Method for manufacturing air distribution blower

A purifier and gas distribution technology, applied in the field of powder metallurgy, can solve the problems of unsatisfactory gas permeability and strength, low strength and wear resistance, and uniform distribution of difficult gases, so as to ensure high strength and uniform deformation. , The effect of strength improvement and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

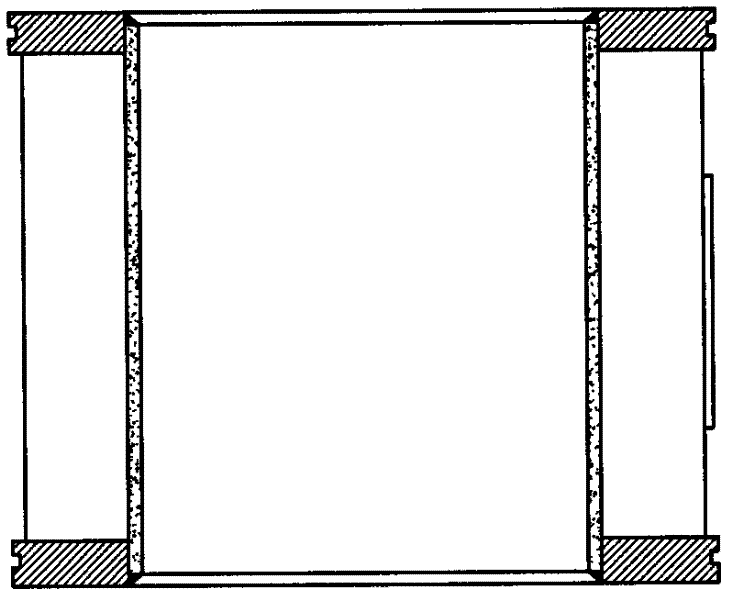

[0025] This example is prepared as figure 1 316L multi-hole tubular purger shown.

[0026] Add 2wt% binder to the stainless steel powder with a particle size of 200 to 300 meshes. The binder in this example is a mixture of carboxymethyl cellulose and polymethyl methacrylate in a weight ratio of 1:4 ; The stainless steel powder and the binder are mixed uniformly by ball milling, pressed in a cold isostatic press, and the pressed blank is sintered in a hydrogen atmosphere.

[0027] A stainless steel wire mesh with a wire diameter of 0.5 mm was selected.

[0028] The surface finish of the pressing mold mandrel is 8.0, the hardness of the rubber sleeve used is 80HA, and the surface finish of the stainless steel shell is 8.0.

[0029] The stainless steel wire mesh and the above-mentioned mixed stainless steel powder are filled in a pressing mold. Under the pressing pressure of 200 MPa, the blank 3 of Ф200×5×400 was pressed in a cold isostatic press. The partial cross-sectional ...

Embodiment 2

[0033] This example is prepared as figure 1 316L multi-hole tubular purger shown.

[0034] Based on the weight of the stainless steel powder, add a binder with a total amount of 3 wt% to the stainless steel powder with a particle size of 200-300 mesh, and mix evenly by ball milling. The binder used is a mixture of carboxymethyl cellulose and polymethyl methacrylate, wherein the amount of carboxymethyl cellulose is 2 wt%, and the amount of polymethyl methacrylate is 1 wt%.

[0035] A stainless steel wire mesh with a wire diameter of 0.1 mm was selected.

[0036] The surface finish of the pressing mold mandrel is 7.5, the hardness of the rubber sleeve used is 70HA, and the surface finish of the stainless steel shell is 7.5.

[0037] The stainless steel wire mesh and the above-mentioned mixed stainless steel powder are filled in a pressing mold. Under the pressing pressure of 150 MPa, the blank 3 of Ф200×5×400 was pressed in a cold isostatic press. The partial cross-sectional...

Embodiment 3

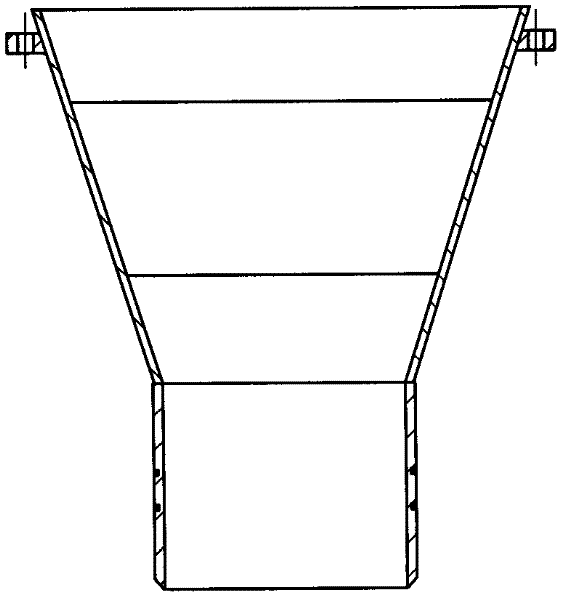

[0041] This example is prepared as figure 2 316L Multi-Porous Cone Purger shown.

[0042] Based on the weight of the stainless steel powder, add a binder with a total amount of 3 wt% to the stainless steel powder with a particle size of 100-160 mesh, and mix evenly by ball milling. The binder used is carboxymethyl cellulose.

[0043] A stainless steel wire mesh with a wire diameter of 0.8 mm was selected.

[0044] The surface finish of the mandrel of the pressing mold is 7.5, the hardness of the rubber sleeve used is 90HA, and the surface finish of the stainless steel shell is 7.

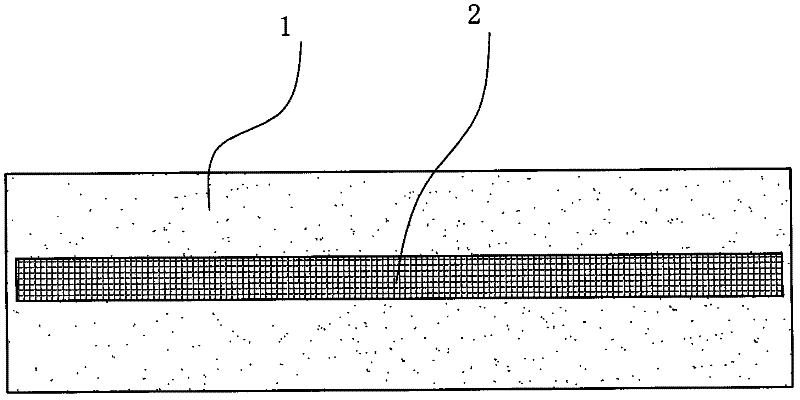

[0045] The stainless steel wire mesh and the above-mentioned mixed stainless steel powder are filled in a pressing mold. Under the pressing pressure of 250MPa, it is pressed into a conical blank of Ф440 / 330, thickness 8mm, and taper 12° in a cold isostatic press, such as figure 2 As shown, the partial cross-sectional view of the blank is as follows image 3As shown, stainless steel wire mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com