Grinding roller of roller grinder

A technology for roller mills and rollers, which is applied in the field of roller mills and rollers, can solve the problems of low utilization rate of wear-resistant materials, uneven grinding force, short service life, etc., achieve flexible operation of media, improve crushing efficiency, The effect of a large amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

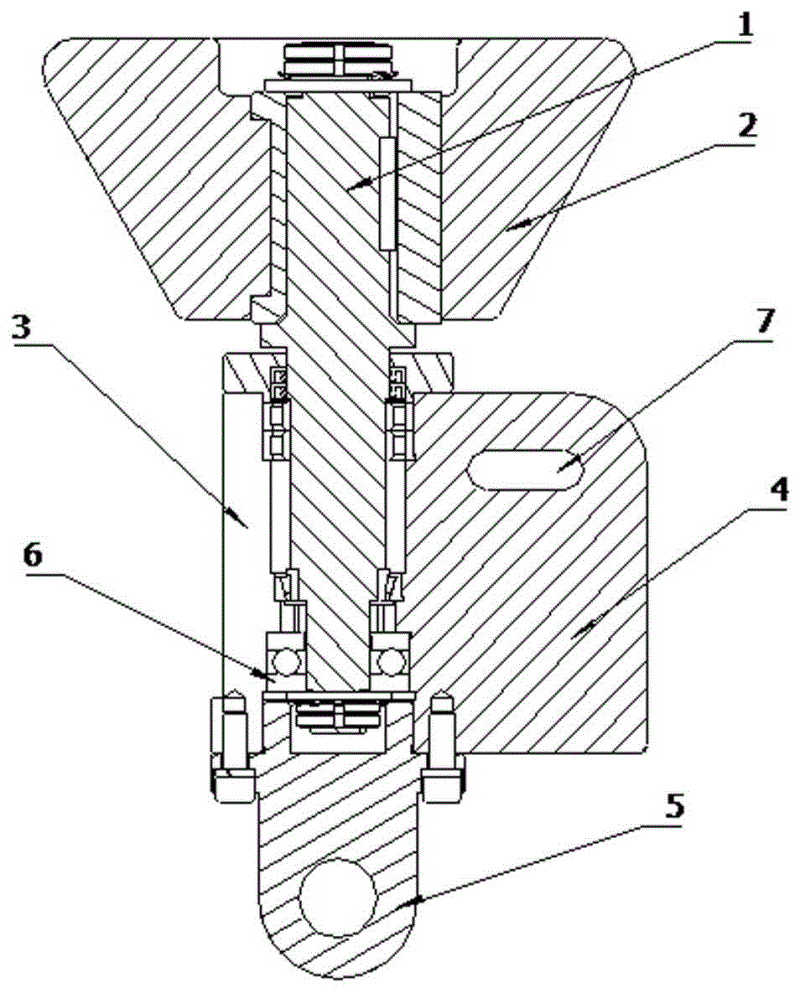

[0010] refer to figure 1 , this embodiment includes a roller shaft 1, a grinding head 2, and a bearing seat 3. The grinding head 2 is fixedly connected to the roller shaft 1, and a twist plate 4 and a swing support sleeve 5 are also provided. The upper part of the swing support sleeve 5 passes through The screw is fixedly connected to the lower end of the bearing seat 3, a bearing 6 is arranged between the bearing seat 3 and the roller shaft 1, and the twist plate 4 is provided with a stop hole 7 for limiting the swing range of the grinding head 2.

[0011] When assembling with the mill turntable, the lower part of the swing support sleeve 5 is connected with the mill turntable (not shown in the figure) through a pin shaft, and the twist plate 4 is inserted into the turntable.

[0012] When working, driven by the turntable of the mill, the grinding head 2 revolves aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com