Bearing seal groove forming plunge-cut grinding method

A technology of plunge grinding and bearing sealing, which is used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of difficult to guarantee the quality of the sealing groove, large dimensional dispersion, and measurement is not very good, to improve the grinding efficiency. The effect of cutting precision, reducing wear and avoiding chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

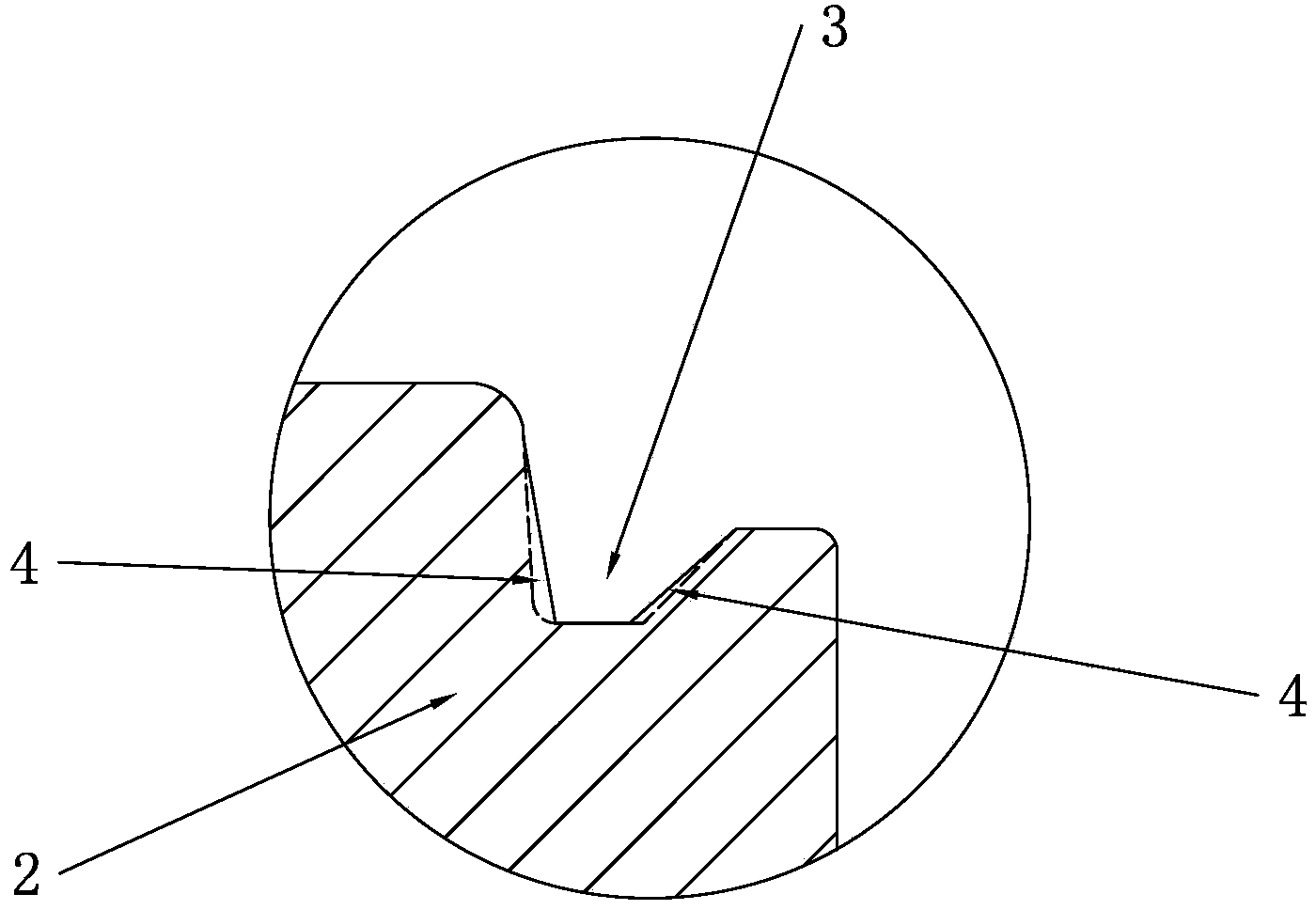

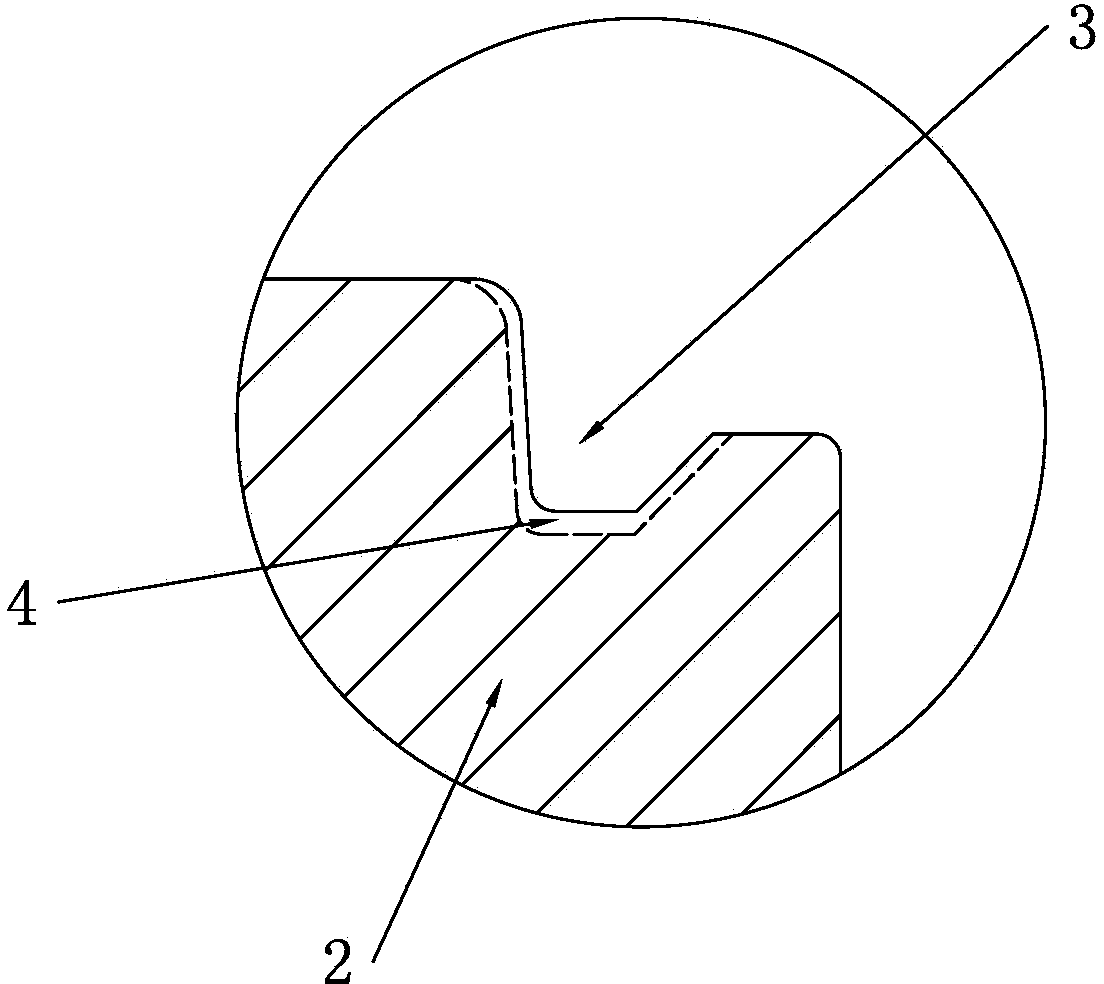

