Abrasion test device and method thereof

A technology of wear test and test method, which is applied in the direction of measuring devices, test wear resistance, instruments, etc., can solve the problems of low accuracy, large numerical deviation, and low efficiency, and achieve high accuracy, small deviation of test data, time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

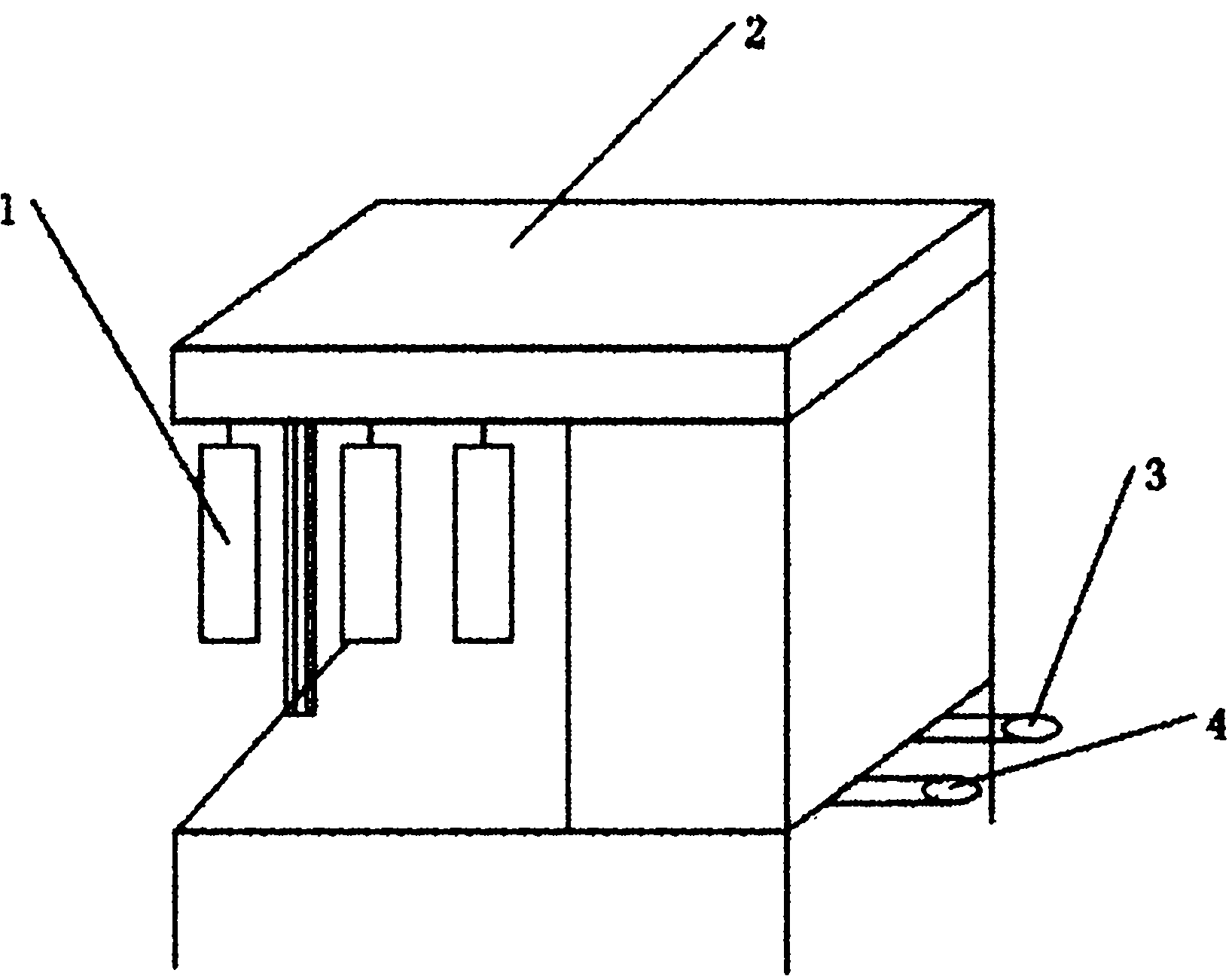

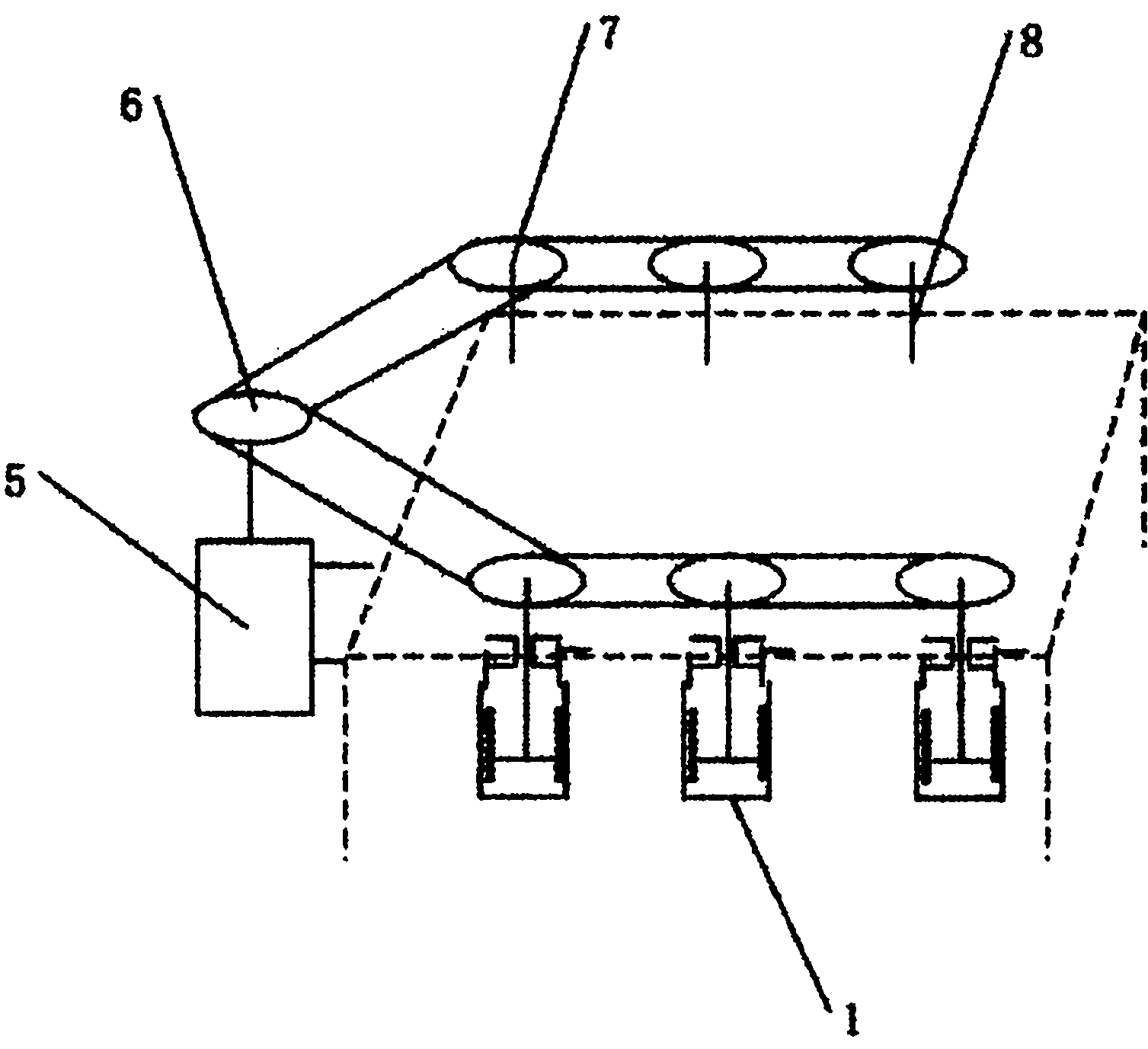

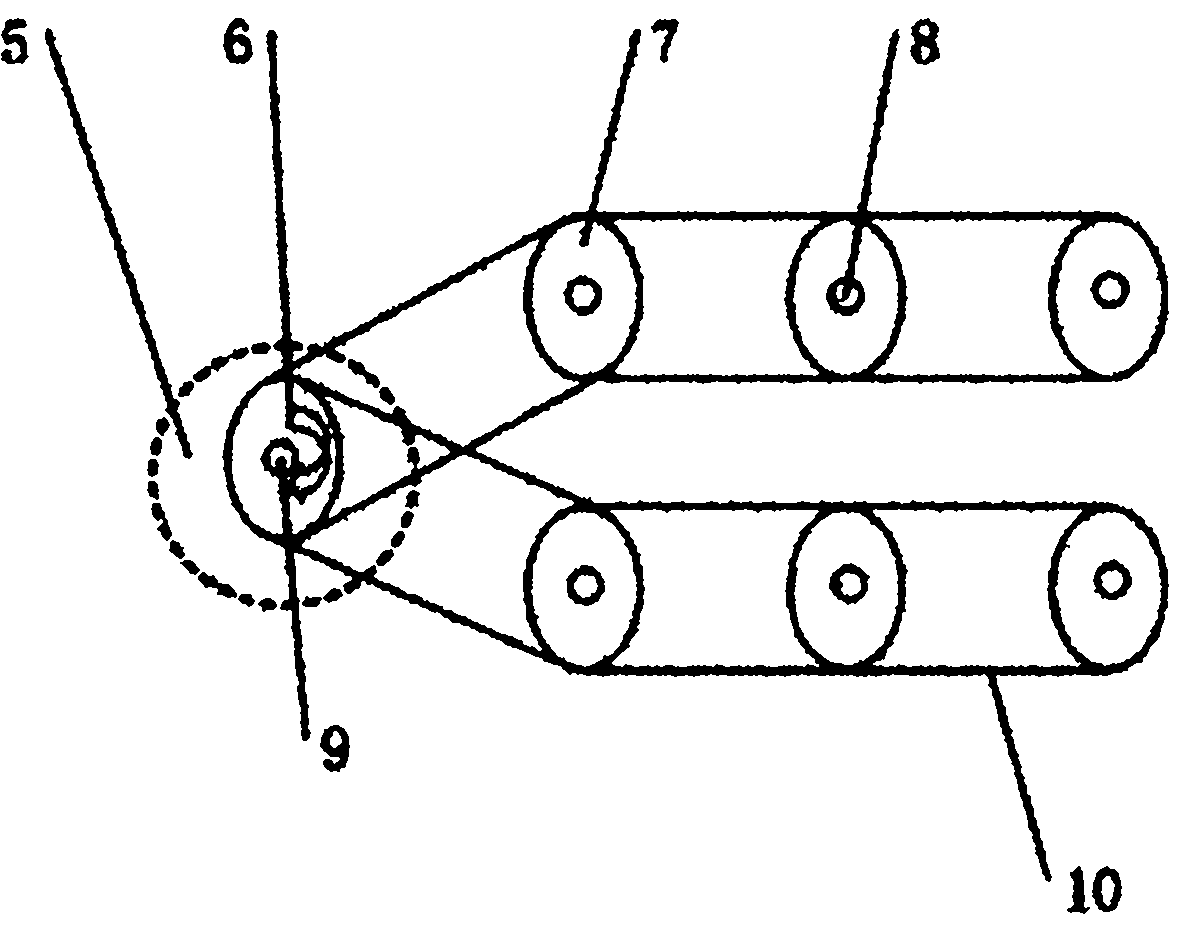

Embodiment 1

[0021] Embodiment 1: Taking ultra-high molecular weight polyethylene material as a sample, select three different grades of ultra-high molecular weight polyethylene material to make six samples, the serial numbers are 1#-1, 1#-2, 2#-1 , 2#-2, 3#-1, 3#-2. see Figure 1-Figure 6 