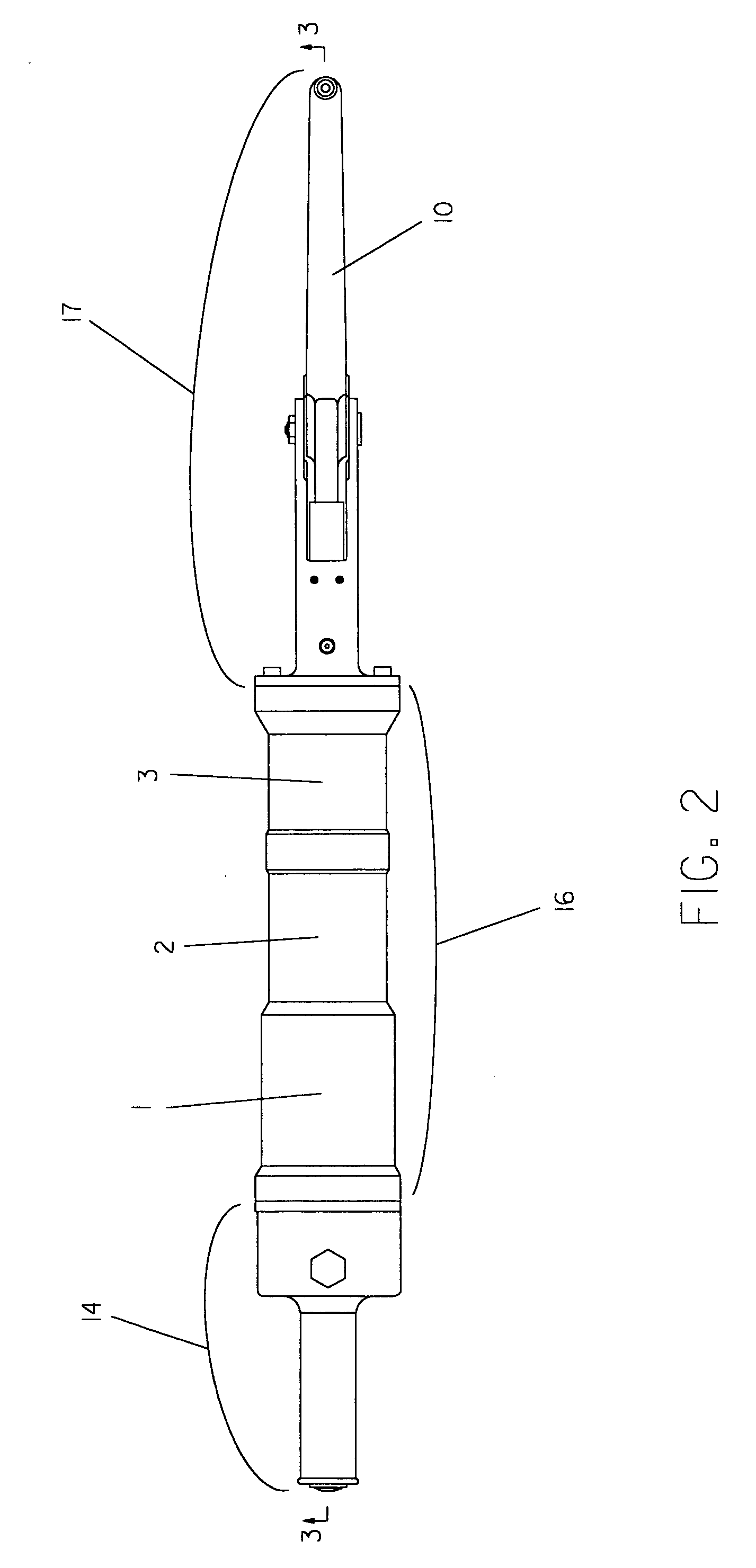

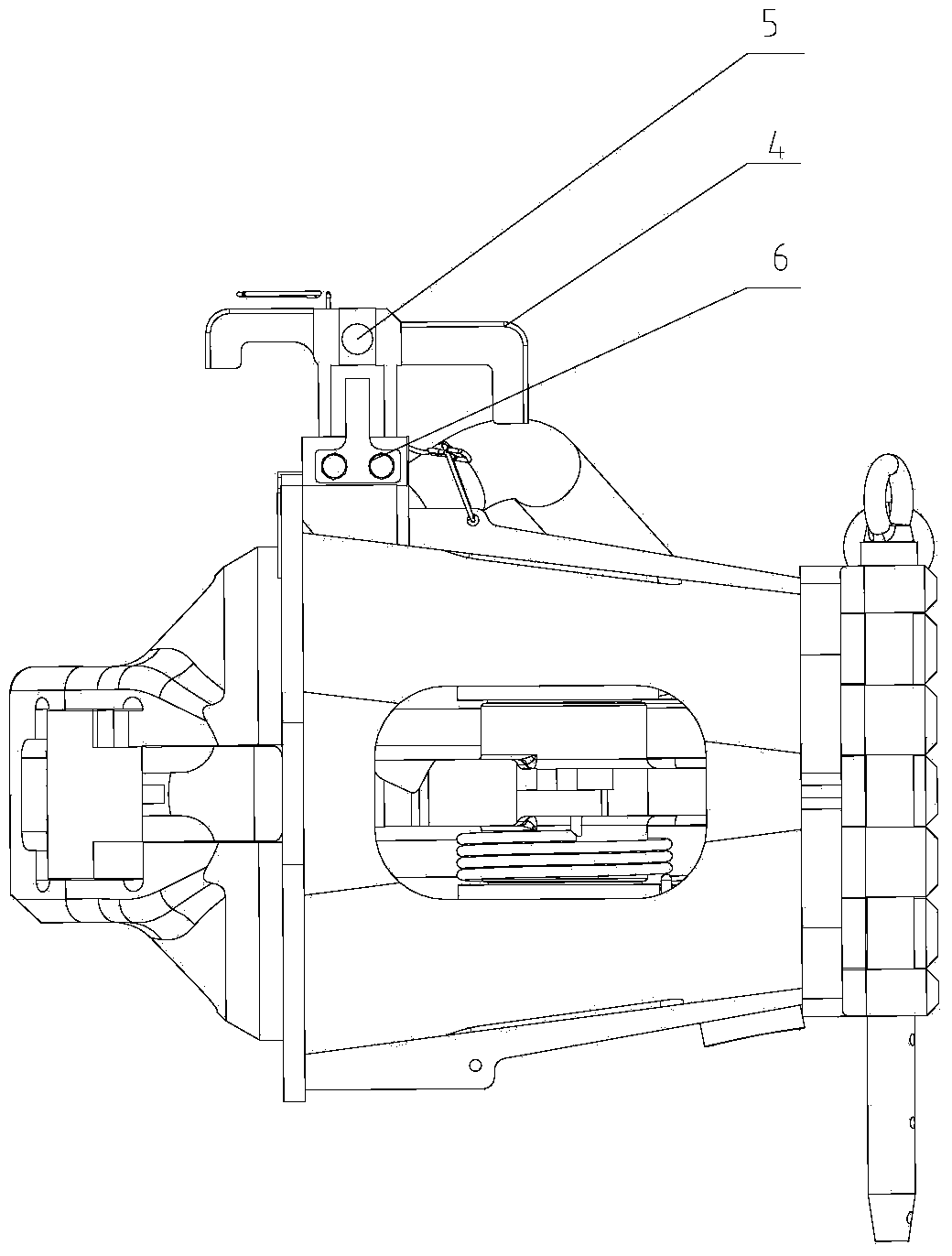

Portable pneumatic compression riveter

A portable pneumatic compression riveter consists of a valve, air cylinder and rivet head assembly consisting of an alligator style set of jaws or a c-yoke style jaw set that is used to upset solid rivets used primarily, but not limited to, the aerospace industry. Disclosed is a series of improvements that make the tool lighter, more reliable and safer to operate.

Owner:HEROD JAMES R

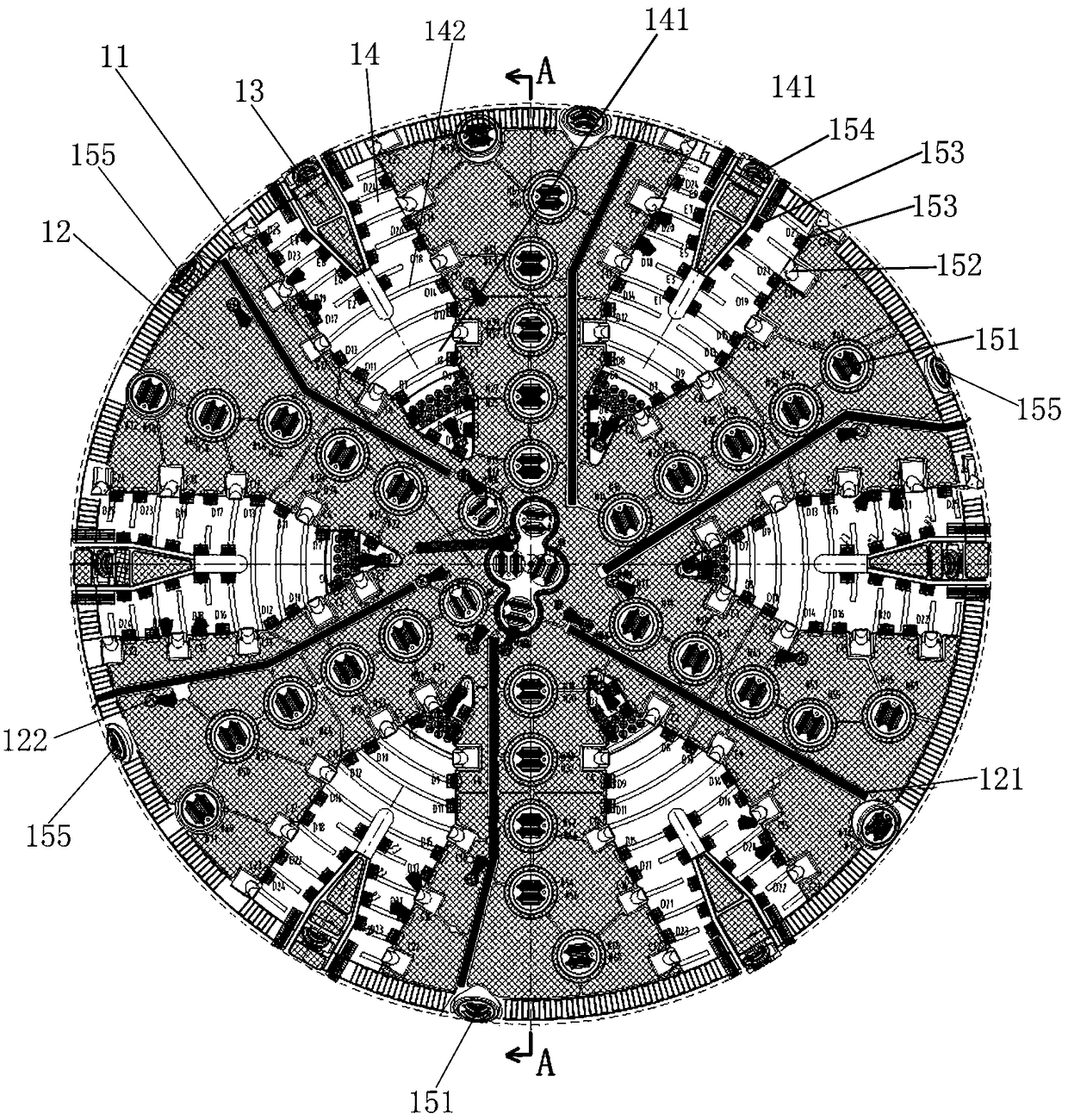

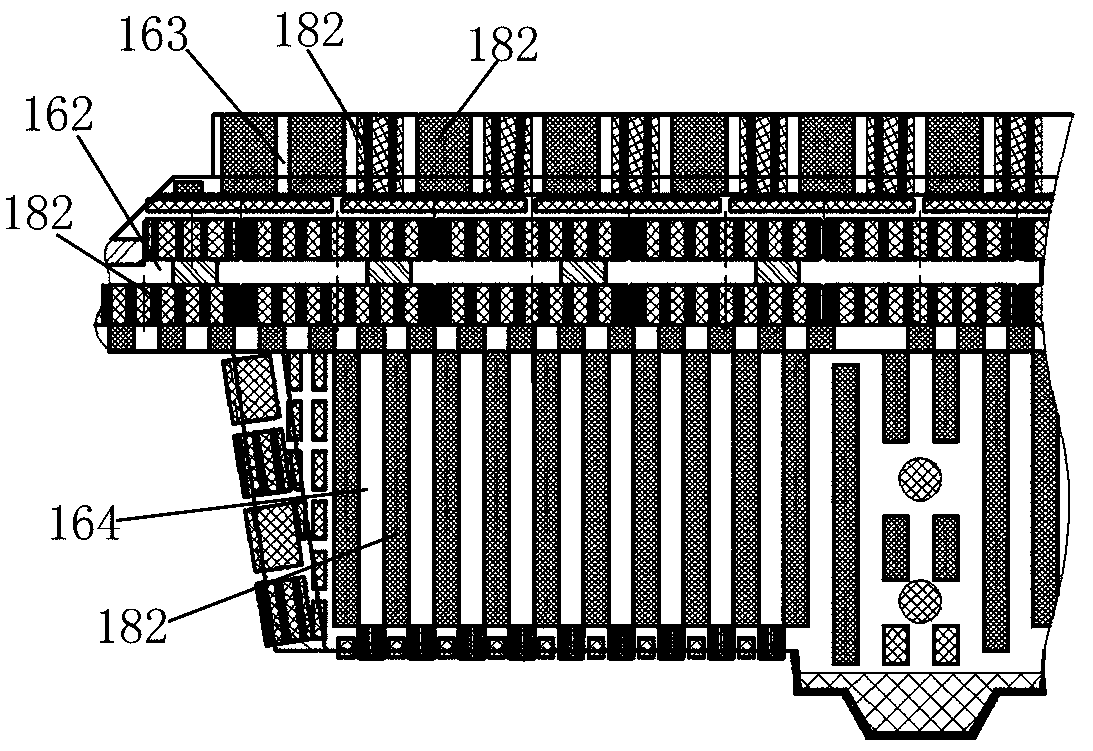

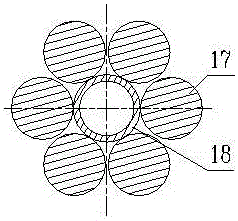

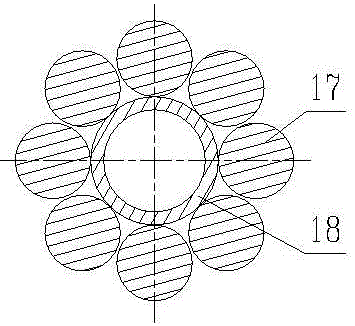

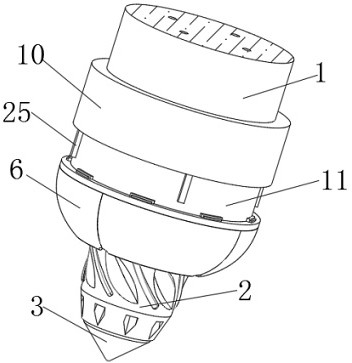

Configuration method for super-large-diameter cutter head and cutter

PendingCN109236311AReduce chance of being trappedImprove wear resistanceTunnelsEngineeringHigh pressure

The invention discloses a configuration method for super-large-diameter cutter head and cutter thereof, which solve the technical problems of inconvenience to transfer the super-large-diameter shieldcutter head and change the cutter in the prior art. The super-large diameter cutter head comprises a central block and a plurality of cutter head edge blocks arranged on the periphery of the central block, wherein the central block and the cutter head edge blocks are assembled into the cutter head, the central block and a main cutter head edge block are hollow box bodies, a cutter head opening isformed between the adjacent main cutter head edge block and an auxiliary cutter head edge block, the opening of the cutter head is connected with a muddy water bin behind the cutter head, and a plurality of normal pressure replaceable cutters are arranged on the front panels of the central block and the main cutter head edge block. The super-large-diameter cutter head is characterized in that theproblem of inconvenience to transport the super-large-diameter shield cutter head is effectively solved, and the center block and the inner part of the main cutter head edge block are separated from the front palm surface of the cutter head and the rear muddy water bin, the front palm surface of the cutter head and the rear muddy water bin are in a high-pressure environment, while the center blockand the main cutter head edge block are in a normal pressure environment, accordingly the cutter is convenient to be replaced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

