Patents

Literature

72results about How to "Improve hydraulic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

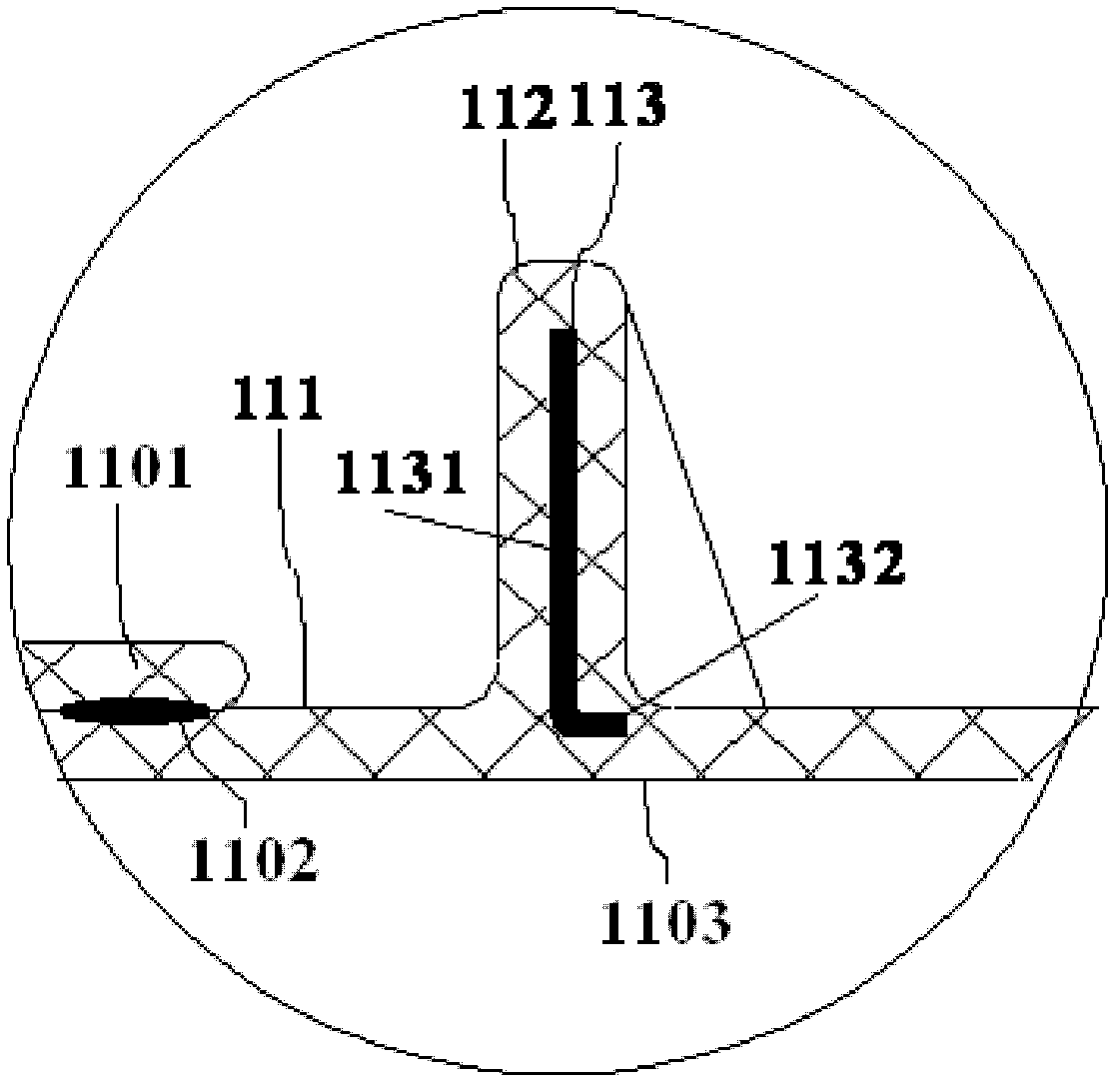

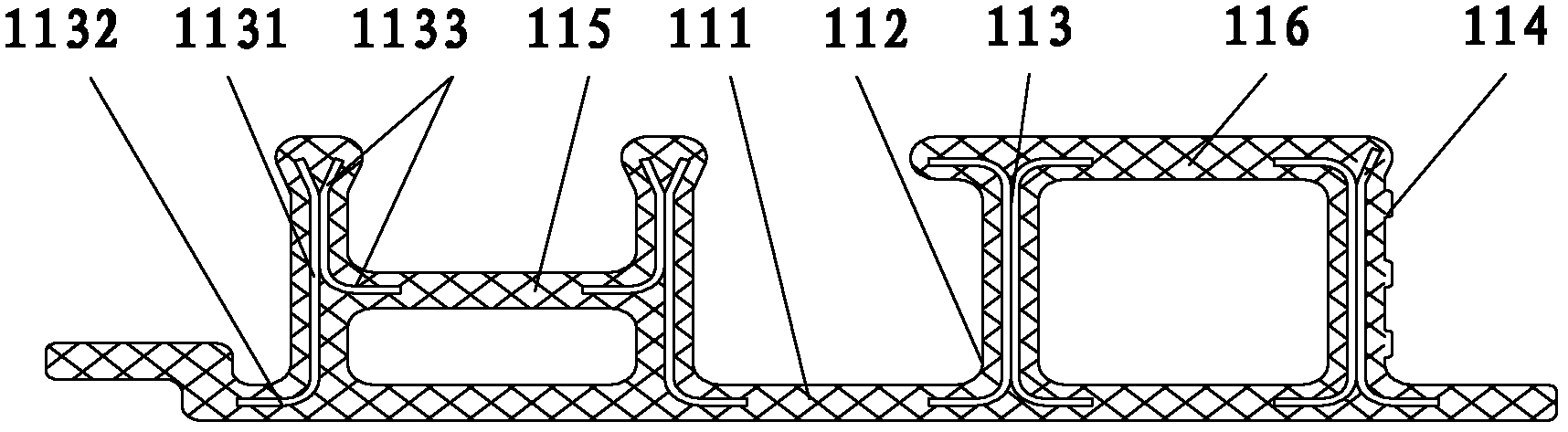

Reinforced thermoplastic composite wall pipe, strip and its complete production equipment

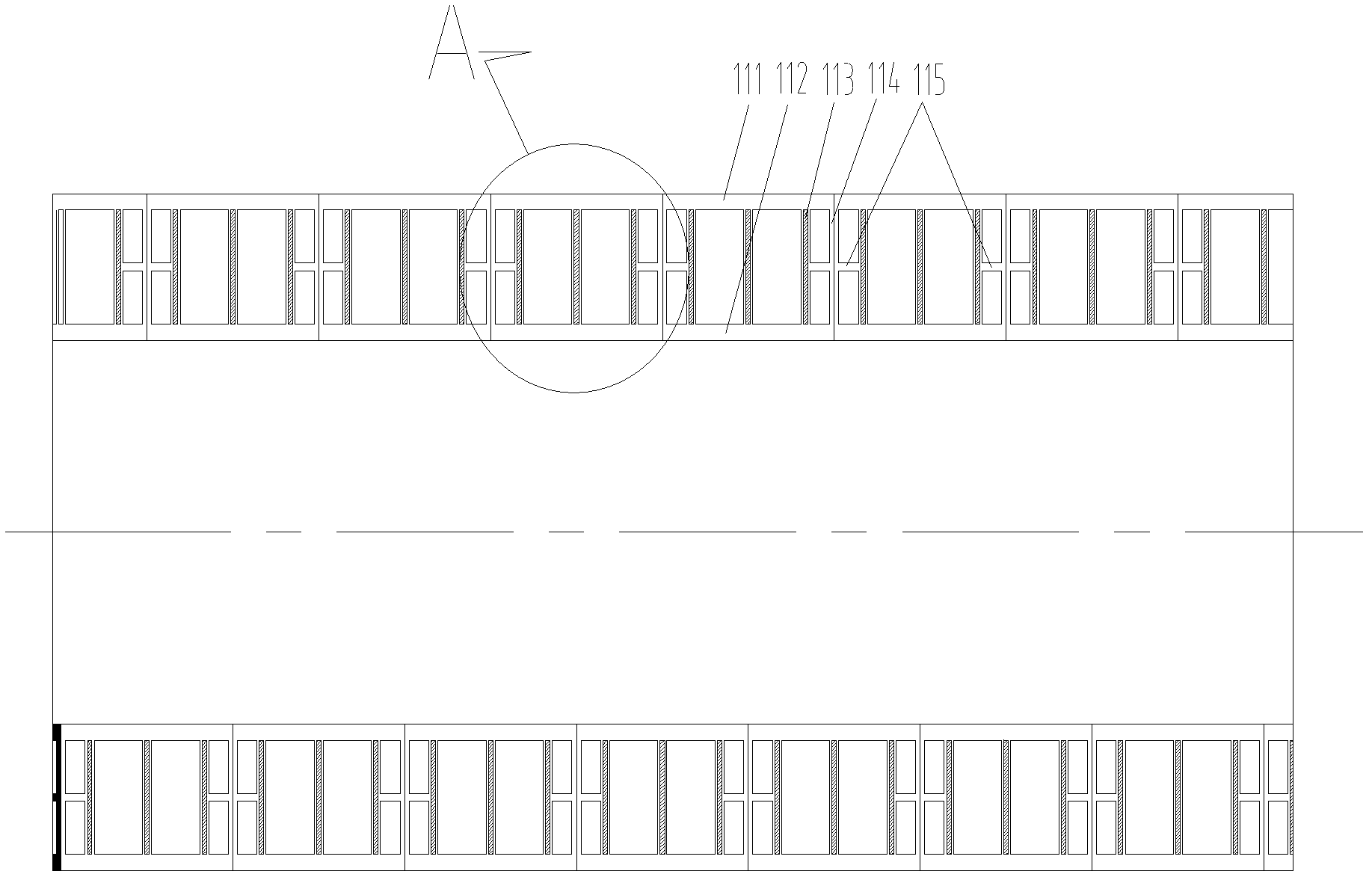

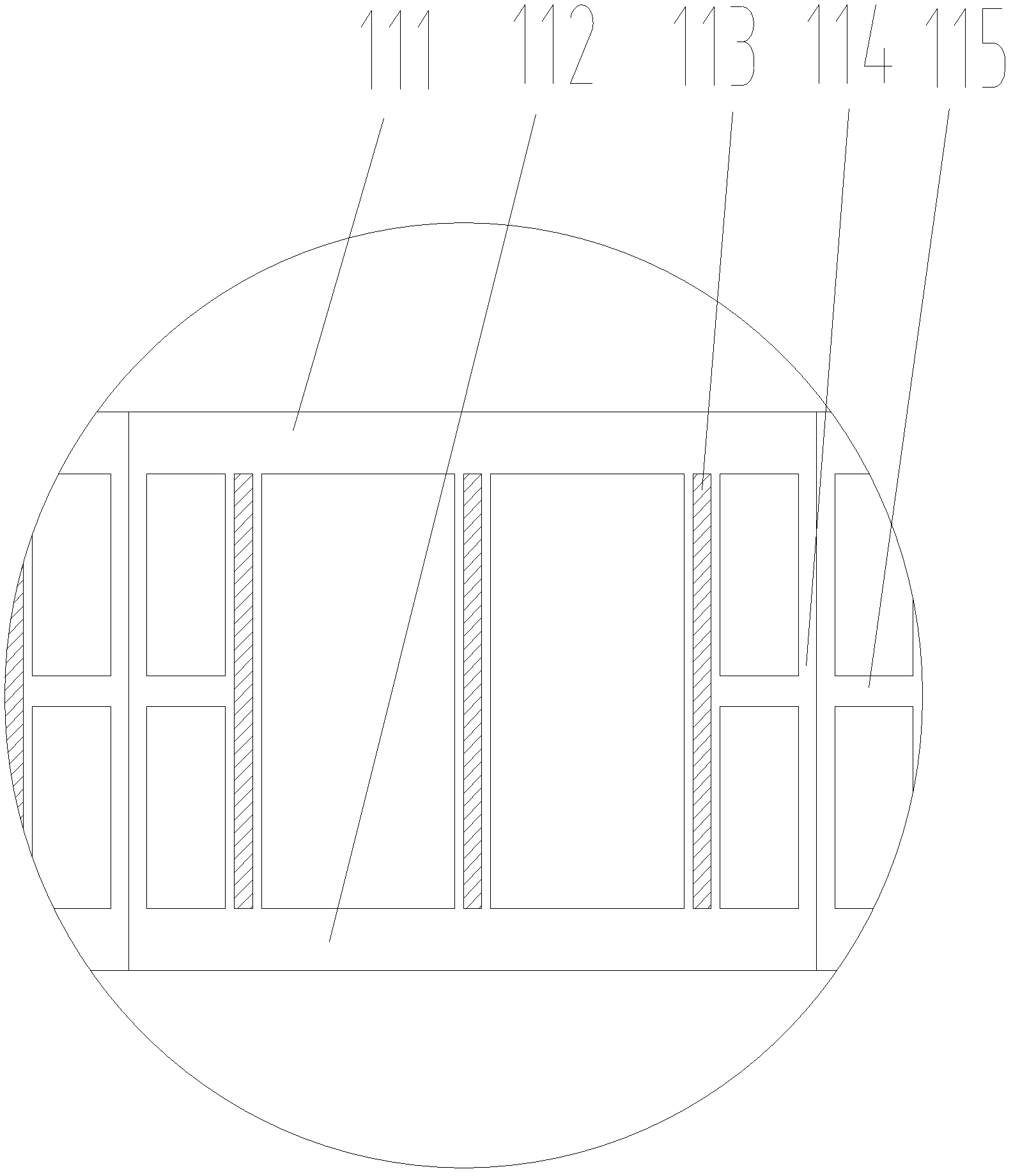

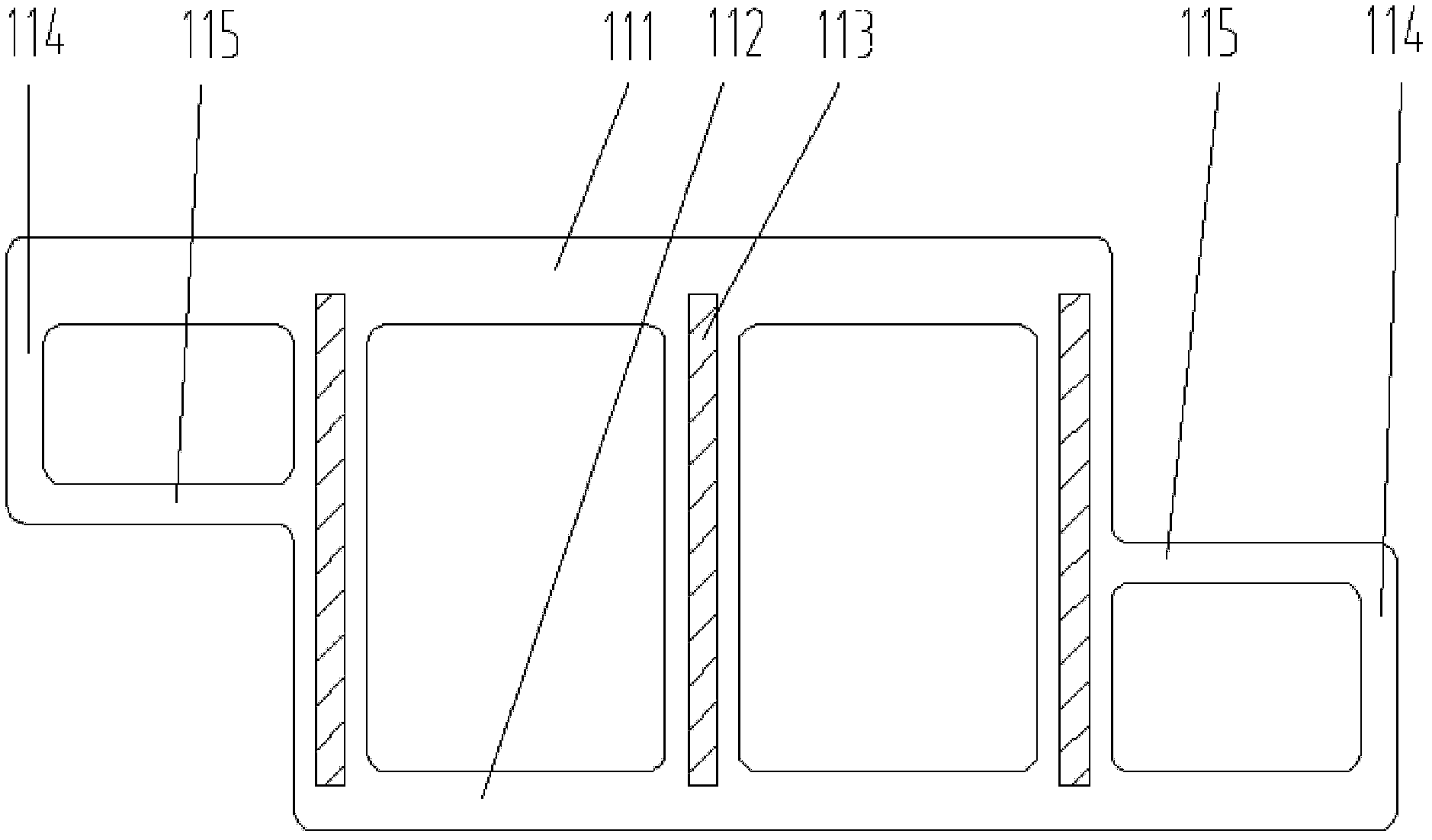

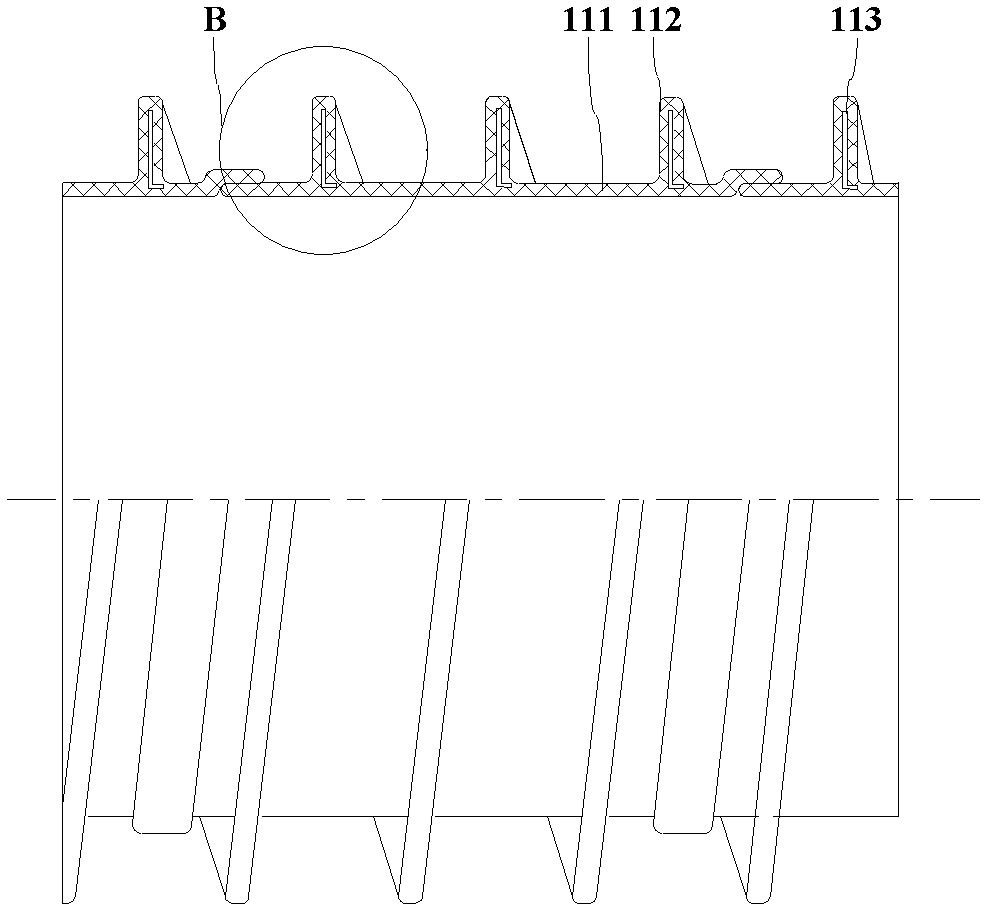

The invention discloses a strip material for a reinforced thermoplastic composite structure wall pipe, which comprises an upper base plate, a lower base plate and at least one reinforcing rib, wherein the reinforcing rib is vertically connected with the upper base plate and the lower base plate into a whole, and a reinforcing sectional material is at least positioned in the reinforcing rib. The composite elastic modulus in a strip material of the reinforced thermoplastic composite structure wall pipe is greater than that of the reinforcing sectional material of a thermoplastic material layer, the ring stiffness of the pipe material can be obviously improved, and in addition, the consumption of raw materials can be obviously reduced. The invention also discloses a pipe material for the reinforced thermoplastic composite structure wall pipe made of a strip material of the reinforced thermoplastic composite structure wall pipe, the pipe material has smooth and flat inner walls and outer walls, and in addition, a plurality of hollow structures are arranged between the inner walls and the outer walls. The invention also discloses a reinforced thermoplastic composite structure wall pipe set production device for producing the pipe material of the reinforced thermoplastic composite structure wall pipe, the production device can synchronously realize the continuous production of the strip material for the reinforced thermoplastic composite structure wall pipe and the pipe material for the reinforced thermoplastic composite structure wall pipe, and the production efficiency is improved.

