Lithium-iron disulfide battery

An iron disulfide battery and iron disulfide technology are applied in the field of lithium-iron disulfide battery non-aqueous electrolyte and lithium-iron disulfide battery, which can solve the problems of damaging positive electrode active materials, reducing battery discharge capacity, etc. Shelf life and discharge capacity, effect of inhibiting dissolution, inhibiting internal micro-short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

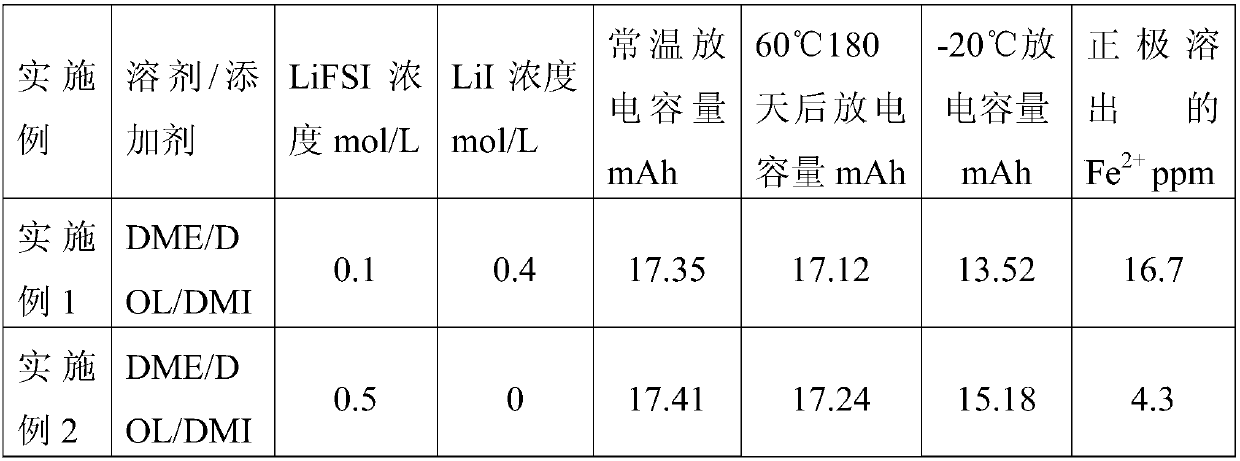

Embodiment 1

[0028] Use DME and DOL as solvents, the concentration of lithium bisfluorosulfonyl imide is 0.1mol / L, the concentration of lithium iodide is 0.4mol / L, and a small amount of additive DMI is added to prepare the non-aqueous electrolyte solution for primary lithium-iron batteries of this embodiment .

Embodiment 2

[0030] DME and DOL were used as solvents, the concentration of lithium bisfluorosulfonyl imide was 0.5 mol / L, and a small amount of additive DMI was added to prepare the non-aqueous electrolyte solution for the primary lithium-iron battery of this embodiment.

Embodiment 3

[0032] Use DME and DOL as solvents, the concentration of lithium bisfluorosulfonyl imide is 1.0mol / L, the concentration of lithium iodide is 1.0mol / L, and a small amount of additive DMI is added to prepare the non-aqueous electrolyte solution for primary lithium-iron batteries of this embodiment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com