High-efficiency module back-stroke displacement heat exchanger

A volumetric, heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as extremely high requirements for civil engineering and load capacity, heavy equipment operation weight, and complex installation process. , to achieve the effect of low maintenance cost, high pressure bearing capacity, and easy maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

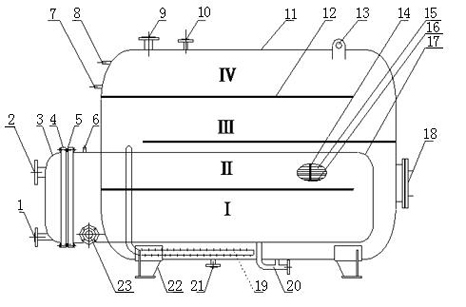

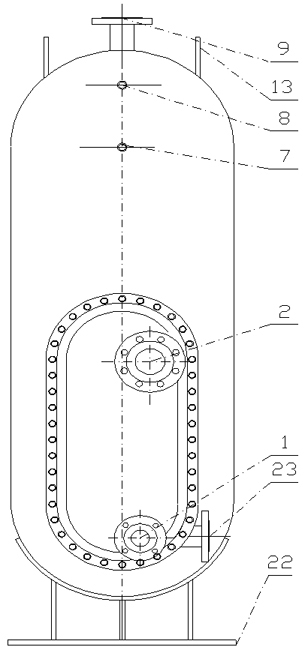

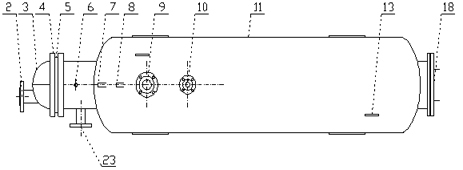

[0042] Such as figure 1 As shown, the high-efficiency module return volumetric heat exchanger includes the primary heat medium inlet flange 2 and the primary heat medium outlet flange 1 connected by the outer pipeline, including the primary heat medium inlet flange 2 and the primary heat medium The tube sheet 5 at the entrance of the outlet flange 1, the fixed heat exchange tube 15 of the tube sheet 5 extends horizontally to the chamber cylinder 17, and is characterized in that it also includes a cylinder 11 with holes on one side of the cylinder 11, and the holes make The chamber cylinder 17 extends horizontally into the cavity of the cylinder 11. In the cavity of the cylinder 11, return partitions 12 are arranged horizontally above and below the chamber cylinder 17 to form multiple return mixing chambers. The horizontal chambers The cylinder body 17 communicates with the vertical cylinder body 11 through a porous radiant tube 19. When working, the primary heat medium enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com