Owner:华瀚管道系统科技有限公司

Reinforced thermoplastic composite structure wall-pipe pipe workpiece and strip material and complete set of production devices thereof

ActiveCN102305344AReduce consumptionLow costElongated constructional elementsFlexible pipesCompound structureEngineering

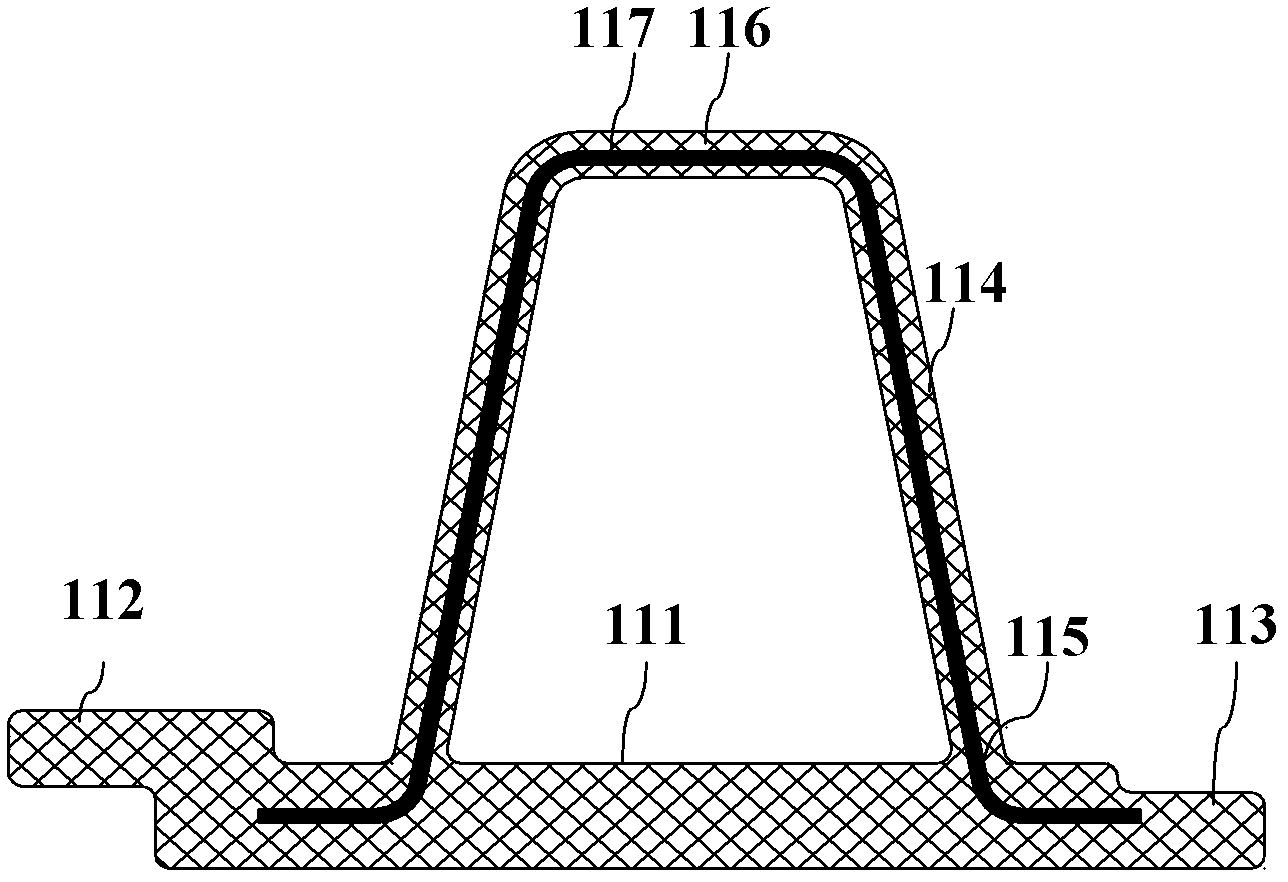

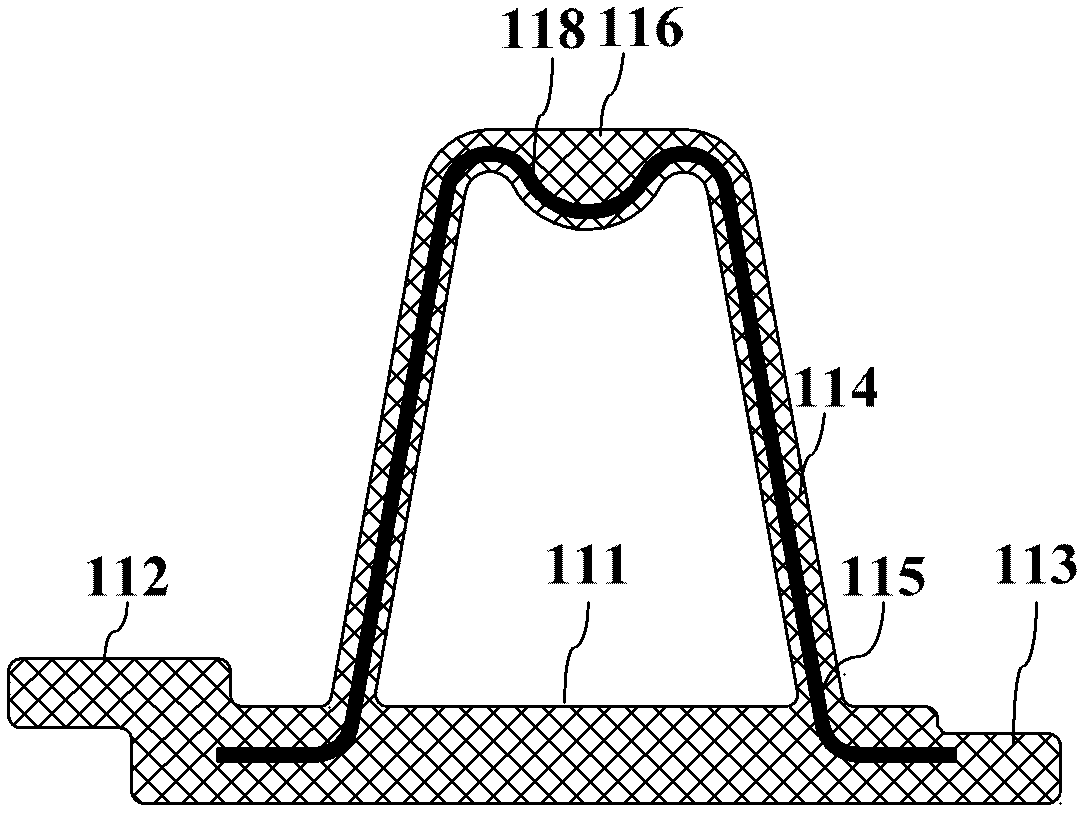

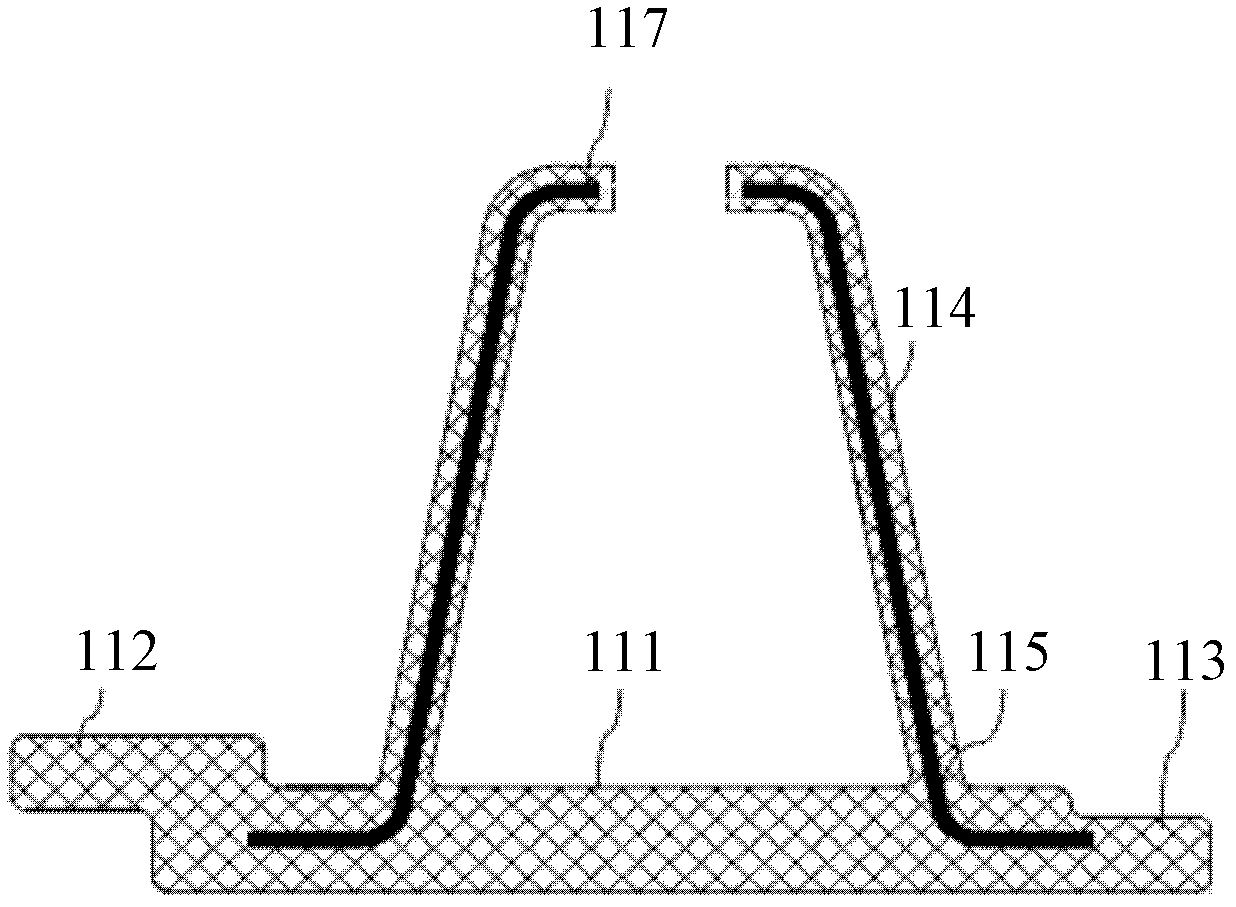

The invention discloses a reinforced thermoplastic composite structure wall-pipe strip material, which comprises a base plate, a reinforcing rib integrated with the base plate, and a reinforcing sectional material integrated with the reinforcing rib or simultaneously integrated with the base plate and the reinforcing rib, wherein the reinforcing sectional material is extruded and compounded with a thermoplastic material layer of the reinforcing rib, or simultaneously extruded and integrated with a thermoplastic material layer of the base plate and the reinforcing rib, and is completely coated by the thermoplastic material layer. The reinforced thermoplastic composite structure wall-pipe strip material can significantly improve the ring stiffness of a pipe workpiece. The invention also discloses a reinforced thermoplastic composite structure wall-pipe pipe workpiece, which is provided with smooth and flat inner walls and spirally surrounding reinforced thermoplastic composite reinforced structure outer walls with separation distances. The invention also discloses a complete set of production devices of reinforced thermoplastic composite structure wall-pipes for producing the reinforced thermoplastic composite structure wall-pipe strip material. By the production device, the continuous production of the reinforced thermoplastic composite structure wall-pipe strip material and the reinforced thermoplastic composite structure wall-pipe pipe workpiece can be synchronously realized and the production efficiency can be improved.

Owner:华瀚管道系统科技有限公司

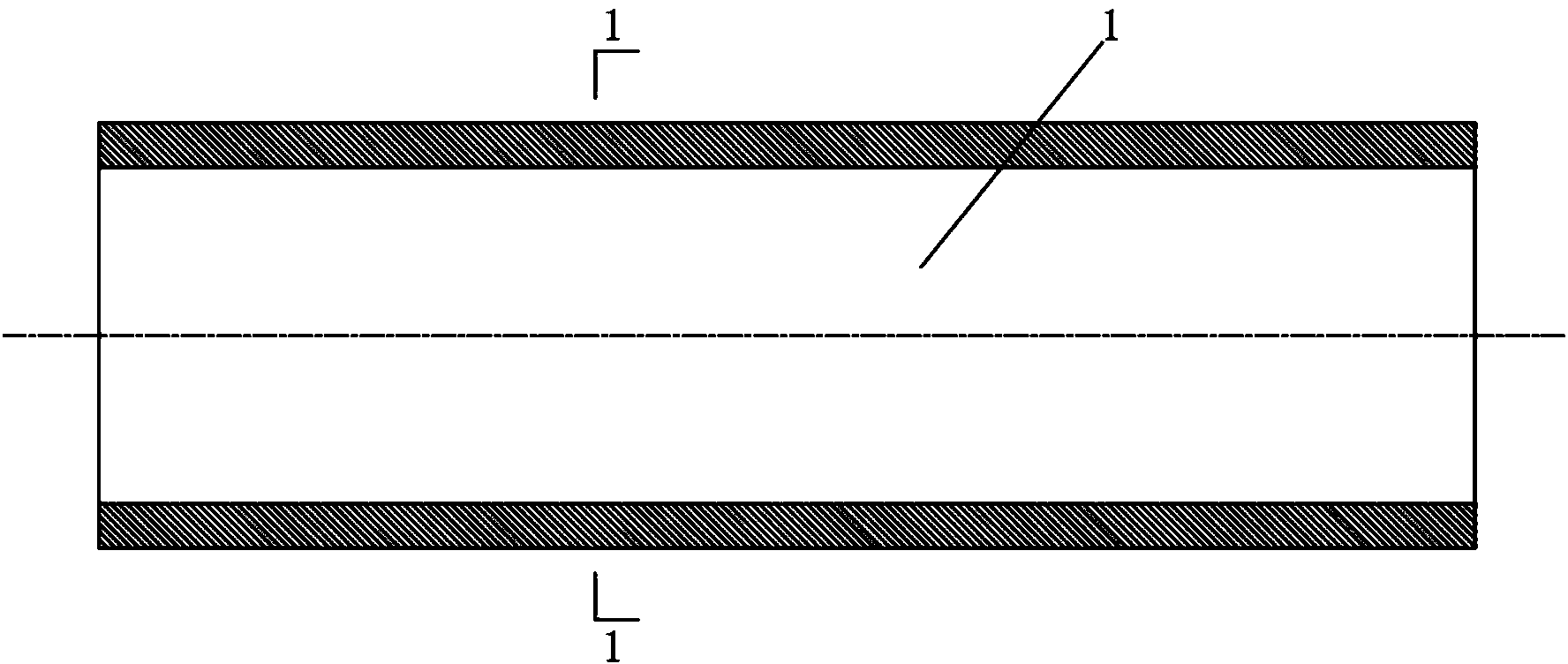

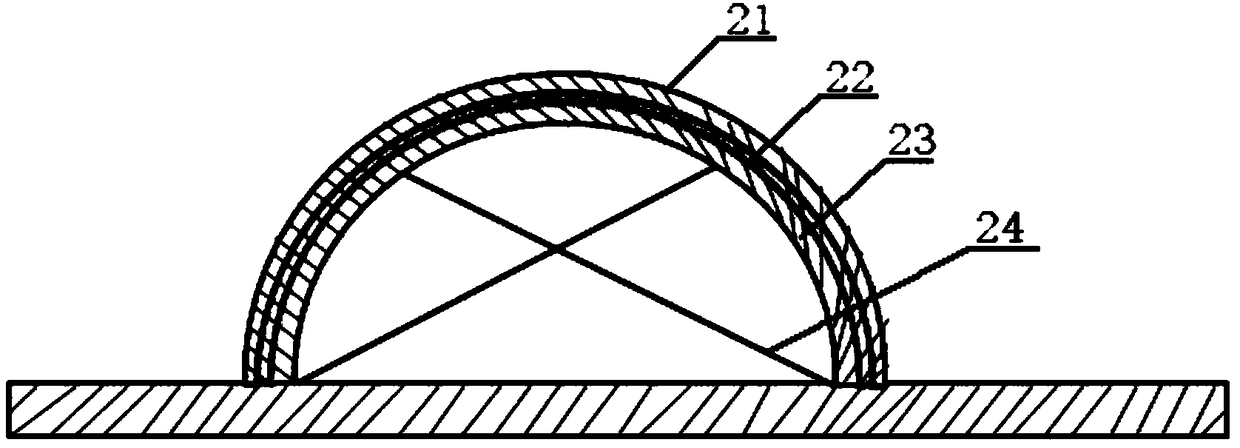

Glass fiber reinforced plastic prestressed concrete cylinder pipe (PCCP) and manufacturing method thereof

InactiveCN103591393AImprove hydraulic propertiesThere will be no pipe explosion accidentsCeramic shaping apparatusRigid pipesCorrosionPre stress

The invention discloses a glass fiber reinforced plastic prestressed concrete cylinder pipe (PCCP) with media inside and outside a pipeline all being corrosive media. The manufacturing method includes the steps that a glass fiber reinforced plastic inside liner is formed by vinyl resin soaked fibers in a winding mode; a vertical type pouring technology is adopted in a resin mortar layer, and quartz sand particles and phthalateunsaturated polyester resin are mixed and stirred and then are poured into a cavity between the glass fiber reinforced plastic inside liner and a steel sleeve to be formed in a vibration molding mode; a concrete structural layer is poured into a cavity between the steel sleeve and a concrete structural layer outer mold by the adoption of the vertical type pouring technology to be formed in a vibration molding mode; a glass fiber reinforced plastic prestressed layer is formed by the way that fiber glass filaments soaked by the phthalate unsaturated polyester resin are manufactured and laid outside the concrete structural layer through a winding technology. Compared with a glass reinforced plastic pipe, the ring stiffness can be improved by 10 times, the cost is lowered by 20%, the rough rate coefficient is 45% smaller than that of a PCCP, and the defects that the stiffness of a fiber reinforced plastic pipe is low, the cost of the fiber reinforced plastic pipe is high, the PCCP can not achieve corrosion resistance, pipe explosion can happen easily and the hydraulic characteristic is poor are overcome.

