Resin grinding wheel and preparation method thereof

A technology of resin grinding wheel and phenolic resin solution, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve problems such as poor flatness, and achieve the effects of improving service life, good heat dissipation, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

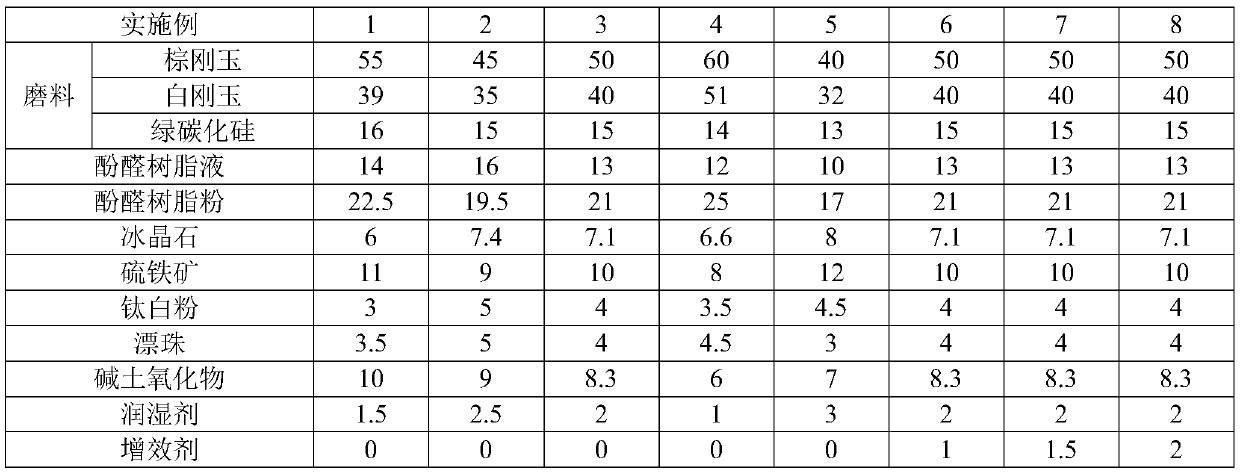

[0040] A kind of resin grinding wheel, its raw material ratio is shown in Table 1.

[0041] S1. Mix brown corundum, white corundum and green silicon carbide evenly to obtain abrasives;

[0042] Among them, Al in brown corundum 2 o 3 The weight content is 95%; Al in white corundum 2 o 3 The weight content of SiC in green silicon carbide is 98%; the weight content of SiC in green silicon carbide is 97%.

[0043] S2, mixing cryolite, pyrite, and titanium dioxide evenly to obtain a mixture a;

[0044] Among them, Na in cryolite 3 AlF 6 The weight content is 97%; FeS in pyrite 2 The weight content is 75%; TiO2 in titanium dioxide 2 The weight content is 97%.

[0045]S3. In the case of constant stirring, spray the phenolic resin liquid into the abrasive, then add floating beads and alkaline earth oxide, then add the mixture a and wetting agent in turn, and mix evenly to obtain the mixture b;

[0046] Among them, the phenolic resin solution is selected from PF5401; the floa...

Embodiment 2

[0053] A kind of resin grinding wheel, its raw material ratio is shown in Table 1.

[0054] S1. Mix brown corundum, white corundum and green silicon carbide evenly to obtain abrasives;

[0055] Among them, Al in brown corundum 2 o 3 The weight content is 95%; Al in white corundum 2 o 3 The weight content of SiC in green silicon carbide is 98%; the weight content of SiC in green silicon carbide is 97%.

[0056] S2, mixing cryolite, pyrite, and titanium dioxide evenly to obtain a mixture a;

[0057] Among them, Na in cryolite 3 AlF 6 The weight content is 97%; FeS in pyrite 2 The weight content is 75%; TiO2 in titanium dioxide 2 The weight content is 97%.

[0058] S3. In the case of constant stirring, spray the phenolic resin solution into the abrasive, then add floating beads and alkaline earth oxide, then add the mixture a, synergist, and wetting agent in sequence, and mix evenly to obtain the mixture b;

[0059] Among them, the phenolic resin solution is selected fr...

Embodiment 3

[0066] A kind of resin grinding wheel, its raw material ratio is shown in Table 1.

[0067] S1. Mix brown corundum, white corundum and green silicon carbide evenly to obtain abrasives;

[0068] Among them, Al in brown corundum 2 o 3 The weight content is 95%; Al in white corundum 2 o 3 The weight content of SiC in green silicon carbide is 98%; the weight content of SiC in green silicon carbide is 97%.

[0069] S2, mixing cryolite, pyrite, and titanium dioxide evenly to obtain a mixture a;

[0070] Among them, Na in cryolite 3 AlF 6 The weight content is 97%; FeS in pyrite 2 The weight content is 75%; TiO2 in titanium dioxide 2 The weight content is 97%.

[0071] S3. In the case of constant stirring, spray the phenolic resin solution into the abrasive, then add floating beads and alkaline earth oxide, then add the mixture a, synergist, and wetting agent in sequence, and mix evenly to obtain the mixture b;

[0072] Among them, the phenolic resin solution is selected fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com