Configuration method for super-large-diameter cutter head and cutter

A technology with a super-large diameter and cutter head, which is applied in the field of shield machines, can solve the problems of inconvenient tool change and inconvenient transportation, and achieve the effects of reducing the probability of being trapped, increasing the allowable wear amount, and improving the rock-breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

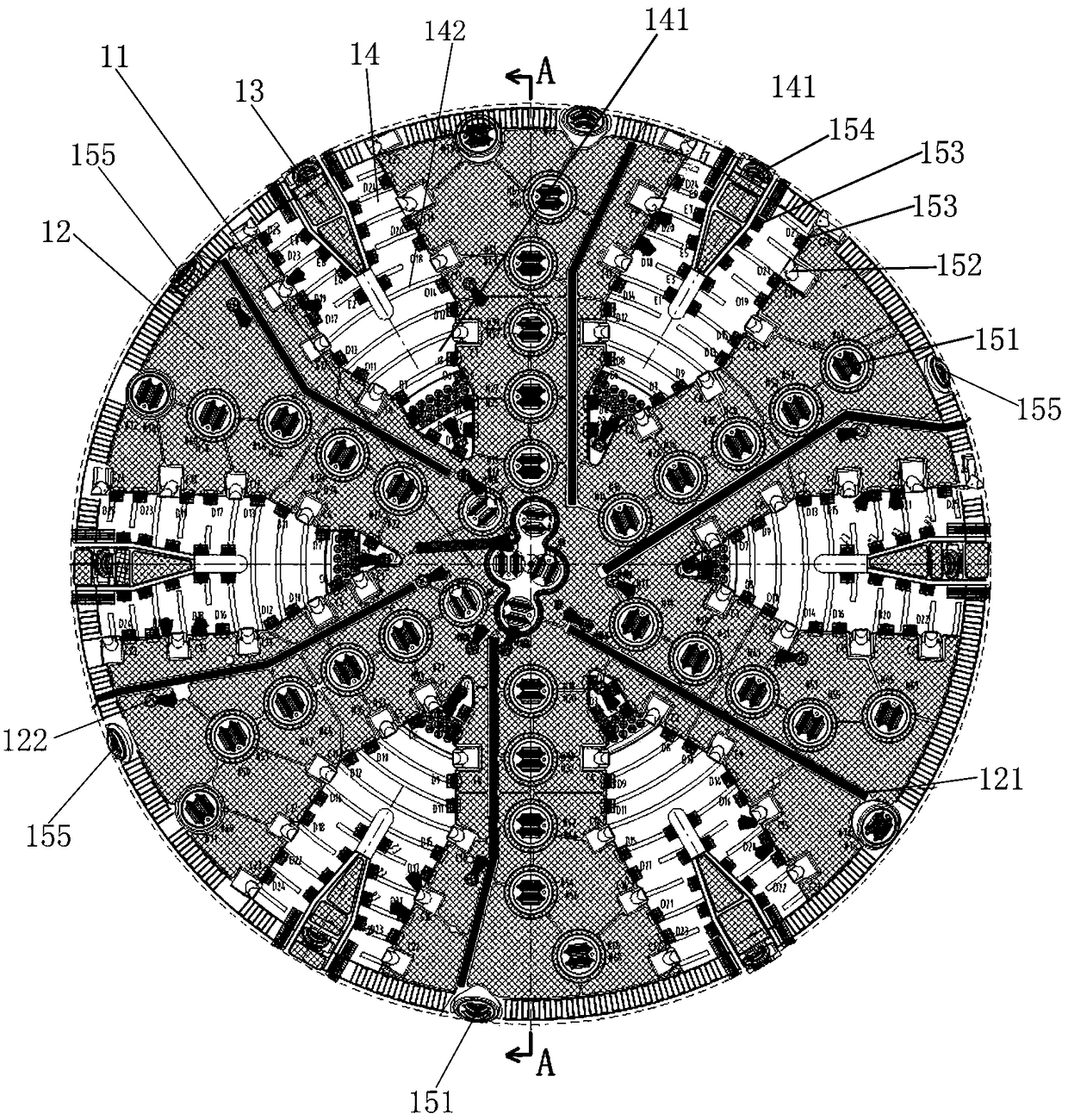

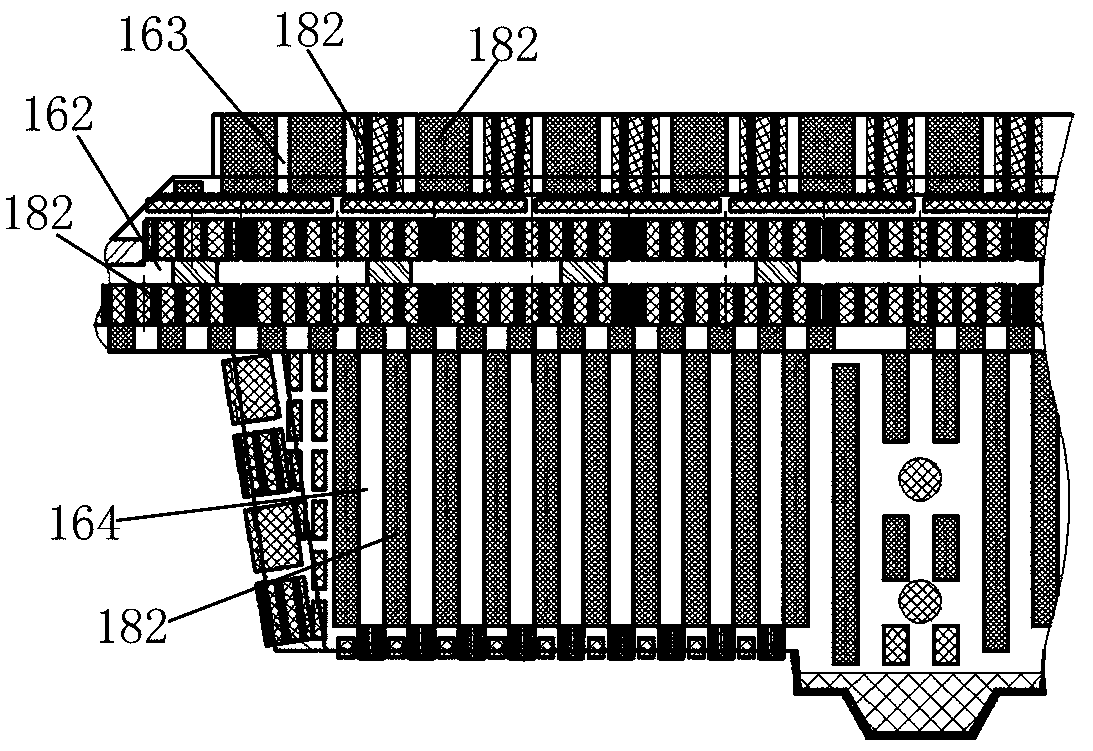

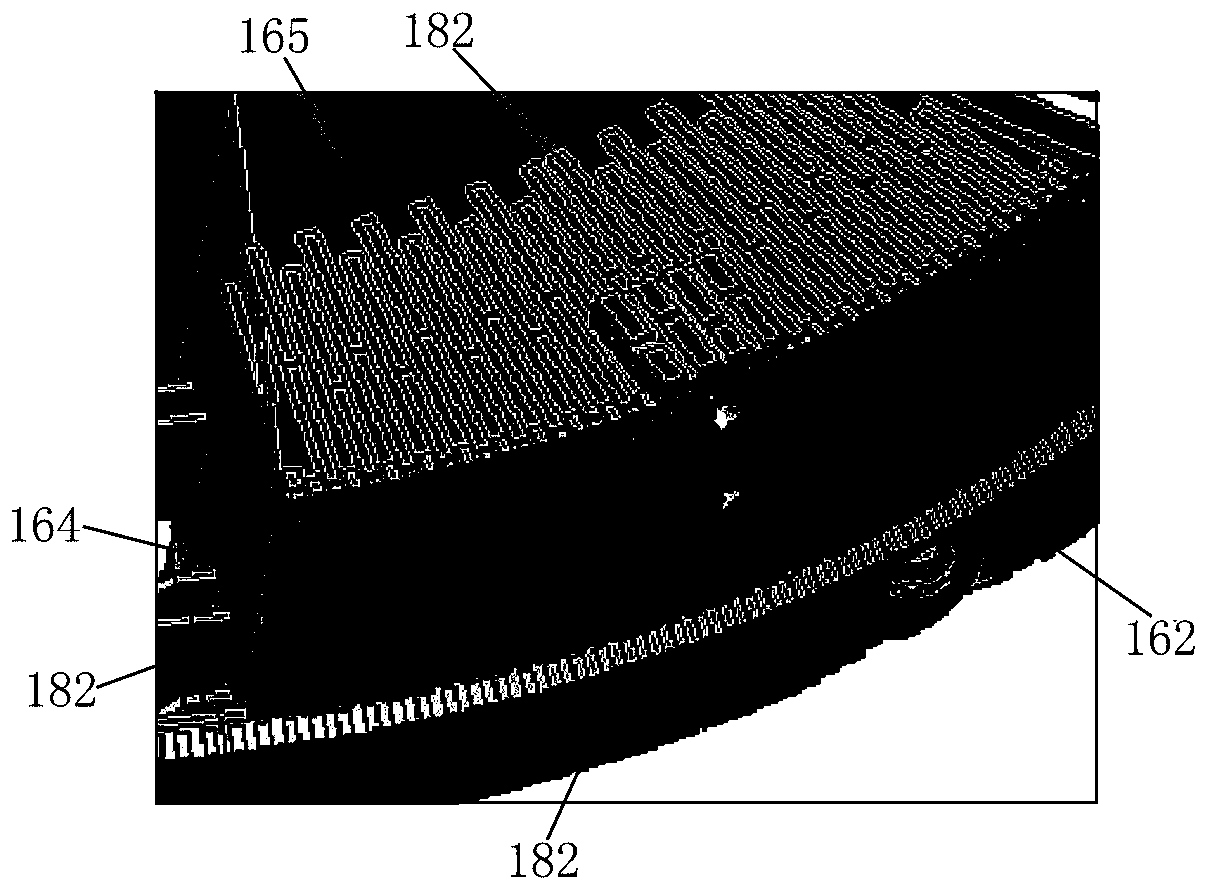

[0056] see Figure 1 to Figure 19 .

[0057] Such as figure 1 and figure 2 As shown, the ultra-large-diameter cutter head provided by the embodiment of the present invention includes a central block 11 and a plurality of cutter head side blocks arranged around the central block 11, and the cutter head side blocks include main cutter head side blocks 12 (Table The hollow main beam in 1) and the sub-cutter side block 13 (the sub-beam in Table 1), the main cutter head side block 12 and the sub-cutter side block 13 each have six. Since the ultra-large diameter cutter head is made in blocks, it is convenient to transport from the production site to the construction site, and then the central block 11, the main cutter head side block 12 and the auxiliary cutter head side block 13 are connected and positioned by bolts and positioning pins, and finally welded As a whole, after welding, remove the bolts and positioning pins.

[0058] Both the central block 11 and the side blocks 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com