Riveting floating type brake pad

A brake pad, floating technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of high riveting pressure, inability to guarantee the quality of riveting, and overall deformation of the rivet, so as to improve the service life and increase the effective wear amount , the effect of large fitting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

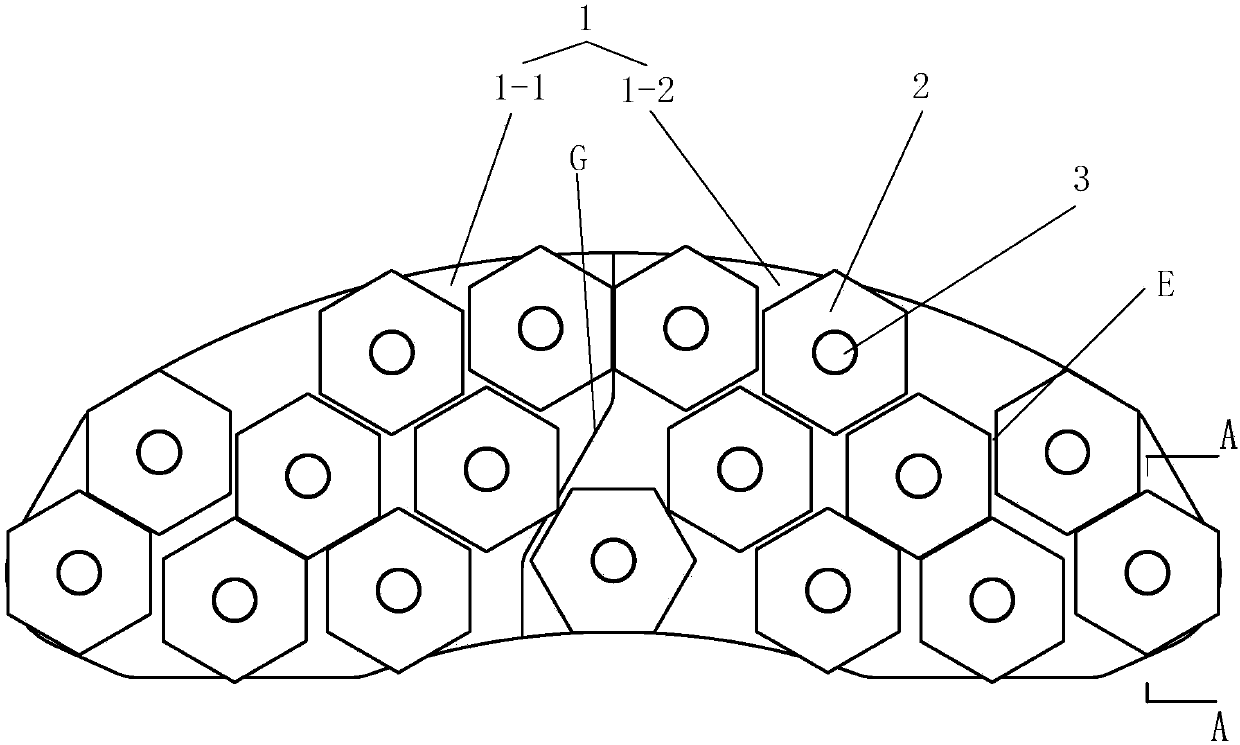

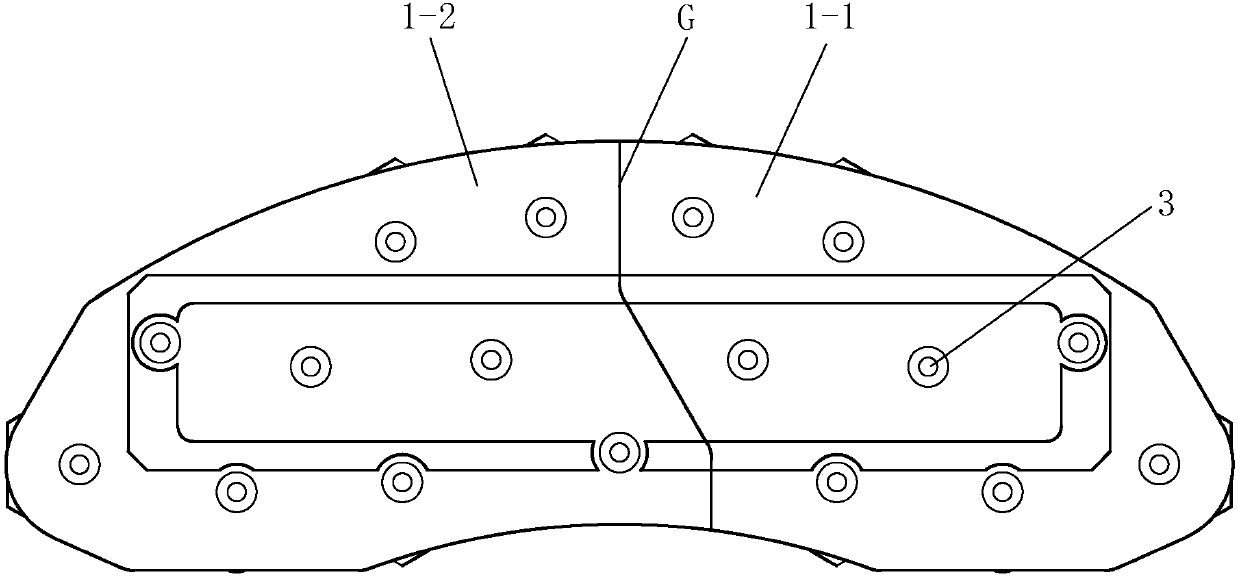

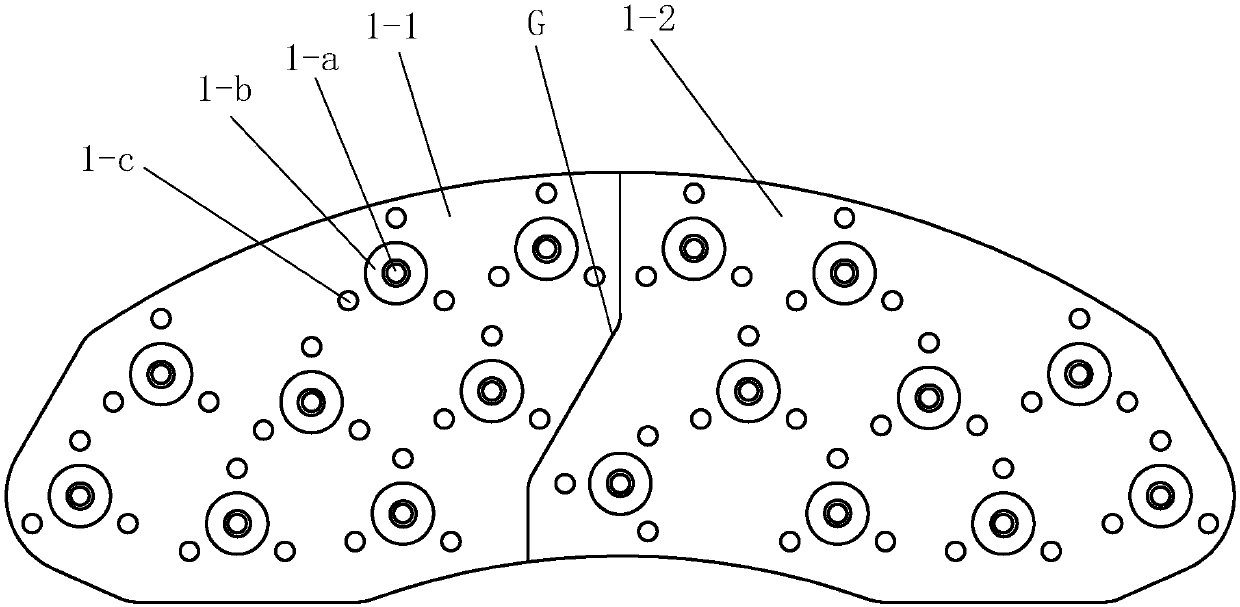

[0020] See Figure 1 to Figure 5 , this embodiment includes a support plate 1 and several friction blocks 2 on the support plate 1 . The friction blocks 2 are hexagonal, and there is a chip removal gap E between the friction blocks 2 . The support plate 1 is composed of a left plate 1-1 and a right plate 1-2. The left plate 1-1 and the right plate 1-2 are spliced asymmetrically along the fold line G along the edge of the friction block, and can be used in a limited area. The maximum number of friction blocks on the support plate is used to increase the area and volume of the friction material. The friction block 2 includes a back plate 2-2 and a friction body 2-1, the friction body 2-1 is a powder metallurgy material, the bottom of the friction body 2-1 has a joint boss 2-1-1, and the corresponding The part has a pit 2-a-4, and the joint boss 2-1-1 of the friction body 2-1 is embedded in the pit 2-a-4 of the back plate 2-2. During the sintering and pressing process, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com