Brush of motor for automotive electronics

A brush and electric equipment technology, applied in the direction of motor generator connectors, electromechanical devices, circuits, etc., can solve the problem of no brush sliding sound and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

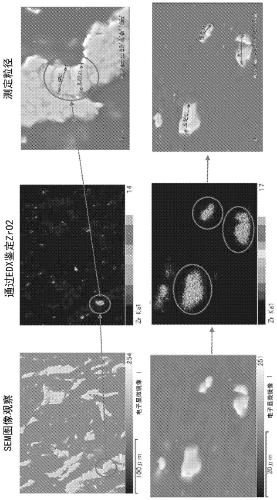

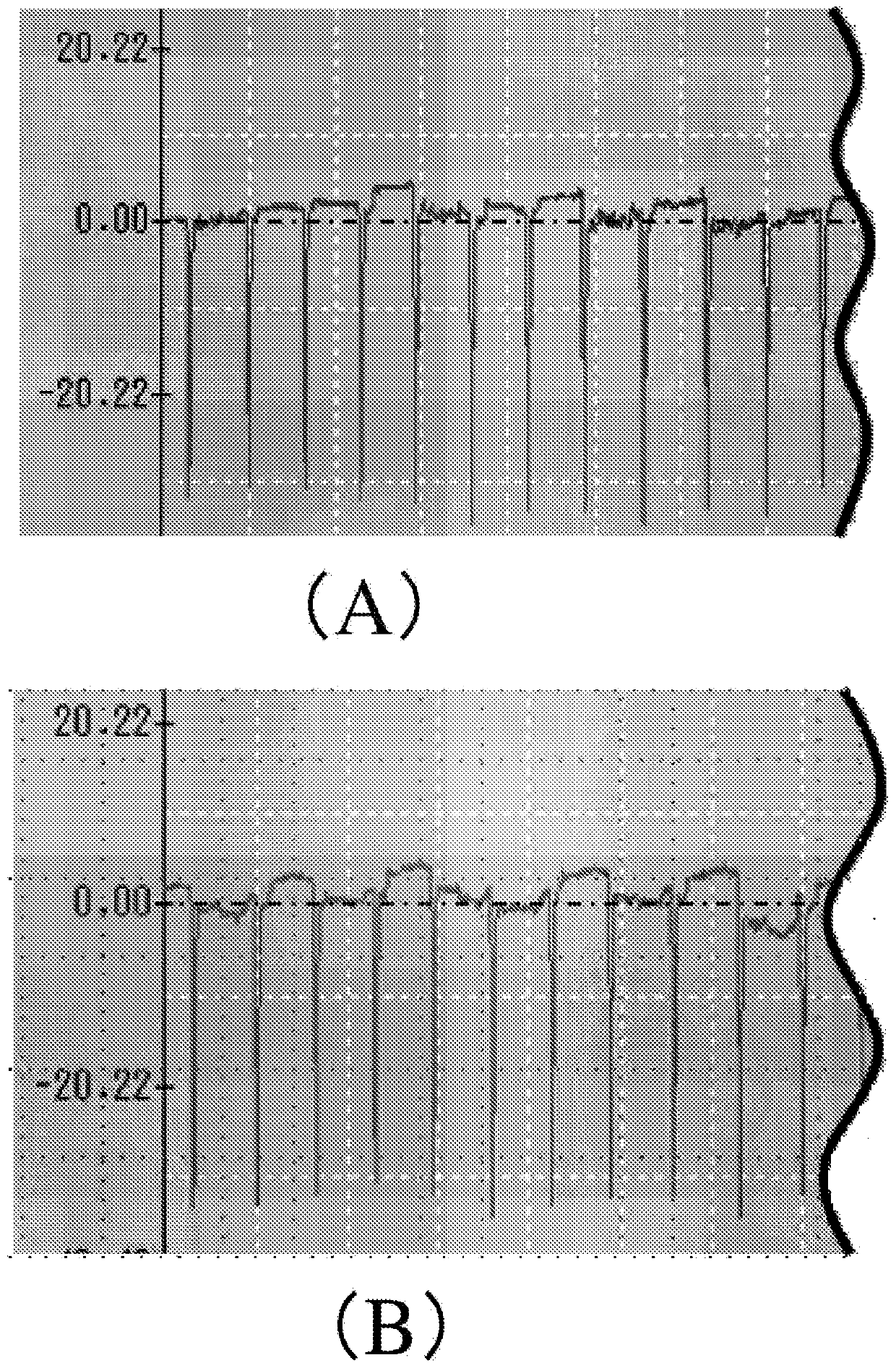

[0024] Flake natural graphite with an average particle size of 50 μm, ZrO 2 (Vickers hardness is 12.3Gpa) and other abrasive materials, solid lubricant MoS 2 (the average particle size is 2.5 μm, the content in the brush is 0.5wt%), and phenolic resin resin binder (the content in the brush is 5wt% in terms of carbon conversion) in the mixer, and pulverized to Make it pass through a 32-mesh sieve to make resin-treated graphite powder. Electrolytic copper powder with an average particle diameter of 30 μm was added to the obtained resin-treated graphite powder, and mixed with a V-type mixer until it became uniform, thereby producing a brush main body material. The obtained material of the brush main body was molded under a pressure of 0.20 MPa, and fired in a predetermined atmosphere to produce a brush for a motor for automotive electrical equipment with lead wires. By firing, the phenolic resin binder is converted into carbon. transform ZrO 2 The average particle size and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com