Dry friction rotary seal device for numerical control punching machine

A CNC punching machine and rotary sealing technology, which is applied in the direction of engine seals, bearing components, engine components, etc., can solve problems such as wear and seal failure, and achieve the effect of ensuring reliability and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

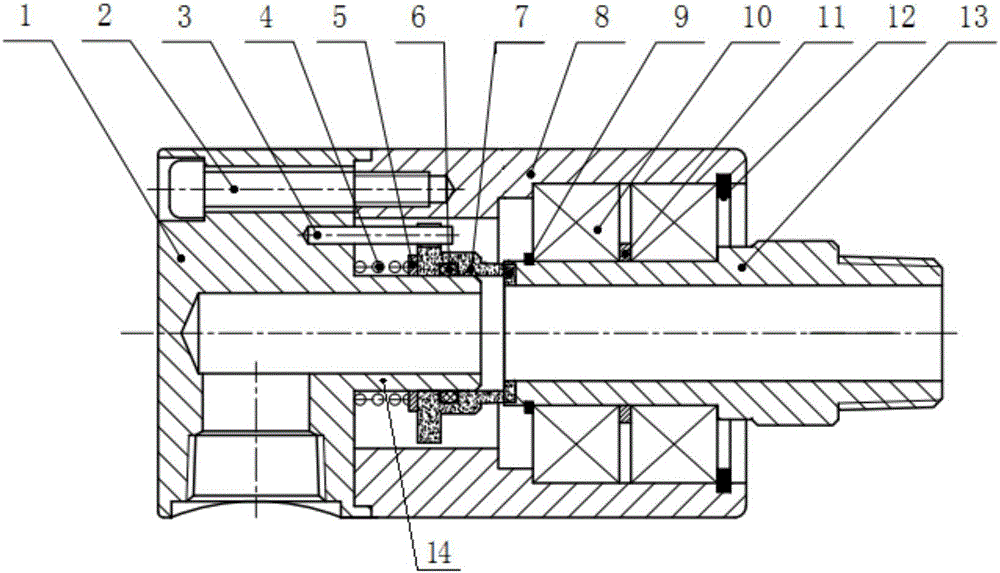

[0030] refer to figure 1 , this embodiment provides a dry friction rotary sealing device for a CNC punching machine, which is suitable for the sealing between the back cover 1 and the corresponding hollow shaft 13 of a CNC punching machine, and the fluid medium flows through the back cover 1 and the hollow shaft in turn. For the rotating shaft 13 , the fluid medium may be used for cooling the hollow rotating shaft 13 , for example. It should be noted that the structure is relatively complicated. In order to simplify the drawings for easy understanding, only the local structure directly related to the sealing device is shown in the drawing. For other structural components of the CNC punching machine, they are all existing structures. For this Invented innovations are not linked and therefore not exhaustively shown in the figure.

[0031] In this embodiment, the rear cover 1 is fixed, and the hollow rotating shaft 13 rotates at a high speed relative to the rear cover 1 . In or...