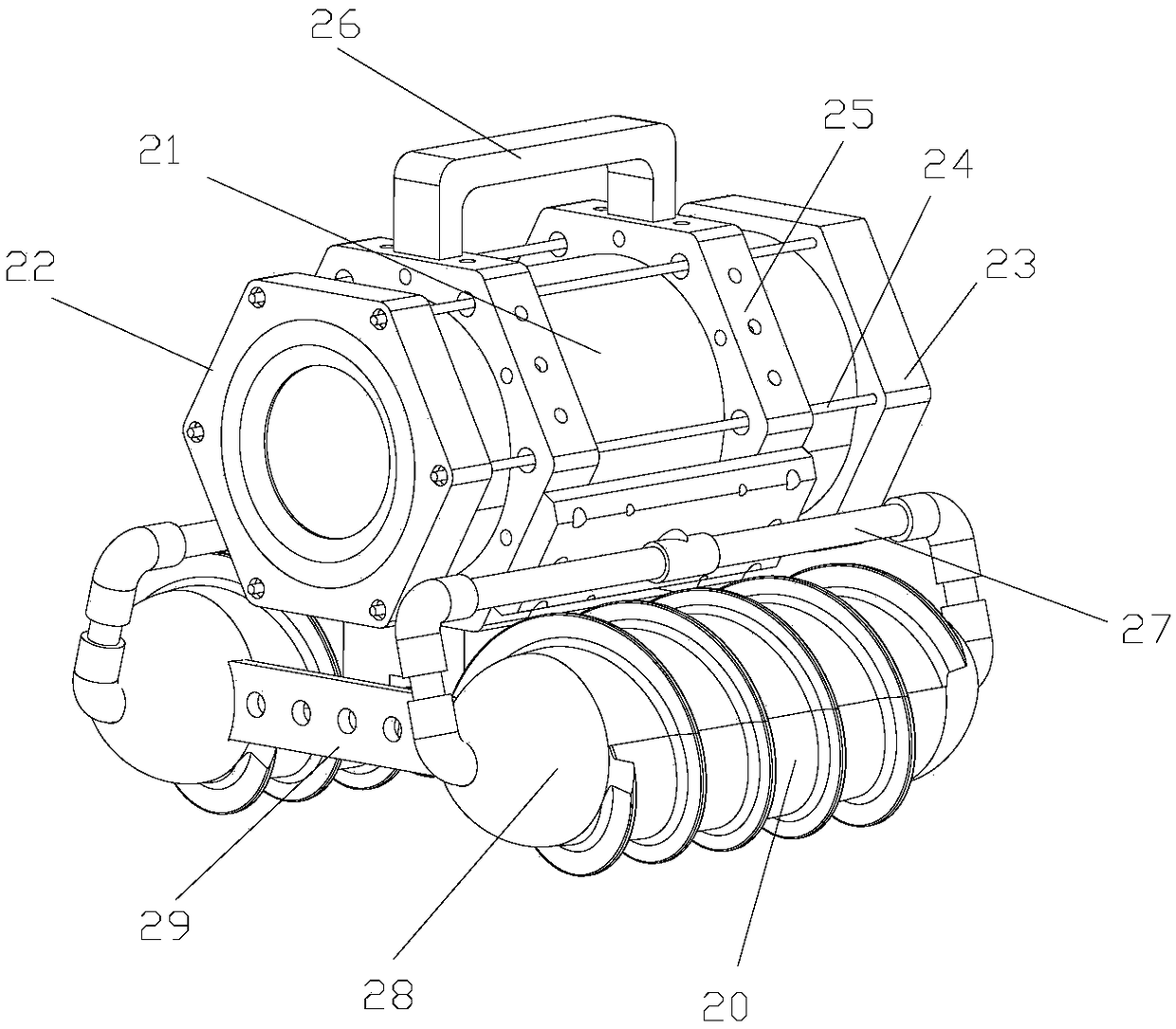

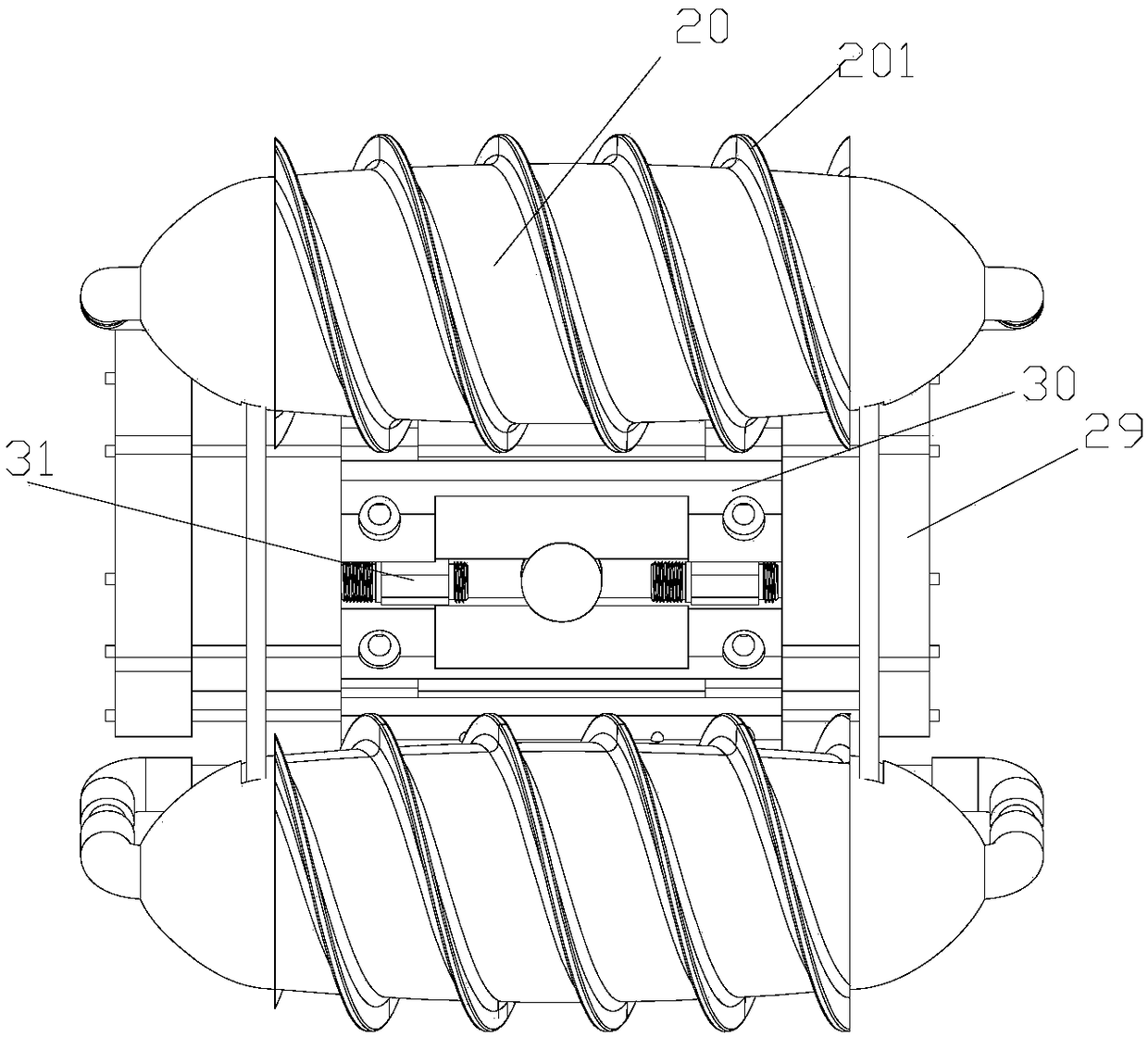

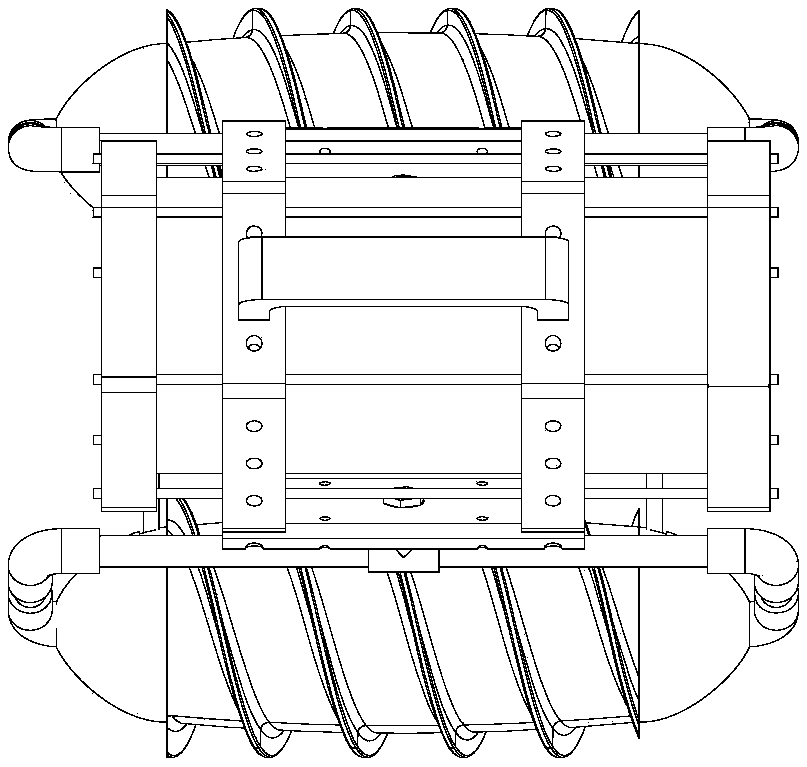

Pipeline robot

The invention discloses a pipeline robot. The pipeline robot comprises a support, at least two driving rollers and a controller fixedly arranged on the support; each driving roller comprises a drivingbody and a shell which wraps around the driving body; the shells are of cylindrical shapes, and spiral blades are fixedly arranged on the outer peripheral surfaces of the shells along the length direction of the shells; each driving body comprises an outer cylinder and an inner cylinder arranged inside the outer cylinder, motors are fixedly arranged inside the inner cylinders, the output shafts of the motors are sleeved with first rotating pieces, and the outer peripheral surfaces of the first rotating pieces are fixedly connected with the inner walls of the outer cylinders in a sealing mode;the other ends of the inner cylinders are provided with second connecting pieces, and the inner cylinders and the outer cylinders are rotationally connected together through the second connecting pieces, and the second connecting pieces are hermetically connected with the inner cylinders and the outer cylinders correspondingly; and the shells sleeve the outer cylinders, and the motor is electrically connected with the controller. The pipeline robot has the beneficial effects that the motor is fixedly arranged inside the inner cylinders in a sealing mode, so that the waterproof performance isgood; the inner cylinders and the outer cylinders are enabled to be connected rotationally through the first connecting piece and the second connecting piece; and the cost is greatly reduced through the shells with the spiral blades which sleeves the outer cylinders.

Owner:南京管科智能科技有限公司

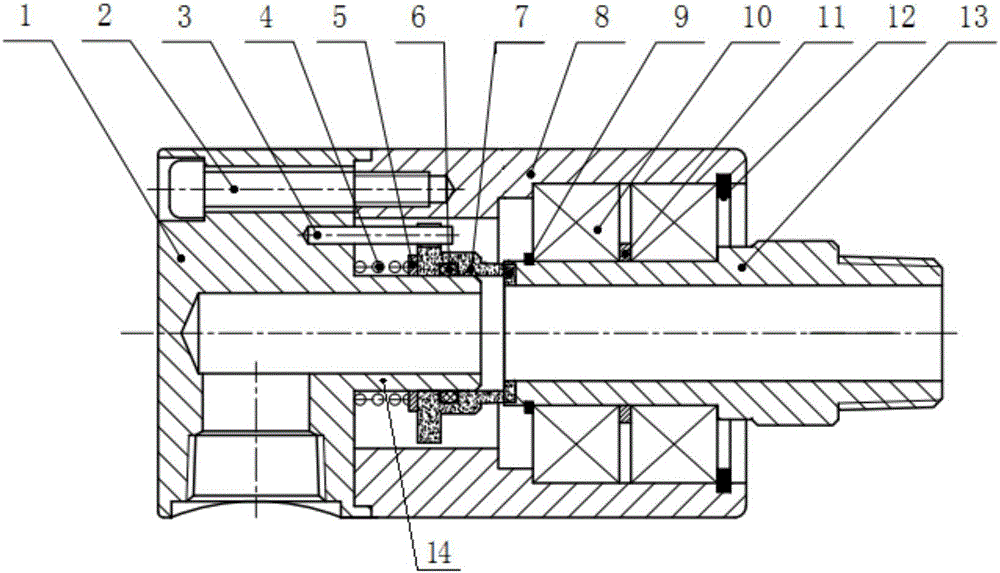

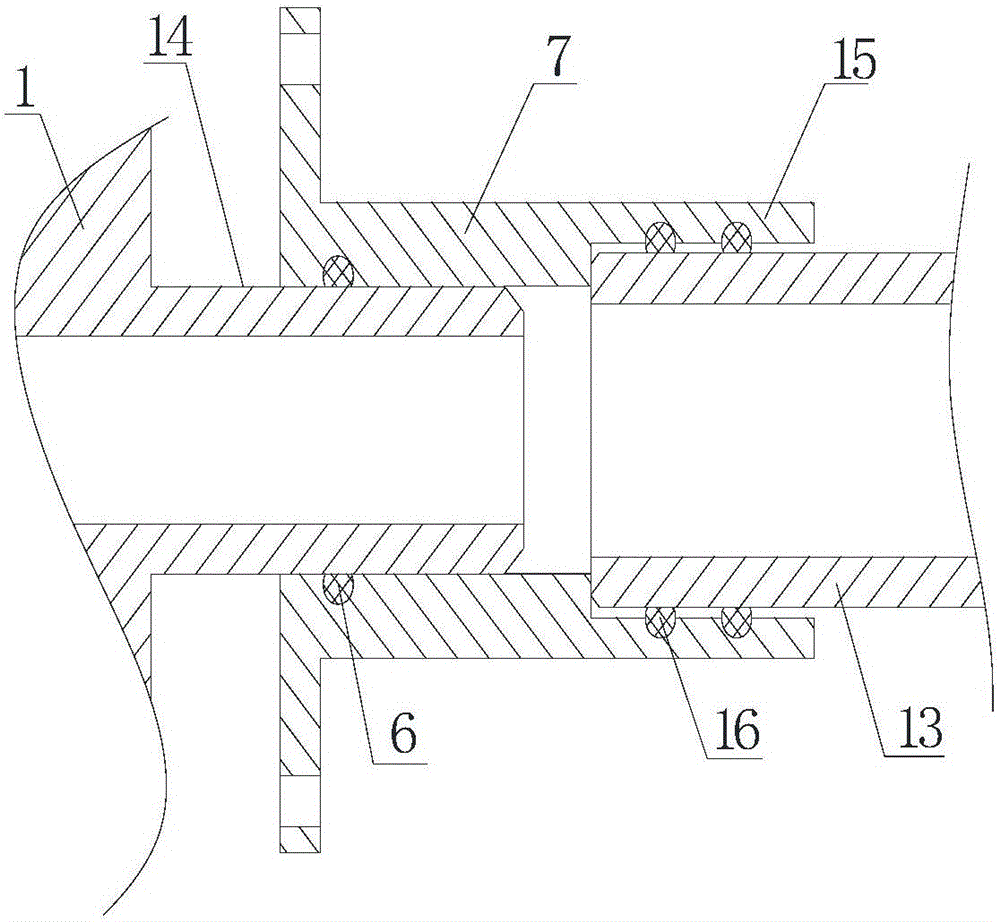

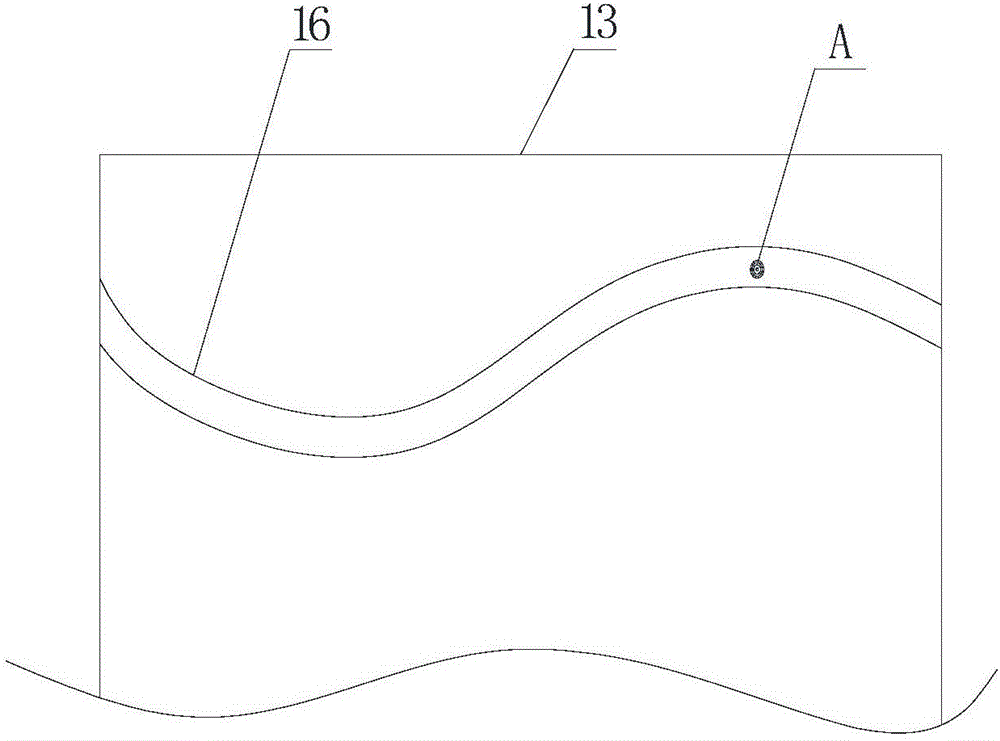

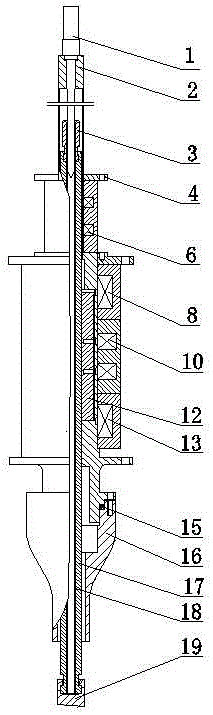

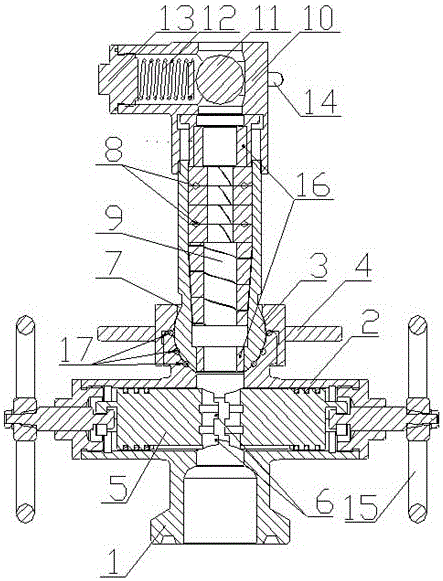

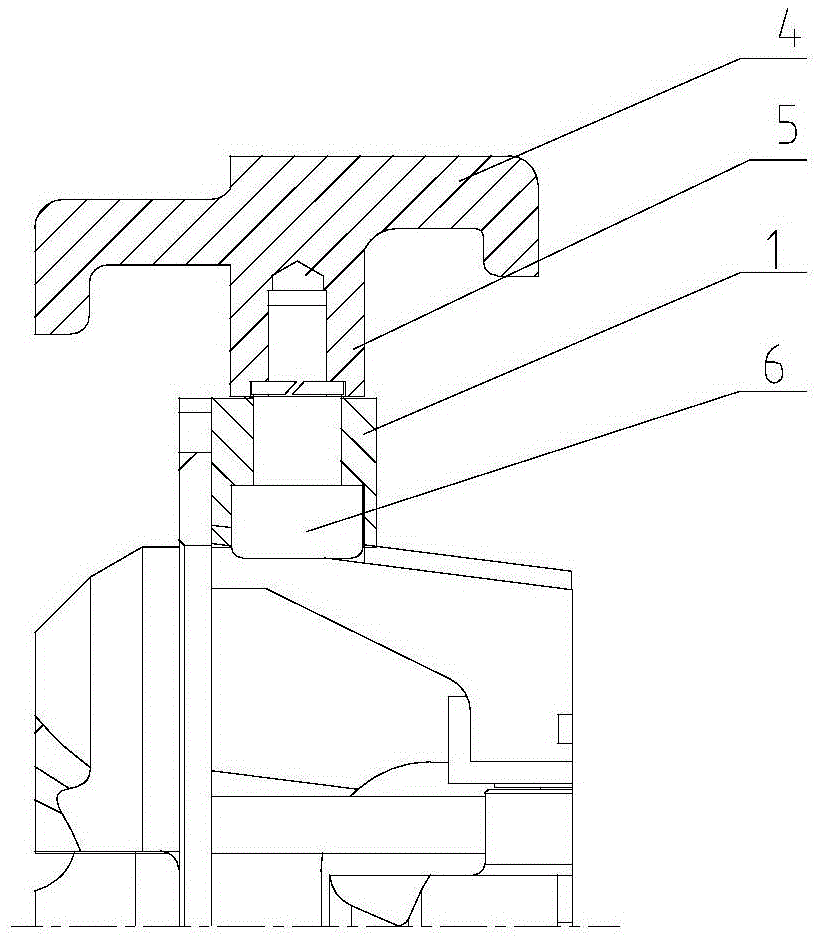

Dry friction rotary seal device for numerical control punching machine

ActiveCN106594286AImprove sealingAvoid corrosionEngine sealsBearing unit rigid supportNumerical controlPunching

The invention provides a dry friction rotary seal device for a numerical control punching machine. The seal device comprises a rear cover boss, a main seal ring and a compensating spring. The rear cover boss is of a shaft structure. A gap is arranged between the head end of the rear cover boss and the corresponding end face of a hollow rotary shaft. A cavity extending in the axial direction of the rear cover boss is formed in the rear cover boss. The rear cover boss is sleeved with the main seal ring. Seal is formed between the end face of the head end of the main sealing ring and the end face of the hollow rotary shaft. The rear cover boss is sleeved with the compensating spring in a compressed state and used for making the main seal ring always in the trend of moving towards the hollow rotary shaft. The dry friction rotary seal device solves the technical problem of the seal failure caused by wear on the basis of lowering the noise.

Owner:朱斌

Portable pneumatic compression riveter

ActiveUS20060243020A1Improve ergonomicsReduce weightForging press detailsForging press drivesAviationEngineering

A portable pneumatic compression riveter consists of a valve, air cylinder and rivet head assembly consisting of an alligator style set of jaws or a c-yoke style jaw set that is used to upset solid rivets used primarily, but not limited to, the aerospace industry. Disclosed is a series of improvements that make the tool lighter, more reliable and safer to operate.

Owner:HEROD JAMES R

Paper pouring gate pipe component for casting cast steel

InactiveCN106747522AReduce carbon contentImprove waterproof and moisture-proof performanceFoundry mouldsFoundry coresFiberMullite

The invention discloses a paper pouring gate pipe component for casting cast steel. The paper pouring gate pipe component is prepared from the following raw material in weight percentage: 1 to 70% of inorganic sintered powder material, 1 to 40% of organic fiber, 1 to 20% of inorganic fiber, 1 to 25% of thermocuring material, 1 to 10% of binding agent, 1 to 5% of waterproof and dampproof agent, 1 to 5% of enhancer and filter aid, 1 to 5% of fluxing agent and 0 to 5% of flame retardant, wherein the inorganic sintered powder material is combination of any several kinds of mullite, high-aluminum clay, attapulgite, montmorillonite, bentonite, high-aluminum powder, quartz, volcanic rock and graphite. The paper pouring gate pipe component has no effects of recarburization, decarbonization, carburization and the like on iron, so that chemical ingredients and material performance of cast steel raw materials are prevented from being changed. The paper pouring gate pipe component has the advantages of light weight, easiness to operate, small waste after cast pouring, labor saving, time saving, energy conservation, environmental friendliness, no environmental pollution, environmental protection and the like; in addition, the waste is easy to treat.

