Sliding bearing device

A sliding bearing and bearing technology, which is applied to sliding contact bearings, bearings, bearings in rotary motion, etc., can solve the problems of not finding friction and wear resistance of sliding bearing devices, low slurry wear resistance, and inability to expect long life, etc. Shortened running-in time, improved slurry abrasion resistance, and high foreign matter removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Refer to the following Figure 1 to Figure 10 Embodiments of the sliding bearing device of the present invention will be described. exist Figure 1 to Figure 10 In , the same reference numerals are assigned to the same or corresponding components, and repeated descriptions are omitted.

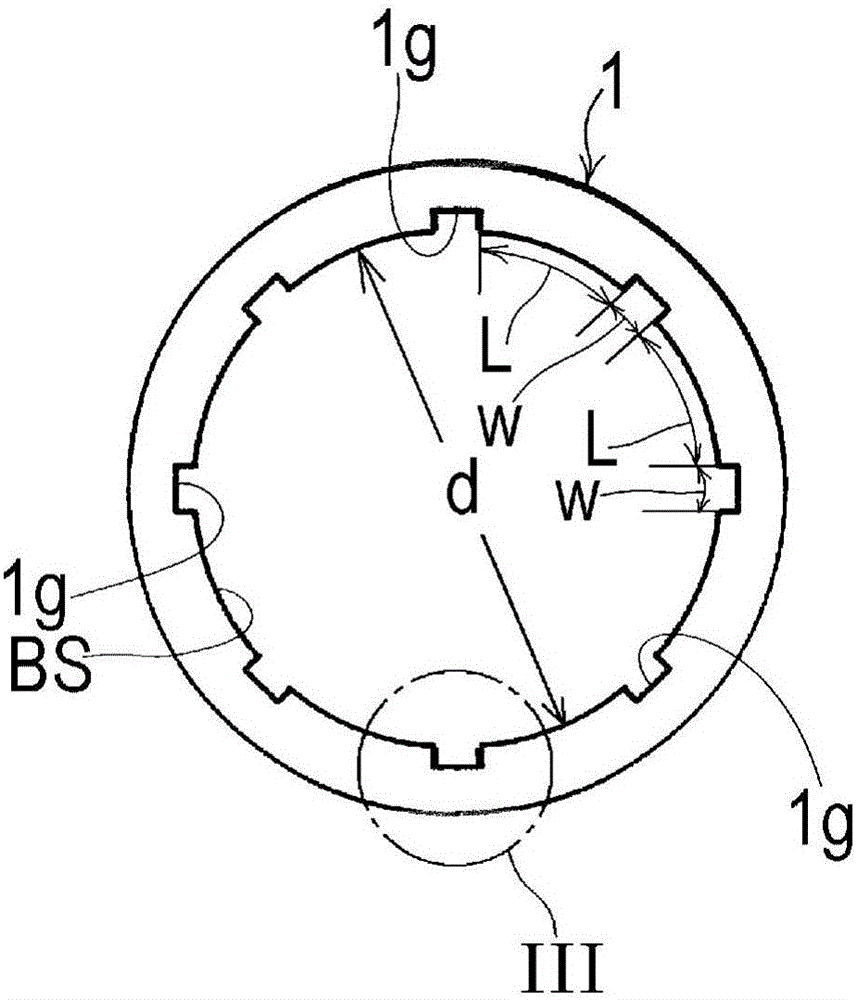

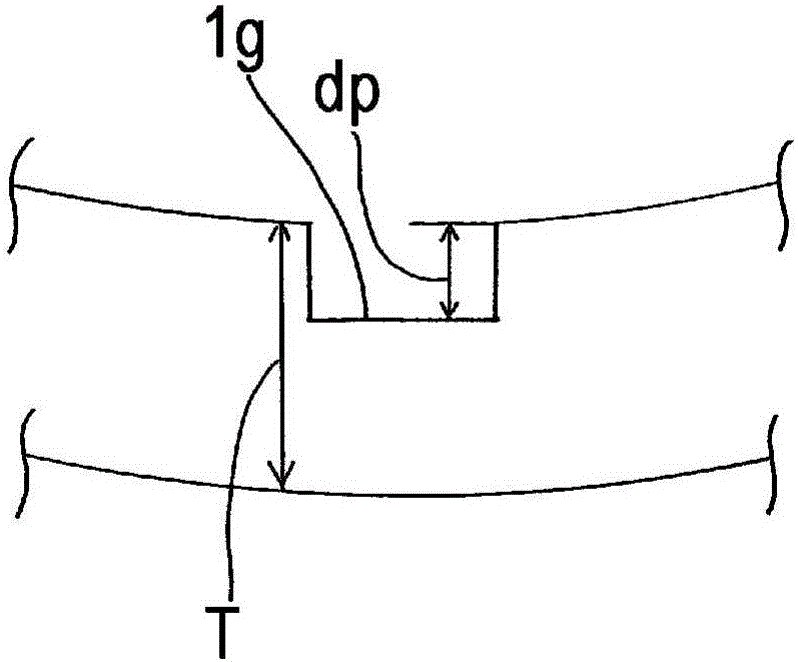

[0048] figure 1 It is a perspective view showing the sliding bearing device of the present invention. like figure 1 As shown, the sliding bearing device 1 is composed of a resin material that does not contain carbon fibers, or a composite material that contains a plurality of carbon fibers whose length is shorter than the circumference of the bearing sliding surface in a resin material that does not contain carbon fibers, and is formed into a cylindrical shape. . Here, the carbon fibers need only be shorter than the circumference of the bearing sliding surface. If a specific numerical value is described, the length of the carbon fibers is preferably 10 μm to 10 mm. The carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com