Active carbon supported felted nylon biocarrier, and preparation method and application thereof

A biological carrier, activated carbon technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor hydrophilicity and biocompatibility, and achieve hydrophilicity. Good, good hydraulic properties, good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

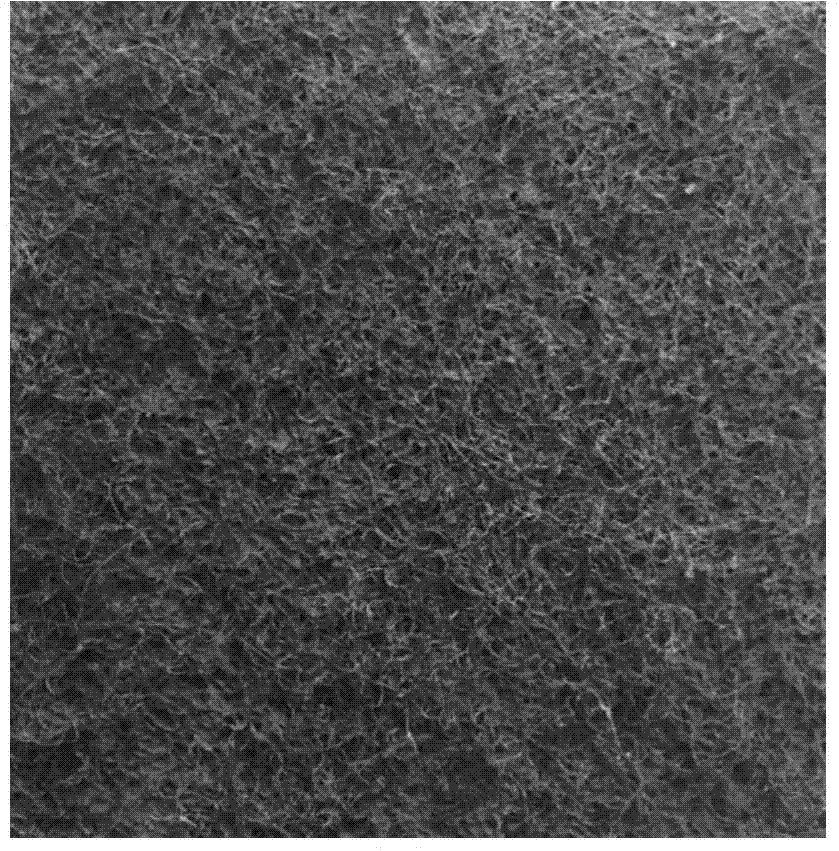

Image

Examples

Embodiment 1

[0025] The felt-like nylon material was rinsed with water to remove contaminants such as dust and dried; then, it was cleaned with acetone for degreasing treatment; then, the felt-like nylon material was immersed in a water-soluble phenolic resin (solid content of 25wt%), taken out and passed through The excess binder is squeezed out by the double rollers, and then the powdered activated carbon with a specific surface area of 1200 square meters / g is evenly distributed on the felt-like nylon material, and the load is 0.1 g / square centimeter. Compression is carried out, and then a curing reaction is carried out to firmly support the activated carbon on the felt-like nylon material, and then cut into a specific size of the activated carbon-loaded felt-like nylon biocarrier according to the requirements.

[0026] The above-mentioned modified carrier was put into a biofilm reactor for the start-up test of film formation (the volume of the reactor was 4 liters, the aeration rate wa...

Embodiment 2

[0028] The felt-like nylon material was rinsed with water to remove contaminants such as dust, and dried; then, it was cleaned with acetone for degreasing treatment; then, the felt-like nylon material was immersed in water-soluble phenolic resin (solid content of 25wt%), taken out and passed through double The roller squeezes out the excess binder, and then the powdered activated carbon with a specific surface area of 600 square meters / g is evenly distributed on the felt-like nylon material, and further pressed by double rollers, and then the curing reaction is carried out. The activated carbon is firmly loaded on the felt-like nylon material, and the loading amount is 0.1 g / cm 2 , and then according to the requirements, it is cut into a felt-like nylon biocarrier loaded with activated carbon of a specific size.

[0029] The above-mentioned modified carrier was put into a biofilm reactor for the start-up test of film formation (the volume of the reactor was 4 liters, the aera...

Embodiment 3

[0031]The felt-like nylon material was rinsed with water to remove contaminants such as dust, and dried; then, it was cleaned with acetone for degreasing treatment; then, the felt-like nylon material was immersed in water-soluble phenolic resin (solid content of 25wt%), taken out and passed through double The roller squeezes out the excess binder, and then the powdered activated carbon with a specific surface area of 2000 square meters / g is evenly distributed on the felt-like nylon material, which is further pressed by double rollers, and then subjected to a curing reaction. The activated carbon is firmly loaded on the felt-like nylon material, and the loading amount is 0.1 g / cm 2 , and then according to the requirements, it is cut into a felt-like nylon biocarrier loaded with activated carbon of a specific size.

[0032] The above-mentioned modified carrier was put into a biofilm reactor for the start-up test of film formation (the volume of the reactor was 4 liters, the aer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com