Owner:BAOJI HUAGUANG CASTING MATERIAL TECH

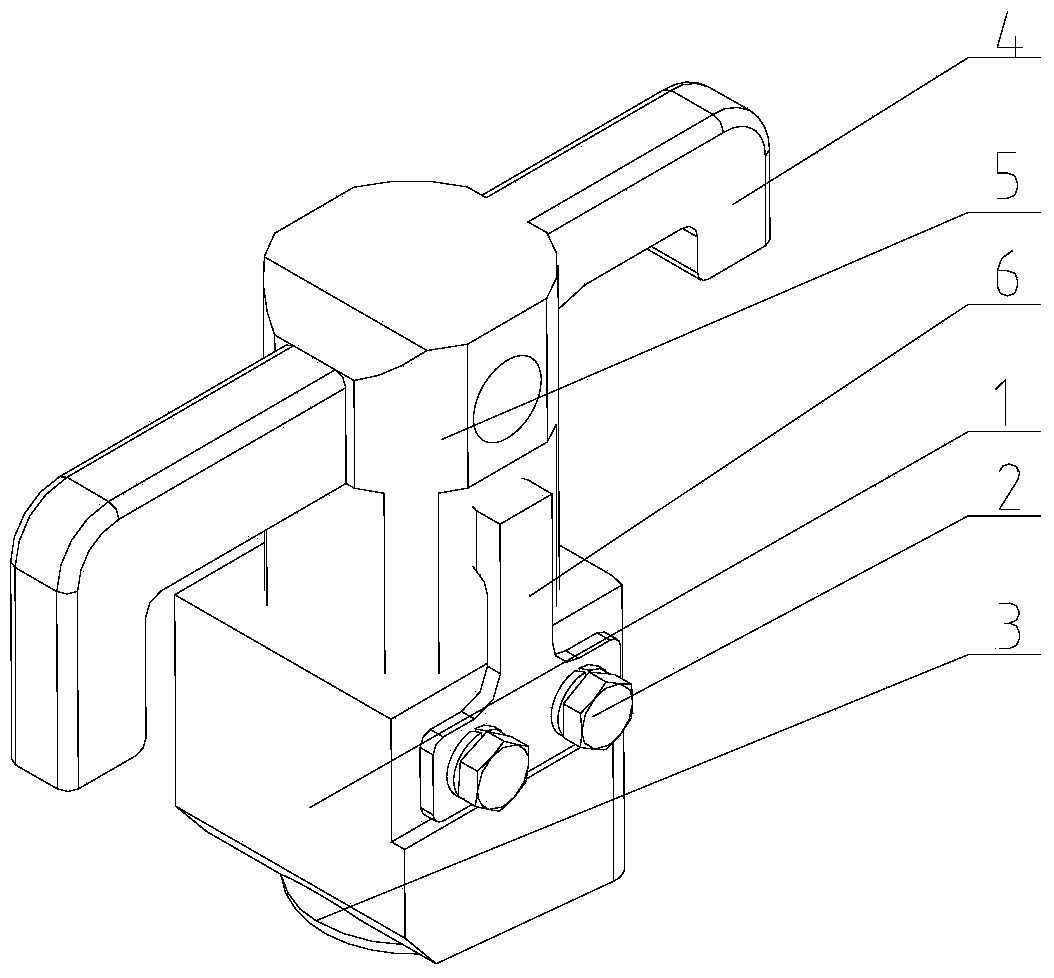

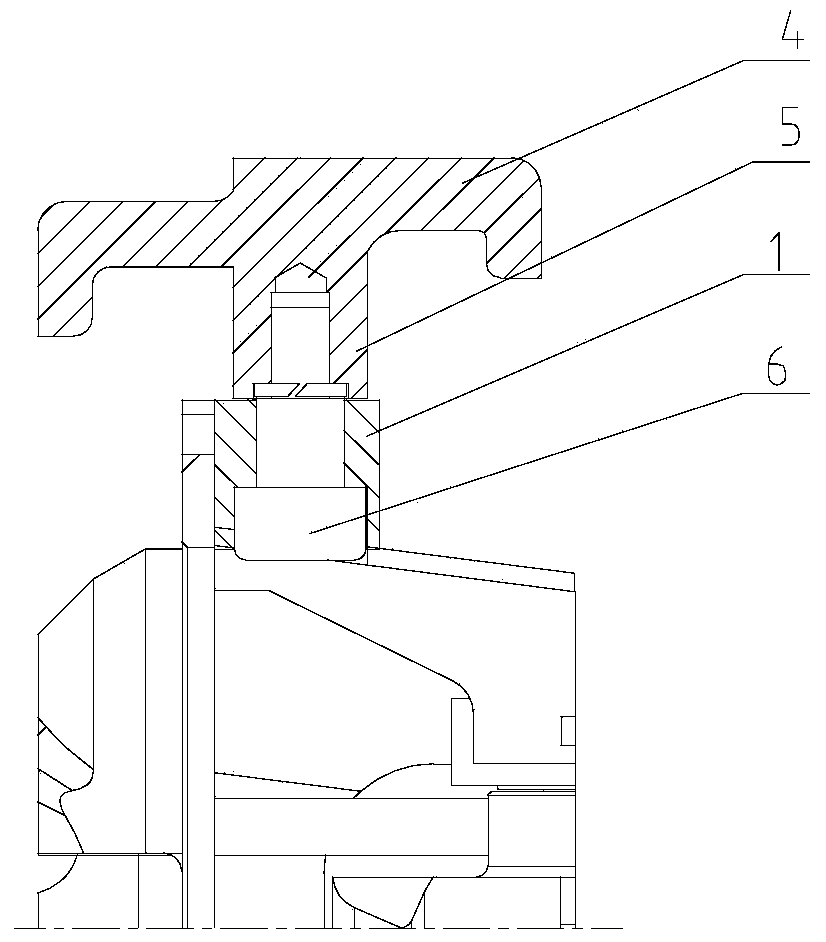

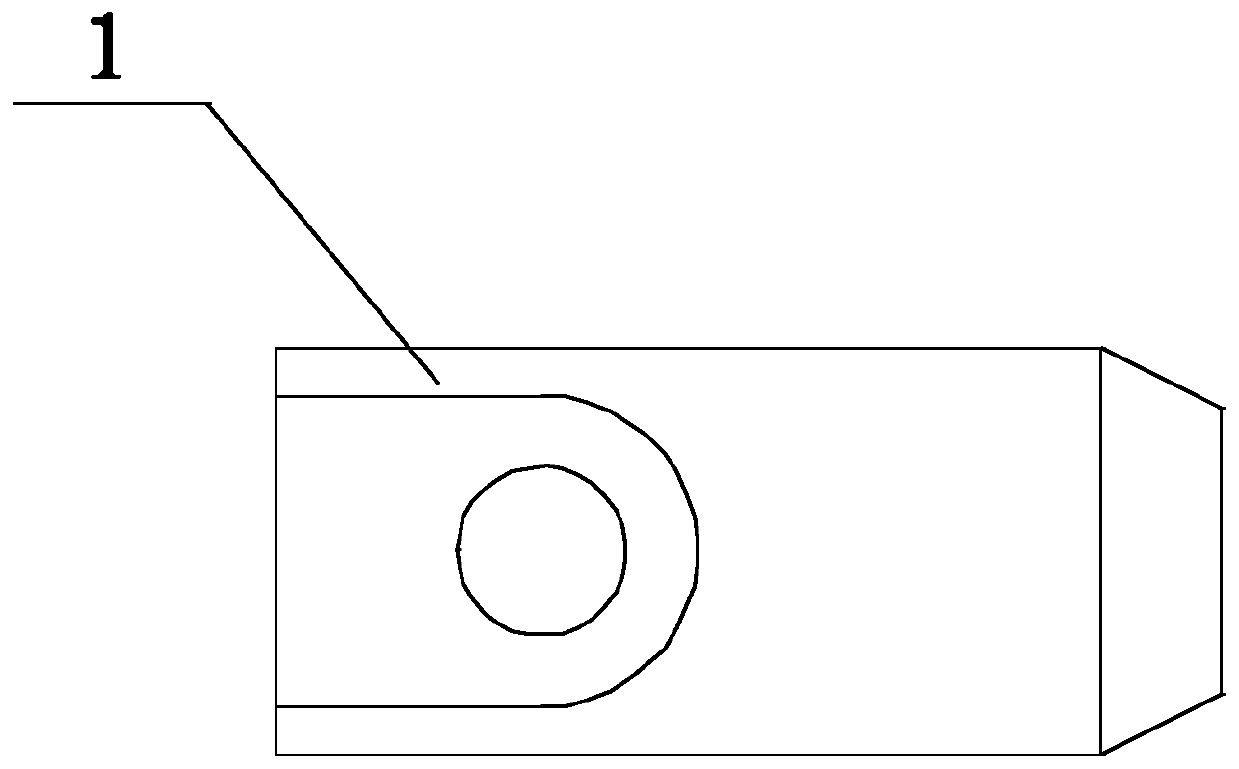

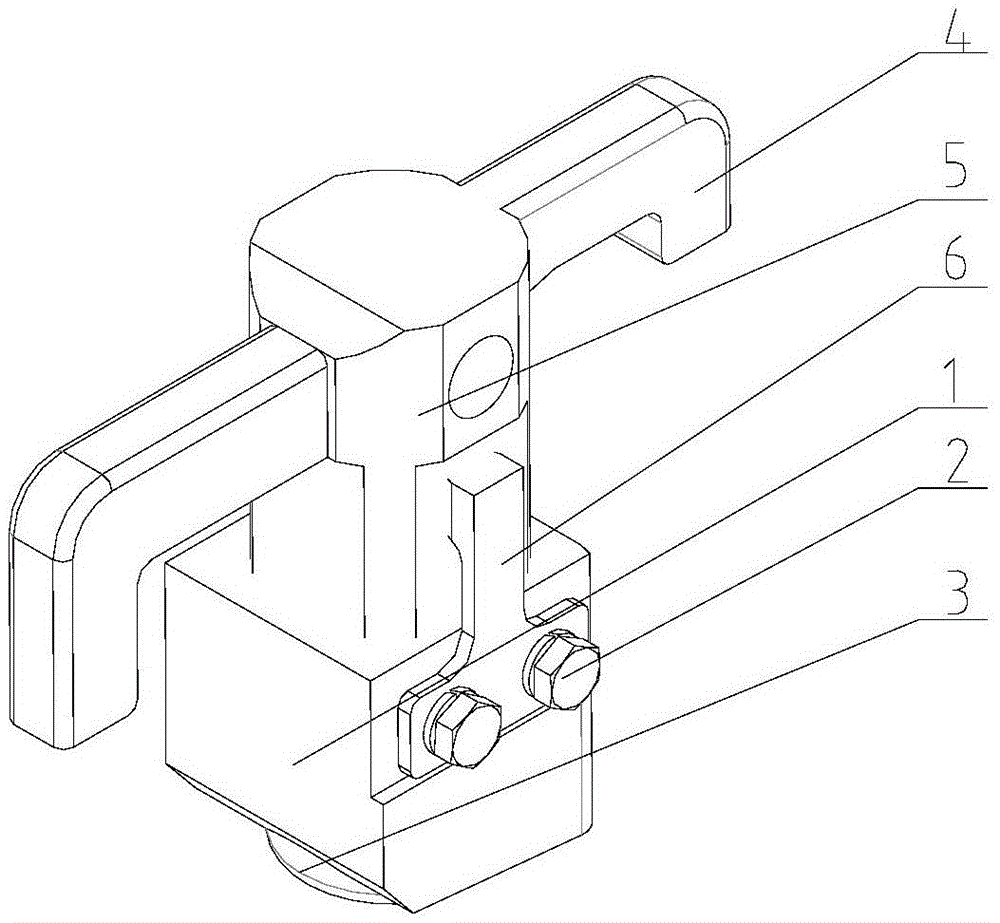

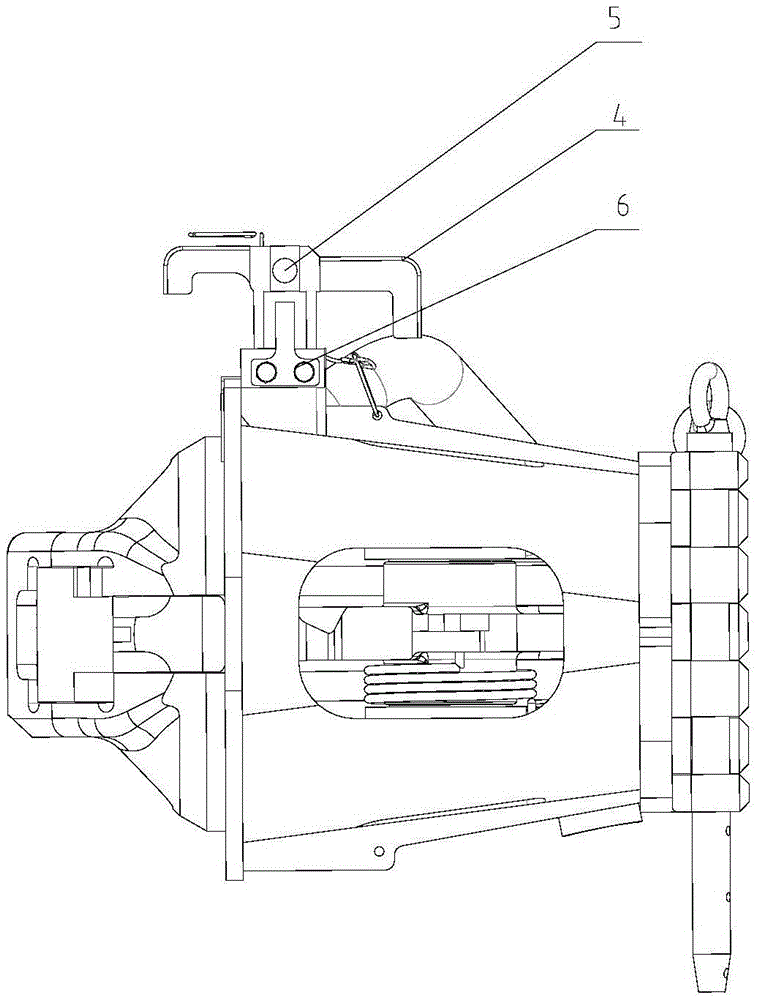

Auxiliary coupling device for transition car coupler

ActiveCN104129401AIncrease flexibilityImprove versatilityRailway coupling accessoriesCouplingEngineering

The invention relates to an auxiliary coupling device for a transition car coupler. The auxiliary coupling device is used for hooking a front-end coupler of a car, and comprises an auxiliary hook, a support, a locking device, fasteners and a rotary shaft pin, the auxiliary hook comprises a downward hook body and a hook connecting column, the upper end of the hook connecting column and the hook body are integrally formed, and the bottom end of the hook connecting column is connected with the rotary shaft pin. A counter bored hole is formed in the middle of the support, the hook connecting column longitudinally penetrates through the counter bored hole, the hook connecting column and the rotary shaft pin synchronously rotate under the supporting function of the counter bored hole, the rotary shaft pin can be rotated to drive the auxiliary hook to rotate by a car coupler coupling angle, the rotary shaft pin can be rotated to drive the auxiliary hook to rotate by a proper angle, it is guaranteed that any hook cannot stretch out of the coupling face, the normal work of automatic coupling is not influenced, manual coupling of the device and the front-end coupler can be achieved, the auxiliary hook can be rotated to different positions, the device can be coupled with a sealing car coupler or a locomotive coupler firstly in the using process, and the flexibility and universality of on-site shunting and reconnexion work are improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

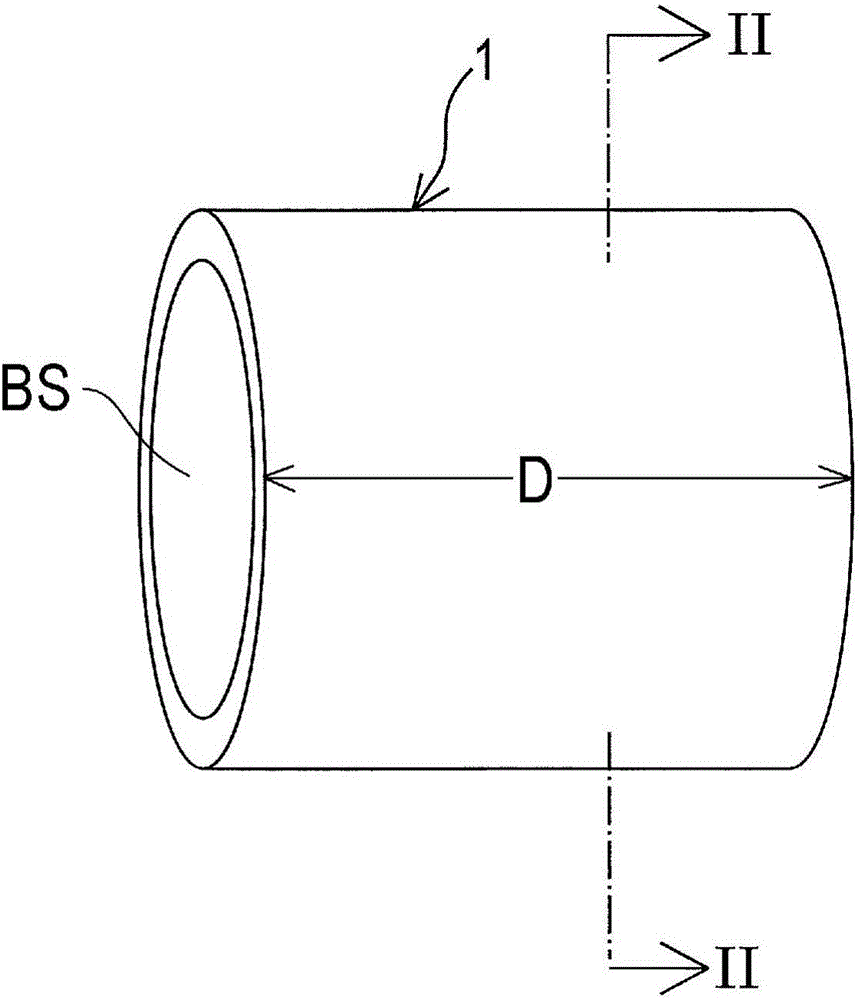

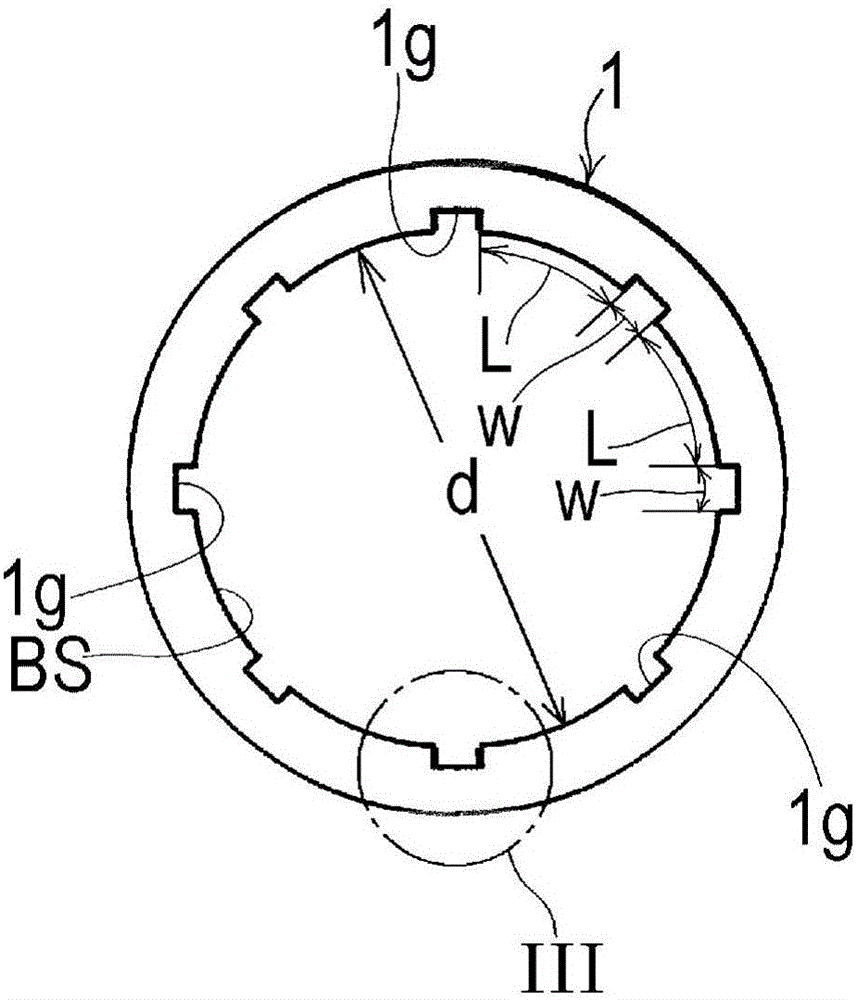

Sliding bearing device

ActiveCN105874230AGood removal effectImprove wear resistanceBearing componentsSliding contact bearingsFiberCarbon fibers

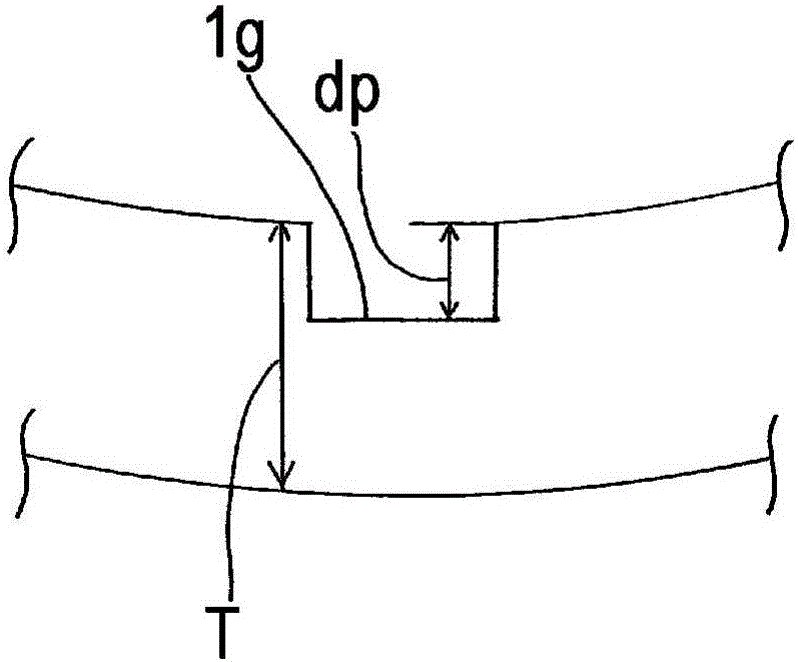

The present invention pertains to a sliding bearing device which can be suitably used as a radial bearing in a rotating machine such as a pump. In this sliding bearing used in a rotating machine, the bearing portion comprises a resin material that does not contain carbon fibers, or comprises a composite material wherein several carbon fibers having a length shorter than the circumferential length of the bearing sliding surface (BS) are included with a resin material which does not contain carbon fibers. Multiple grooves (1g) are provided in the bearing sliding surface (BS) so as to pass through the bearing sliding surface in the axial direction, and the multiple grooves (1g) are formed such that the percentage of the total surface area occupied by the grooves (1g) (the percentage surface area of the grooves) with respect to the entire sliding surface area of the bearing sliding surface (BS) is 15-50%, and the distance between adjacent grooves is 10-60 mm.

