Manufacturing process of resistor plate, obtained resistor plate and application thereof

A resistance plate and resistance film technology, applied in the direction of conductive pattern formation, containing printed electrical components, etc., can solve the problems of poor plane roughness, peeling off of the resistance film, and affecting product life, so as to improve the working life, linearity, and flatness Excellent performance and wear resistance, long connection life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

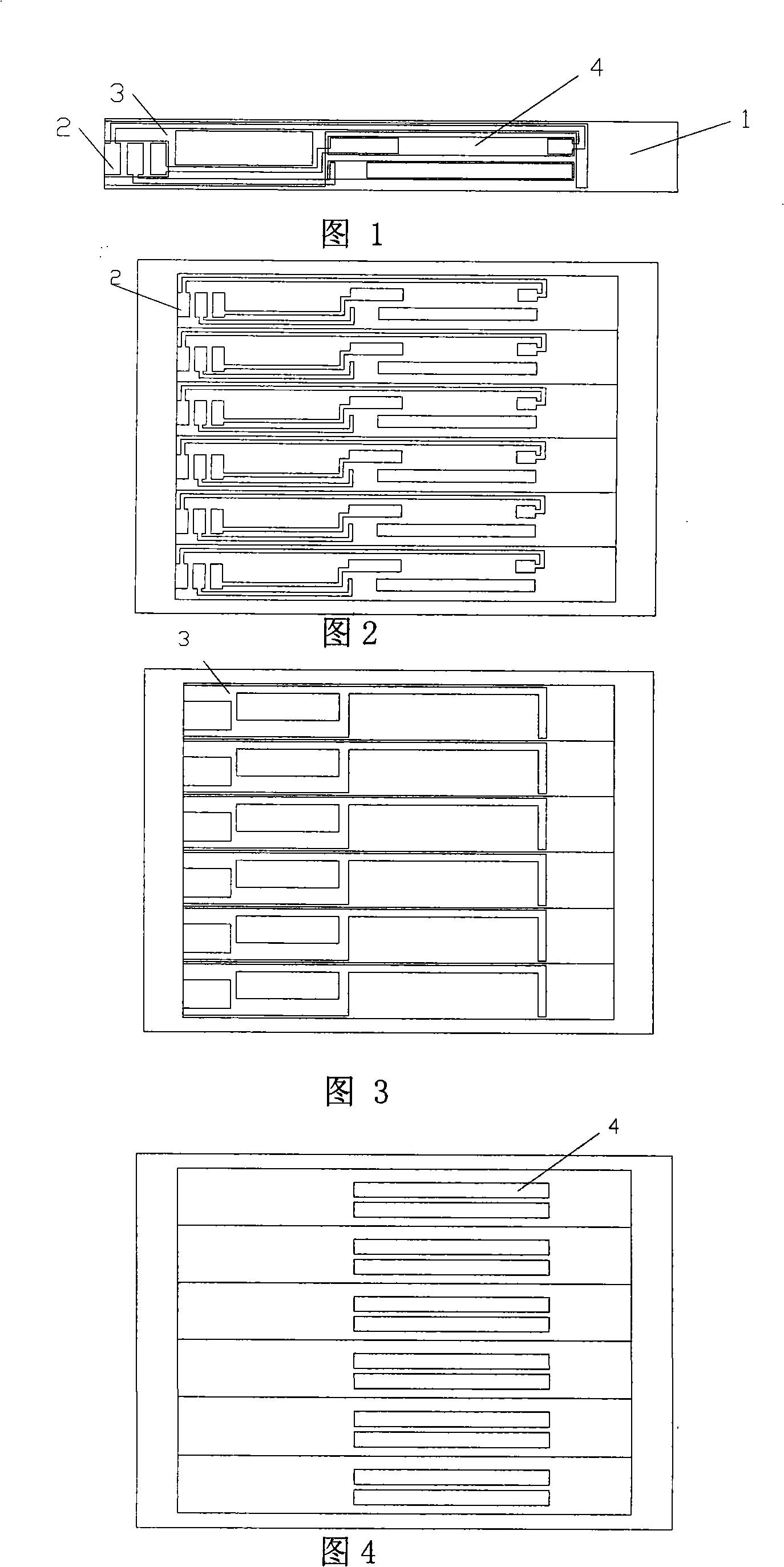

[0015] The gist of the present invention is to use the polyimide film material as the substrate, select the electrode paste, the protective film layer paste, and the resistance paste with a very matching thermal expansion coefficient, and use the technology of screen printing to make a resistance plate. The flatness and wear resistance of the resistance film layer of the resistance plate and the connection life of the resistance film layer and the electrode film layer are guaranteed, thereby successfully improving the working life and linearity of the throttle position sensor. The content of the present invention will be described in further detail below in conjunction with the examples. The content mentioned in the examples is not a limitation of the present invention, and the selection of each parameter in the method can be adapted to local conditions and has no substantial impact on the results. At first, briefly describe the basic scheme of the method of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com