In the wear test device shown, the number of mortar cylinders 1 is 6, and the shape of the baffle plate 18 is Image 6 The number of triangles shown in 6-1 is 4. The stirring speed is 1400r / min, the size of quartz sand is 20-40 mesh, the mass ratio of quartz sand to water is 3:2, the abrasion test time is 3 hours, cooling water is passed through the cooling jacket 20, and the mortar temperature is controlled at 23°C Below, the test data are shown in Table 1:

[0022] It can be seen from the data in the table that the present invention can better evaluate the wear resistance of different grades of ultra-high molecular weight polyethylene, and the deviation of the test data is small and the data is re...

Embodiment 2

[0024] Example 2: The number of baffles 18 is 4, cooling water is passed through the cooling jacket 20, the temperature of the mortar is controlled below 23°C, and the wear rate data in Table 2 are obtained.

Embodiment 3

[0025] Example 3: The number of baffles 18 is 2, cooling water is passed through the cooling jacket 20, the temperature of the mortar is controlled below 23°C, and the wear rate data in Table 2 are obtained. Example 4: The number of baffles 18 is 6, cooling water is passed through the cooling jacket 20, the temperature of the mortar is controlled below 23°C, and the wear rate data in Table 2 are obtained. Example 5: The number of baffles 18 is 8, cooling water is passed through the cooling jacket 20, the temperature of the mortar is controlled below 23°C, and the wear rate data in Table 2 are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com