Owner:EBARA CORP

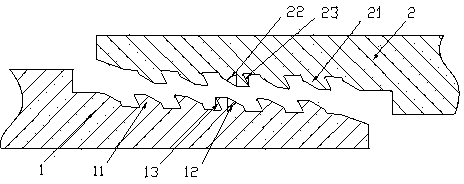

Drill rod joint with thread profiles

InactiveCN104018788AIncreased torsional strengthImprove fatigue strengthDrilling rodsDrilling casingsScrew threadWear resistance

The invention relates to a drill rod joint used in an oil and gas drilling and extraction processes, in particular to a drill rod joint with thread profiles. The drill rod joint comprises an external thread joint and an internal thread joint. The external thread joint and the internal thread joint are provided with threads of the same taper in the axial direction. The drill rod joint is characterized in that thread profiles of the external thread joint and thread profiles of the internal thread joint are both deformed trapezoids; in each thread profile of the external thread joint, a first flank angle ranges from 30 degrees to 75 degrees, a second flank angle ranges from 0 degree to minus 30 degrees, the thread taper is 1:6 to 1:32, and the thread pitch is larger than or equal to 6.35 mm; in each thread profile of the internal thread joint, a first flank angle ranges from 30 degrees to 75 degrees, a second flank angle ranges from 0 degree to minus 30 degrees, the thread taper is 1:6 to 1:32, and the thread pitch is larger than or equal to 6.35 mm. The torsional property, abrasive resistance and anti-fatigue performance of the drill rod joint can be improved, and the drill rod joint can be rapidly screwed on.

Owner:上海海隆石油钻具有限公司 +1

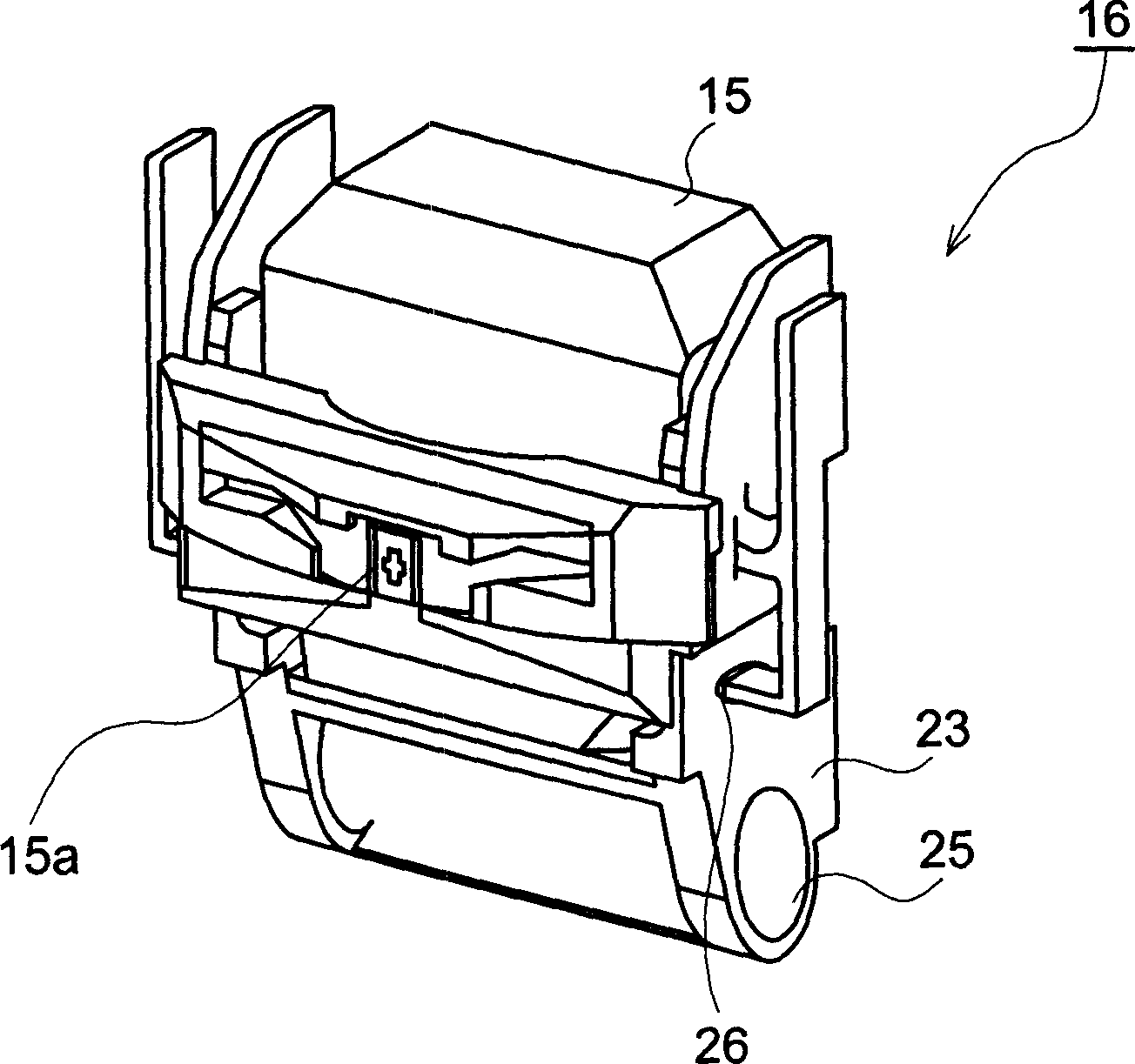

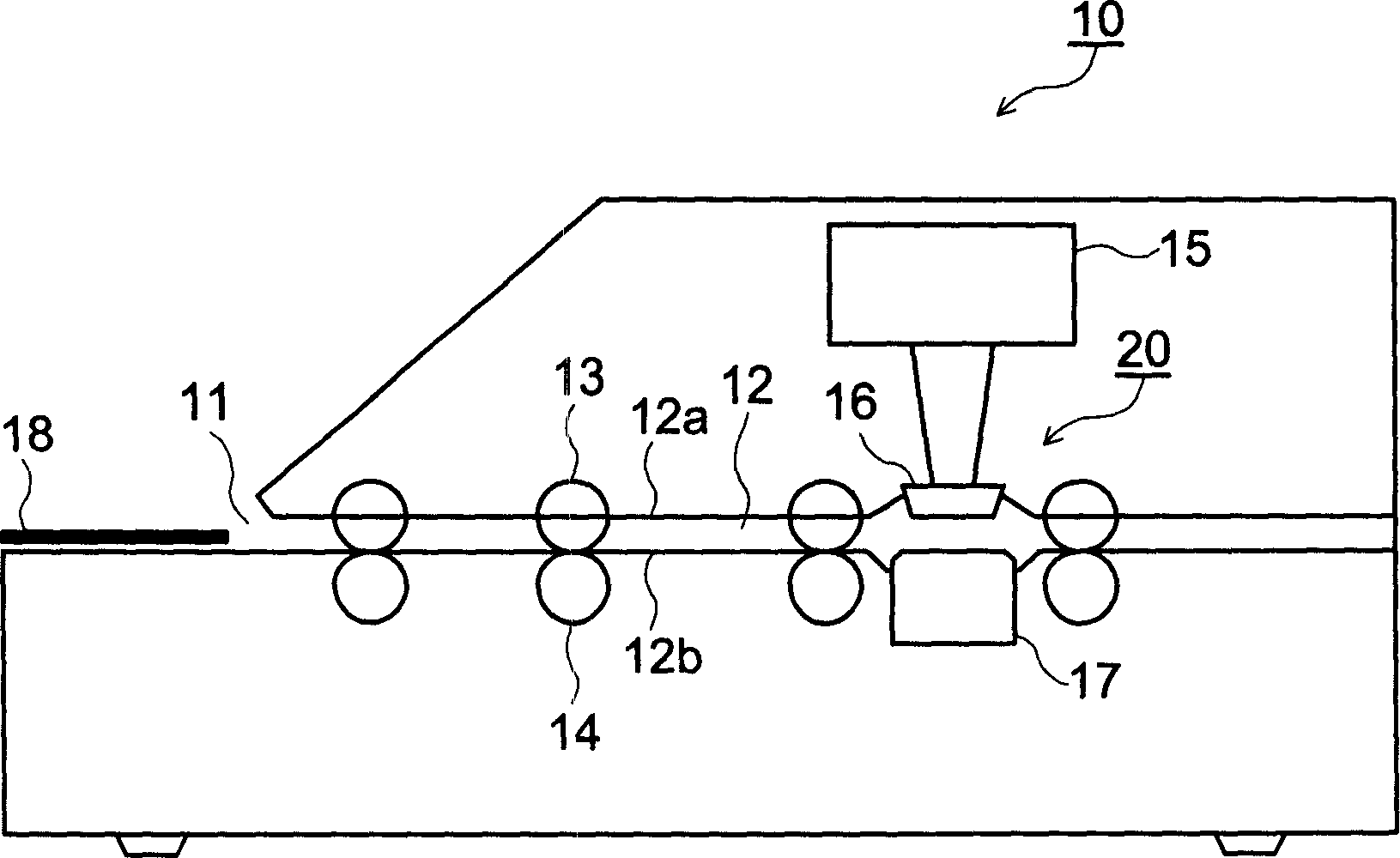

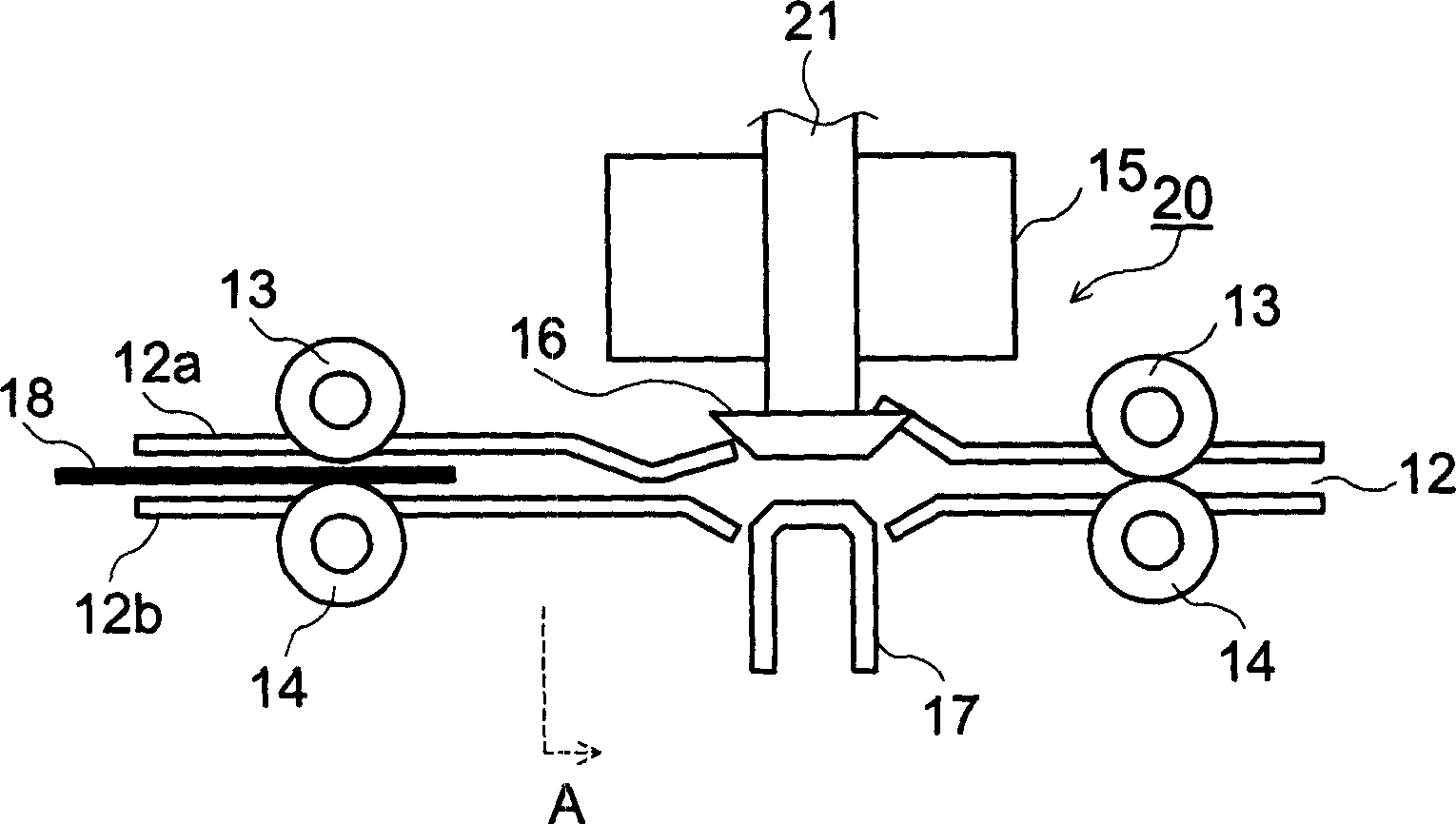

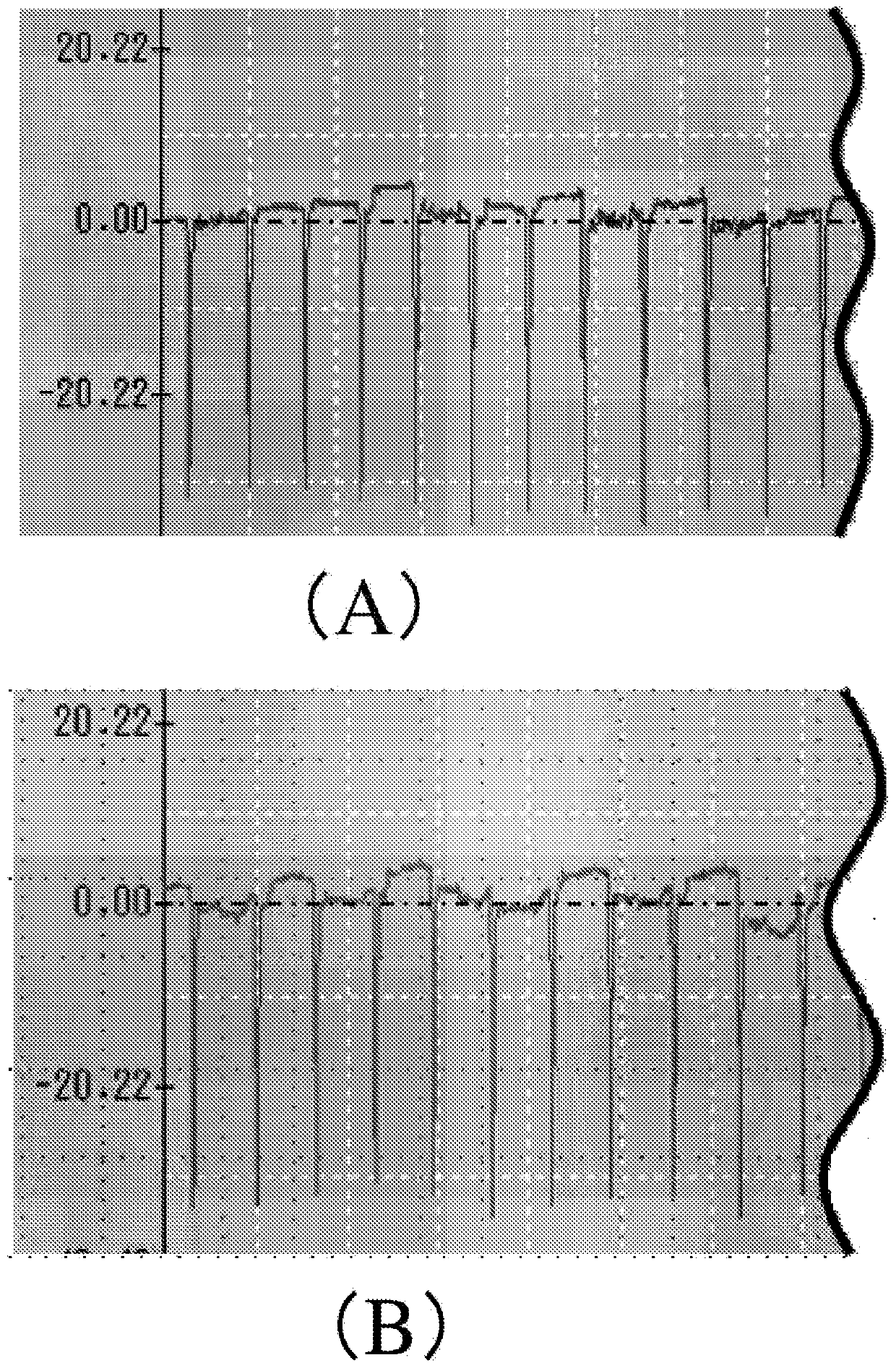

Printer

InactiveCN1809467AEasy to replaceLarge amount of wearPrinting mechanismsInking apparatusMechanical engineeringEngineering

The printer comprises a carriage 23 moving in the direction perpendicular to the carrying direction of a medium, a print head 15 mounted on the carriage 23 and printing on the medium, and a ribbon guide 16 for guiding the ink ribbon to the forward end face of the print head 15. The ribbon guide 16 has a medium guide surface abutting against the medium and engages removably with the carriage 23 or the print head 15. Thus, the printer in which a ribbon guide can engage removably with a print head or a carriage mounting the print head and an ink ribbon can be replaced easily, surface of the ink ribbon abutting against a medium is prevented from abrading significantly to vary the interval between the upper surface of the medium and the print head, print quality is prevented from deteriorating, and winding of the ink ribbon is carried out with no trouble.

