Thermo-photovoltaic direct conversion power generating device

A power generation device, thermo-photovoltaic technology, applied in the field of thermo-photovoltaic direct conversion power generation devices, can solve the problems of reducing structural heat dissipation, increasing structural heat dissipation, vacuum leakage, etc., achieving the goal of reducing internal combustion temperature, reducing ineffective heat loss, and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

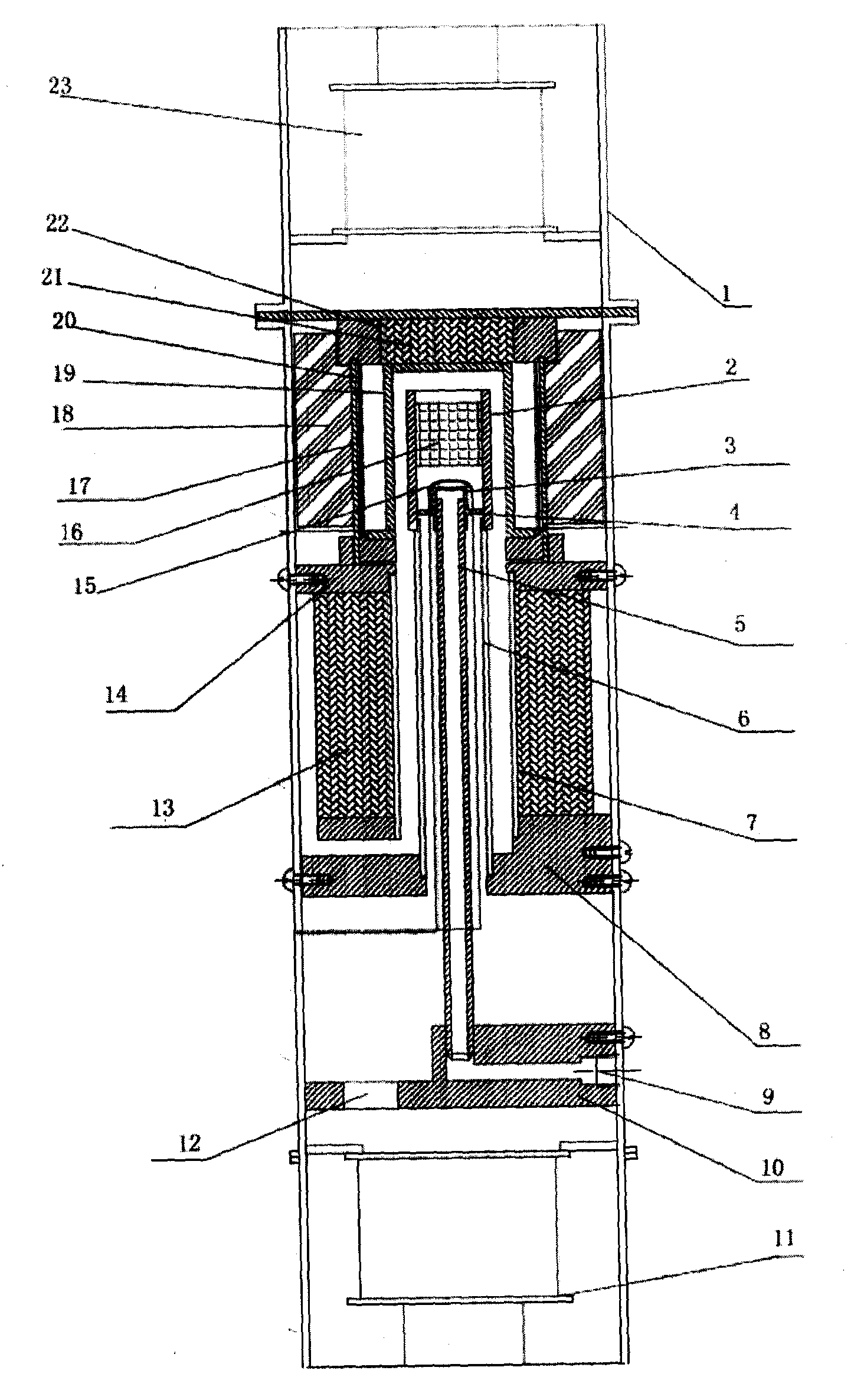

[0012] Embodiment: The fuel of the present invention enters the fuel pipe 5 through the fuel inlet 9 of the lower base 10 . The lower base 10 mainly provides fuel and air inlets, and provides support for the fuel pipe 5 , and the lower base 10 is fixed on the casing 1 by bolts. The fuel pipe 5 is connected to the lower base 10 by means of threads at its lower end. The fuel enters the porous media burner through the fuel pipe 5 and the wind cap 3. The function of the wind cap 3 is to disperse the fuel air flow to enhance the mixing of fuel and air, thereby ensuring complete combustion of the fuel. The wind cap 3 is connected to the fuel pipe 5 through threads.

[0013] The air required for fuel combustion is provided by the blower fan 11, enters the air chamber through the air inlet 12 of the lower base 10, and the air chamber is the space formed by the lower base 10, the middle base 8 and the shell 1, and then passes through the fuel pipe 5 and the fins. The channel formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com