Friction locking type magnetic lifter and control method thereof

A control method and lifter technology, applied in the field of friction-locking magnetic lifters, can solve the problems of stuck moving parts, small fitting gaps between parts, small guide gaps between mover components and sealing shells, etc., and achieve high reliability , the effect of not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

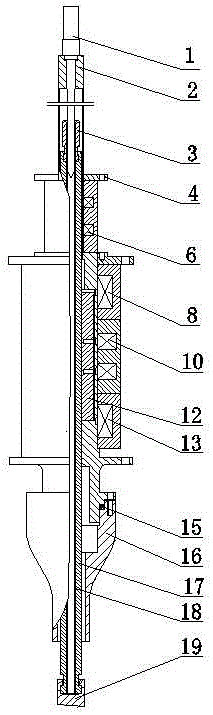

[0048] Such as figure 1 A friction-locking magnetic lifter is shown, comprising a sealing case 2, a driving rod assembly and an armature 12 all located in the sealing case 2, and the driving rod assembly includes a friction rod 17; The armature housing cavity where the shaft of the rod 17 moves, the armature 12 is placed in the armature housing cavity; the sealing shell 2 is provided with a holding assembly, a moving assembly and a lifting assembly outside, and the holding assembly, the moving assembly, and the lifting assembly all include a yoke and are installed on the yoke The internal coil, the electromagnetic force generated after the coil 6 of the holding component is energized makes the friction rod 17 close to the sealing shell 2, the electromagnetic force generated after the coil 10 of the moving component is energized makes the friction rod 17 close to the armature 12, and the coil 8 of the lifting component The electromagnetic force generated after electrification d...

Embodiment 2

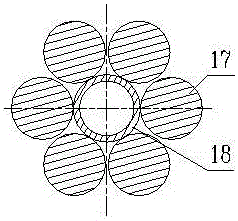

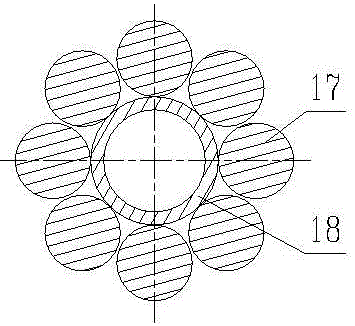

[0070] This embodiment is refined on the basis of the above-mentioned embodiment, that is, the drive rod assembly also includes a core rod 18 and a plurality of friction rods, and a plurality of friction rods 17 are arranged in parallel with the core rod 18 and surround the core rod 18, as Figure 2 to Figure 7 It is a radial cross-sectional view of six different core rods 18 and friction rods 17; the two ends of the core rod 18 and friction rod 17 are respectively provided with a magnetic block 3 and a control rod connecting rod 19 for fixing and limiting the two. The rod connecting rod is connected with the control rod assembly; the rod position detector 1 is installed on the sealed shell 2, and the rod position detector 1 detects the position of the magnetic block 3 to obtain the actual position of the driving rod assembly and the control rod assembly connected to it .

[0071] The rod position detector 1 can be arranged on the top of the sealed casing, and inserted into th...

Embodiment 3

[0074] An elastic component 20 that can drive the armature 12 to move down along the axis of the drive rod assembly is arranged in the sealing shell 2 . The elastic member is preferably a spring, and the spring has a downward force on the armature, which can accelerate the downward movement of the armature and ensure the stability of the armature and drive rod assembly in the control step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com