Owner:OKI ELECTRIC IND CO LTD

Friction locking type magnetic lifter and control method thereof

ActiveCN106409347ALarge amount of wearNot easy to get stuckNuclear energy generationNuclear reaction controlEngineeringMechanical engineering

The invention discloses a friction locking type magnetic lifter and a control method thereof. The lifter comprises a sealed casing as well as a drive rod assembly and an armature which are located in the sealed casing, wherein the drive rod assembly comprises a friction rod; an armature accommodating cavity for the armature to axially move along the friction rod conveniently is formed between the drive rod assembly and the sealed casing, a retaining assembly for enabling the friction rod to be closely attached to the sealed casing, a moving assembly for enabling the friction rod to be closely attached to the armature and a lifting assembly for driving the armature to move upwards along the friction rod are arranged on the sealed casing, and each of the retaining assembly, the moving assembly and the lifting assembly comprises a magnetic yoke and a coil winding around the magnetic yoke. The lifter adopting the structure is large in wear allowance and high in rod falling reliability.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

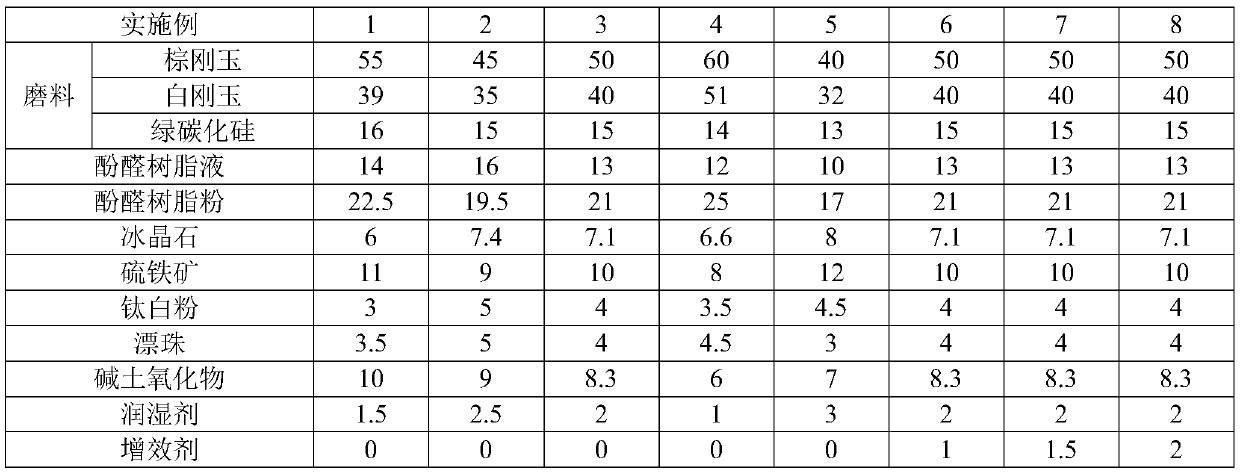

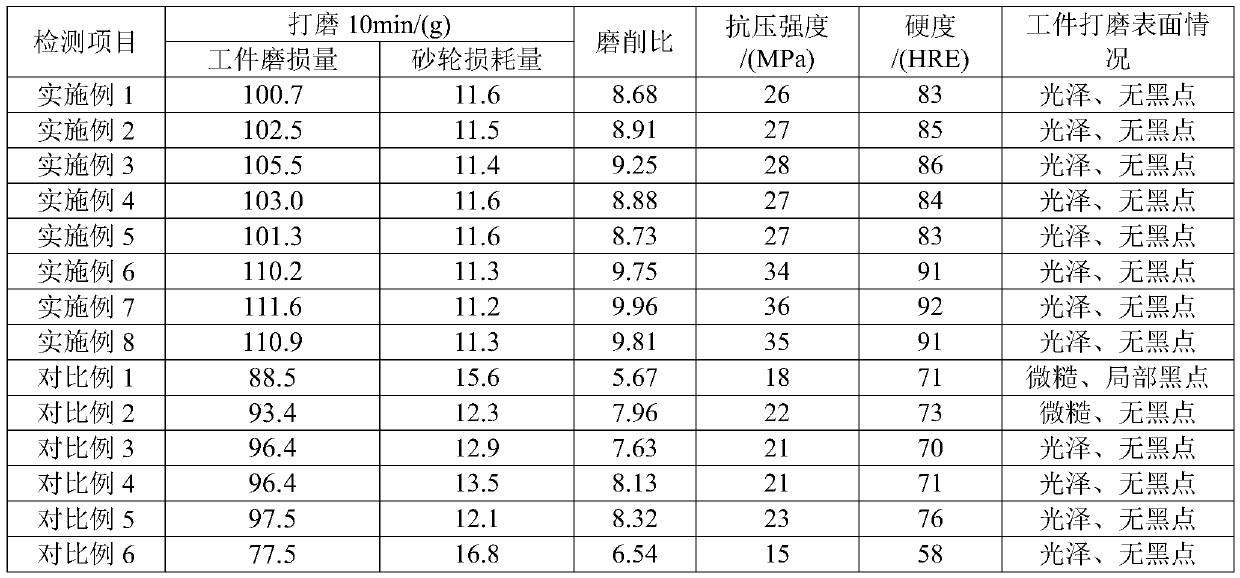

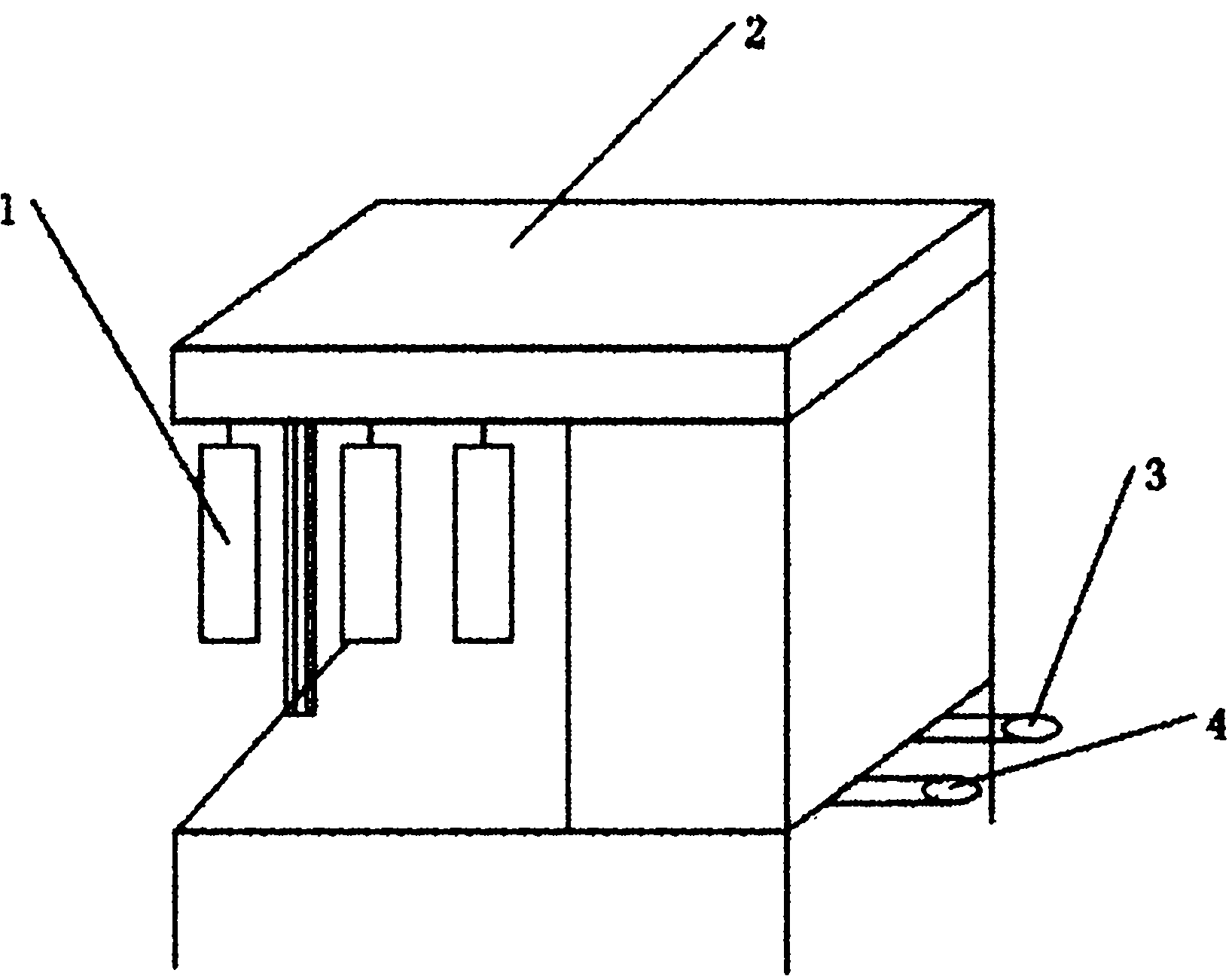

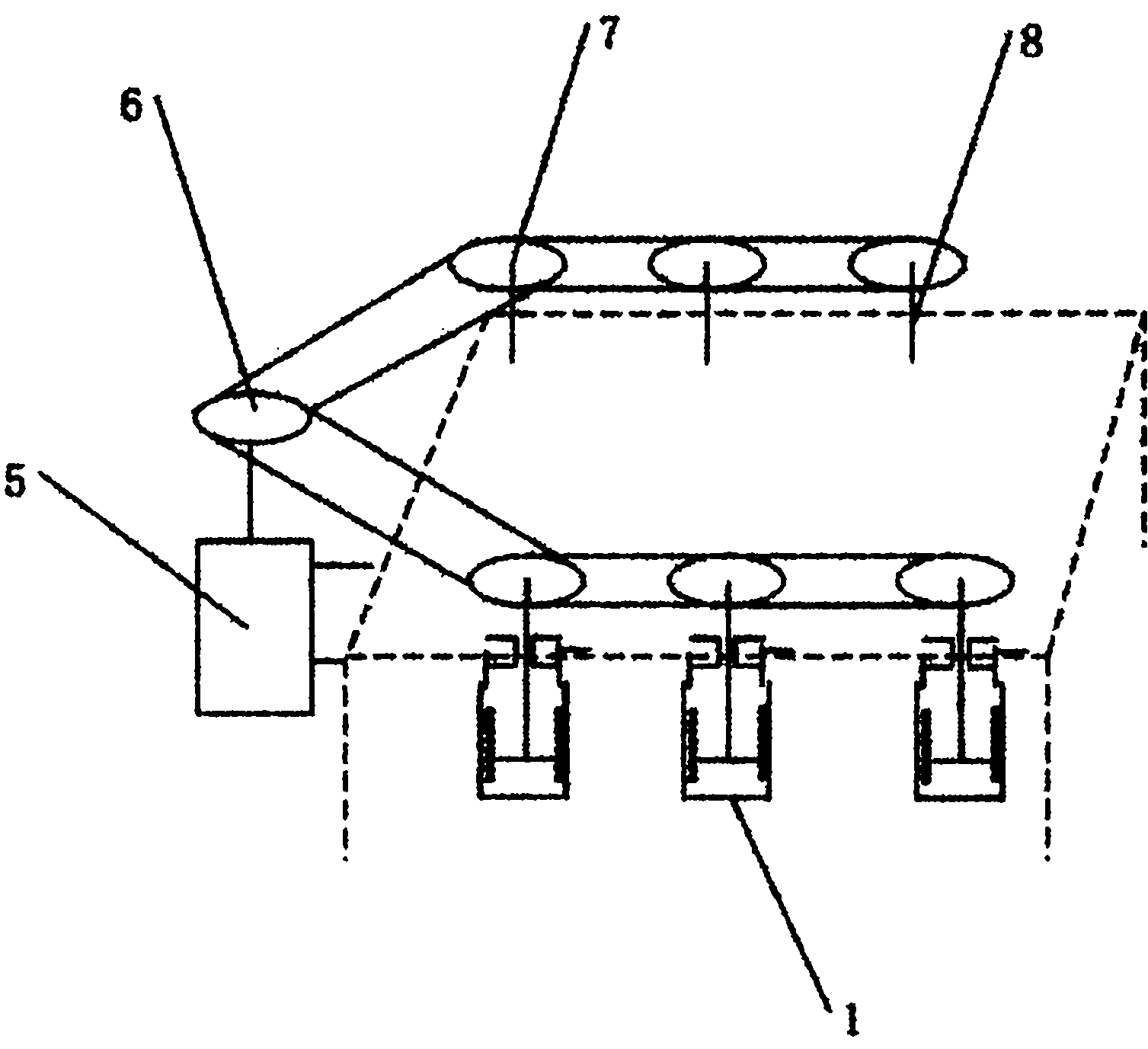

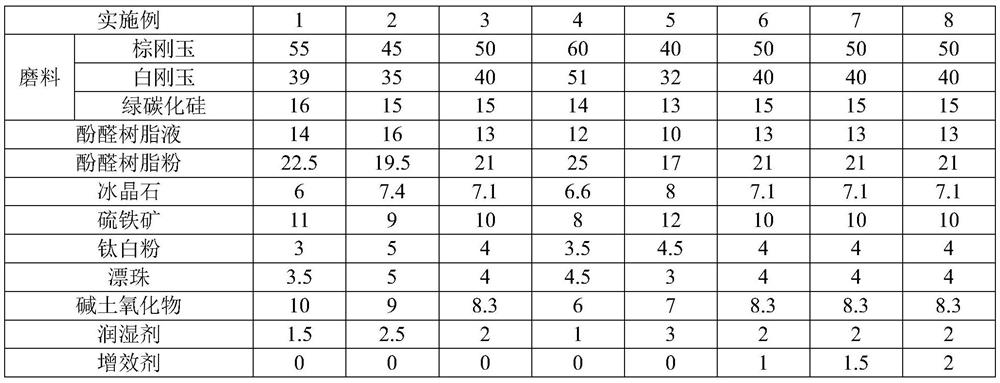

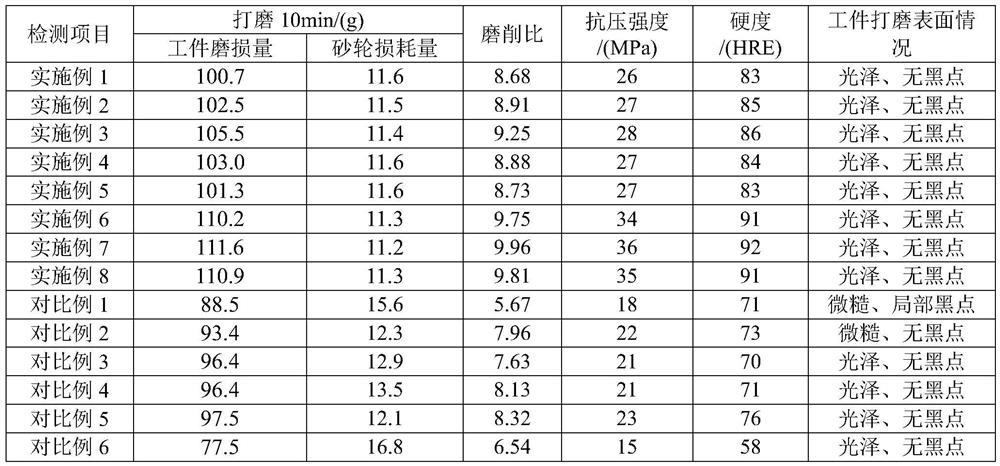

Resin grinding wheel and preparation method thereof

ActiveCN110977793AFull responseFully associativeAbrasion apparatusCompressive resistanceAlkaline earth oxides

The invention relates to a resin grinding wheel and a preparation method thereof, and belongs to the technical field of resin grinding wheel production, and the resin grinding wheel comprises the following raw materials of an abrasive, phenolic resin liquid, phenolic resin powder, cryolite, pyrite, titanium dioxide, floating beads, alkaline earth oxide and a wetting agent. According to the resin grinding wheel, the raw materials are cooperated, under the conditions that the polished surface of a workpiece is glossy and free of black spots, the resin grinding wheel has high workpiece abrasion loss and grinding ratio and low grinding wheel loss, the service life of the resin grinding wheel is prolonged, meanwhile, the resin grinding wheel further has high compressive strength and hardness, and the resin grinding wheel has a good using effect. According to the preparation method of the resin grinding wheel, by adding the annular magnetic field, twice mechanical pressing and twice curing,the raw materials are fully reacted and self-combined, the density and bonding strength of the resin grinding wheel are improved, the resin grinding wheel shows good comprehensive performance, and meanwhile the preparation method has the advantage of being convenient to control.

Owner:郑州九天工贸有限公司

Abrasion test device and method thereof

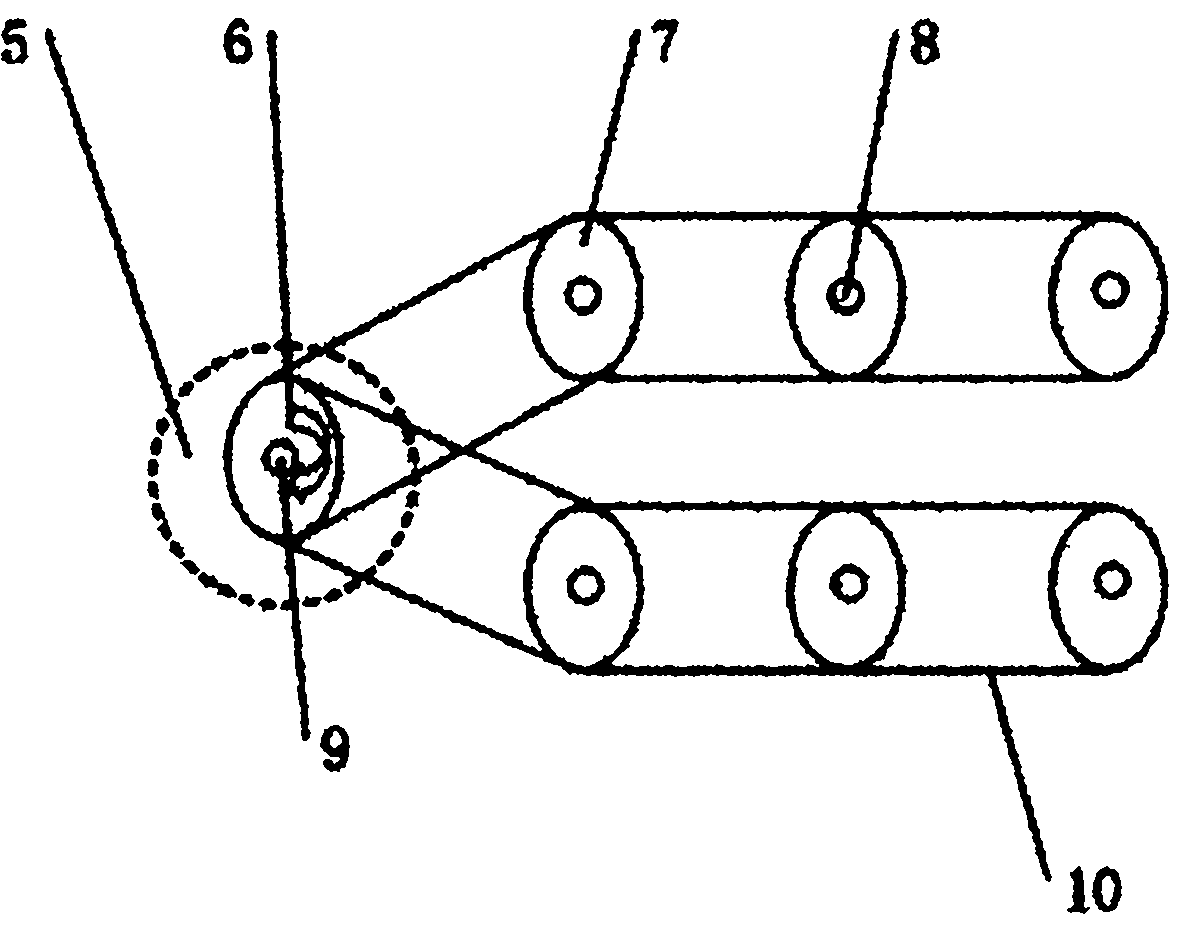

InactiveCN102374957ALarge amount of wearHigh efficiency of abrasion testInvestigating abrasion/wear resistanceTest efficiencyMotor drive

The invention relates to an abrasion test device and a test method, in particular to a mortar abrasion test device and a test method. The abrasion test device comprises a motor, a drive system, a mortar charging barrel, a rotating shaft and a supporting frame. The drive system consists of a primary driving wheel, a secondary driving wheel and a connecting piece, wherein the primary driving wheel is fixed at an output shaft end of the motor, and the secondary driving wheel is positioned on one side of the motor and in the same plane with the primary driving wheel. The rotating shaft is fixed on an outer shell through a bearing, one end of the rotating shaft is connected with the secondary driving wheel of the drive system, and the other end of the rotating shaft stretches into the mortar charging barrel which is fixed on the outer shell. The motor drives the rotating shaft through the drive system to perform synchronous rotation. The abrasion test method comprises the following steps of: fixing a sample on the rotating shaft, and filling a grinding mortar which is formed by mixing quartz sand and water into the mortar charging barrel; starting the motor to perform an abrasion test, and when the temperature of the mortar is overhigh, adding water for cooling; and taking the sample out after the test, and calculating the abrasion ratio of the sample. By the device and the method, the test efficiency is high, the time consumption is less, the test data deviation is small, and the accuracy is high.

Owner:CHINA PETROLEUM & CHEM CORP

High-wear-resistant blowout-control deviation adjustment polished rod sealer

InactiveCN105863547APrevent sprayingAvoid churnSealing/packingWear resistantElectrical energy consumption

The invention provides a highly wear-resistant anti-blowout adjustable polarizing rod sealer, which belongs to the field of oil pumping equipment. There is a vent-free assembly between them; there is a deflection adjustment gap between the universal sphere and the first locking handle, and the deflection adjustment gap enables the sealer to swing 10°-20° in any direction of 360°, realizing The automatic radial adjustment and centering of the polished rod solves the problem of increased eccentric load wear, greatly reduces the load of the pumping unit, and saves about 20% of electricity consumption; the inner cavity of the middle and upper part of the universal sphere is sequentially arranged from top to bottom The wear-resistant V-cylindrical packing with openings and the wear-resistant tapered packing with openings are provided, which have good sealing performance and long service life; the top of the universal sphere is provided with a blowout prevention device to prevent downhole liquid from ejecting, avoiding Problems such as crude oil loss and environmental pollution caused by breaking off.