Owner:WUHAN UNIV OF TECH +1

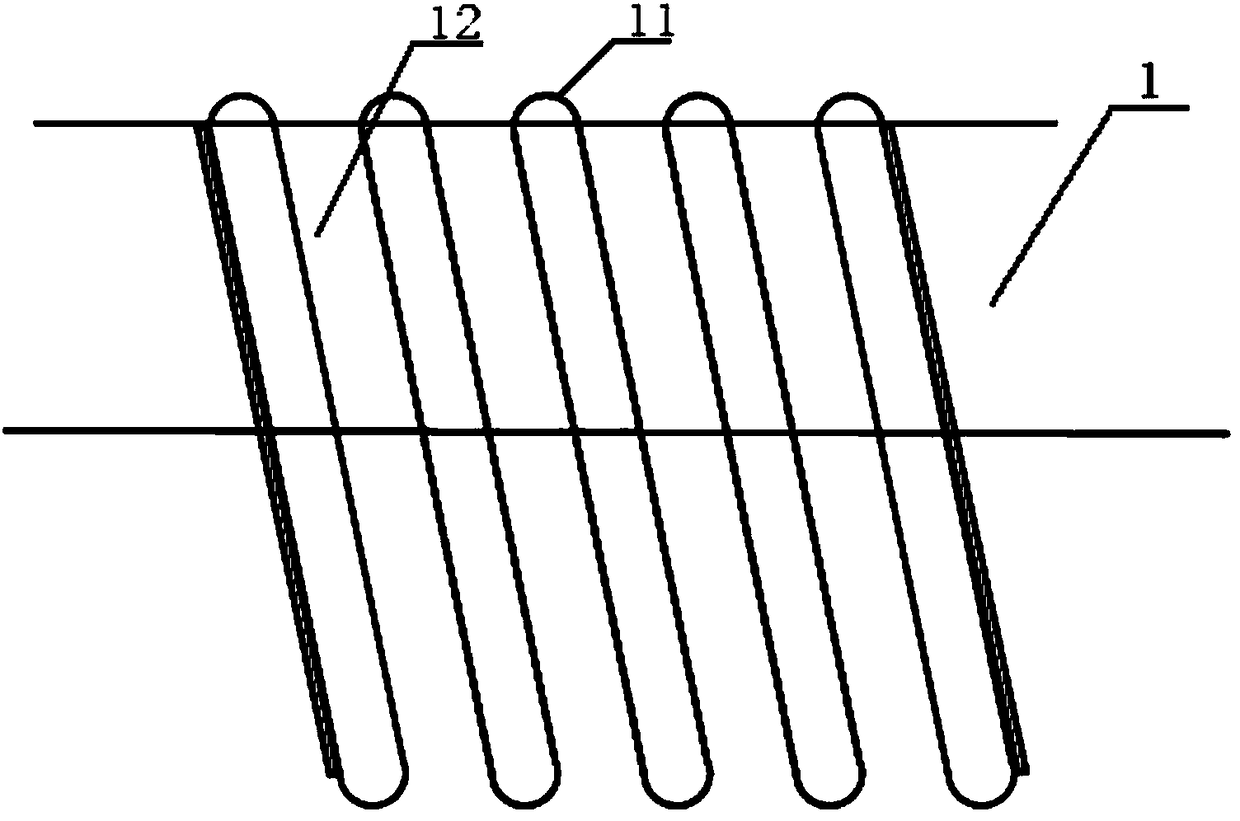

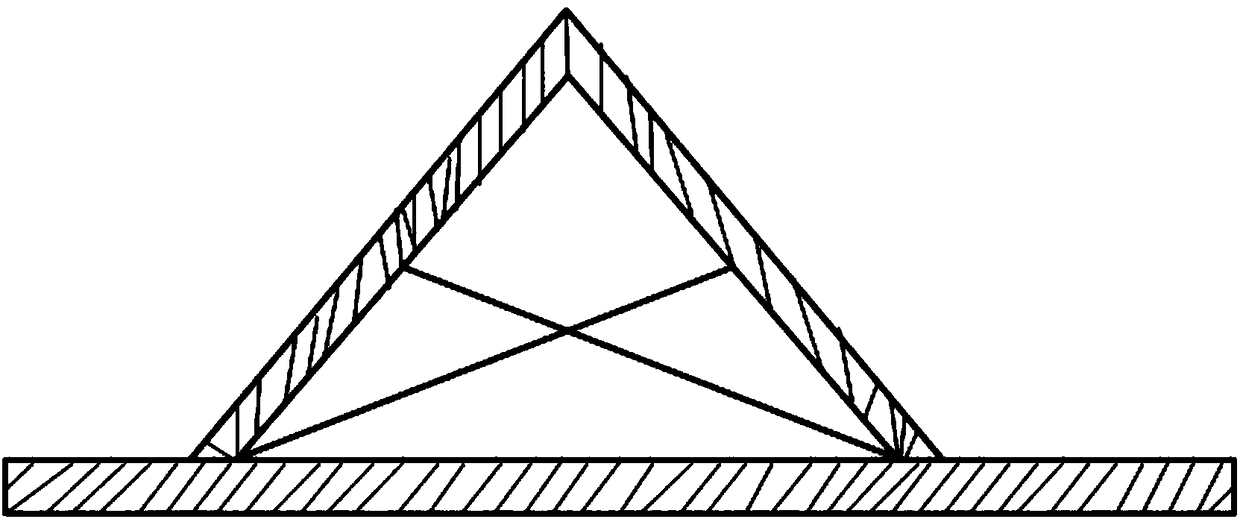

Reinforced thermoplastic composite structure wall pipe and strip and complete-set production device thereof

InactiveCN102322551AReduce consumptionLow costFlexible pipesRigid pipesComposite constructionCross wall

The invention discloses a reinforced thermoplastic composite structure wall pipe strip, which comprises a substrate, at least one corrugated reinforcing rib forming a whole together with the substrate as well as a reinforcing section, wherein the reinforcing section forms a whole together with the corrugated reinforcing rib or forms a whole together with the substrate and the corrugated reinforcing rib simultaneously; the corrugated reinforcing rib is protruded towards the same direction from one side of the substrate and extends along the length direction of the substrate; and the corrugated reinforcing rib consists of two adjacent reinforcing wall boards and a reinforcing cross wall. According to the reinforced thermoplastic composite structure wall pipe strip disclosed by the invention, by using the composite reinforcing section, the ring stiffness of the pipe can be remarkably improved and the consumption of raw materials can be remarkably reduced. The invention also discloses a reinforced thermoplastic composite structure wall pipe adopting the reinforced thermoplastic composite structure wall pipe strip. The reinforced thermoplastic composite structure wall pipe is provided with a smooth and flat inner wall and an outer wall of the reinforced thermoplastic composite structure, which is spirally encircled at intervals. The invention further discloses a reinforced thermoplastic composite structure wall pipe complete-set production device for producing the reinforced thermoplastic composite structure wall pipe, which is used for realizing continuous production and improving the production efficiency.

Owner:SHENZHEN JIN HONG MASCH CO LTD

Quick-speed clarification tank

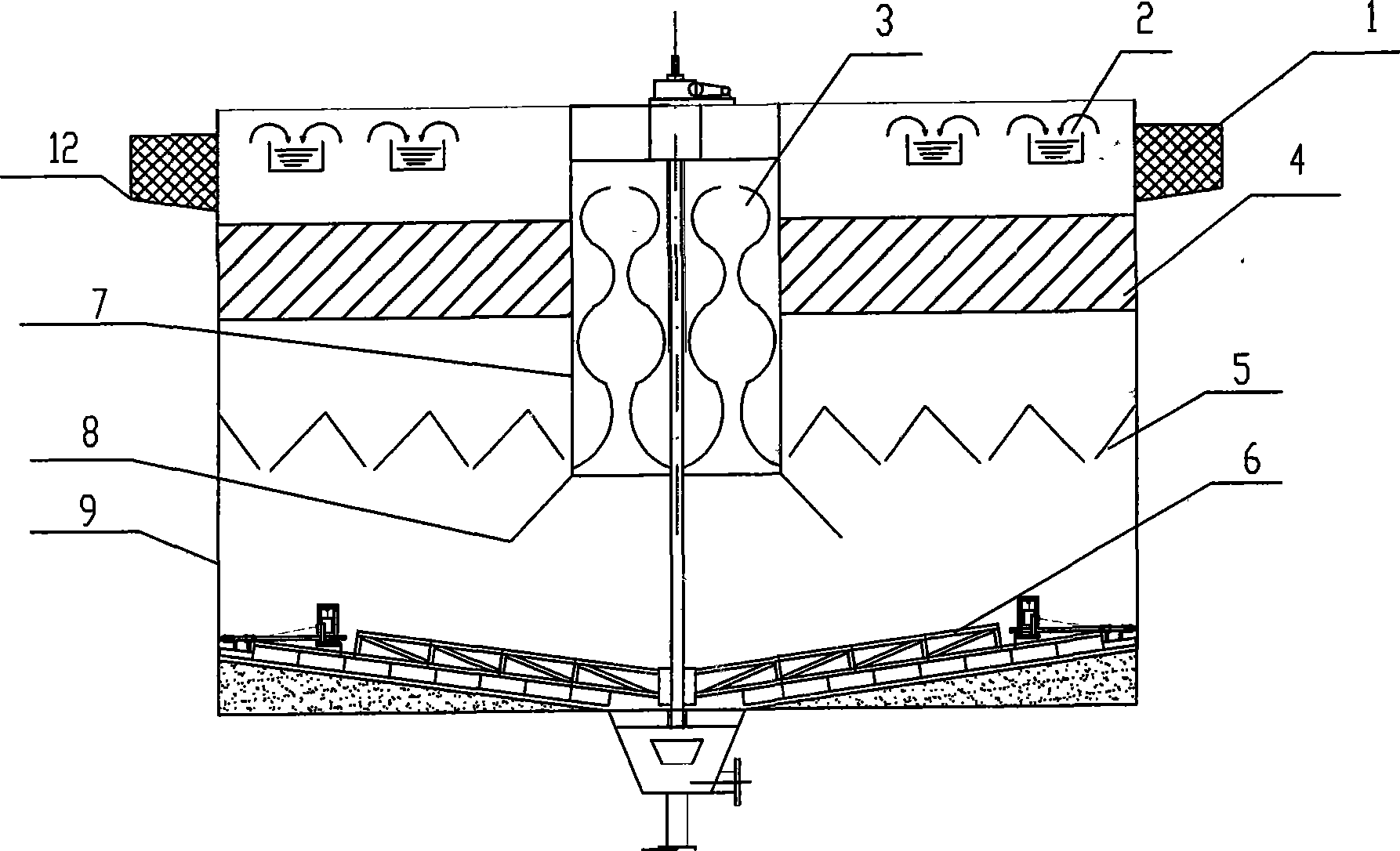

ActiveCN101456614AEasy to separateGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationWater channel

The invention relates to an improvement on a clarification tank, which is characterized in that: a concrete reaction groove is arranged around the upper part of the wall of the clarification tank; a turbulent devices are arranged in the concrete reaction groove at intervals; vertical spaced corrugated boards are arranged in a built-in reaction chamber; a communicated water channel is arranged between the surrounding reaction groove and the concrete reaction chamber; and vortex coagulation reaction devices with a herringbone or reverse W-shaped structure are arranged at the middle lower part of the clarification tank at intervals. The improved clarification tank well solves the contradiction between full flocculation and land occupation and a plurality of times of mud and water separation due to the fact that the sedimentation, clarification and contacting sedimentation are completed in one tank. An outstanding characteristic of the improved clarification tank is fully improving coagulation and flocculation reaction effects and clarification and separation effects without increasing land occupation, so the clarification tank can realize quick clarification, strong processing capacity, land occupation processing capacity maximization, high-quality effluent and strong impact-resistant and loading capacity.

Owner:JIANGSU NEW EPOCH ENVIRONMENTAL PROTECTION

Super large pore ball shaped cellulose fixed tannin adsorbent and its preparation method and application

InactiveCN1657157ASimple and safe operationMild conditionsOther chemical processesAlcoholic beverage preparationChemistryChromatography column

Owner:EAST CHINA UNIV OF SCI & TECH +1

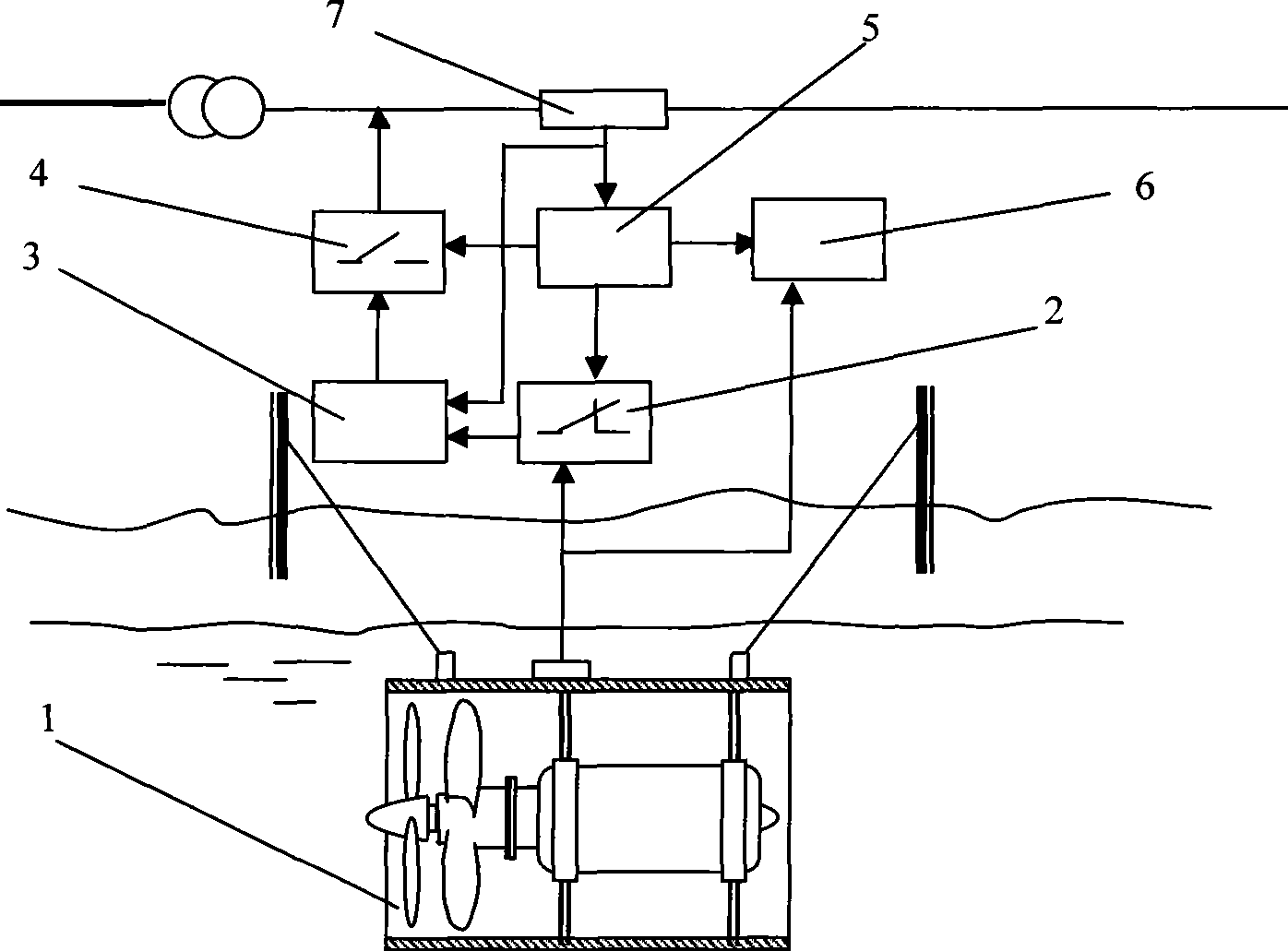

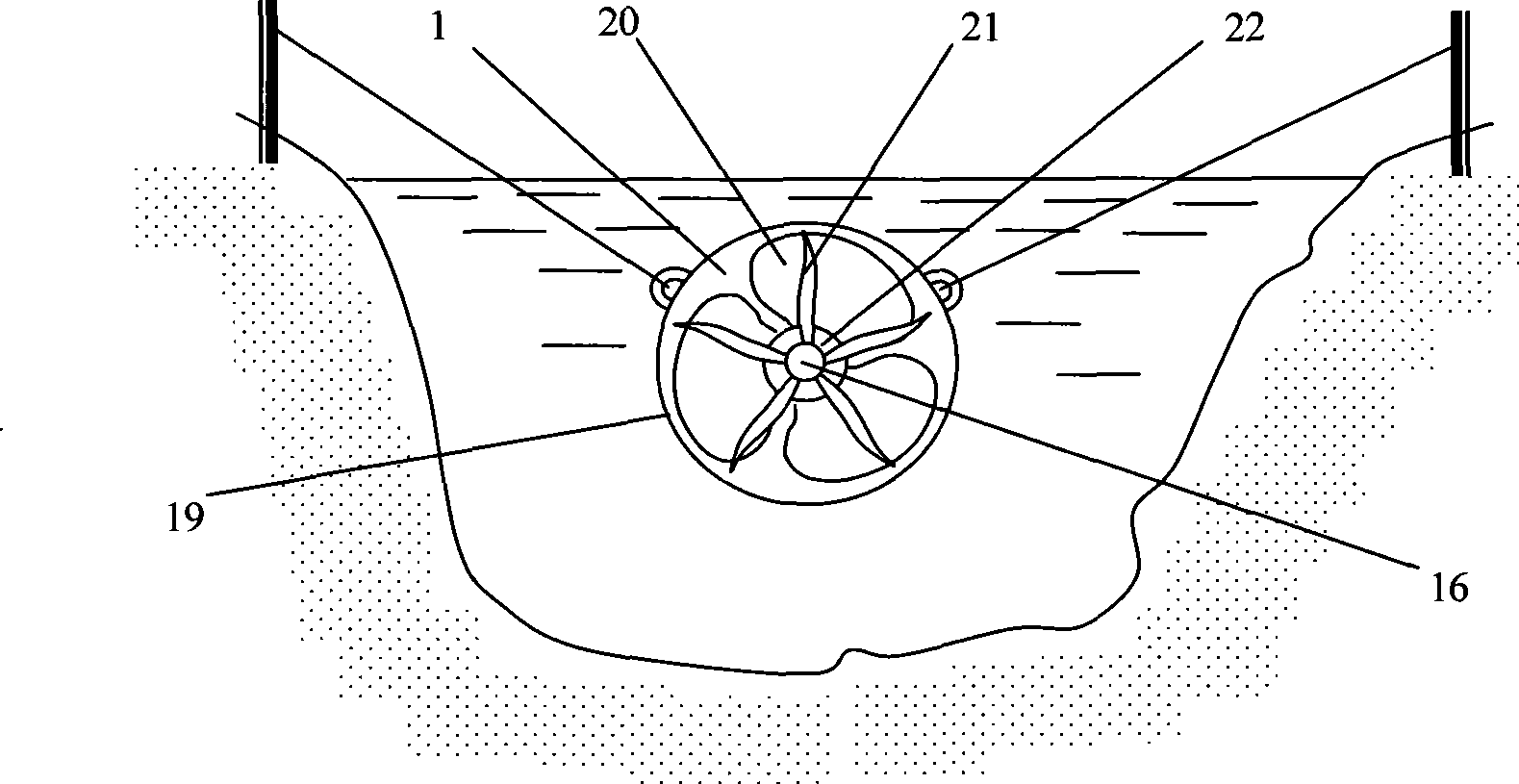

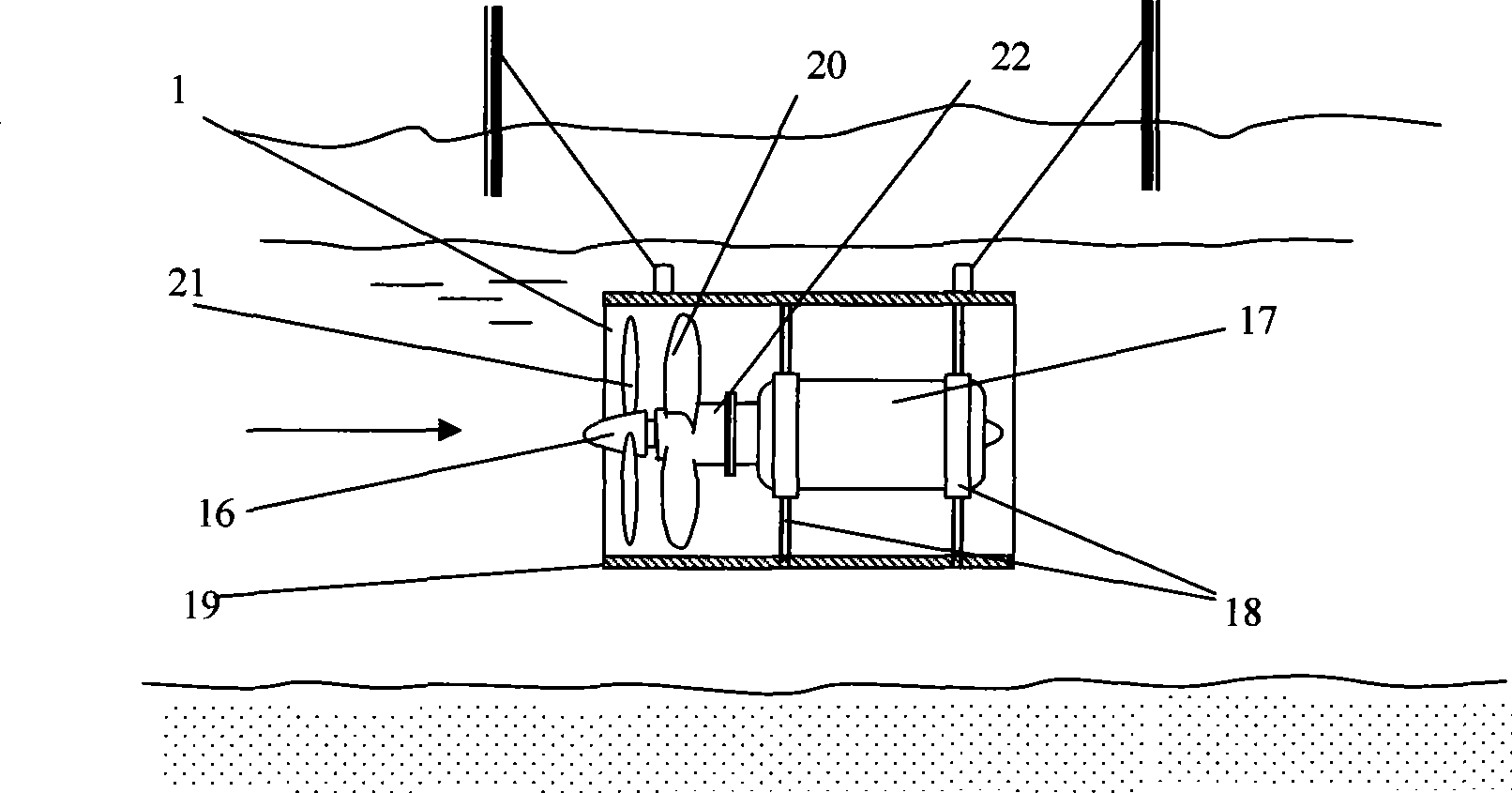

Free style electric generating apparatus of river water stream

InactiveCN101413472AOvercome Radial VibrationImprove conversion efficiencyClimate change adaptationSingle network parallel feeding arrangementsWater turbineEngineering

The invention relates to a free type power generating unit for river flow, which belongs to the technical field of renewable energy source power generation. The generating unit comprises a propeller hydroelectric generating set, a motor output connector, an inverter, an inverter output connector, an auxiliary circuit module, a damping load and an electric power parameter sensing module. The river flow flows into from a prepositive propeller of the propeller hydroelectric generating set, sequentially passes through a main propeller and a hydraulic generator, and flows out from the rear end of a cylindrical shell. The main propeller converts hydraulic energy into rotative moments of the main propeller and a rotating main shaft under effective push of water flow, and the main propeller drives a rotor of the hydraulic generator to rotate; a three-phase alternating current electric power is formed at an output interface and is outputted; and the three-phase alternating current electric power is transmitted to the inverter for realizing synchronical following of electric power parameters outputted by the hydraulic generator with electric fence parameters and controlling the operation of the device under the decision of the auxiliary circuit module. The generating unit improves converting efficiency of hydraulic energy, and realizes the limitation on extra-high rotating speed of a propeller hydraulic generator.