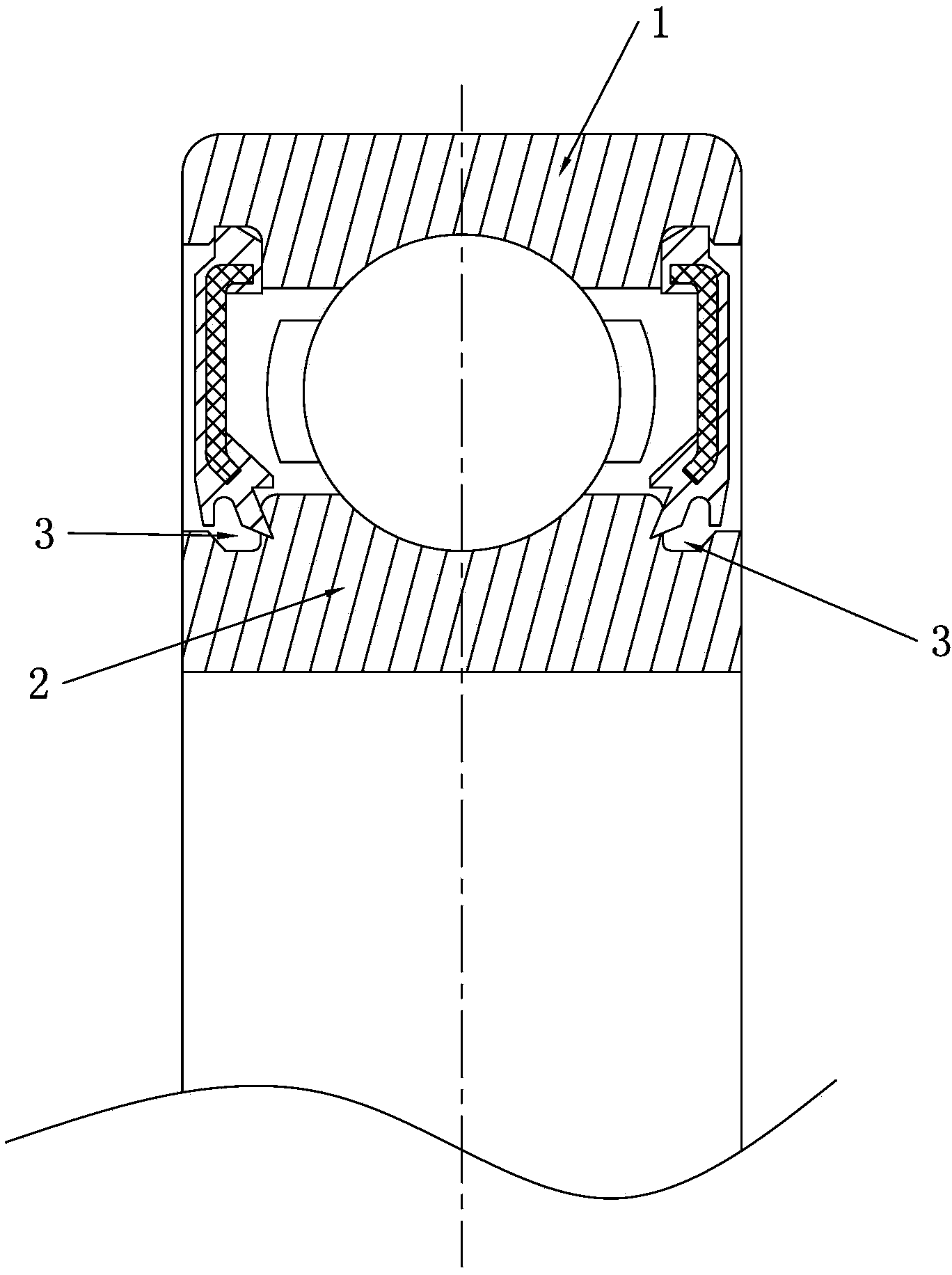

[0032] Implementation mode one: if figure 1 As shown, the forming plunge grinding method of the bearing seal groove 3 of the present invention includes the following steps:

[0033] Step 1: Process the sealing groove 3 of the bearing inner ring 2 into a preform, and leave a margin 4;

[0034] Step 2: use the diamond roller to grind the sealed groove 3 and the raceway of the inner ring 2 with the trimmed grinding wheel;

[0035] Step 3: Finish grinding;

[0036] The margin 4 in the seal groove 3 of the inner ring 2 is a gradual margin 4; the gradual margin 4 means that the margin 4 in the seal groove 3 gradually thickens from the mouth of the seal groove 3 to the bottom of the seal groove 3; The external shape of the above-mentioned grinding wheel is correspondingly matched with the sealing groove 3 and the raceway.

[0037] When grinding the inner ring 2 of the bearing with the design of gradual allowance 4, it has high efficiency. As long as the preform is processed by tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com