Owner:史志升

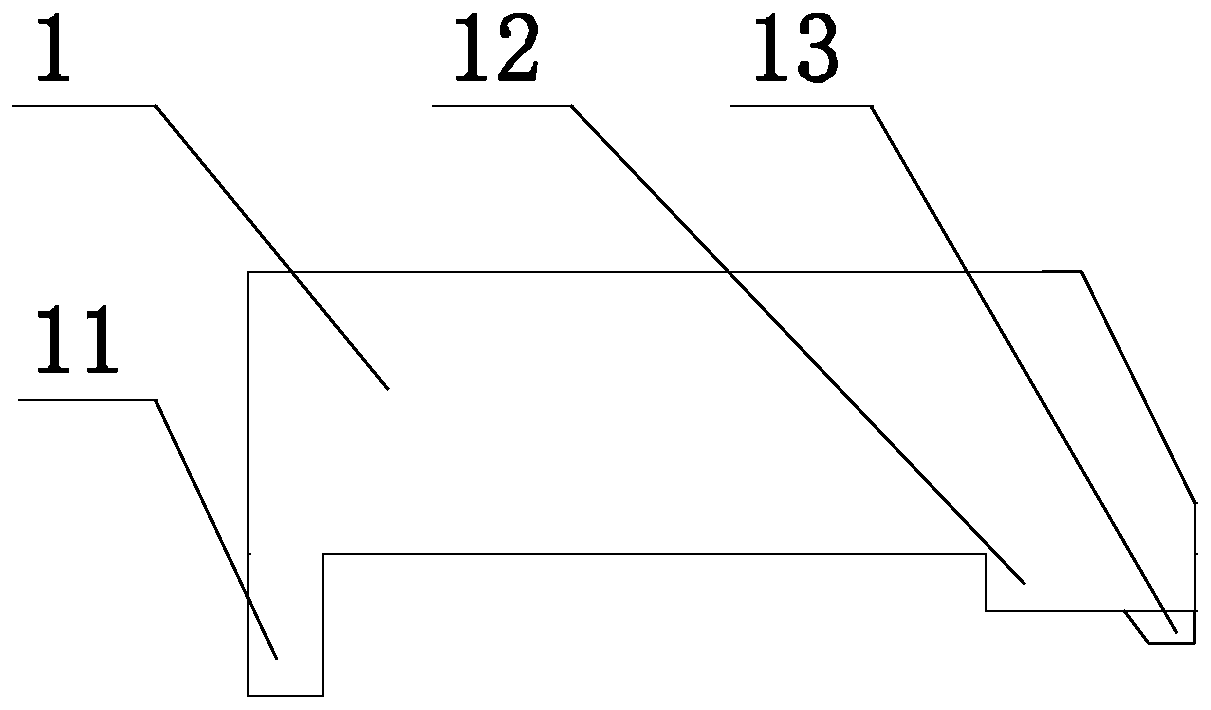

High-strength impact-resistant pressing plate and cutting tool bit assembly comprising same

PendingCN110899741AExtend your lifeReduce the explosive situationTurning toolsTool bitStructural engineering

The invention discloses a high-strength impact-resistant pressing plate and a cutting tool bit assembly. The positioning size of a pressing head of the impact-resistant pressing plate is increased, the abrasion loss of the pressing head is increased, the service life of the pressing plate is prolonged, the pressing head of the pressing plate is seriously abraded after the positioning size of the pressing head is increased, the pressing head can be easily found and replaced in time, and the situation that a tool is exploded when the pressing plate is seriously abraded and loses efficacy is reduced. In addition, the shape of the pressing plate is optimized, a blade limiting protrusion is arranged at the tail of the pressing plate, after the cutting tool bit assembly is assembled and a bolt is tightened, the pressing plate generates high-strength pressure on a blade through the blade limiting protrusion, and the stability and reliability of the blade in the machining process are guaranteed.

Owner:广德亚太汽车智能制动系统有限公司

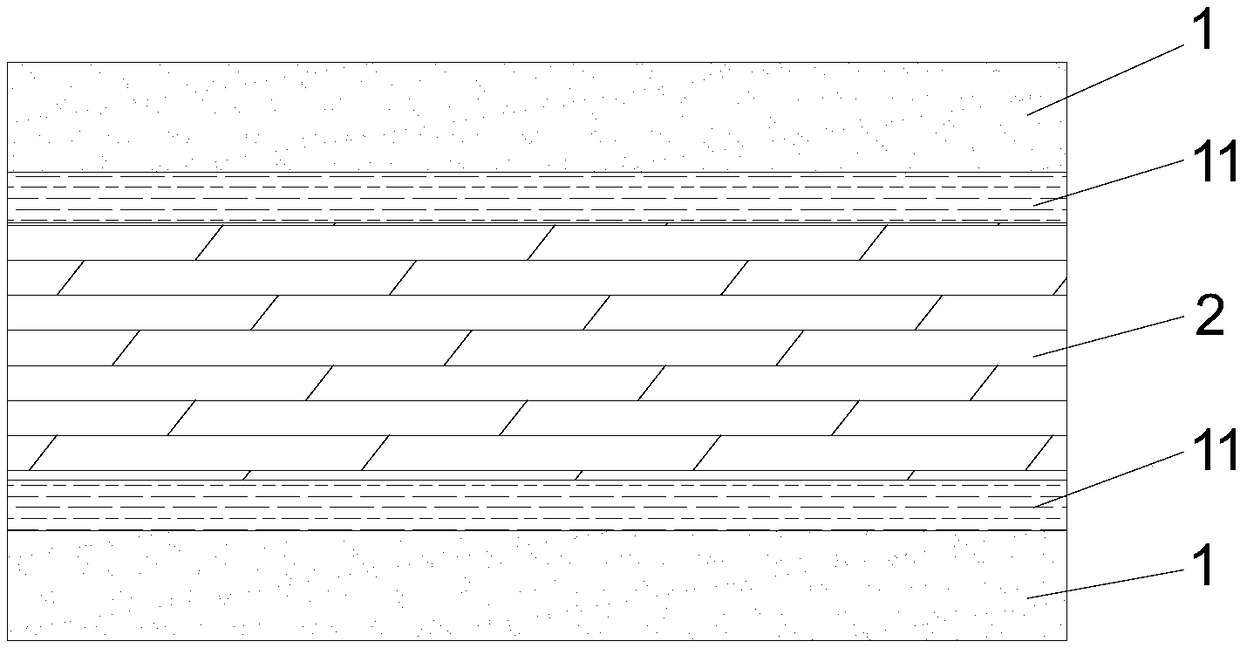

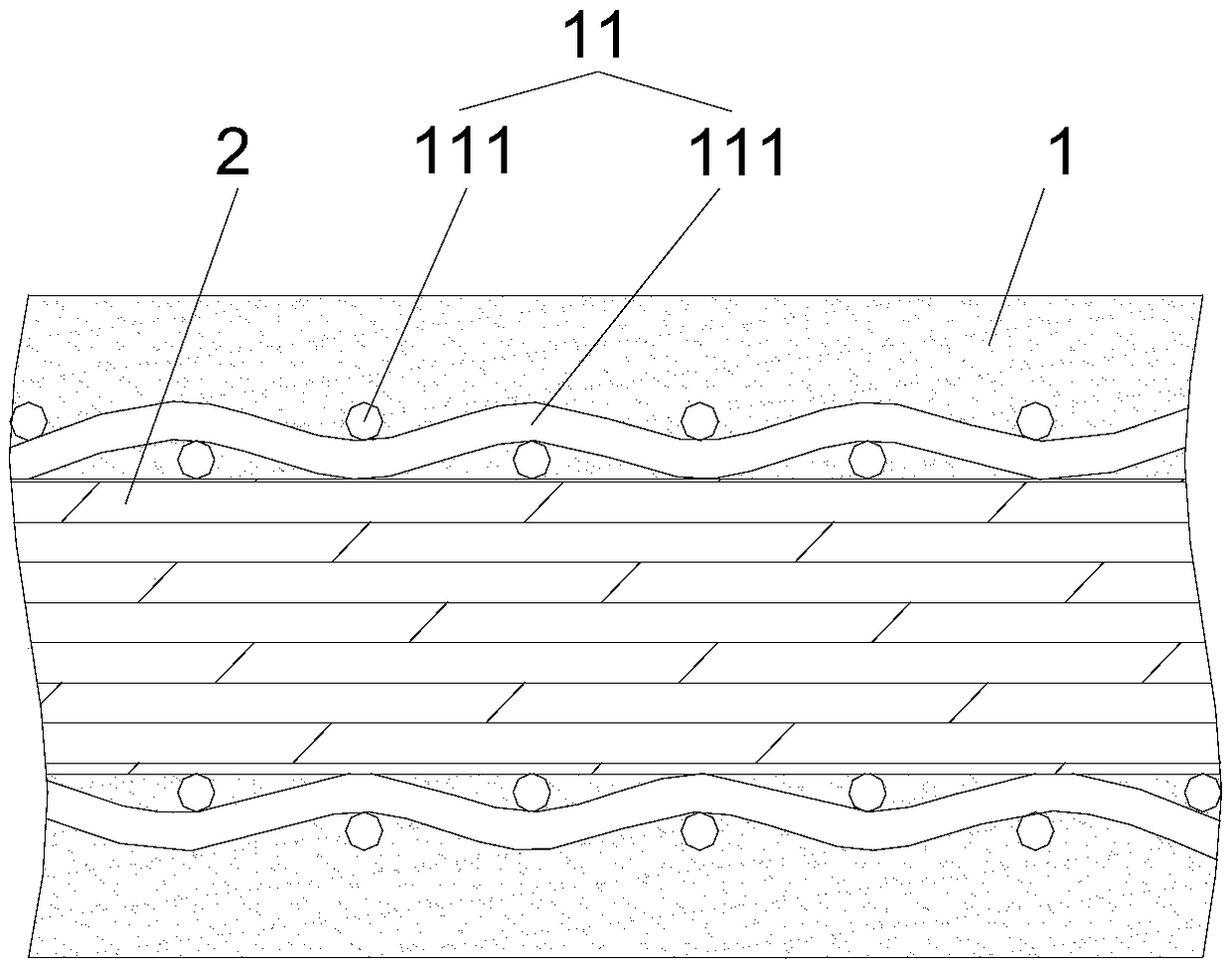

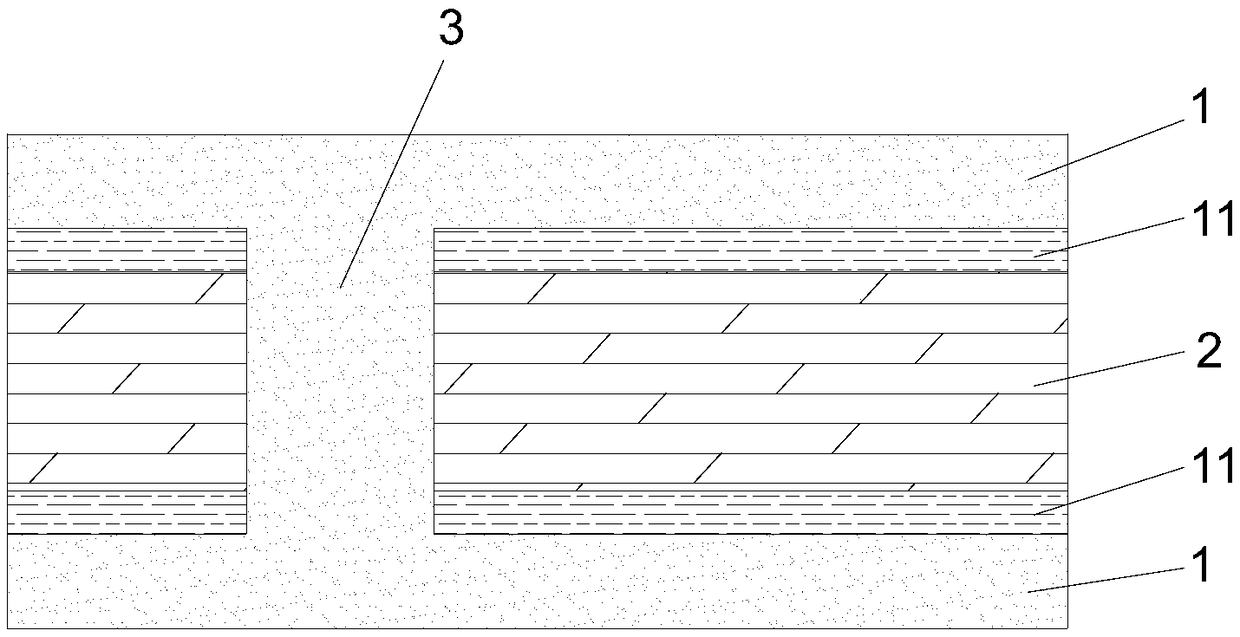

Building formwork

PendingCN109372252AImprove fire resistanceExtended service lifeForming/stuttering elementsWear resistantFire resistance

The invention provides a building formwork, relates to the technical field of building materials, and mainly solves the technical problem that in the prior art, a building formwork is poor in wear resistance and poor in fireproof performance. The building formwork comprises wear-resistant layers and a base layer, wherein the wear-resistant layers are positioned on the upper surface and the lower surface of the base layer; each wear-resistant layer comprises a wear-resistant surface and a reinforcing surface; each reinforcing surface comprises a channel and collateral layer; each channel and collateral layer is positioned on the surface, which is close to the base layer, of the corresponding wear-resistant layer; and each wear-resistant surface is positioned on the surface, which is away from the base layer, of the corresponding wear-resistant layer. The base layer is positioned between the wear-resistant layers, friction and / or scratching between the outside and the base layer can be prevented effectively, furthermore, the base layer can be isolated from a heat source of the outside by the wear-resistant layers, the base layer is prevented from being in direct contact with a fire source, and the fire resistance of the building formwork is improved. Each channel and collateral layer is close to the surface, which is close to the base layer, of the corresponding wear-resistant layer, the wearing capacity of the wear-resistant layers can be improved, and thus, the service life of the building formwork is prolonged.

Owner:卢志宣

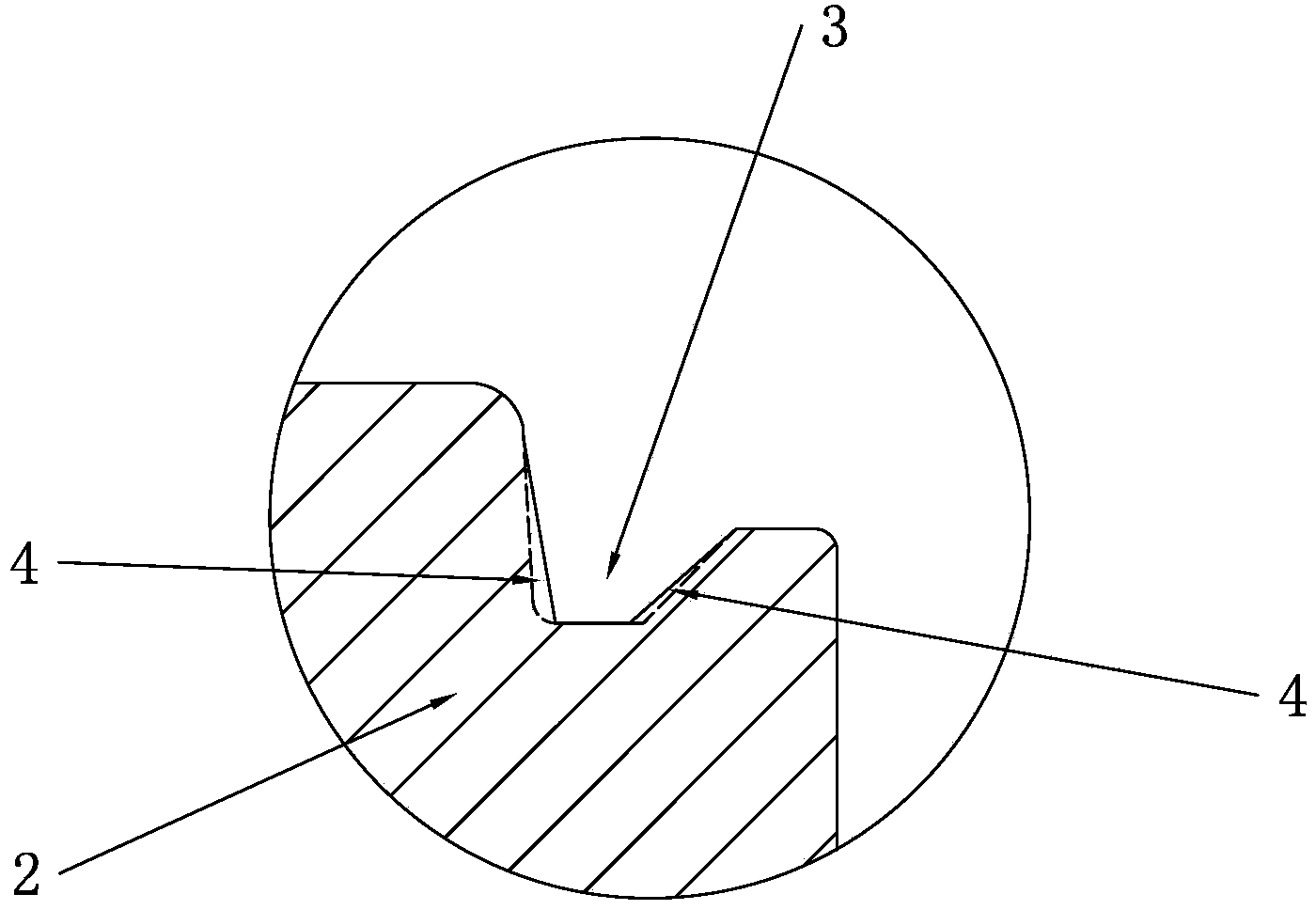

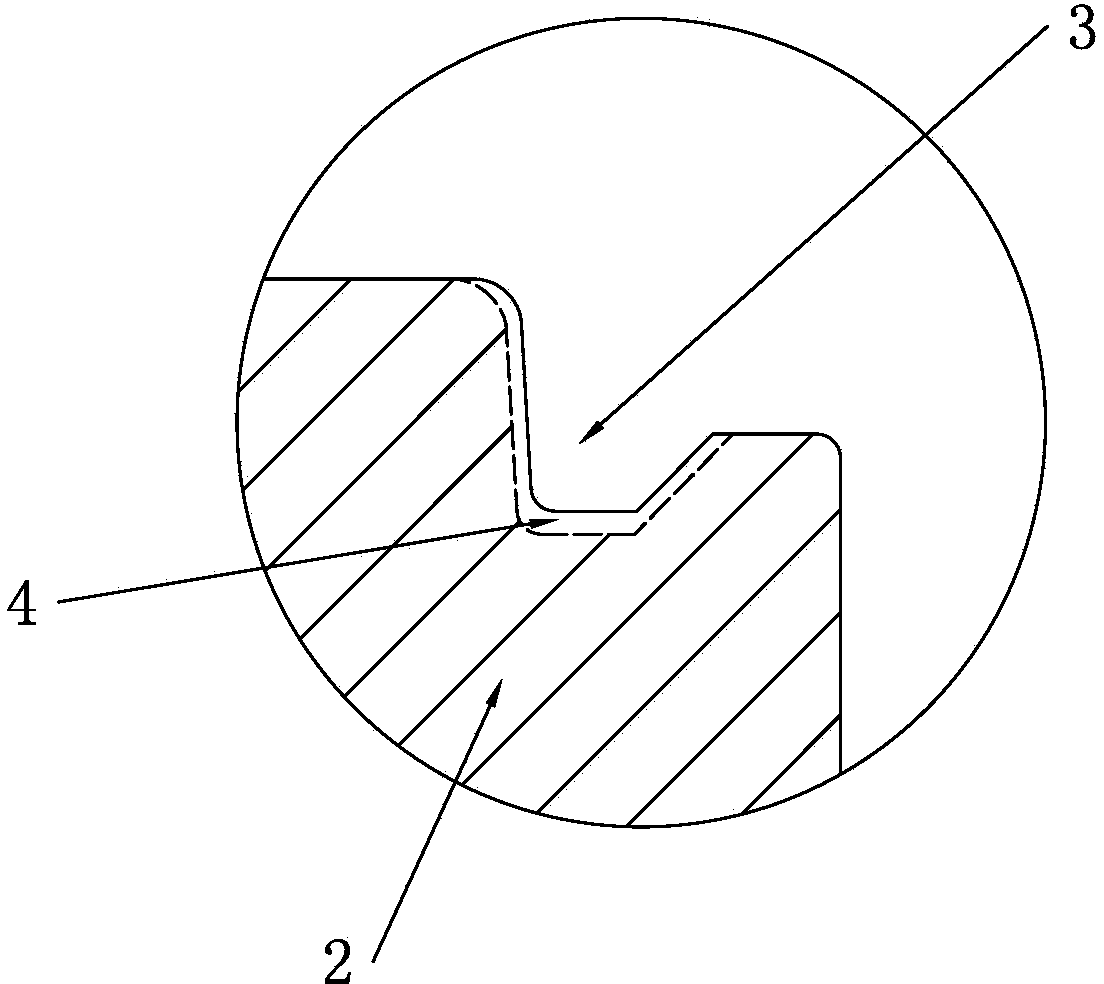

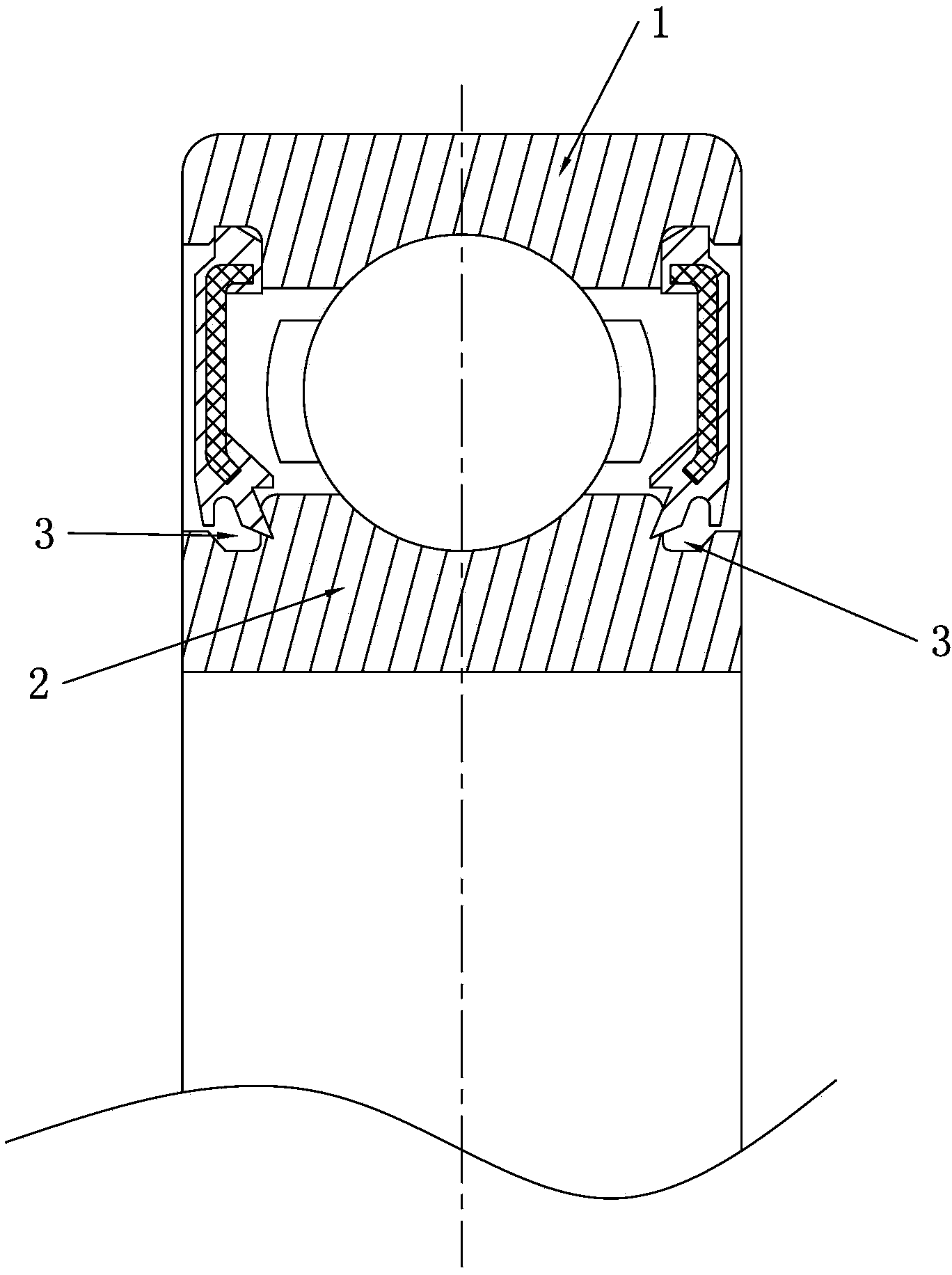

Bearing seal groove forming plunge-cut grinding method

The invention discloses a bearing seal groove forming plunge-cut grinding method. The method includes the steps: firstly, machining a seal groove of an inner ring of a bearing into a preform and reserving margins; secondly, grinding the seal groove and a roller path of the inner ring by a dressed grinding wheel; thirdly, finishing grinding. The margins in the seal groove of the inner ring are gradual margins. When the seal groove with the design of the gradual margins is used, the margins grinded by the grinding wheel are gradually increased, impact force on the grinding wheel is small, abrasion of the grinding wheel is effectively reduced, so that grinding accuracy of the seal groove is improved, the service life of the grinding wheel is prolonged, two slopes of the seal groove are designed into the gradual margins, two sides of a grinding edge of the grinding wheel uniformly bear axial force when the seal groove is grinded, collapse of the grinding edge of the grinding wheel is avoided, and the method can also avoid the problem that a margin at the bottom of a groove frequently cannot be grinded due to the defect of collapse of the grinding edge of the grinding wheel when the seal groove is grinded.