Embodiment 2

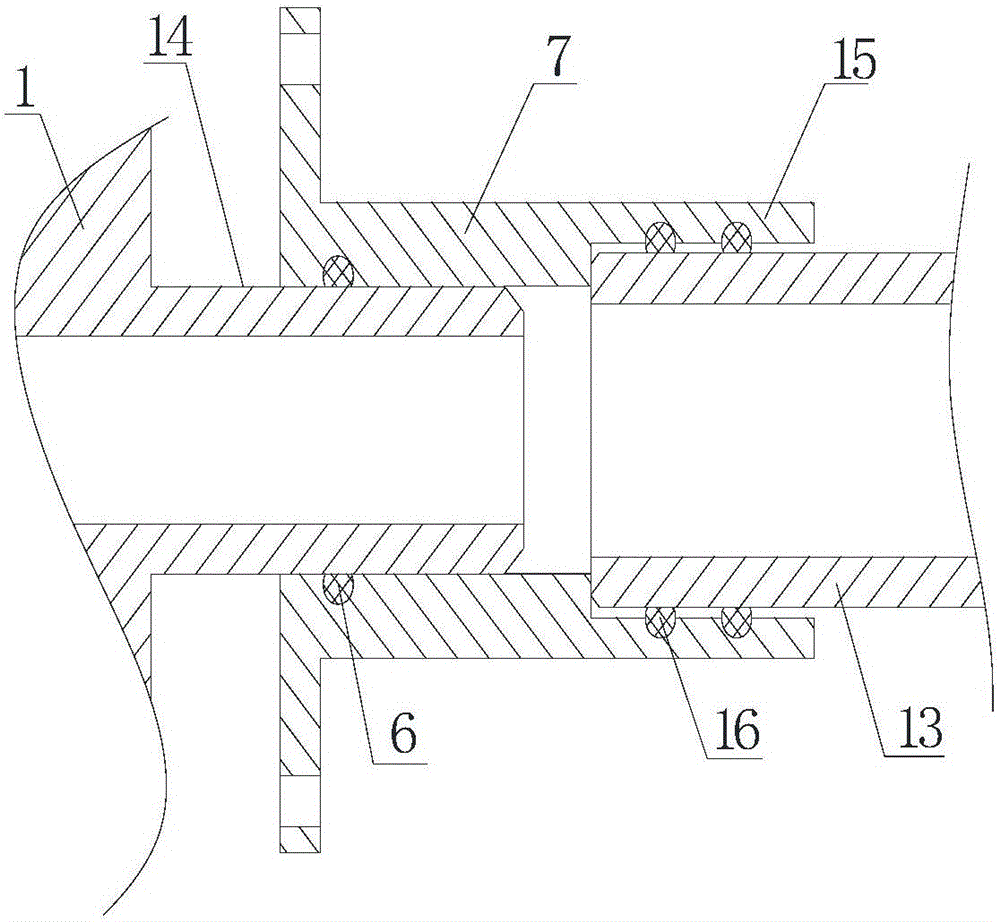

[0044] refer to figure 2 , this embodiment also provides a dry friction rotary sealing device for a CNC punching machine, which is a further improvement on the basis of the technical solution of the first embodiment, and the technical solution described in the first embodiment also belongs to this embodiment, and the first embodiment The described technical solutions will not be repeated.

[0045] It should be noted, figure 2 mainly shows the relative figure 1 features further improved by the structure shown and, therefore, are not shown in full figure 1 other structures.

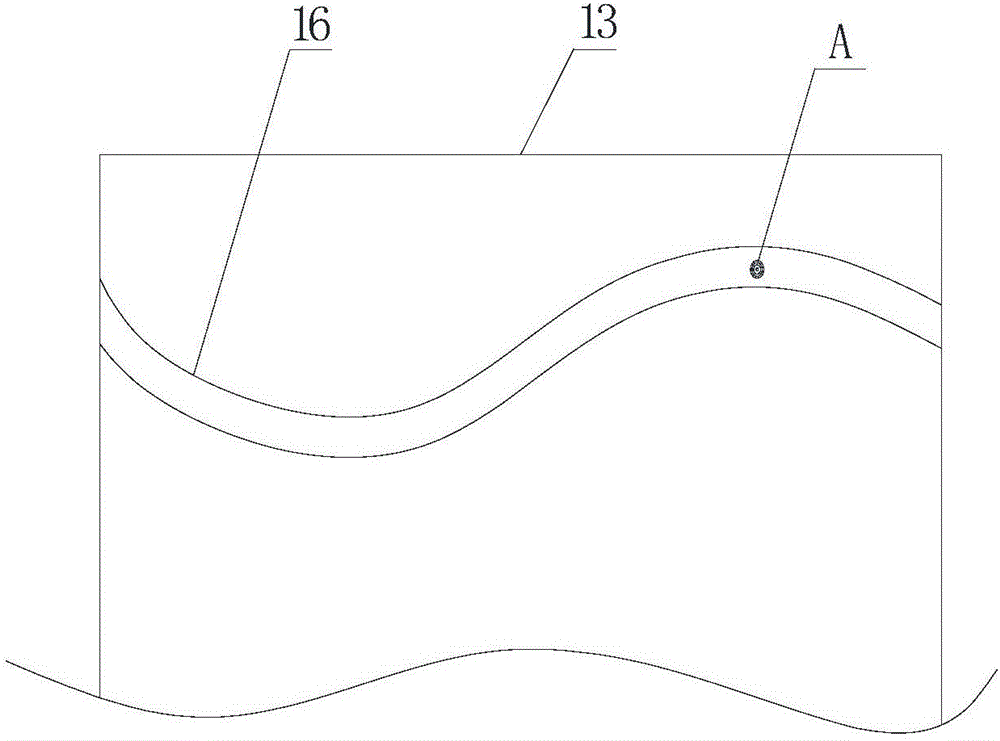

[0046] On the basis of the technical solution of Embodiment 1, this embodiment mainly adds a main seal extension ring 15, whose main function is that when the alarm in Embodiment 1 fails or other reasons cause the main seal ring 7 to be replaced in time , the end face seal fails unexpectedly, and the main seal extension ring 15 can ensure the sealing effect on the main seal ring 7 and the hollow rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com