Owner:SHANGHAI JIAO TONG UNIV

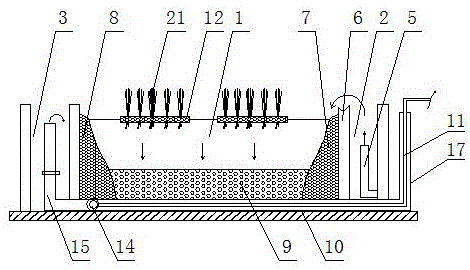

Culture tail water recycling aquatic rice farming method

ActiveCN106630385AHigh volume loadIncrease hydraulic loadWater treatment parameter controlWater contaminantsBiological filterWater quality

The invention relates to a culture tail water recycling aquatic rice farming method, and belongs to the technical field of the treatment of culture wastewater. According to the culture tail water recycling aquatic rice farming method, wastewater from a culture pond is purified through a water-collecting well, a filter tank and a modifying pool, and then is reused again; the wastewater in a purification process can be used for carrying out the plantation of paddy rice; a solid particle in the wastewater is adsorbed and intercepted through a developed root system of the paddy rice; an aerobiotic / anoxic zone is formed at a root segment of the paddy rice to promote the reaction processes of nitrification and denitrification; by using the culture tail water recycling aquatic rice farming method, the characteristics that an aerated biological filter tank is high in the volumetric load of an organic matter, high in hydraulic load and short in hydraulic retention time, and the like, are combined; the investment, running and maintenance costs are relatively reduced; the purification effect on the wastewater is improved. According to the culture tail water recycling aquatic rice farming method, through introducing the wastewater from the culture pond into a planting tank, not only is the water quality purified, but also a nutrient substance is provided for the growth of the paddy rice in the planting tank at the same time; the purification of the water quality and the plantation of a commercial crop are organically combined together; the mutualism relation among different organisms is realized; the nutrient substance is circulated.

Owner:双鱼(武汉)水生态科技有限公司 +1

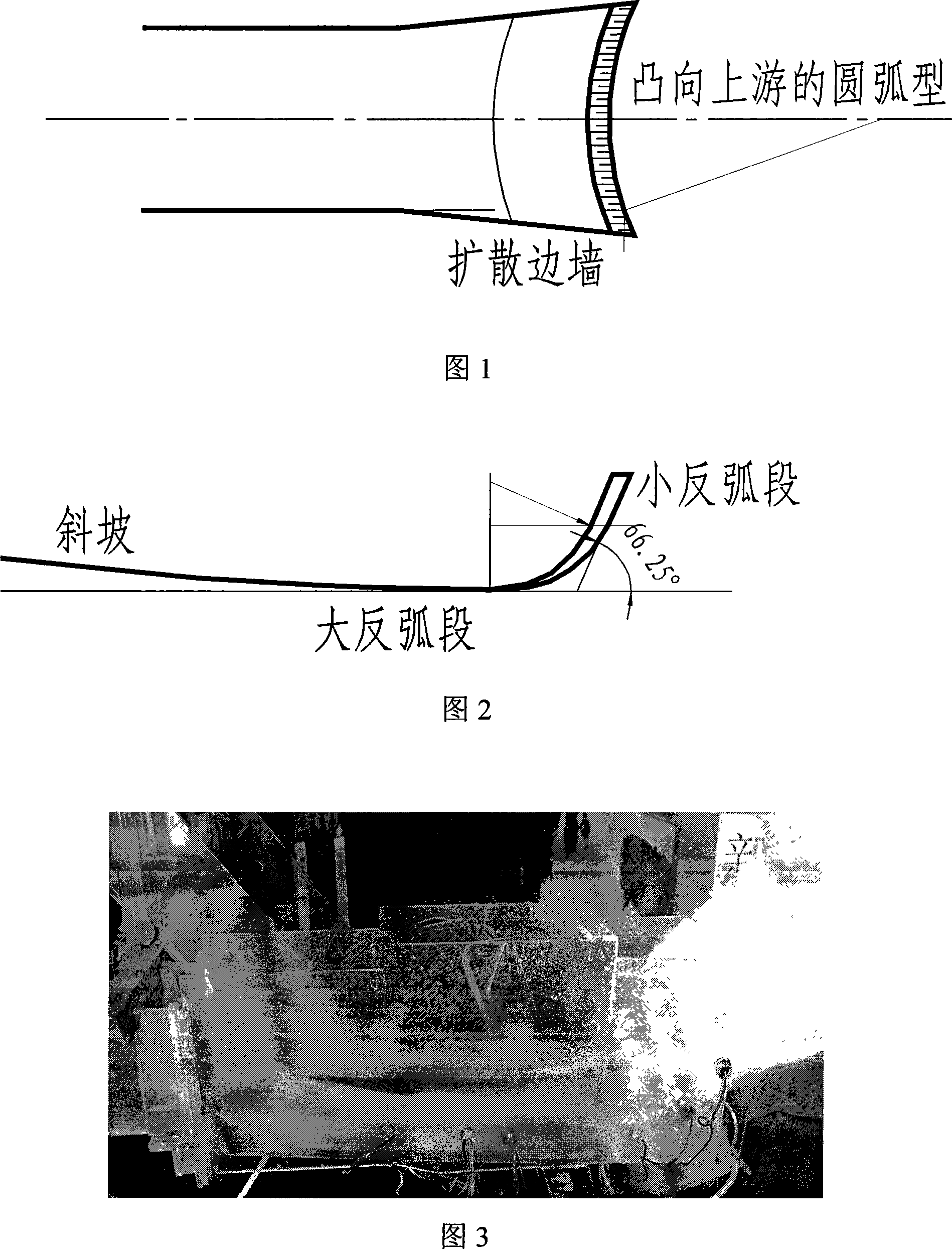

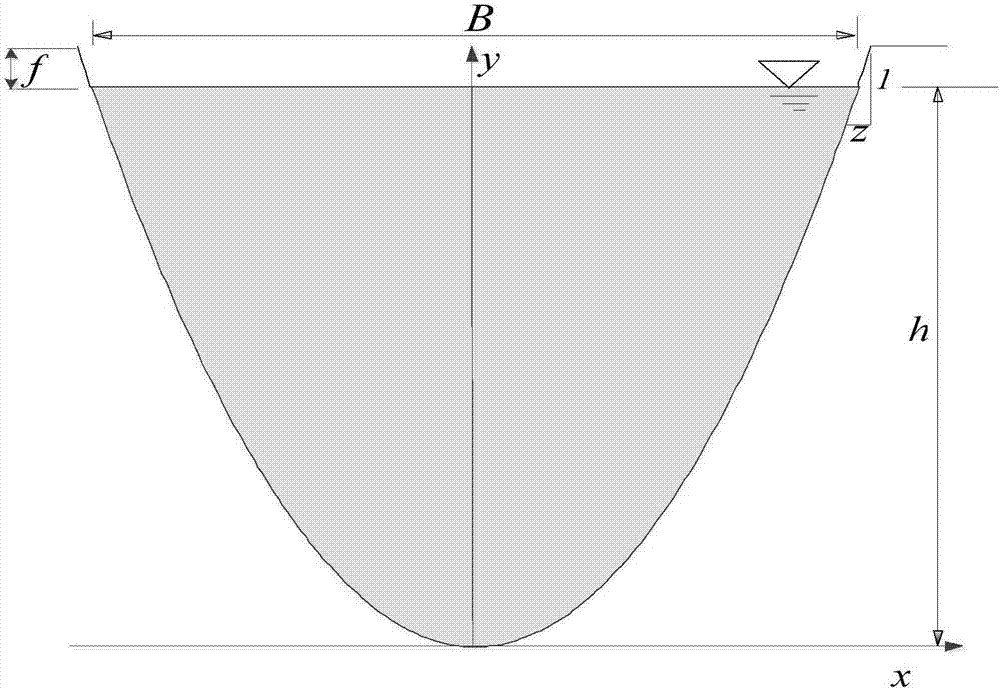

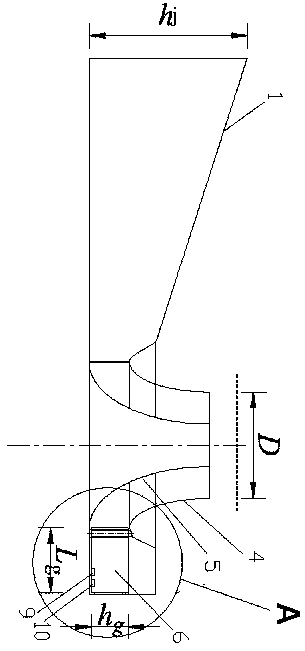

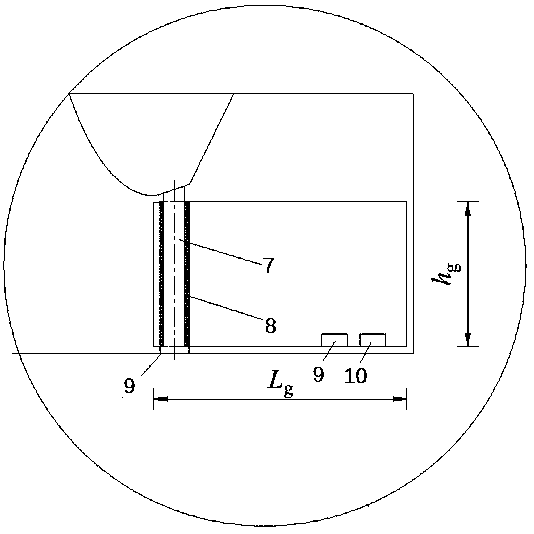

Diffusion type curve trajectory bucket

InactiveCN101100849AImprove hydraulic propertiesReduce washoutBarrages/weirsEngineeringCavitation erosion

This is a novel outstretch curve bucket lip for drain hole. A reverse arc curve of bigger diameter is connected to the slop of a pressure drain hole with the slop tangent to the curve. Another reverse arc curve of smaller diameter is then tangent to the previous curve. Drained water is heaved up after the curves of an angle 66.25 deg.. The traditional bucket lip is of a rectangle outlet, while the novel one is of an outstretching angle o f6-8 deg. at 5-8 meters from the outlet. With the novel design, water diffusion is enhanced as well as avoiding cavitation erosion and decreasing drained water speed.

Owner:DALIAN UNIV OF TECH

Hydrogenation and deoxidization method for palladium ion type catalytic resin

InactiveCN1699195AWide temperature rangeQuick responseWater/sewage treatment by degassingStrong acidsCatalytic effect

The invention discloses a hydrogenation and deoxidization method for palladium ion type catalytic resin, which comprises dissolving palladium chloride in distilled water, agitating homogeneously, passing palladium chloride solution through contacting tower containing strong acid type cationic ion-exchange resin, rinsing with water, drying at room temperature, letting hydrogen gas into resin for reduction, letting water with dissolved oxygen from the top of the packed column, sprinkling onto the whole cross-section homogeneously through a liquid distribution apparatus, lifting the water with dissolved hydrogen gas with a pump, injecting into a contacting tower incorporating palladium ion type catalytic resin, and passing water through palladium ion type catalytic resin.

Owner:HARBIN INST OF TECH

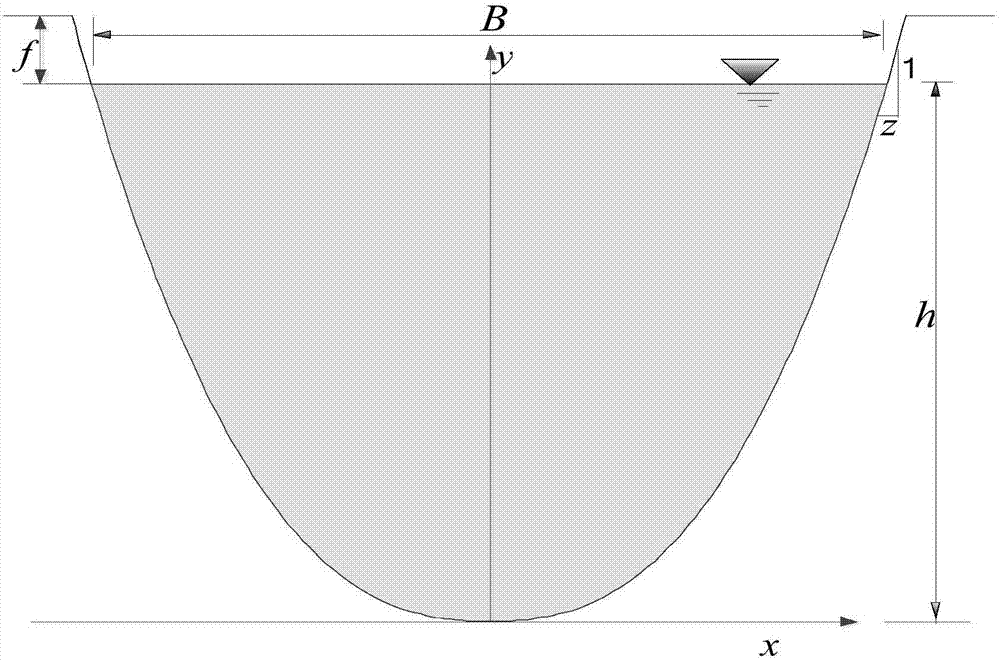

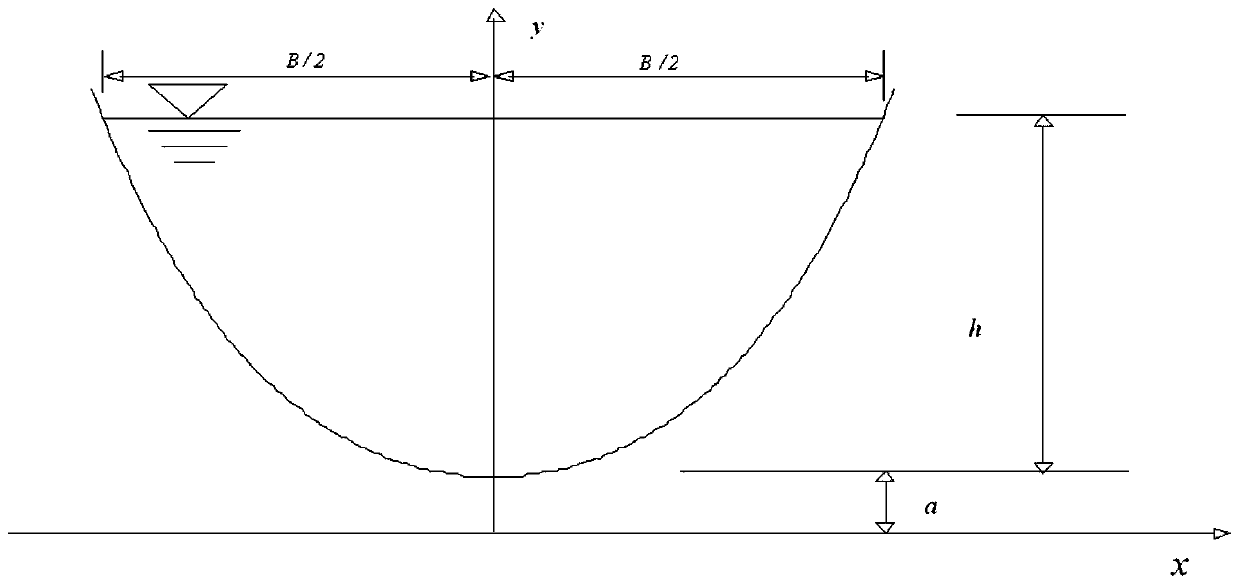

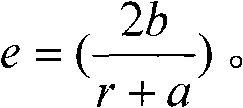

5/2 power parabola-shaped open channel and waterpower optimum section thereof

ActiveCN107958095AImprove hydraulic propertiesIncrease construction costsGeometric CADIrrigation ditchesCarrying capacityWater depth

The invention discloses a 5 / 2 power parabola-shaped open channel. A channel section shape of the open channel is a 5 / 2 power parabola shape and the opening of the open channel is upwards; a curve expression of a section of the 5 / 2 power parabola-shaped open channel is a formula (as shown in the specification), wherein the shape coefficient a is a formula (as shown in the specification), h is a water depth and B is a water surface width; an area of a water-carrying section of the channel is a formula (as shown in the specification); a wetted perimeter of the channel is a formula (as shown in the specification); and an optimum width to depth ratio of an optimum section of the open channel is a formula (as shown in the specification), wherein the shape coefficient a is a formula (as shown inthe specification), the normal water depth h is a formula (as shown in the specification), the critical water depth hc is a formula (as shown in the specification), the open area A is equal to 1.4916h2 and the wetted perimeter P is equal to 3.09633h. The 5 / 2 power parabola-shaped open channel is not only capable of improving the hydraulic characteristics of parabola-shaped sections, but also capable of improving the water carrying capacity.

Owner:UNIV OF JINAN

Two-stage method of applying white rot fungus to degrade hard-to-degrade environment pollutant

InactiveCN1608755AReduce energy consumptionReduce refill costsSolid waste disposalBiotechnologyPollution

The present invention is two-stage method of applying white rot fungus to degrade hard-to-degrade environment pollutant, and belongs to the field of environmental pollutant treating technology. Based on the research of the biochemical characteristic of white rot fungus, the present invention proposes intermittent running mode including two separated stages of growth and degradation. The present invention adopts high temperature culture and normal temperature degradation, agricultural waste corn cob and timber as nutrients source, high nutrients concentration for growth and low nutrients concentration for degradation and natural ventilation in growth stage, and thus has low power consumption and low cost. Adding carrier can maintain higher exocellular enzyme concentration, speed reaction, maintain higher decolorizing efficiency and separate mud from water. The present invention has good oxygen supply, good hydraulics characteristic and high hetero bacteria pollution resistance.

Owner:TSINGHUA UNIV

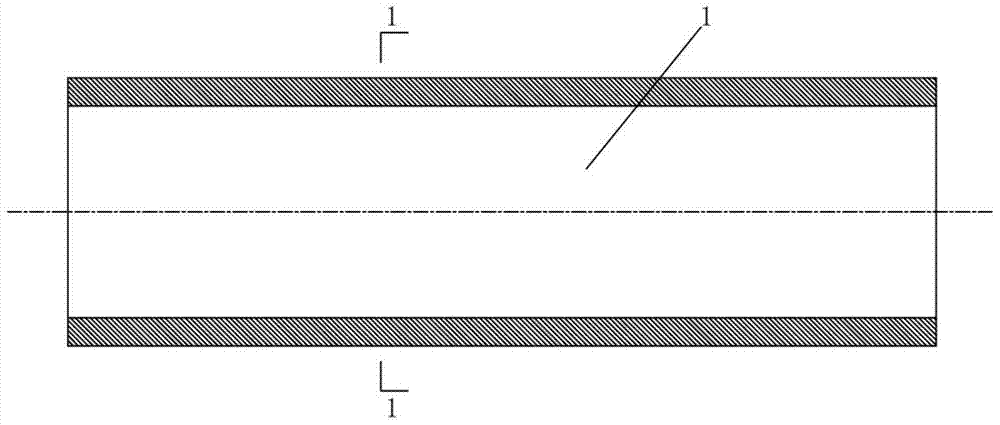

Inner rib reinforced polyethylene spiral corrugated pipe and joint connecting method thereof

PendingCN108253199AStable structureSufficient ring stiffnessPipe connection arrangementsRigid pipesEngineeringSmelting

The invention provides an inner rib reinforced polyethylene spiral corrugated pipe and a joint connecting method thereof. The spiral corrugated pipe comprises a corrugated pipe body. The corrugated pipe body comprises a spiral corrugation and a pipe body. The spiral corrugation structurally comprises an outer polyethylene layer, a glass fiber reinforced layer and an inner polyethylene layer from outside to inside in sequence, wherein a hollow cavity is formed in the spiral corrugation; and reinforcement inner ribs are arranged in the hollow cavity. The construction method comprises the following steps that firstly, a corrugated pipe joint is cleaned to make sure that the end face of the joint is flat; secondly, the corrugated pipe joint is connected through an electric smelting band; and thirdly, a shrinkage pipe and / or a hoop is used for reinforcement construction of the joint. The inner ribs are additionally arranged in the corrugation of the corrugated pipe, in addition, the invention provides the fusion type joint connecting method, the ring stiffness of the corrugated pipe can be effectively improved, and the section positions are stable in structure and not prone to being broken.