Owner:MOS GROUP CO LTD

Highly-wear-resistant plastic sheave liner and preparation method thereof

ActiveCN105482447AGood thermodynamic compatibilityImprove impact resistanceCrack resistanceWear resistant

The invention discloses a highly-wear-resistant plastic sheave liner and a preparation method thereof. The liner consists of the following components in parts by weight: 100 parts of nylon, 10-20 parts of aramid fiber, 15-20 parts of hollow glass beads, 5-15 parts of bauxite, 5-15 parts of barite, 1-3 parts of magnesium stearate, 0.5-1.5 parts of a titanate coupling agent, 10-15 parts of dioctyl phthalate, 1-3 parts of antimony trioxide, 5-10 parts of decabromodiphenyl ether, 10-15 parts of conductive carbon black and 0.5-1.5 parts of an antioxidant. The preparation process is simple, and the prepared plastic liner has good antistatic and flame-retardant properties, can keep relatively high tensile property, and is long in service life; and the sheave liner is good in seasoning crack resistance and moisture resistance, and is particularly suitable for use in severe environments with sprinkling water, strong corrosivity and the like in mines.

Owner:中实洛阳机械工程科技有限公司

Auxiliary coupling device for transitional coupler

ActiveCN104129401BIncrease flexibilityImprove versatilityRailway coupling accessoriesAngular rotationArticulated vehicle

The invention relates to an auxiliary coupling device for a transition coupler, which is used for coupling the front-end coupler of a vehicle. Column, the upper end of the hook connecting column is integrally formed with the hook, the bottom end of the hook connecting column is connected with the shaft pin; the middle part of the support is provided with a counterbore, the hook connecting column passes through the counterbore longitudinally, and the hook connecting column and the described The rotating shaft pin rotates synchronously under the support of the counterbore. The rotating rotating shaft pin can drive the auxiliary hook to rotate to the coupling hook angle, and the rotating shaft pin can also rotate the rotating shaft pin to drive the auxiliary hook to rotate to an appropriate angle to ensure that any hook does not protrude from the connecting surface. Affecting the normal operation of the automatic coupling, the manual coupling with the front coupler can be realized, and by turning the auxiliary coupling to a different position, it can be connected to the close coupling or the locomotive coupling first, which improves the on-site shunting and reconnection. Flexibility and versatility of work.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

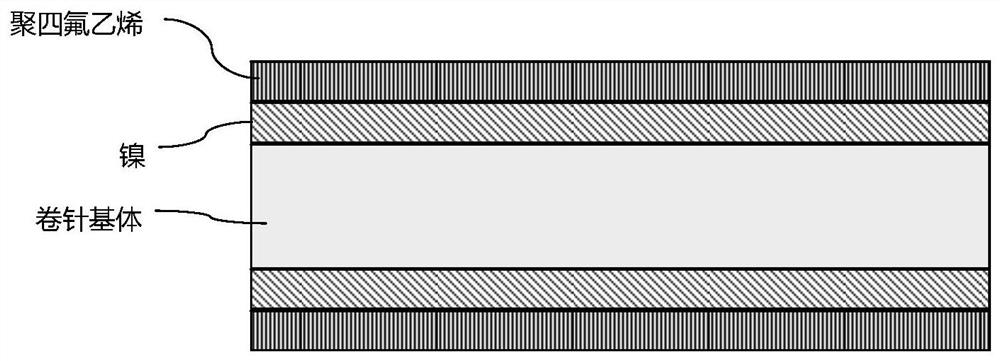

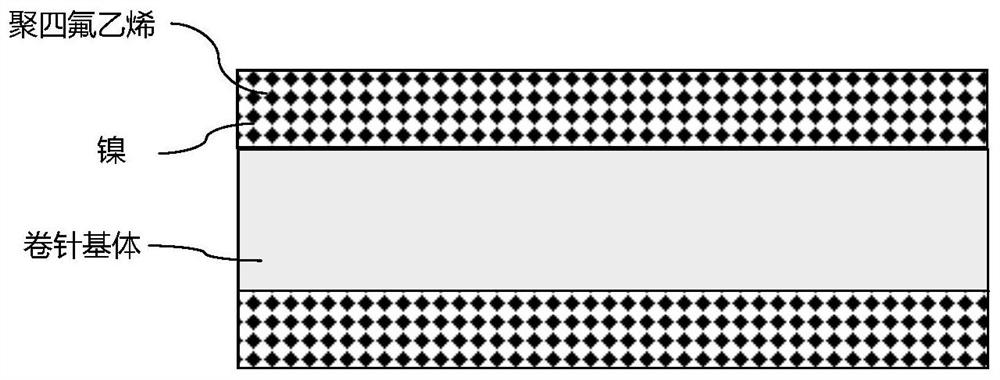

Nickel-polytetrafluoroethylene plating and wear-resistant anti-static rolling needle comprising plating

ActiveCN111636090AReduce frictional resistanceReduce defective rateElectrolytic coatingsFinal product manufactureTetrafluoroethyleneNickel salt

The invention provides a nickel-polytetrafluoroethylene plating and a wear-resistant anti-static rolling needle comprising the plating. The plating comprises nickel metal particles and polytetrafluoroethylene particles, wherein the nickel metal particles and the polytetrafluoroethylene particles are dispersed in the plating. The plating is obtained by electroplating of a mixed plating solution containing ammonia water, nickel salt and the polytetrafluoroethylene particles, wherein the mixed plating solution is stable in performance, and the polytetrafluoroethylene particles have high dispersity in the mixed plating solution and do not coagulate. In the electroplating process, when nickel ions of nickel-ammine complexing cations adsorbing the polytetrafluoroethylene particles are reduced and deposited on a cathode plate, the polytetrafluoroethylene particles can be released and uniformly co-deposited on the cathode plate along with the nickel ions, and therefore the nickel-polytetrafluoroethylene mixed plating with a smooth and dense surface is obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

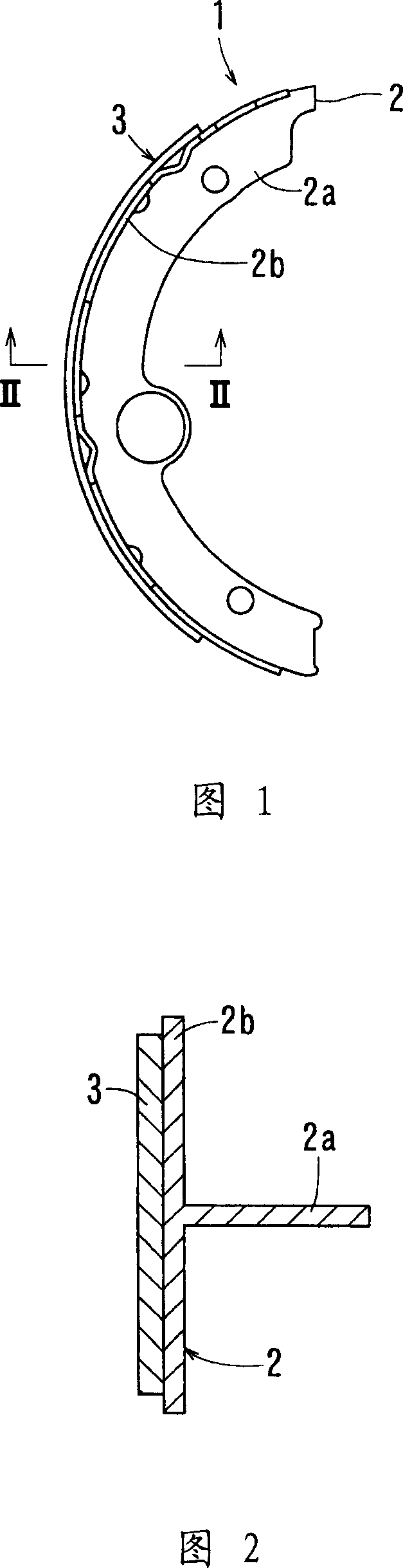

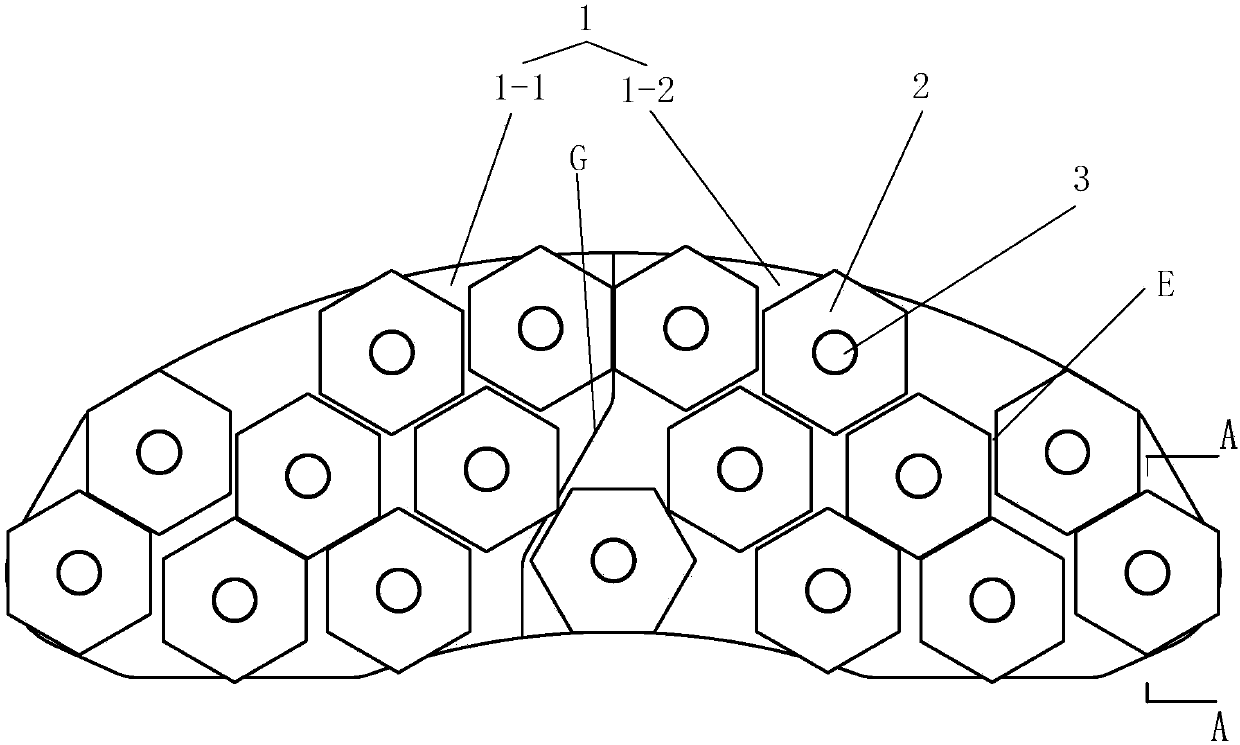

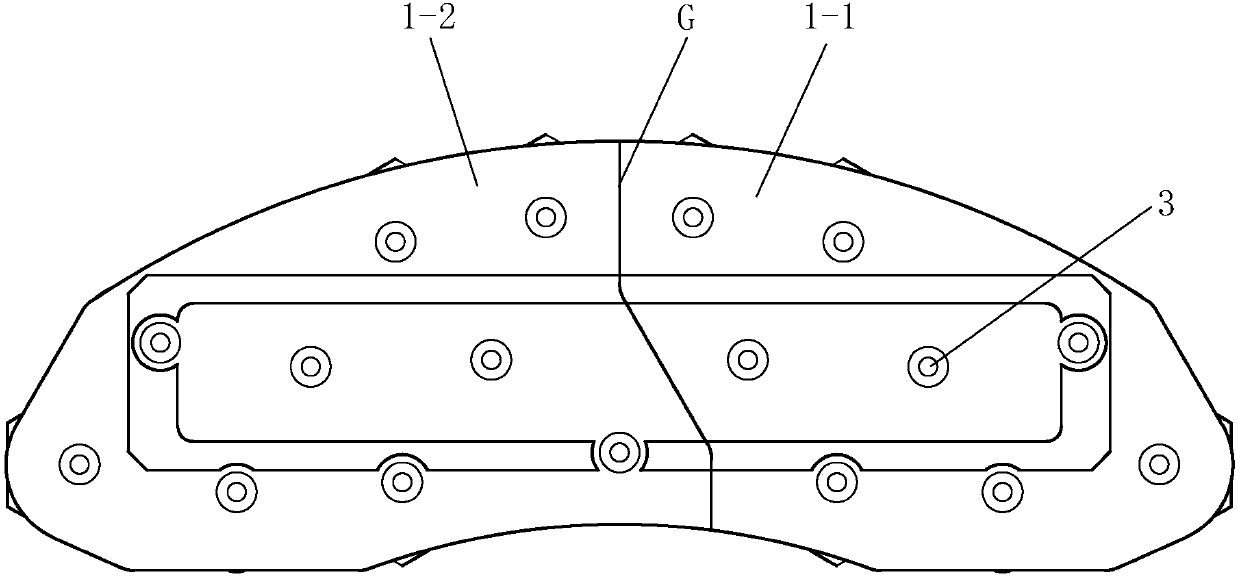

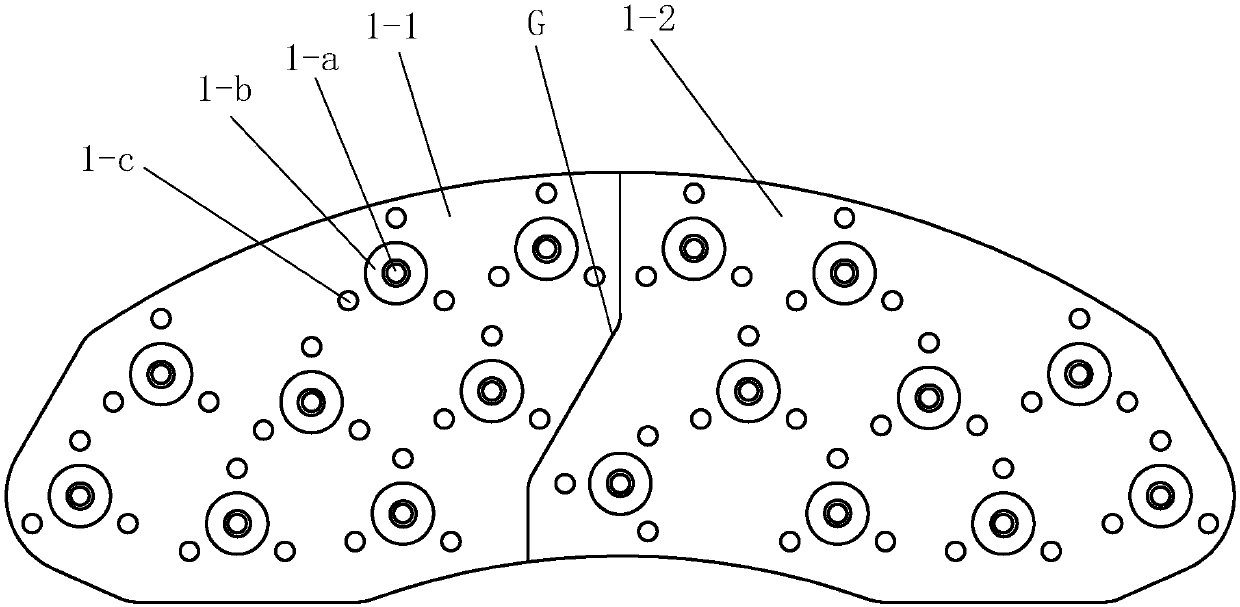

Riveting floating type brake pad

The invention discloses a riveting floating type brake pad. The brake pad comprises a supporting plate and a plurality of friction blocks, wherein the supporting plate and each friction block are connected through rivets, and floating gaps are formed between the supporting plate and the friction blocks; the friction blocks comprise back plates and friction bodies, and friction block connecting holes composed of friction block large-diameter holes and friction block small-diameter holes are formed in the centers of the friction blocks; supporting plate connecting holes formed by supporting plate small-diameter holes and supporting plate large-diameter holes and annular elastic grooves which are concentric with the supporting plate connecting holes are formed in the positions, correspondingto the friction blocks, on the supporting plate; and elastic elements are arranged in the annular elastic grooves, the friction blocks are hexagonal, the supporting plate is formed by splicing a leftplate and a right plate, the left plate and the right plate are spliced in a broken line along the edges of the friction blocks, and the tail parts of the rivets are hollow, and are positioned in thelarge-diameter holes of the supporting plate in a flanging shape. According to the brake pad, the friction blocks can be effectively prevented from being eccentrically worn, and the structural stability and safety of the brake pad are improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

