High-efficiency Taichi modular high-efficiency heat exchanger

A heat exchanger and taiji technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of inconvenient installation and complicated installation process, achieve easy maintenance and cleaning, save construction investment, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

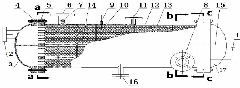

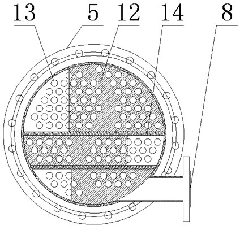

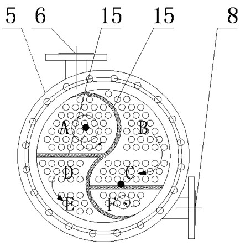

[0038] Such as figure 1 , figure 2 , Figure 4 As shown, the high-efficiency Taiji module high-speed heat exchanger includes at least the shell side and the tube side, the primary heat medium inlet flange 2, the primary heat medium outlet flange 1, the head, and the heat exchange tube 13 to form the tube side, and the primary heat medium inlet The flange 2 is on the left head 3, the primary heat medium outlet flange 1 is on the right head 17, and the left head 3 and the right head 17 are respectively connected to the shell flange 4 at both ends of the shell 12. The plates 5 are welded in the inner tubes at both ends of the housing 12, and the tubes are divided into three independent sealed cavities: left, middle and right. The heat exchange tubes 13 are fixed on the tube plates 5 at both ends.

[0039] The secondary heat medium inlet flange 8 and the secondary heat medium outlet flange 6 are connected to the shell 12 to form a shell side, the secondary heat medium inlet fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com