Owner:江苏桓通环境科技有限公司

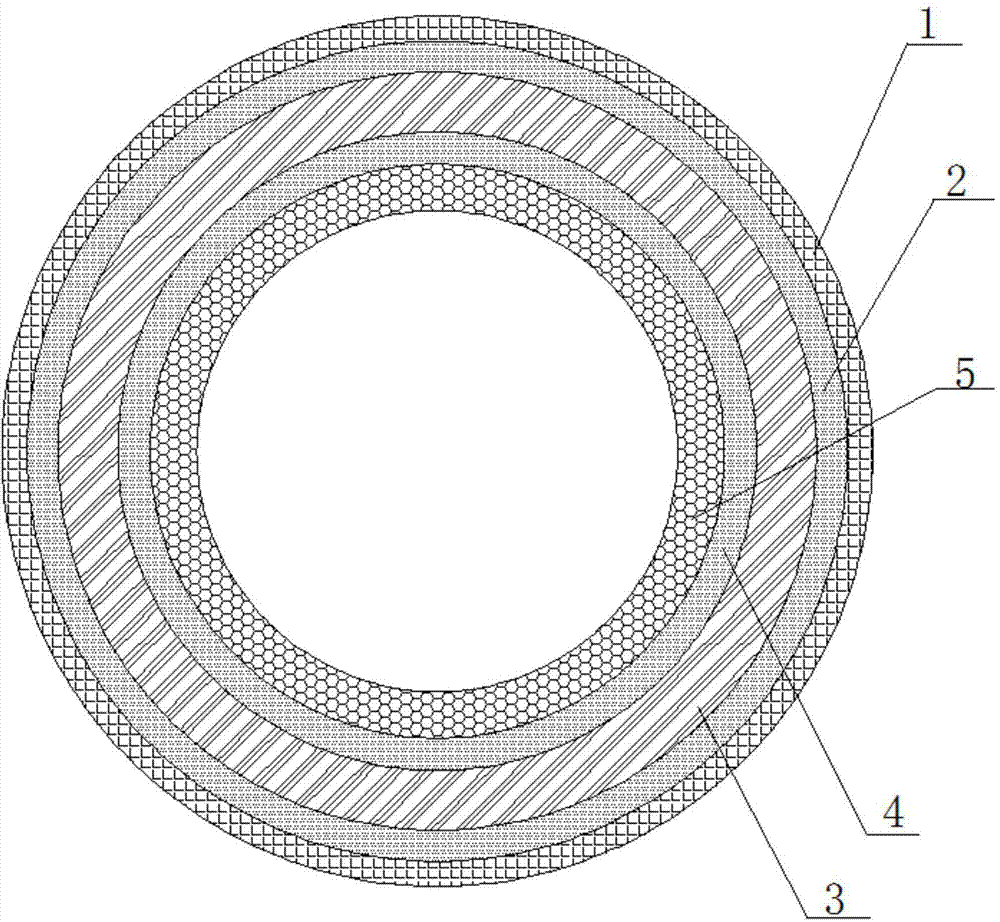

Glass fiber-reinforced plastic polyurethane TPU composite tube and manufacturing process thereof

InactiveCN104847977AExtended service lifeReduced operating and maintenance costsThermal insulationFlexible pipesPolyesterCorrosion resistant

The invention discloses a glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube comprises an outer protective layer, an outer reinforcing layer, a sand inclusion structure layer, an inner reinforcing layer and a lining layer which are sequentially arranged from outside to inside, wherein the outer protective layer is a composite layer with quartz sand and unsaturated polyester resin, the outer reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, the sand inclusion structure layer is a composite layer with quartz sand, glass fibers and unsaturated polyester resin, the inner reinforcing layer is a composite layer with glass fibers and unsaturated polyester resin, and the lining layer is a low free nanometer polyester layer. The invention further discloses a manufacturing process of the glass fiber-reinforced plastic polyurethane TPU composite tube. The glass fiber-reinforced plastic polyurethane TPU composite tube has reliability, safety and economy, is mainly used for pulp conveying, bittern conveying, sea water desalination and corrosion-resistant and abrasion-resistant process pipelines, has the advantages of being light, high in strength, resistant to corrosion, high in abrasion resistance, long in service life, low in operation and maintenance cost and the like, and saves a large number of expenses for construction engineering.

Owner:张俊达 +1

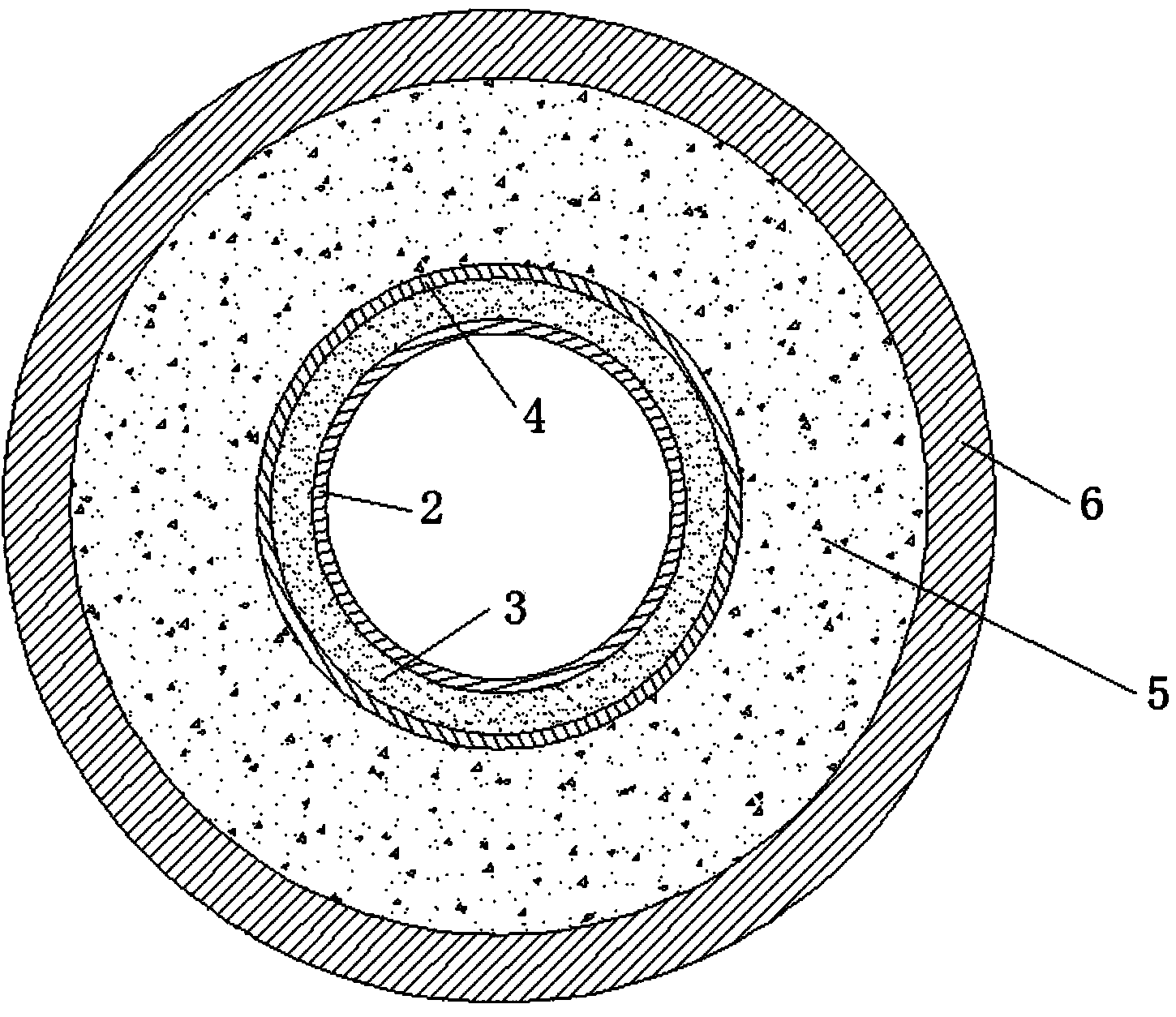

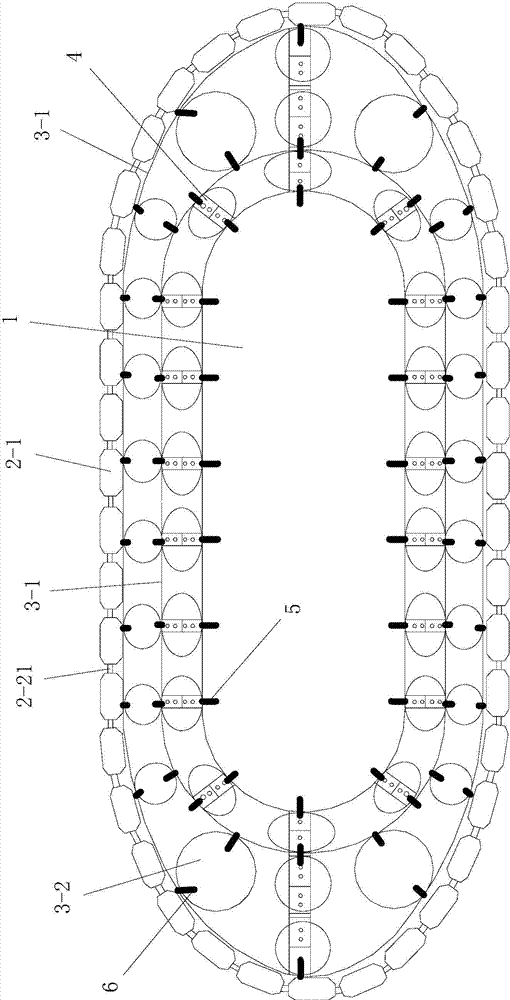

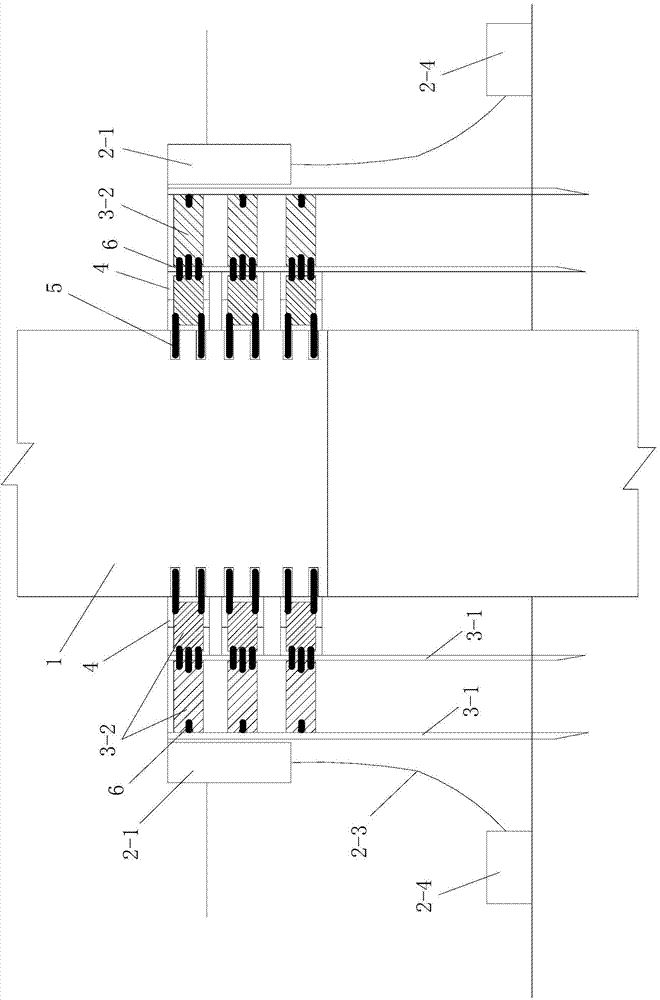

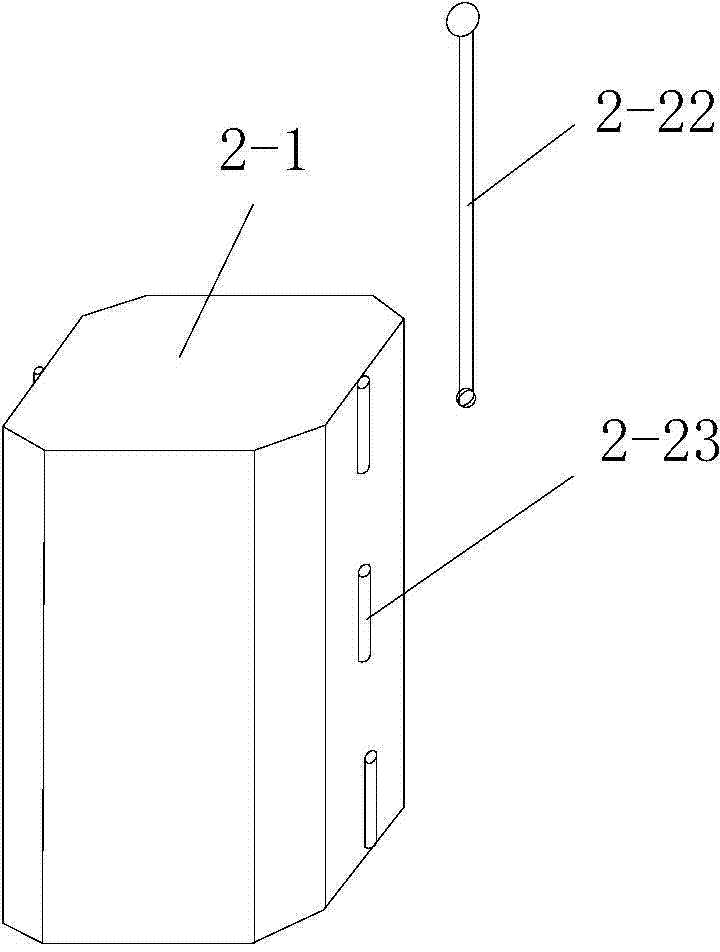

Date-pit-type composite anti-collision system for pier and construction method for date-pit-type composite anti-collision system for pier

InactiveCN104775355ASimple structureReasonable designClimate change adaptationBridge structural detailsArchitectural engineeringCofferdam

The invention discloses a date-pit-type composite anti-collision system for a pier and a construction method for the date-pit-type composite anti-collision system for the pier. The composite anti-collision system comprises a prepressing-type anti-collision device which is arranged at the outer side of the pier, and a floating-type external retaining device which sleeves the outer side of the prepressing-type anti-collision device, wherein the floating-type external retaining device is in a date pit shape, and is formed by connecting a plurality of anti-collision boxes which float on the water surface; the prepressing-type anti-collision device comprises one or a plurality of date-pit-type anti-collision structures; each date-pit-type anti-collision structure comprises an external cofferdam, and an energy consumption layer which is arranged at the inner side of the external cofferdam and is composed of a plurality of energy consumption rings; each external cofferdam is in the date pit shape; each energy consumption ring comprises an elastic ring which is formed through prepressing, and an external protective sleeve which sleeves the outer side of the elastic ring. The construction method comprises the following steps of (1) building a horizontal construction platform; (2) conveying parts in place; (3) constructing fixing elements at the outer side of the pier; (4) constructing the prepressing-type anti-collision device; (5) constructing the floating-type external retaining device. The date-pit-type composite anti-collision system for the pier and the construction method for the date-pit-type composite anti-collision system for the pier have the advantages that the design is reasonable, the construction is simple and convenient, the use effect is good, and the pier can be effectively protected.

Owner:XIAN UNIV OF SCI & TECH

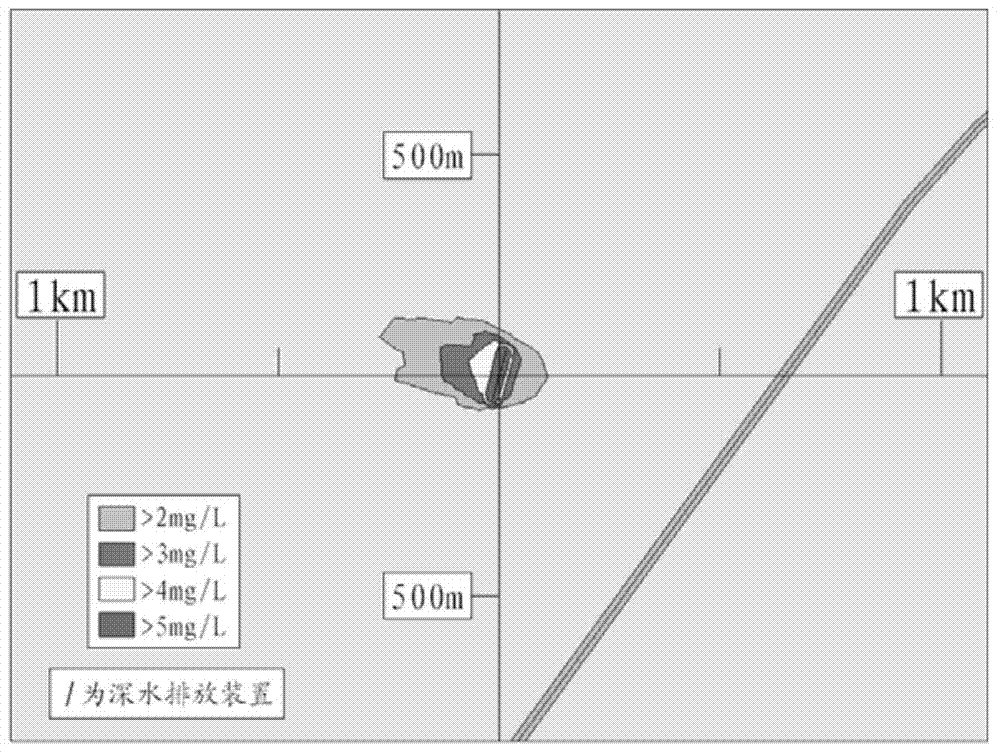

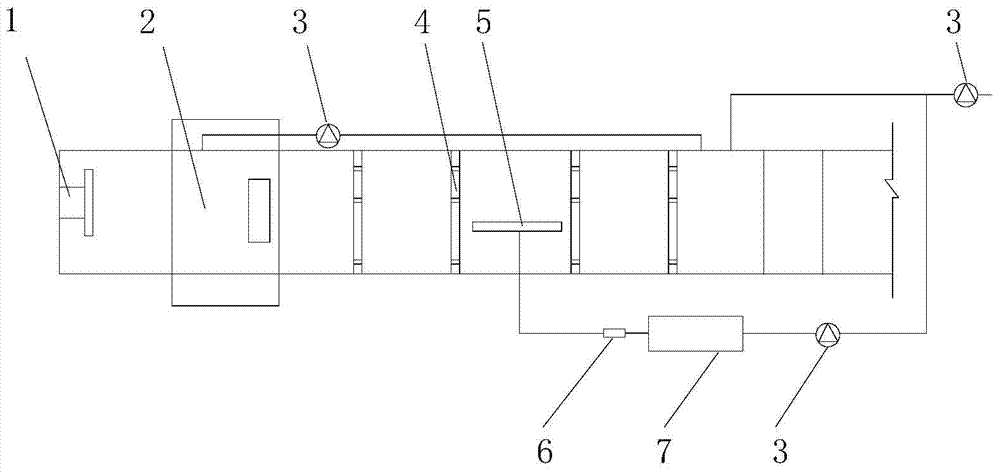

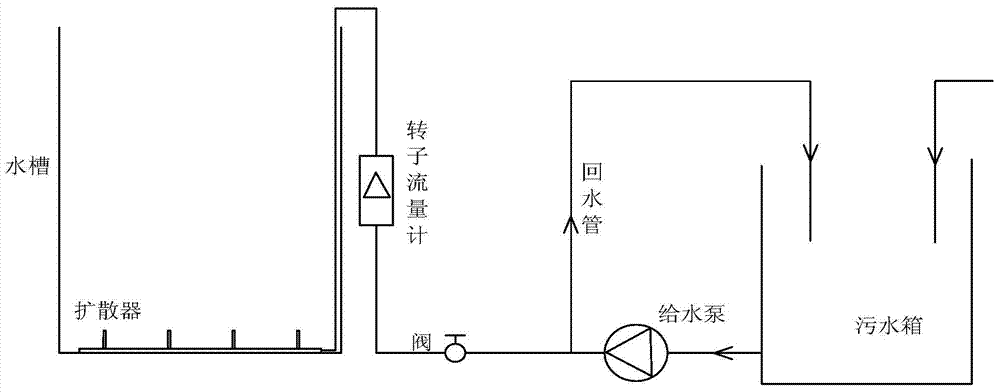

Method for determining length of sewage diffuser based on cooperation of physical model test and numerical simulation