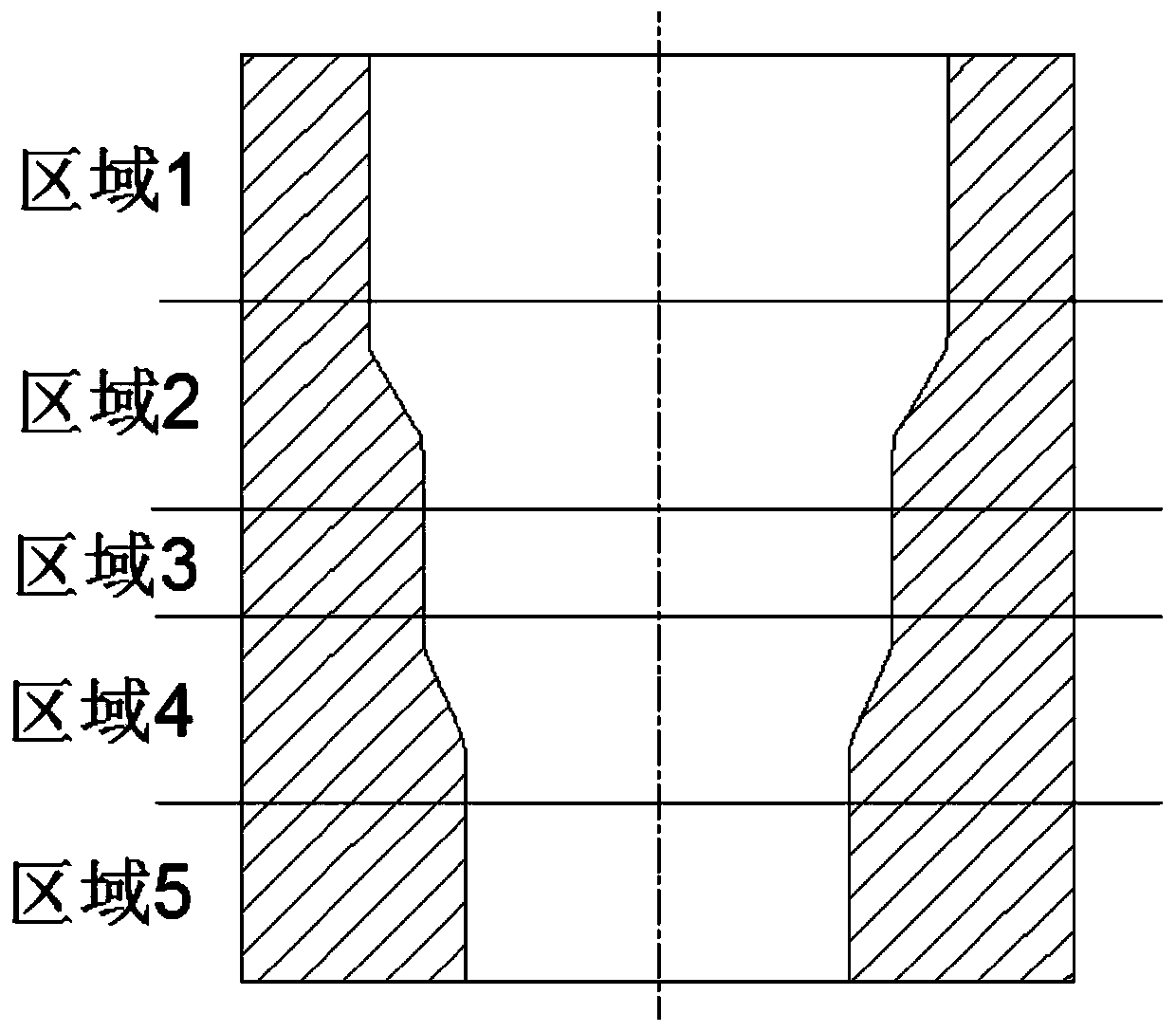

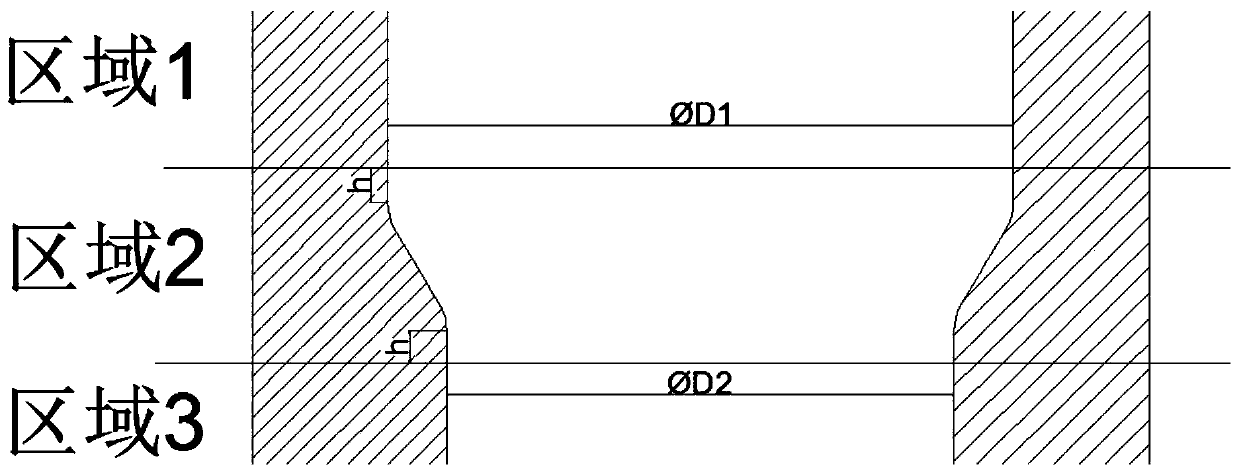

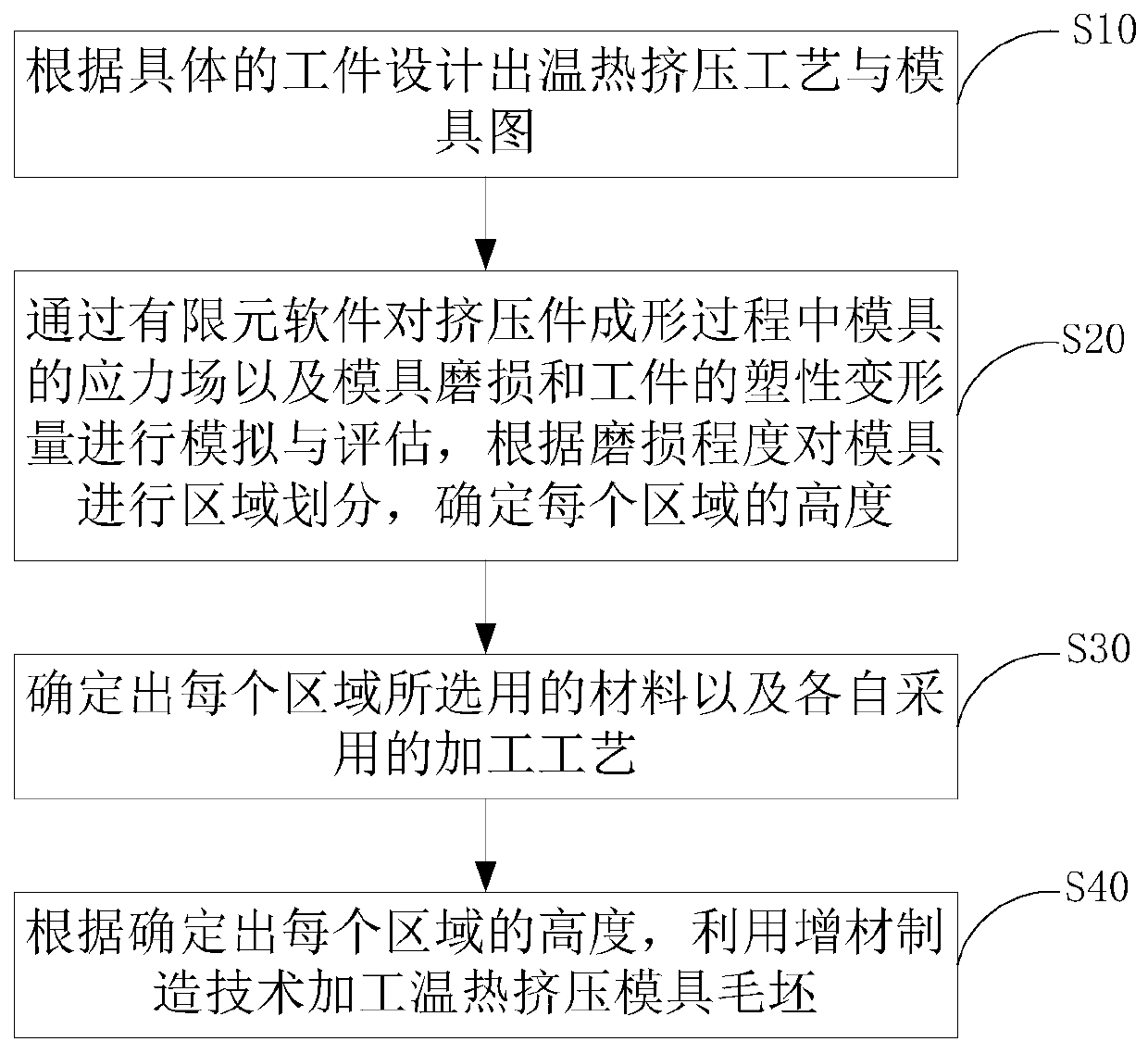

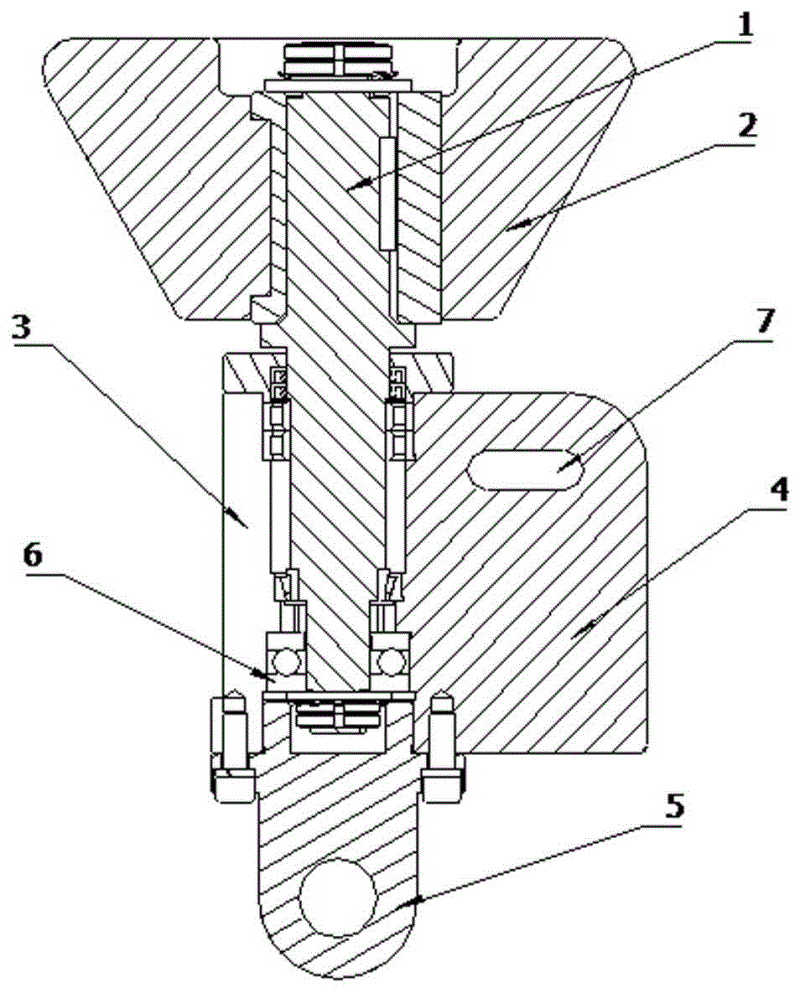

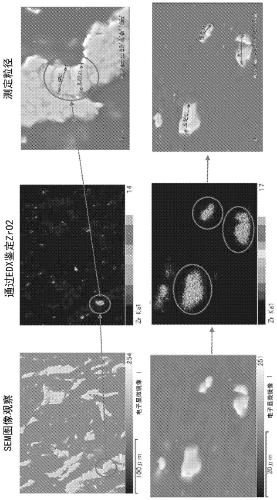

Multi-region heterogeneous material composite structure warm extrusion die and its preparation method

ActiveCN108817117BLow priceExcellent thermodynamic propertiesAdditive manufacturing apparatusExtrusion diesChromium carbideManufacturing technology

The present invention disclosed a warm squeezing mold in the composite structure of multi -region heterogeneous materials. In the direction of the axial direction of the mold, the mold is divided into the unchanged area and the cross -corner transition area. Among themThe area of unchanged areas and the cut -off area reduces the area of the rounded corner transition are all prepared by alloy powder through additive manufacturing technology;The rounded transition area is made of composite material powder prepared with tungsten carbide or chromium carbide and self -fused alloy powder.The multi -regional heterogeneous material composite structure proposed by the present invention can improve the comprehensive performance and service life of the mold, and use the materials reasonably.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of high wear-resistant plastic sky wheel liner

ActiveCN105482447BGood thermodynamic compatibilityImprove impact resistanceCrack resistanceWear resistant

Owner:中实洛阳机械工程科技有限公司

Grinding roller of roller grinder

InactiveCN102161011BLarge amount of wearHigh torque transmissionGrain treatmentsEngineeringMechanical engineering

Owner:XIANGTAN XIANGKE MECHANICAL & ELECTRICAL EQUIP

Brush of motor for automotive electronics

InactiveCN111434013ALarge amount of wearReduce wearRotary current collectorDynamoelectric machine connectorsElectric machineryScrub brushes

This brush of a motor for automotive electronics contains, in a main body of the brush, carbon and an abrasive material having a Vickers hardness of 10 to 14 GPa. Accordingly, the sliding noise of thebrush is reduced in the brush of a motor for automotive electronics.

Owner:TRIS

A kind of resin grinding wheel and preparation method thereof

ActiveCN110977793BIncrease grinding ratioExtended service lifeAbrasion apparatusBlack spotCompressive strength

The invention relates to a resin grinding wheel and a preparation method thereof, belonging to the technical field of resin grinding wheel production. The raw materials of the resin grinding wheel include abrasive, phenolic resin liquid, phenolic resin powder, cryolite, pyrite, titanium dioxide, floating beads, alkaline earth oxide ,lubricant. The resin grinding wheel, through the synergistic effect between the raw materials, makes the resin grinding wheel have a higher workpiece wear and grinding ratio under the condition of the polished surface of the workpiece and no black spots, and also has a lower grinding wheel loss. The service life of the resin grinding wheel is improved, and the resin grinding wheel also has good compressive strength and hardness, so that the resin grinding wheel has a good use effect. The preparation method of the resin grinding wheel, by adding a circular magnetic field, twice machine pressing, and twice curing, the raw materials are fully reacted and self-combined, the density and bonding strength of the resin grinding wheel are increased, and the resin grinding wheel shows good comprehensive performance. , but also has the advantage of being easy to control.

Owner:郑州九天工贸有限公司

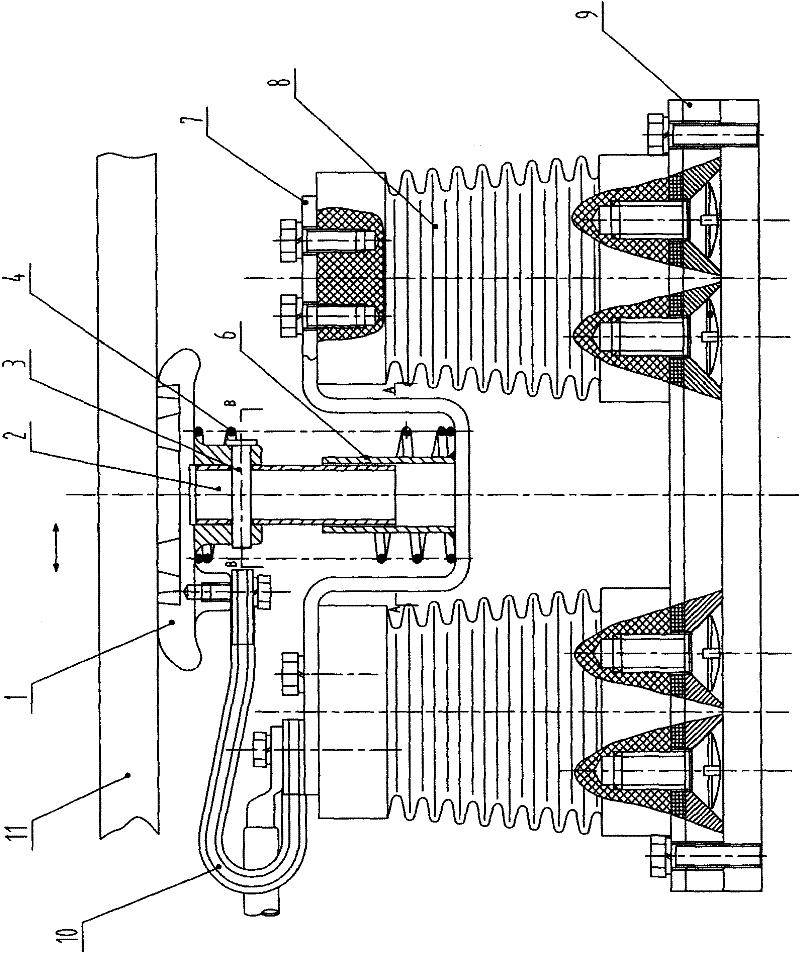

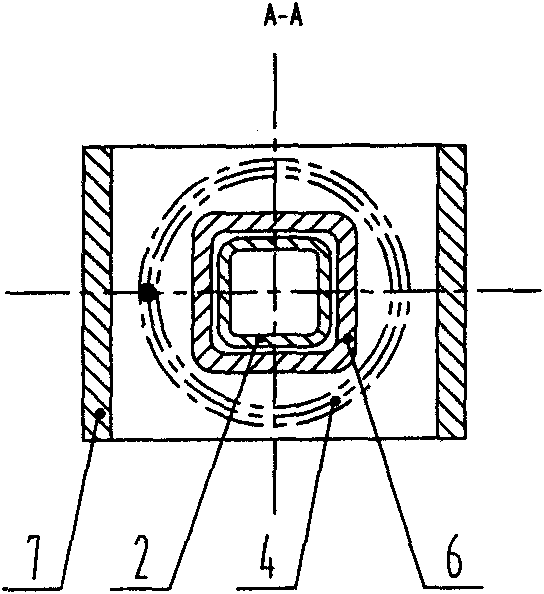

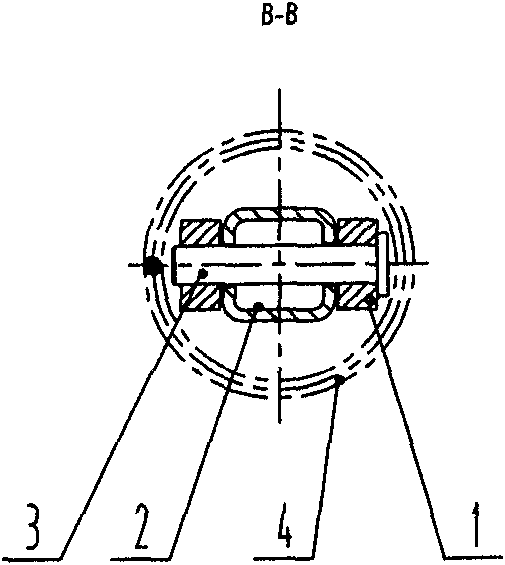

High-voltage slide shoe for excavators

InactiveCN101839006BExtended service lifeLarge amount of wearSoil-shifting machines/dredgersElectricityHigh pressure

The invention discloses a high-voltage slide shoe for excavators, which relates to a mechanical excavator. The invention solves the problems of the conventional high-voltage slide shoe for excavators, including short service life and poor high-voltage electricity transmission reliability. The high-voltage slide shoe is characterized in that: an upper linking part (2) is a special-shaped sliding pin (2-1), the upper part of which is a square guide rod and the lower part of which is a round end, a lower linking part (6) is a round guide pipe (6-1), the upper part of the guide pipe (6-1) is integrated with a special-shaped guide cap (5), the inner square hole of the special-shaped guide cap (5) is matched with the upper square guide rod of the special-shaped sliding pin (2-1) in a sliding manner, and the inner round hole of the round guide pipe (6-1) is matched with the lower round end of the special-shaped sliding pin (2-1) in a sliding manner. The high-voltage slide shoe can transmit high-voltage electricity less than 10000V, and can provide safe and reliable power supply.

Owner:TAIYUAN HEAVY IND

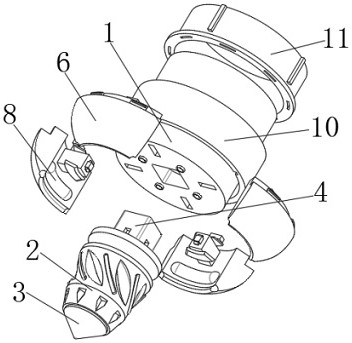

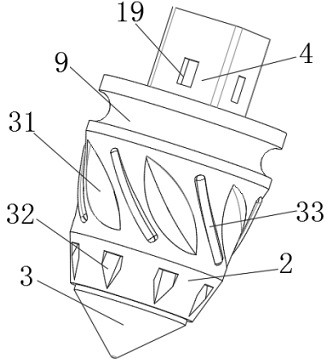

Novel rotary excavating tooth coal cutting tooth of shield tunneling machine

The invention discloses a novel rotary excavating tooth coal cutting tooth of a shield tunneling machine, and relates to the technical field of shield tunneling machine accessories. The novel rotary excavating tooth coal cutting tooth comprises a mounting seat, a rotary excavating tooth body and an alloy tooth head, wherein the alloy tooth head is fixedly connected to the bottom of the rotary excavating tooth body, a transmission slot is formed in the bottom of the mounting seat, a square transmission rod is fixedly connected to the top of the rotary excavating tooth body, the square transmission rod is matched with the transmission slot, a main damping spring rod is fixedly connected to the inner wall of the top of the square transmission rod, and a damping plate is fixedly connected to the bottom end of the main damping spring rod. According to the novel rotary excavating tooth coal cutting tooth, during installation, only the square transmission rod needs to be inserted into the transmission slot, four arc-shaped installation plates are pushed so as to clamp the rotary excavating tooth body, a splicing sleeve slides downwards so as to sleeve the arc-shaped installation plates, the splicing sleeve is fastened through a fastening unit, the installation is completed, the rotary excavating tooth can be installed only by one person without other tools, time and labor are saved, and the operation is convenient.

Owner:山东易得通机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com