Sticking type dumbbell-shaped test piece mold for testing concrete axial tensile performance and test method

A concrete and paste-type technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and strength characteristics. The effect of regular parts, uniform and reasonable force on the mold, and accurate size of the test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

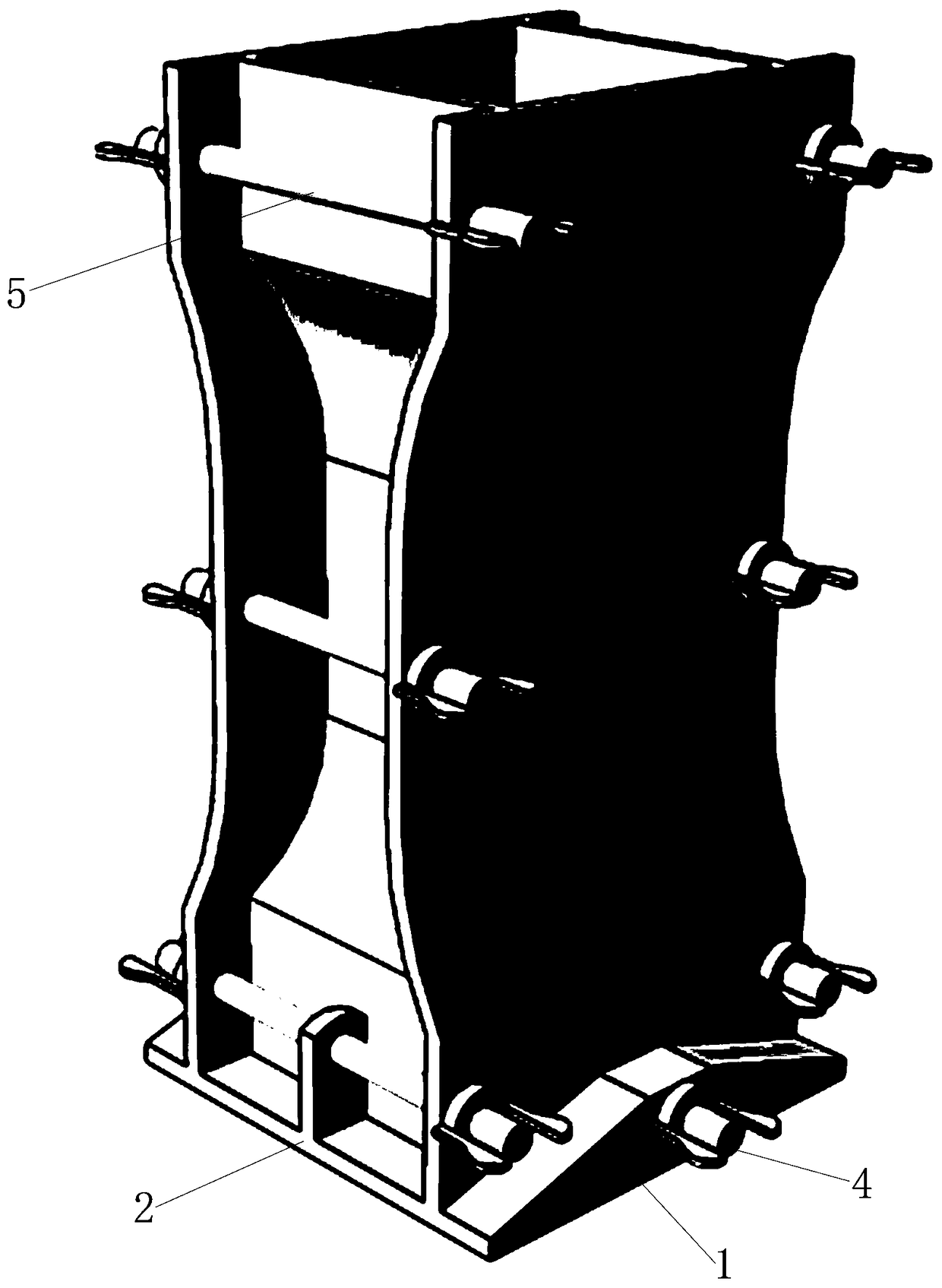

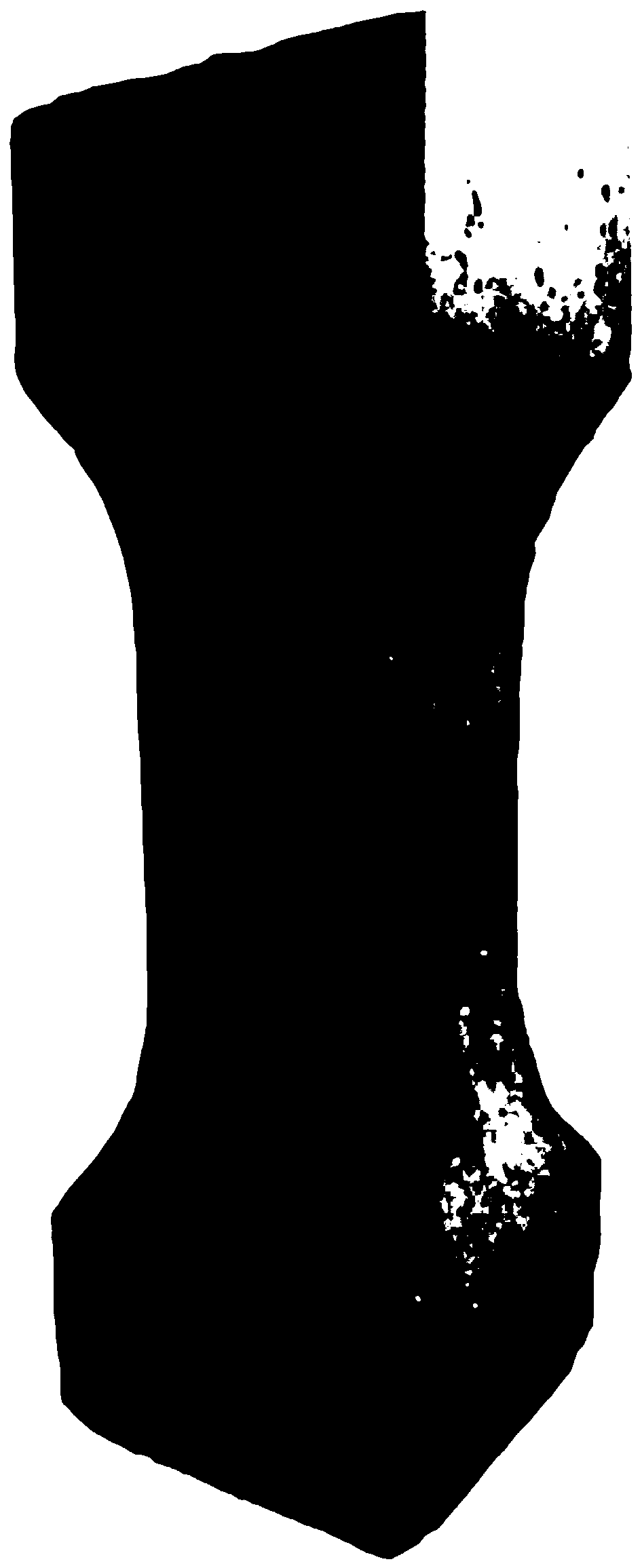

[0050] The present invention is a vertical mould. It consists of bottom plate, front and rear side plates, left and right side plates, and three different thumb bolts. The front and rear of the base plate are respectively fixedly connected with the side plates, and both the base plate and the side plates are reserved with fixing holes and mounting holes; the two ends of the base plate are provided with fixing plates, the front and rear side plates are embedded in the two fixing plates, and the fixing plates are provided with automatic The bolt holes are used to hold against the side plates to prevent the side plates from slipping; the front and rear side plates are installed through the mounting holes and fixing holes through the bolts, and the front and rear side plates and the bottom plate are fixed together by bolts to form a A whole; the left and right side plates are embedded in the front and rear side plates, and the front and rear side plates are provided with fixed blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com