InactiveCN103577645AGuaranteed dilution and diffusion effectRealize normal outflowSpecial data processing applicationsPhysical modelEconomic benefits

The invention discloses a method for determining the length of a sewage diffuser based on the cooperation of a physical model test and numerical simulation. The method includes the following steps that the length of the diffuser is preliminarily estimated, the number of ascending tubes contained in the diffuser is determined, the sewage diffusion effect is analyzed by the utilization of numerical simulation, the sewage diffusion effect in a near region is simulated by the utilization of a physical model, hydraulic power numerical simulation of the diffuser is conducted, the hydraulic power physical model test of the diffuser is conducted, and the length with the good hydraulic power feature is the finally-determined length. According to the method, sewage diffusion and hydraulic power outflow are analyzed, and the defects that a traditional method is too single and a computed result cannot be verified are overcome; through the length of the diffuser determined through the method, the sewage dilution diffusion effect can be guaranteed, sewage normal outflow can be also achieved, and a sewage discharge project can be efficiently operated; cost can be saved for a construction unit through the result, and good economic benefits are possessed.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

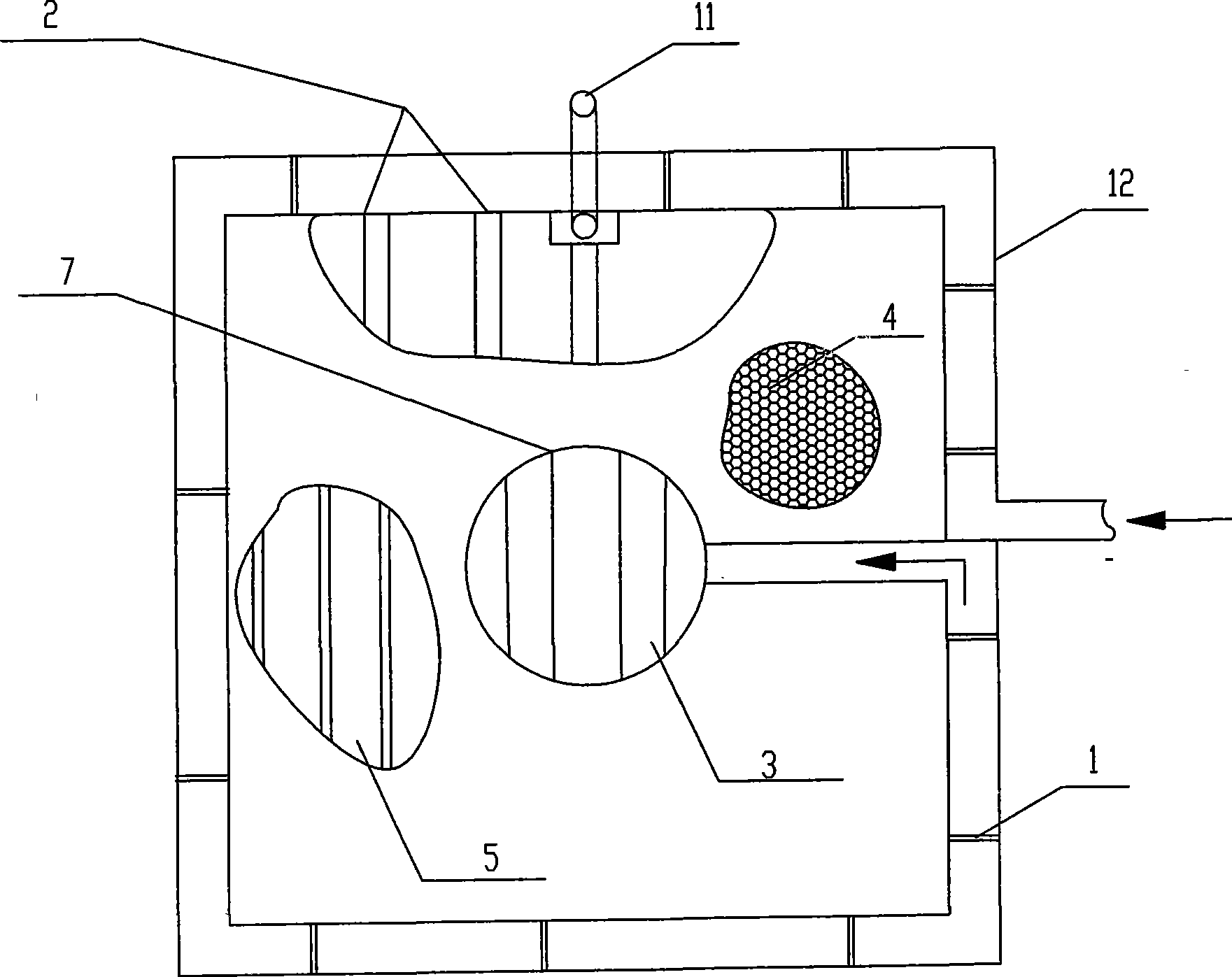

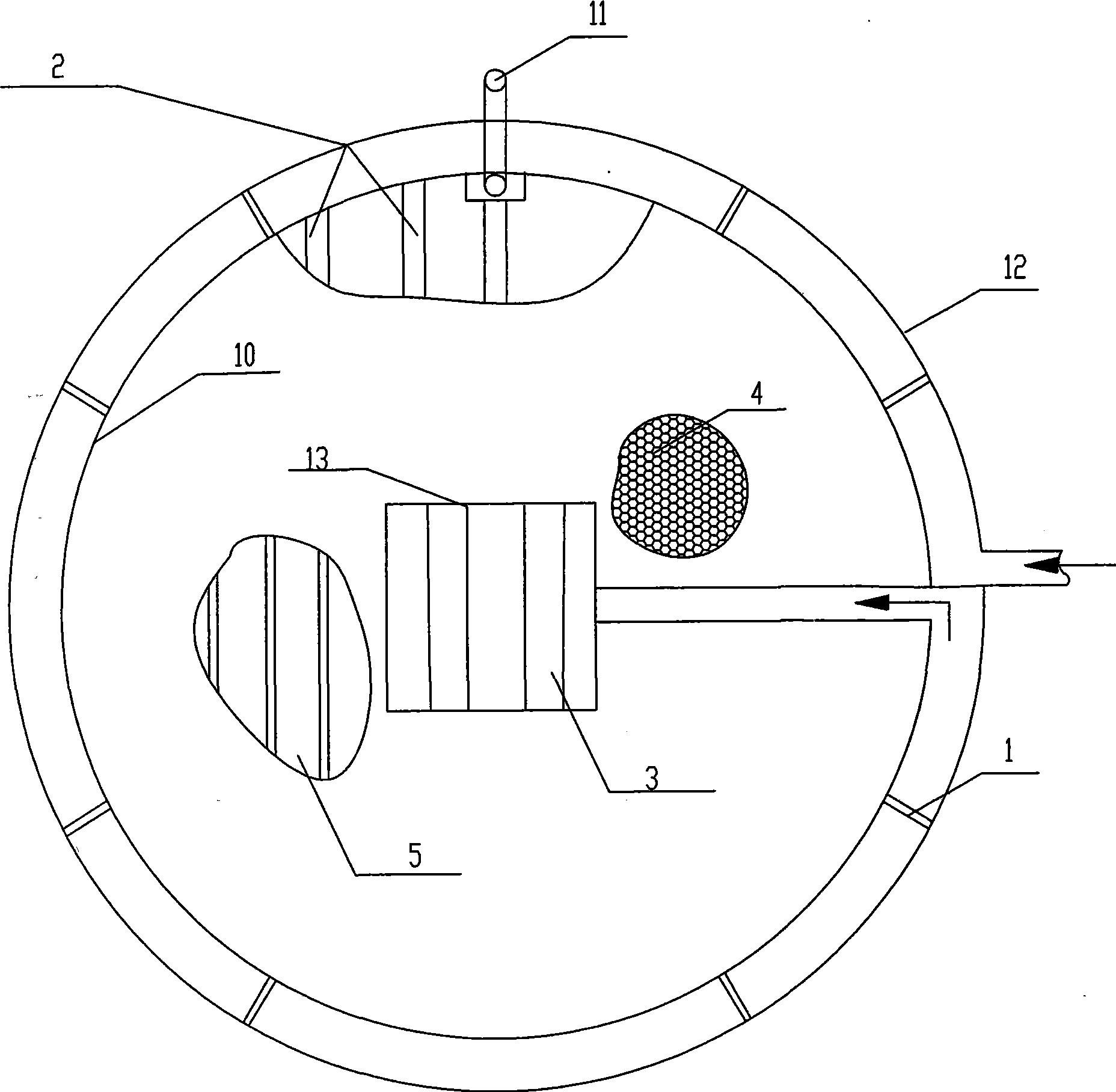

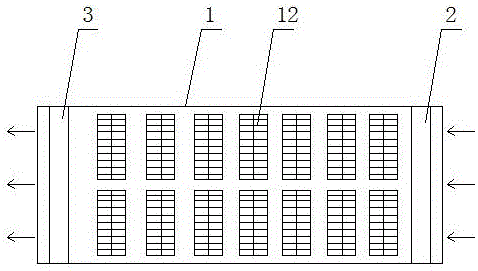

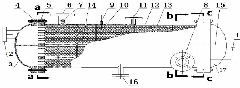

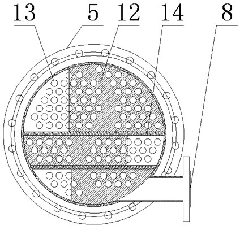

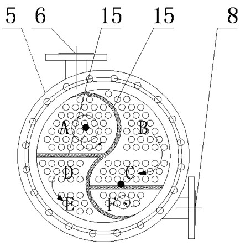

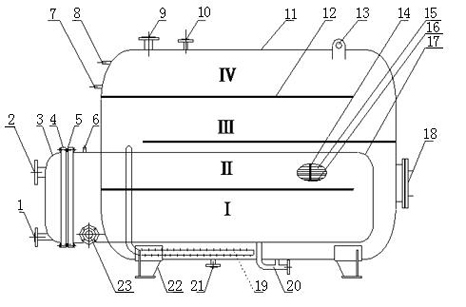

High-efficiency Taichi modular high-efficiency heat exchanger

ActiveCN101799248AImprove pressure bearing capacityHigh zone heating efficiencyStationary tubular conduit assembliesHeat exchange apparatusEngineeringFlange

The invention relates to heat exchange equipment, in particular to a high-efficiency Taichi modular high-efficiency heat exchanger which at least comprises a shell side and a tube side. The high-efficiency heat exchanger is characterized in that a primary fluid inlet flange, a primary fluid outlet flange, end enclosures and heat exchange tubes form the tube side, wherein the primary fluid inlet flange is arranged on the left end enclosure; the primary fluid outlet flange is arranged on the right end enclosure; a secondary fluid inlet flange, a secondary fluid outlet flange and a shell form the shell side; a primary fluid enters a left sealing cavity through the primary fluid inlet flange, flows through the heat exchange tube extending into the left sealing cavity, enters a right sealing cavity, and is output by a heat exchange tube outlet extending into the right sealing cavity through the primary fluid outlet flange; and a secondary fluid passes through a plurality of upper and lower chambers via the secondary fluid inlet flange and is drained by the secondary fluid outlet flange. The invention has the advantages of high-speed and high-efficiency heat exchange, occupied area saving, modular arrangement, convenient installation, energy source saving, no noise and convenient maintenance and cleaning.

Owner:西安华广电站锅炉有限公司

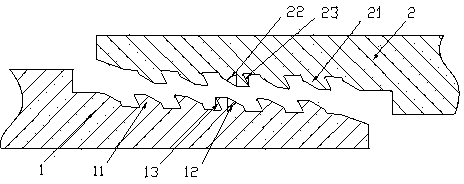

Drill rod joint with thread profiles

InactiveCN104018788AIncreased torsional strengthImprove fatigue strengthDrilling rodsDrilling casingsScrew threadWear resistance

The invention relates to a drill rod joint used in an oil and gas drilling and extraction processes, in particular to a drill rod joint with thread profiles. The drill rod joint comprises an external thread joint and an internal thread joint. The external thread joint and the internal thread joint are provided with threads of the same taper in the axial direction. The drill rod joint is characterized in that thread profiles of the external thread joint and thread profiles of the internal thread joint are both deformed trapezoids; in each thread profile of the external thread joint, a first flank angle ranges from 30 degrees to 75 degrees, a second flank angle ranges from 0 degree to minus 30 degrees, the thread taper is 1:6 to 1:32, and the thread pitch is larger than or equal to 6.35 mm; in each thread profile of the internal thread joint, a first flank angle ranges from 30 degrees to 75 degrees, a second flank angle ranges from 0 degree to minus 30 degrees, the thread taper is 1:6 to 1:32, and the thread pitch is larger than or equal to 6.35 mm. The torsional property, abrasive resistance and anti-fatigue performance of the drill rod joint can be improved, and the drill rod joint can be rapidly screwed on.

Owner:上海海隆石油钻具有限公司 +1

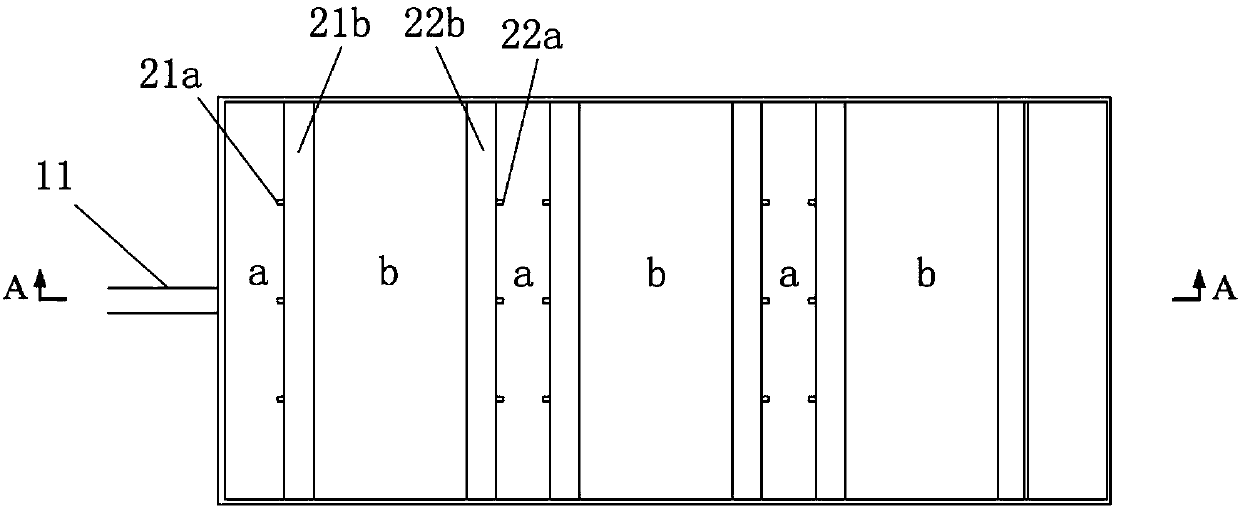

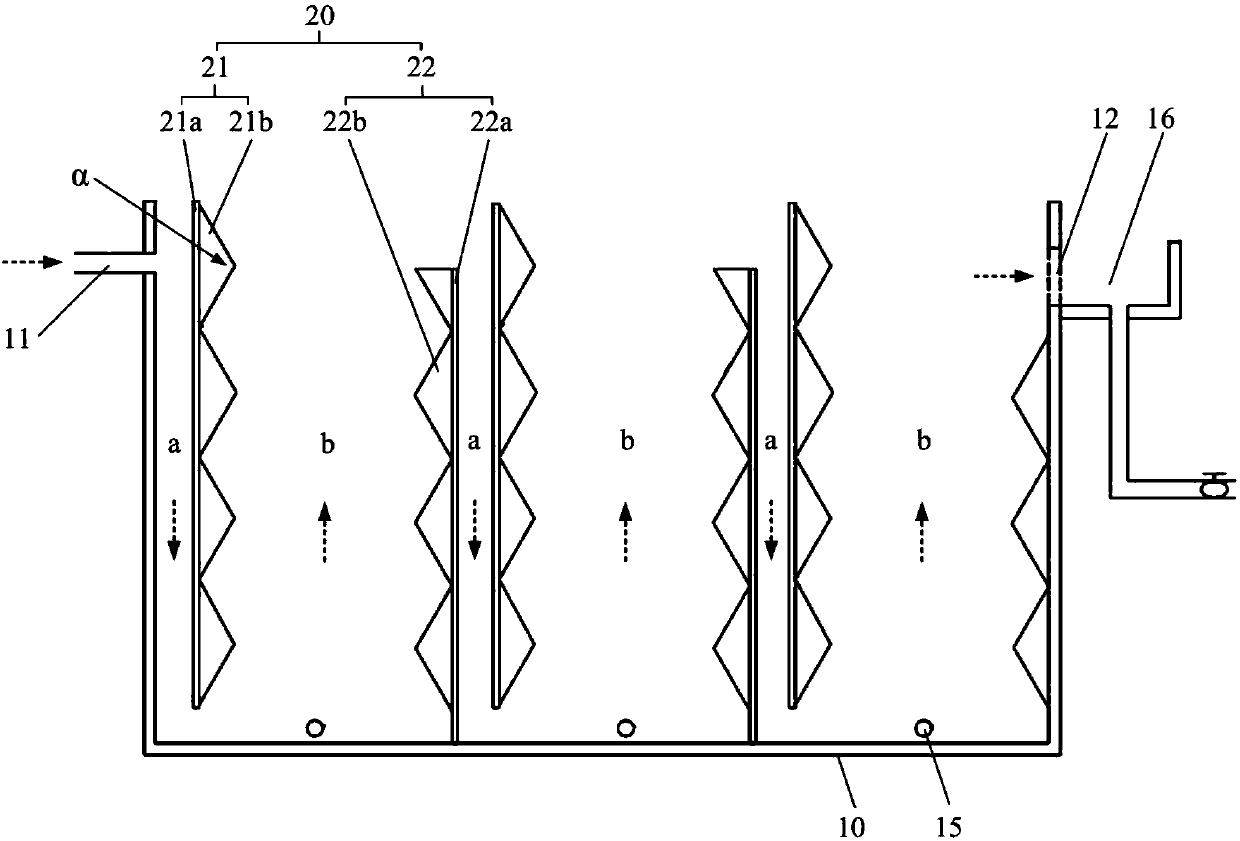

Surface reoxygenation biological pretreatment reactor and method

PendingCN107673467AImprove hydraulic propertiesPromote growthTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesAtmospheric airSewage

The invention relates to a surface reoxygenation biological pretreatment reactor and a method, relates to the technical field of sewage treatment, and aims at solving the problem that the ideal sewagetreatment effect is difficult to reach through the existing plug-flow or up-flow processing method. A plurality of baffle components are arranged in a shell of the reactor in parallel at intervals, each baffle component comprises a guidance baffle and a deflection baffle, the guidance baffle and the deflection baffle are vertically arranged at an interval and are both corrugated plates; the top end of the guidance baffle is flush with the top end of the side wall of the reactor, the bottom end of the guidance baffle and the bottom of the reactor are arranged at an interval, the bottom end ofthe deflection baffle is connected to the bottom of the reactor, the top end of the deflection baffle is lower than that of the guidance baffle, and a guidance chamber and an anaerobic hydrolysis reaction chamber are formed through the guidance baffle and the deflection baffle, are communicated, and are both communicated with the atmosphere. The method comprises the steps that an elastic three-dimensional filler is arranged in the reactor, the sewage sequentially goes by the guidance chamber and the anaerobic hydrolysis reaction chamber formed by the baffle components, so that the sewage and the elastic three-dimensional filler are fully stirred and are contacted and reacted, and the purified water is discharged out of the reactor through a water outlet.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

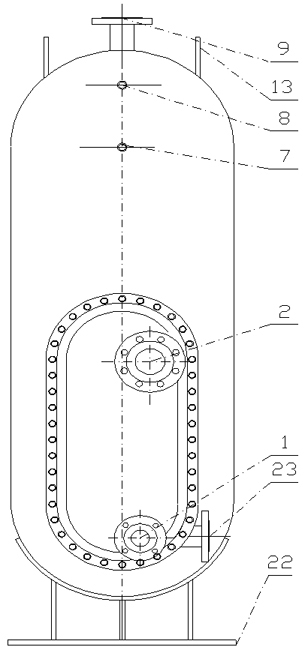

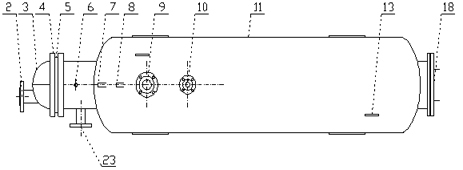

High-efficiency module back-stroke displacement heat exchanger

ActiveCN101839655AImprove pressure bearing capacityThe pressure drop loss is smallHeat exchanger casingsStationary tubular conduit assembliesEngineeringVertical cylinder

The invention relates to a heater exchanger, in particular to a high-efficiency module back-stroke displacement heat exchanger which is characterized by also comprising a cylinder. One side of the cylinder is provided with an open hole which enables chamber cylinders to horizontally extend into the cavity of the cylinder. Back stroke partition plates are vertically and horizontally arranged at intervals above the chamber cylinder in the cavity of the cylinder to form a plurality of back stroke mixing chambers, and horizontal chamber cylinders and vertical cylinders are communicated with each other through porous radiant tubes. When in working, primary fluid enters an end socket from a primary fluid inlet flange, flows through a horizontal heat exchange tube extending into the end socket, and flows out from the outlet of the heat exchange tube extending into the end socket and the primary fluid outlet flange through back strokes partitioned by a U-shaped heat exchange tube and an end socket partition plate. Secondary fluid flows through a secondary fluid inlet flange at the lower end of the chamber cylinder at the outer side of the cylinder, and is sufficiently mixed and stirred through a back stroke mixing chamber, back stroke is carried out, and the secondary fluid subjected to the treatment is discharged from a secondary fluid outlet flange on the upper end of the cylinder. The invention provides the high-efficiency module back-stroke displacement heat exchanger which can improve the thermal efficiency, the energy utilization rate and the water yield, reduce the cost andreduce the architectural space, is convenient to maintain and clean, and has simple manufacturing process.

