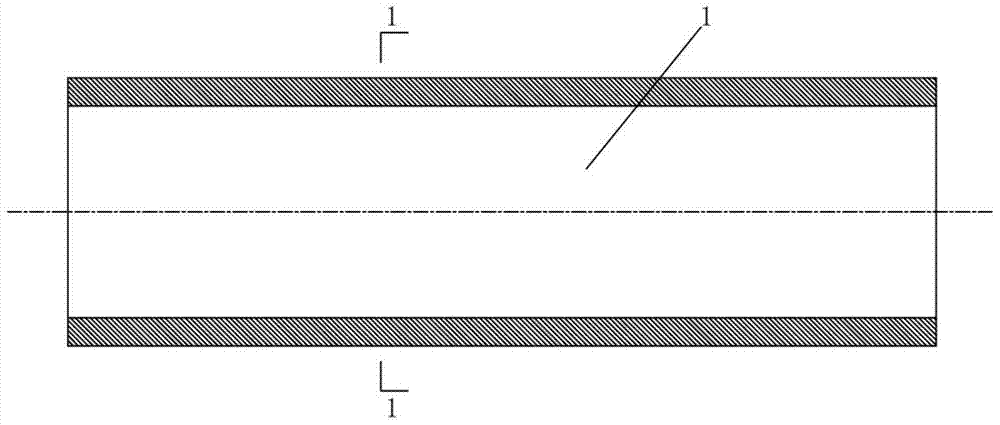

High-ductility concrete hollow pipe and manufacturing method thereof

A high-ductility concrete and hollow pipe technology, applied in the direction of rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of high quality reinforced concrete pipes, easy cracking and damage of ordinary concrete, and high roughness coefficient of the inner wall of concrete. Achieve good economic performance, reduce the roughness coefficient, and avoid the effects of corrosion and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The high ductility concrete hollow structural pipe with an inner diameter of 2000mm is produced by the above process, and the process parameters are selected as follows:

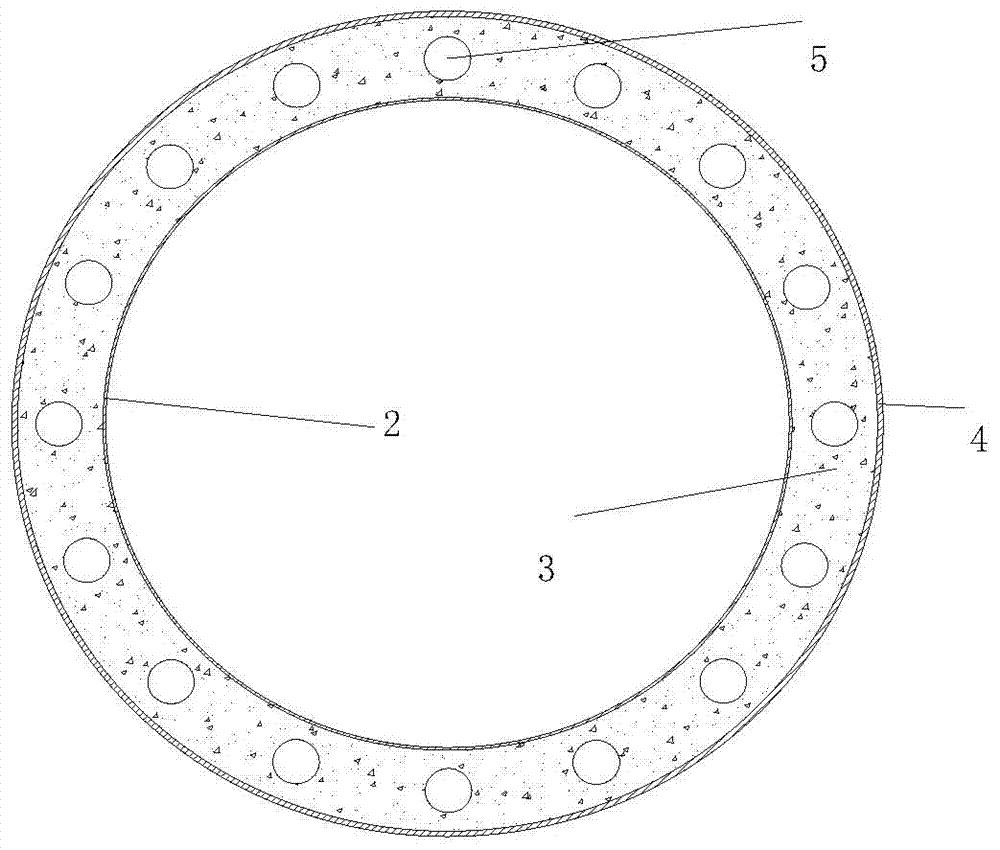

[0042] The ECR surface felt impregnated with epoxy vinyl ester resin is used as the primer, and the ECR jet yarn and grid cloth are alternately laid and wound to form a resin-based composite lining layer with a thickness of 1.5mm;

[0043] The mass ratio of polyvinyl alcohol fiber to cement is 4.0%, the mass ratio of fly ash to cement is 1.5, the mass ratio of quartz sand to cement is 1.2, and the high ductility concrete is made by mixing, and the thickness of the high ductility concrete hollow structure layer is 50mm;

[0044] The prestressed layer of resin-based composite material is made of carbon fiber filaments impregnated with isophthalic unsaturated polyester resin, with a thickness of 2mm.

[0045] After performance test: tube stiffness ≥ 60000, roughness coefficient ≤ 0.0084. The test standa...

Embodiment 2

[0047] Using the above process to manufacture high ductility concrete hollow structural pipes with an inner diameter of 3000 mm, the process parameters are selected as follows:

[0048] The glass fiber prepreg yarn impregnated with polyethylene resin is wound into the inner lining layer of resin matrix composite material, with a thickness of 4mm;

[0049] The mass ratio of ultra-high molecular weight polyethylene fiber to cement is 2.0%, the mass ratio of fly ash to cement is 2.5, and the mass ratio of river sand to cement is 1.6. The high ductility concrete is made by mixing, and the thickness of the high ductility concrete hollow structure layer is 500mm;

[0050]The prestressed layer of resin-based composite material is made by winding glass fiber filaments impregnated with epoxy vinyl ester resin, with a thickness of 40mm;

[0051] After performance test: tube stiffness ≥ 500000, roughness coefficient ≤ 0.0084.

Embodiment 3

[0053] Using the above process to manufacture high ductility concrete hollow structural pipes with an inner diameter of 2000 mm, the process parameters are selected as follows:

[0054] The glass fiber prepreg yarn impregnated with polyethylene resin is wound into a resin-based composite lining layer of 2.5mm;

[0055] The mass ratio of polyvinyl alcohol fiber to cement is 4.5%, the mass ratio of fly ash to cement is 2.0, the mass ratio of quartz sand powder to cement is 1.5, and the high ductility concrete is made by mixing, and the thickness of the high ductility concrete hollow structure layer is 250mm;

[0056] The prestressed layer of resin-based composite material is made by winding glass fiber prepreg yarn impregnated with polyetheretherketone resin, with a thickness of 4mm;

[0057] After performance test: tube stiffness ≥ 150000, roughness coefficient ≤ 0.0084.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com