Pipeline robot

A pipeline robot and controller technology, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of poor driving performance and poor waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

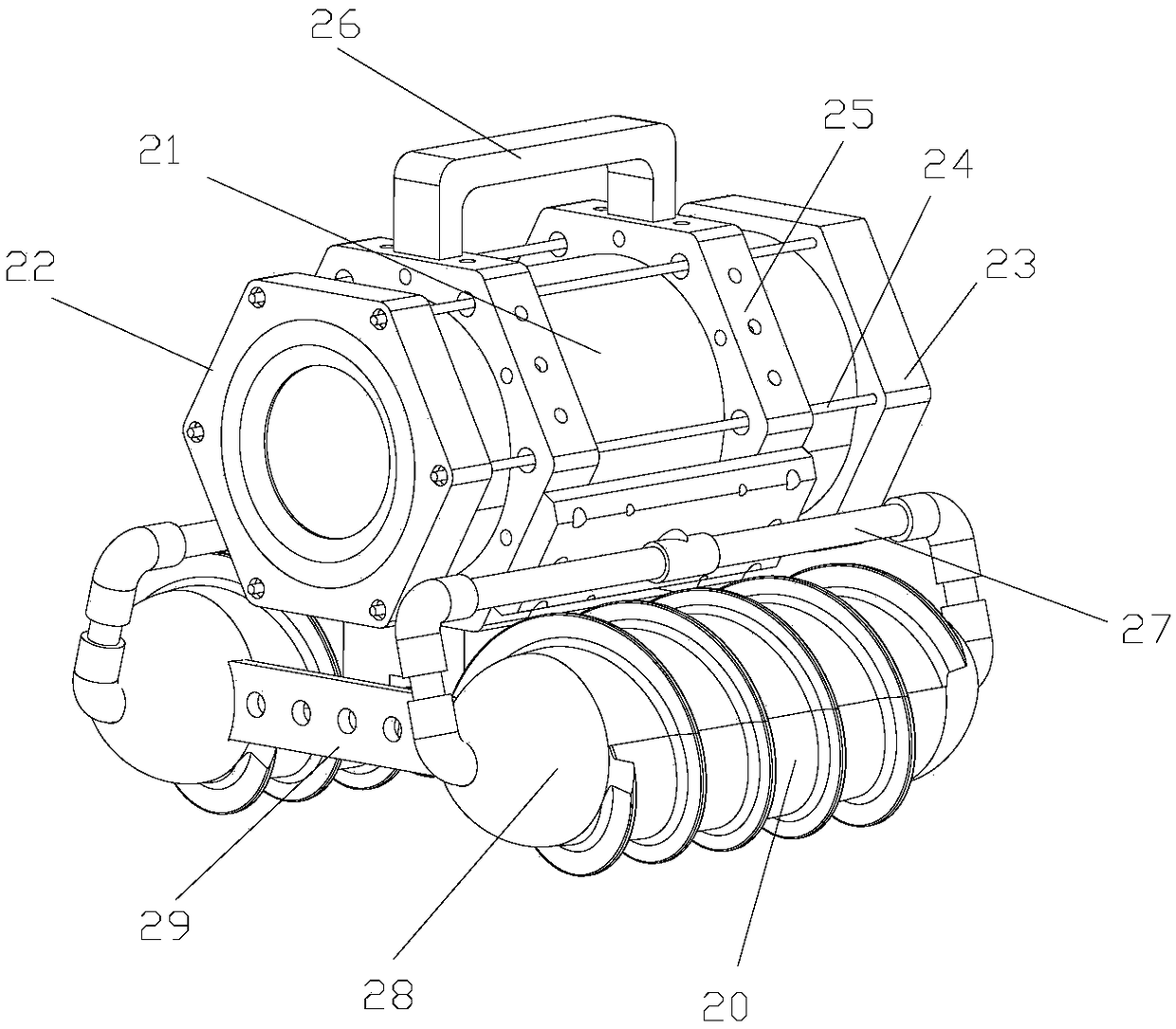

[0057] Such as Figure 1-18 As shown, a pipeline robot includes a bracket and two driving rollers that are rotatably arranged on the bracket, and a controller fixed on the bracket. The controller is arranged in the first cylinder 21, and the first cylinder is fixed on the bracket. above; the two ends of the first cylinder 21 are provided with internal threads, the front end cover 22 and the rear end cover 23 are provided with external threads, the first cylinder is threadedly connected with the front end cover and the rear end cover, and the threaded connection is convenient for disassembly installed and connected securely. The front end cover includes a front cavity and a transparent cover plate, a camera is arranged in the front cavity, the transparent cover plate is sealed and arranged at the front end of the cavity, and the camera is electrically connected to the controller.

[0058] In other embodiments, the first cylinder may be a structure with one end integrally close...