Owner:西安华广电站锅炉有限公司

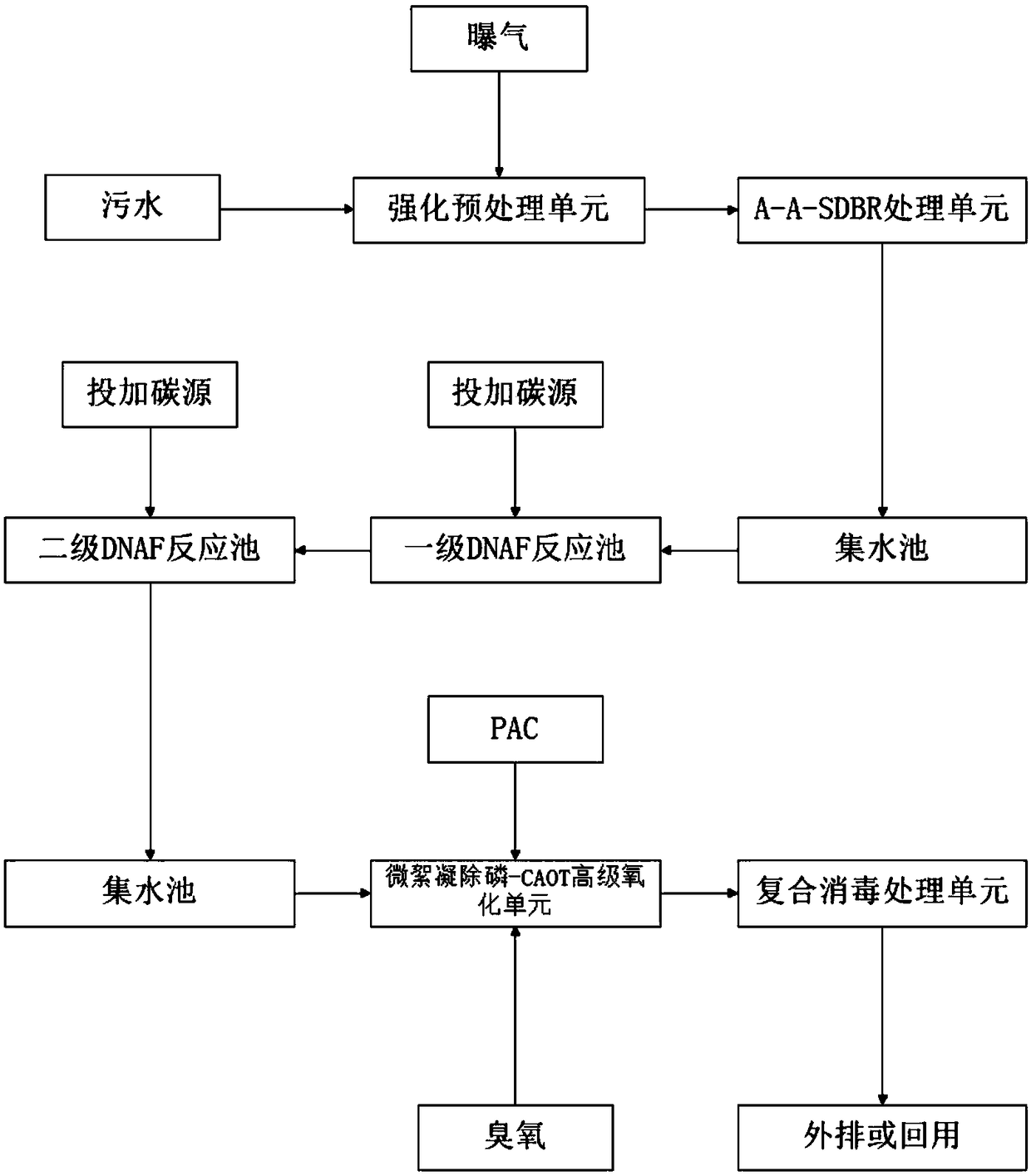

Municipal wastewater treatment integrated process

InactiveCN109320011APrevent eutrophicationReduce pollutionWater/sewage treatment by centrifugal separationSpecific water treatment objectivesIndustrial wastewater treatmentChemistry

The invention discloses a municipal wastewater treatment integrated process. The municipal wastewater treatment integrated process comprises the following steps: removing a floating objects and gravels in wastewater through a reinforcing pre-treating unit; performing phosphorus and nitrogen removal on the wastewater treated by the reinforcing pre-treating unit through an A-A-SDBR treating unit; performing deep denitrification on the wastewater treated by the A-A-SDBR treating unit through a DNAF reaction treating unit; performing efficient phosphorus removal and ozone catalytic oxidization onthe wastewater treated by thean DNAF reaction treating unit through a micro-flocculation phosphorous-removal-CAOT advanced oxidization unit; and disinfecting the wastewater treated by the micro-flocculation phosphorous-removal-CAOT advanced oxidization unit through a composite disinfecting unit. The municipal wastewater treatment integrated process can treat municipal wastewater to meet surface water IV-type water quality standards, and avoids water eutrophication, wherein total nitrogen content of outlet water is smaller than 1.5 mg / L, and total phosphorus content of the outlet water is smaller than 0.3 mg / L; and moreover, the treated wastewater can be recycled for industrial non-drinking water and landscape water which is not in contact with a human body, and the process not only reducespollution on environment, andbut also recycles the waster resource.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

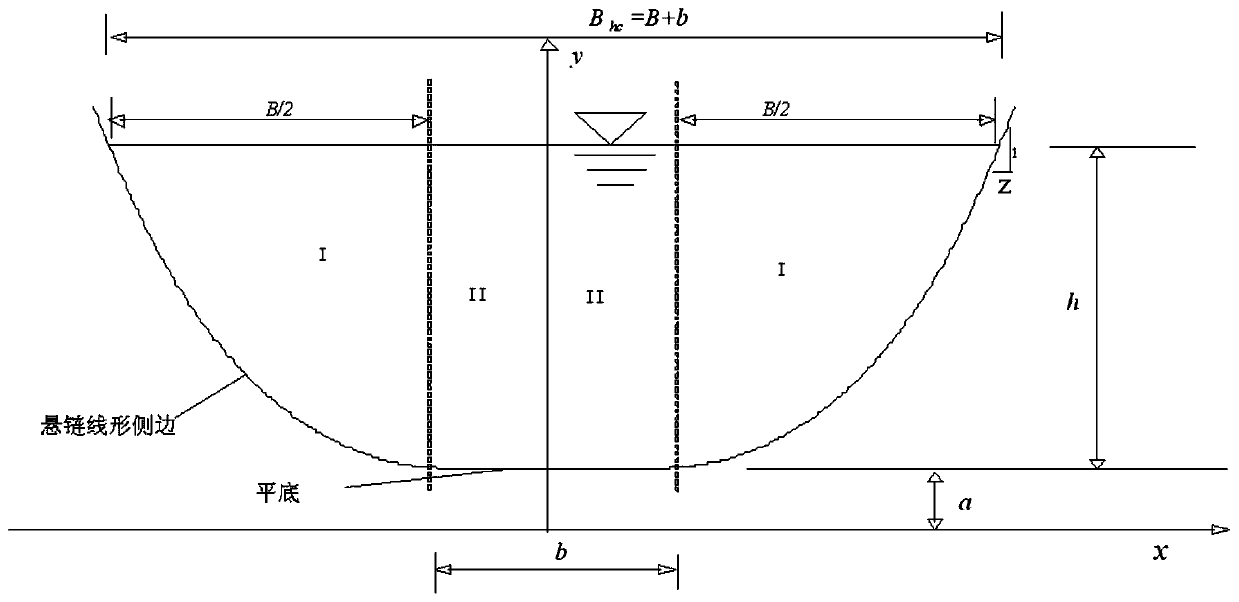

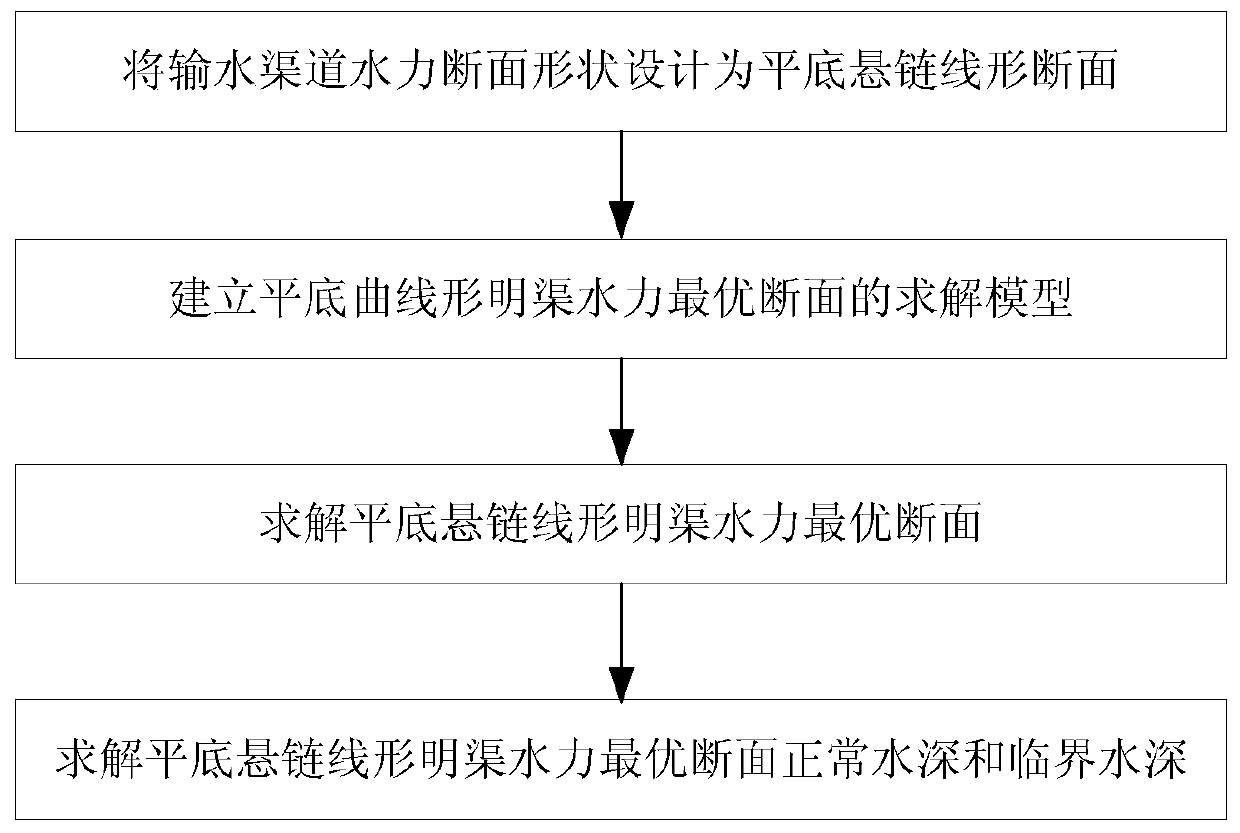

Novel flat-bottom catenary open channel and solving method of hydraulic optimal section thereof

ActiveCN110008513AEasy maintenanceFlexible constructionGeometric CADData processing applicationsStress concentrationAnti freezing

The invention discloses a novel flat-bottom catenary open channel and a solving method of a hydraulic optimal section thereof. An opening of the flat-bottom catenary open channel is upward, and the section of the flat-bottom catenary open channel comprises a flat bottom and two catenary side edges which are positioned on two sides of the flat bottom and are smoothly connected with the flat bottom.The solving method comprises the following steps: designing the shape of the hydraulic section of the water conveying channel into a flat-bottom catenary section; establishing a solution model of thehydraulic optimal section of the flat-bottom curved open channel; solving the hydraulic optimal section of the flat-bottom catenary-shaped open channel; and solving the normal water depth and critical water depth of the hydraulic optimal section of the flat-bottom catenary open channel. The method has the advantages that the catenary section has no stress concentration point, and the open channelis not prone to have cracks caused by stress concentration. The open channel is small in leakage, good in stability, excellent in hydraulic characteristic, high in anti-freezing capacity and the like, also has the advantages of being flexible in flat-bottom section design, low in construction difficulty, easy to manage and maintain, easy to compact at the bottom and the like, and can improve thewater delivery efficiency, reduce the water delivery loss and reduce the construction cost.

Owner:UNIV OF JINAN

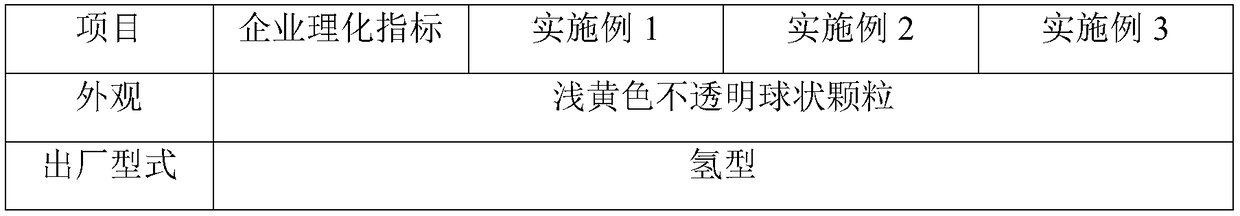

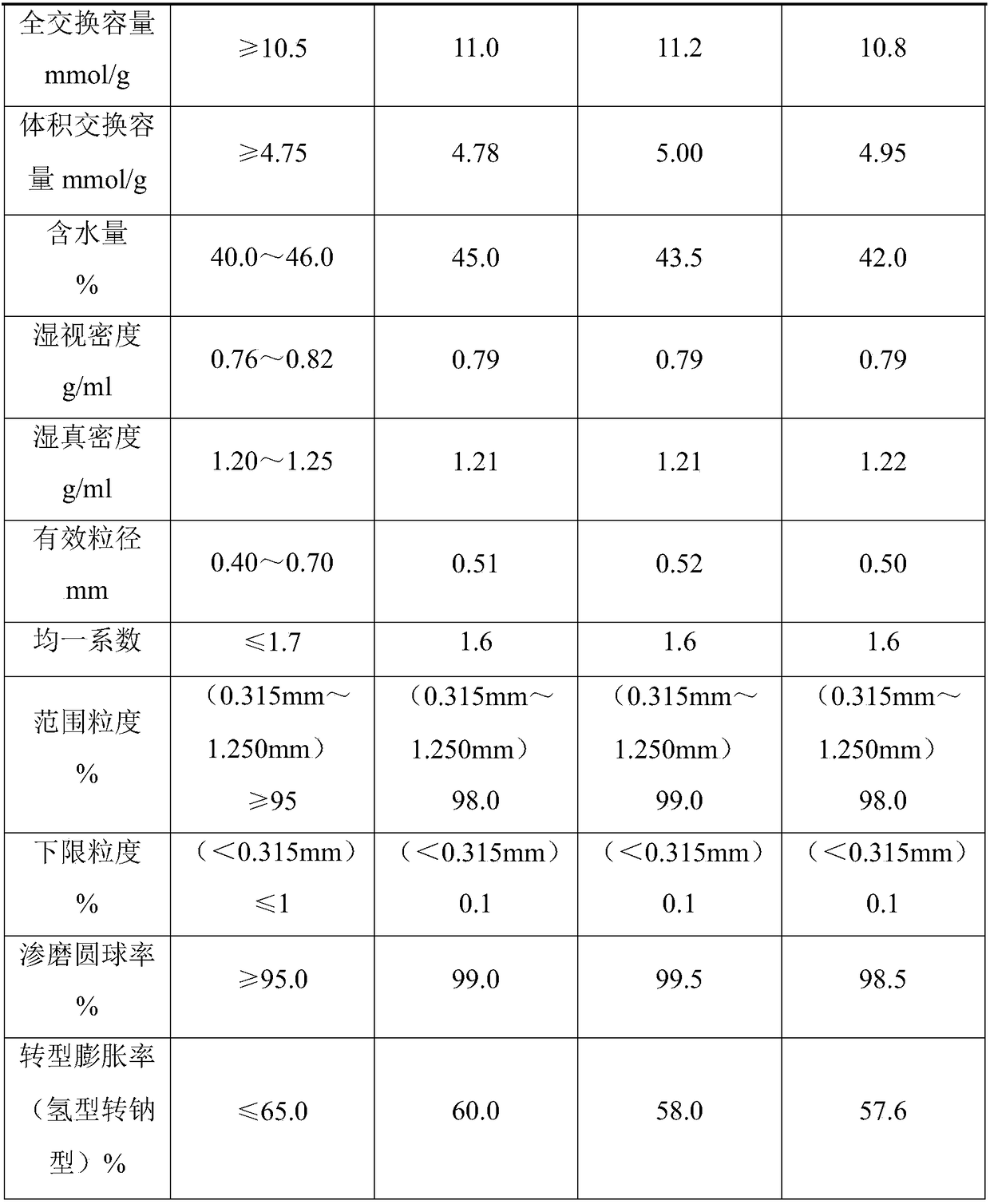

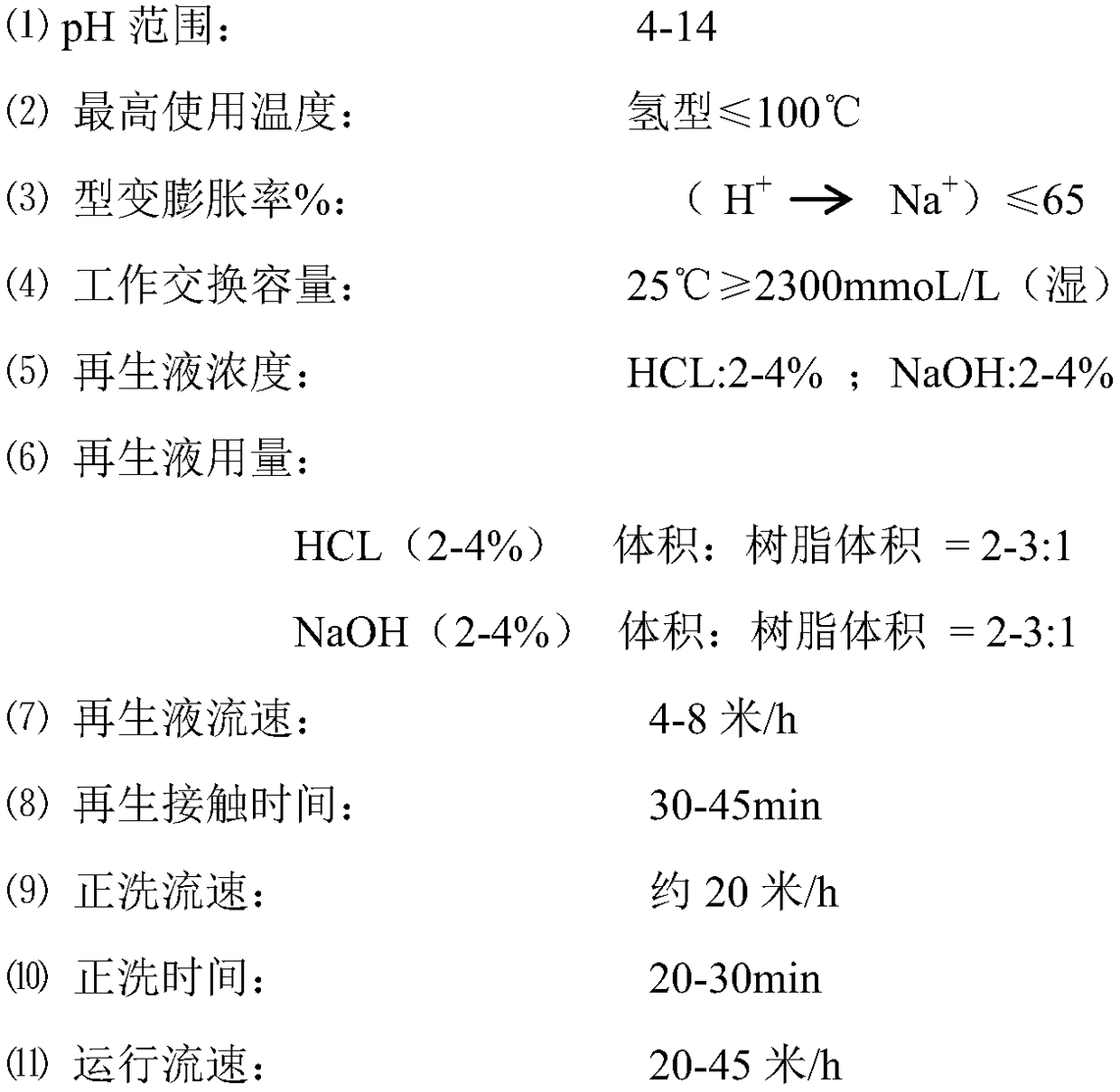

A method for preparing macroporous type highly-crosslinked acrylic acid ion exchange resin

InactiveCN109021165AHigh volumetric exchange capacitySmall expansionCation exchanger materialsBenzoyl peroxideSoftened water

The invention belongs to the technical field of ion exchange resin and relates to a method for preparing macroporous type highly-crosslinked acrylic acid ion exchange resin. The method includes a stepof adding softened water into a reaction kettle, adding industrial salt, stirring the mixture, adjusting the specific gravity and temperature, then adding hydroxyethyl cellulose, and heating and stirring the mixture to obtain a water phase; a step of adding acrylonitrile, methyl acrylate and triallyl isocyanurate into a burdening kettle; a step of adding benzoyl peroxide into divinylbenzene, adding the mixture after the mixture is stirred into the burdening kettle, adding toluene, and fully stirring the mixture to obtain an organic phase; a step of mixing the organic phase and the water phasein a mass ratio of 1:3.3-3.5; a step of heating and reacting the mixture, transferring the reaction solution to a stripper, performing filtration to remove filtrate completely, adding hot water, stirring the mixture, heating and reacting the mixture and performing hot-air drying; and a step of adding sulfuric acid, heating and reacting the mixture, cooling a reaction product, and adding water fordilution. The method is innovative in China and large-scale production has not been found in enterprises. The resin prepared by the method is simple in process, excellent in effect, environmentally friendly, and pollution-free and has a wide application prospect.

