Drill rod joint with thread profiles

A technology of drill pipe joints and external thread joints, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., to achieve the effects of improving drilling work efficiency, reducing make-up and breakout time, and improving hydraulic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

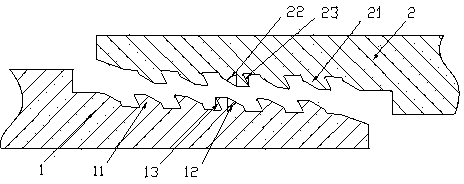

[0014] Such as figure 1 , the invention discloses a drill pipe joint of thread profile, which comprises an externally threaded joint 1 and an internally threaded joint 2, the externally threaded joint 1 and the internally threaded joint 2 have threads with the same taper along the axial direction, and the externally threaded joint 1 Both the thread profile 11 and the thread profile 21 of the internal thread joint 2 are deformed trapezoids, the first flank angle 12 of the thread profile 11 of the external thread joint 1 is 30°-75°, and the second flank angle 13 is 0° ~-30°, thread taper 1:6~1:32, pitch ≥ 6.35mm, first flank angle 22 of internal thread joint 2 thread profile 21 is 30°~75°, second flank angle 23 is 0°~-30°, thread taper 1:6~1:32, pitch ≥6.35mm. The first flank angle 12 of the thread profile 11 of the external thread joint 1 is equal to the first flank angle 22 of the thread profile 21 of the internal thread joint 2, and the second flank angle 13 of the thread pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com