Embodiment 2

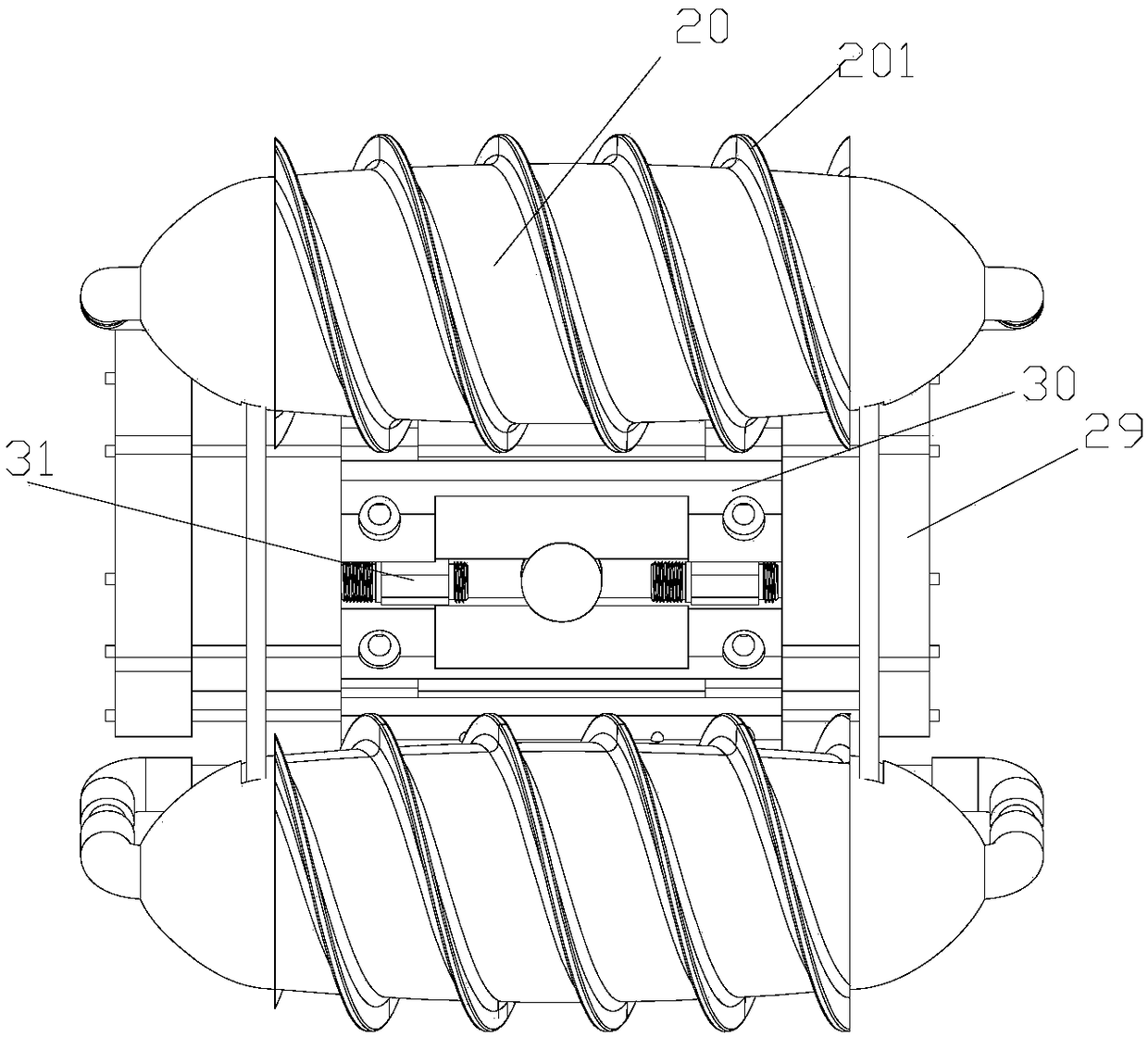

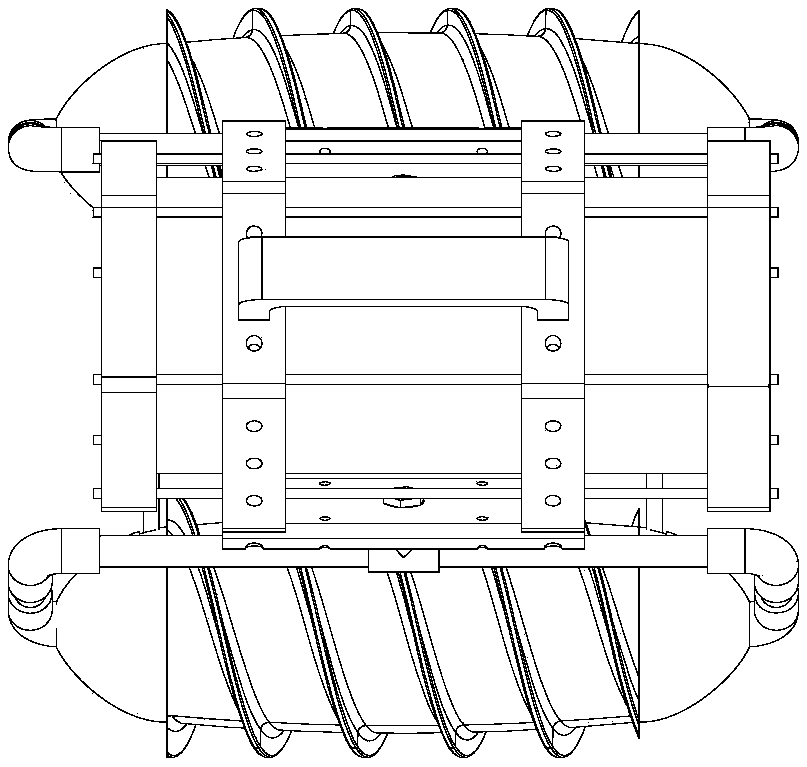

[0088]In this example, if Figure 19 As shown, the outer peripheral surface of the housing 20 is uneven, with spiral grooves and spiral protrusions, and the intersection line between the plane passing through the axis of the housing and the outer peripheral surface of the housing is a sinusoidal curve; the spiral blade 201 is located on the protrusions.

[0089] Because there will be some silt in the pipeline, when the pipeline robot walks in the pipeline, the lower part of the shell will sink into the silt, and the outer peripheral surface of the shell will be in full contact with the silt. By designing the surface of the shell to be uneven, the distance between the shell and the The contact surface of the inner ratio of the pipe increases the friction, prevents slipping and improves the driving performance.

[0090] In this embodiment, the profile of the end face of the spiral blade is a horizontal line at the top and symmetrical arcs on both sides;

[0091] In the plane wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com