Owner:扬州金珠树脂有限公司

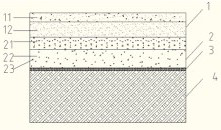

Impact-resistant wear-resistant environment-friendly pavement and construction method

The invention discloses an impact-resistant wear-resistant environment-friendly pavement. The pavement comprises a surface layer (1), a base layer (2), a soil cloth layer (3) and a road foundation (4), and is characterized in that the surface layer (1) is provided with a wear-resistant layer (11) and a gravel-grade steel slag layer (12); the wear-resistant layer (11) is made of ultra-high performance concrete doped with glass powder and rice hull ash; the interior of the gravel-grade steel slag layer (12) is prepared from gravel-grade waste steel slag, epoxy resin, asphalt and other materials,the base layer (2) is provided with a high-modulus epoxy asphalt steel slag layer (21) and a building reclaimed material layer (22), the building reclaimed material layer (22) is provided with a stone chip filling body (23), and the soil cloth layer (3) is located below the building reclaimed material layer (22) and above the road foundation (4) and is firm in connection. The pavement disclosed by the invention can bear received vertical, transverse and vibration impact loads, and is high in firmness, good in durability, high in comfort, high in flexibility and high in high-temperature resistance.

Owner:XIANGTAN UNIV

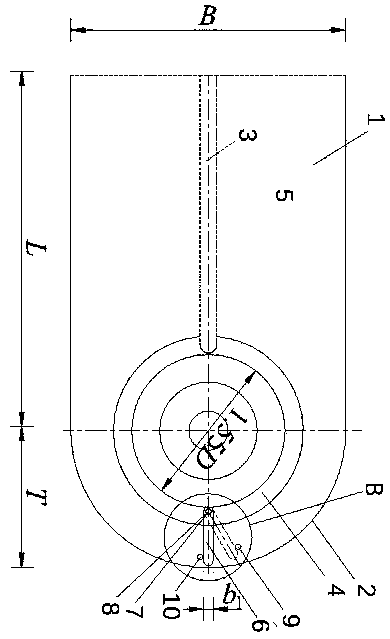

Pump unit bell-shaped inlet channel with movable flow plate

ActiveCN107489655BImprove velocity distributionGuaranteed uptimePump componentsPumpsCouplingWater flow

The invention relates to a bell-shaped water inlet channel of a pump device with a movable flow-adjusting plate, which belongs to the technical field of water conservancy engineering. It includes a pier placed in the water inlet channel, a semicircular rear wall, a trumpet pipe and a water guide cone, and is equipped with a movable flow-adjusting plate and a positioning pin. The flow-adjusting plate can make changes to adapt to asymmetric flow by using the pressure difference. The movable flow fitting plate is located at the rear wall of the water inlet channel and there is a gap between it and the rear wall; the section where the flow fitting plate is located is perpendicular to the bottom surface of the flow channel, and the two ends of the connecting shaft are respectively fixed on the bottom of the bell-shaped water inlet channel and the horn On the outer wall of the tube, one end of the flow adapting plate is connected to the connecting shaft through a sleeve, and can rotate around the connecting shaft; there are two positioning pins, which are respectively placed on both sides of the flowing plate and fixed at the bottom of the bell-shaped water inlet channel. The distances to the coupling shafts are all less than the length of the flow plate. The invention is suitable for bell-shaped water inlet channels and box-shaped water inlet channels, can adapt to various operating conditions, improves pump device efficiency, reduces operating costs, and is more energy-saving and efficient.

Owner:YANGZHOU UNIV

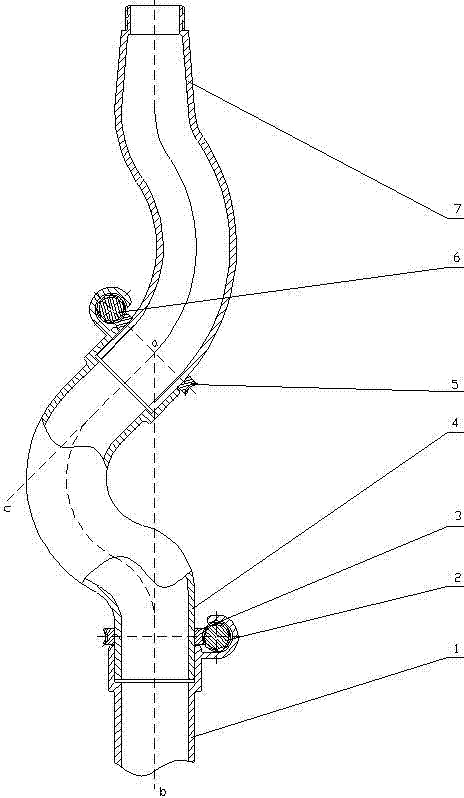

Pitching slewing mechanism linked with horizontal slewing for fire monitor

InactiveCN104759054ARealization of tilting and turningRealize pitch and turn jetFire rescueEngineering

The invention belongs to the technical field of fire fighting apparatuses and in particular relates to a pitching slewing mechanism linked with horizontal slewing for a fire monitor. The pitching slewing mechanism is composed of a gun support, a lower bending pipe, an upper bending pipe, a horizontal slewing worm gear, a horizontal slewing worm, a pitching slewing worm gear and a pitching slewing worm. According to the pitching slewing mechanism linked with horizontal slewing for the fire monitor, a structure that the horizontal slewing of the fire monitor is linked with the pitching slewing is adopted to realize pitching slewing of the fire monitor, a phenomenon that the existing fire monitor realizes pitching slewing by utilizing the pitching slewing worm gear and the pitching slewing worm independently is changed, the quantity of elbows of the fire monitor is reduced, the hydraulic characteristic of an internal flow passage of the fire monitor is optimized, the injection performance of the fire monitor is improved and the structure of the fire monitor is relatively compact.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

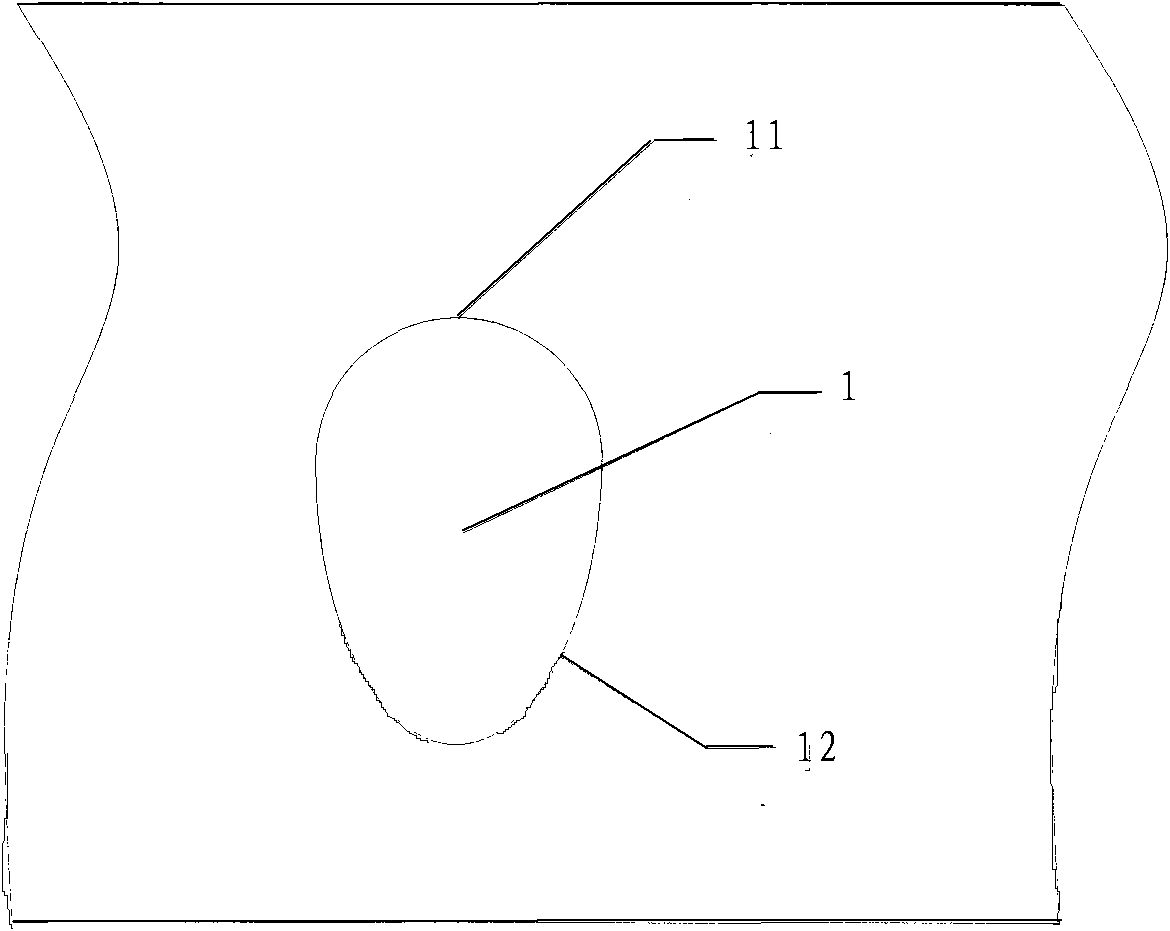

Fish way with ovoid fish-passing holes

InactiveCN101570967ADiversity guaranteedImprove the ecological environmentBarrages/weirsClimate change adaptationEngineeringMinor axis

The invention discloses a fish way with ovoid fish-passing holes which are formed on the channel partitioning board of the fish way, wherein, each ovoid fish-passing hole comprises a circular first half part and an elliptic second half part; and the diameter of the first half part is equal to the minor axis length of the second half part. The invention has the advantages of simple structure, easy manufacture, convenient maintenance, high economic efficiency and practicability and good hydraulic characteristics; and the invention can generate the flow structure for fishes to migrate.

Owner:ZHEJIANG UNIV OF TECH

Artificial wetland composite packing for treating rural domestic sewage

InactiveCN106477725ALower build costsEfficient resource utilizationWater contaminantsWater/sewage treatment by sorptionConstructed wetlandOyster shells

The invention discloses artificial wetland composite packing for treating rural domestic sewage. The artificial wetland composite packing is prepared from oyster shells, waste haydite and zeolite. Aquatic wastes such as the oyster shells, the industrial wastes such as ceramics and the zeolite are used as the main raw materials of the composite packing, and are machined into particles with suitable sizes, and the particle size range is 3-20 mm. According to the filling mode, the particle size of packing on the lower layer is large, and the particle size of the packing on the upper layer is small. Preferably, the mixed mass ratio of the oyster shells, the waste haydite and the zeolite is (3-4): 2: 1.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

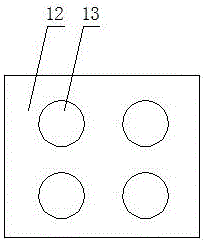

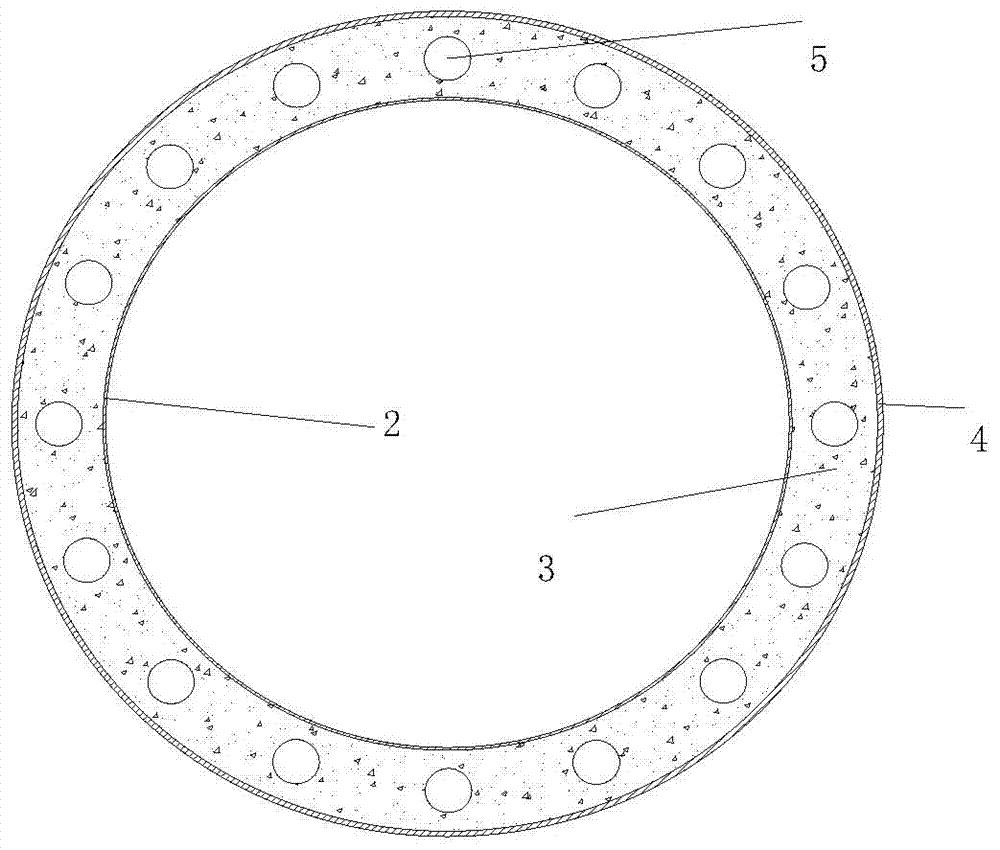

High-ductility concrete hollow pipe and manufacturing method thereof

InactiveCN104500856AThe pipe is light in weightAvoid local stress concentrationsRigid pipesCorrosion resistantDuctility

The invention discloses a high-ductility concrete hollow pipe and a manufacturing method thereof. The high-ductility concrete hollow pipe comprises a resin-based composite material lining layer, a high-ductility concrete hollow structure layer and a resin-based composite material pre-stressed layer in sequence from inside to outside; uniformly-distributed hollow holes are formed in the cross section of the high-ductility concrete hollow structure layer; the resin-based composite material lining layer is formed by winding glass fiber fabrics of a resin-impregnated polyester felt, a glass fiber surface felt, a short cut felt or the like; the resin-based composite material pre-stressed layer is formed by winding a resin-based material formed by compounding fibers or resin; an inner wall adopts the resin-based composite material lining layer, is corrosion-resistant and impermeable, can convey corrosive mediums and has excellent hydraulic performance; with the adoption of the resin-based composite material pre-stressed layer, not only can the corrosion be prevented, but also the occurrence of corrosion and fracture of a pre-stressed steel wire in a PCCP (Pre-stressed Concrete Cylinder Pipe) can be avoided, so that the durability of the pipe is improved; the high-ductility concrete hollow pipe has the characteristics of light mass, high resistance to inside and outside corrosive mediums, excellent hydraulic characteristic, great rigidity, low cost, high durability and the like.

Owner:WUHAN UNIV OF TECH +1

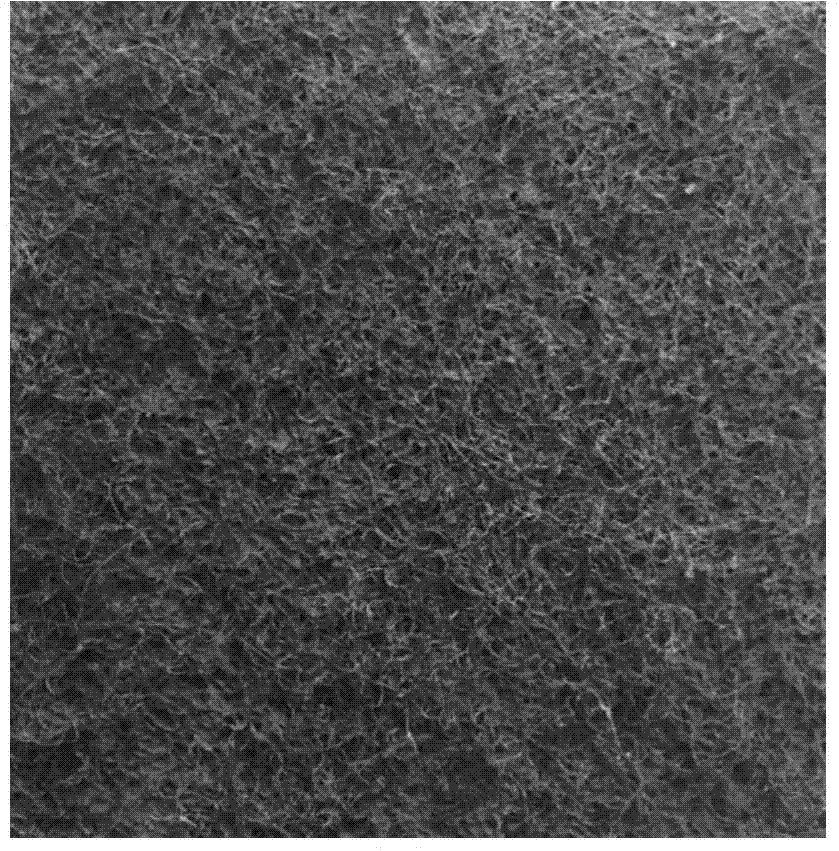

Active carbon supported felted nylon biocarrier, and preparation method and application thereof

ActiveCN103936170AImprove hydrophilicityImprove hydraulic propertiesBiological water/sewage treatmentSewage treatmentWater treatment

The invention relates to an active carbon supported felted nylon biocarrier, and a preparation method and an application thereof, and belongs to the technical filed of water treatment microorganism carriers. Active carbon is uniformly bonded to the surface of a felted nylon material through a binder, or / and is bonded in the pore structure of the felted nylon material in an inlay manner, and the felted nylon material has a planar surface and has a netted porous structure. The preparation method comprises the following steps: preprocessing the felted nylon material; dipping the processed felted nylon material in a binder; and uniformly loading the active carbon onto the binder dipped felted nylon material in order to form the active carbon supported felted nylon biocarrier. The active carbon supported felted nylon biocarrier can be used in sewage treatment as a microorganism carrier.

Owner:上海复沅环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com