System for optimizing optimal furnace temperature set value based on data mining

A data mining and setting value technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as long heat preservation time for rolling, fuel waste, exhaust emissions, etc., to guide performance management and assessment, improve Intuitiveness and fairness, the effect of stable improvement of heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

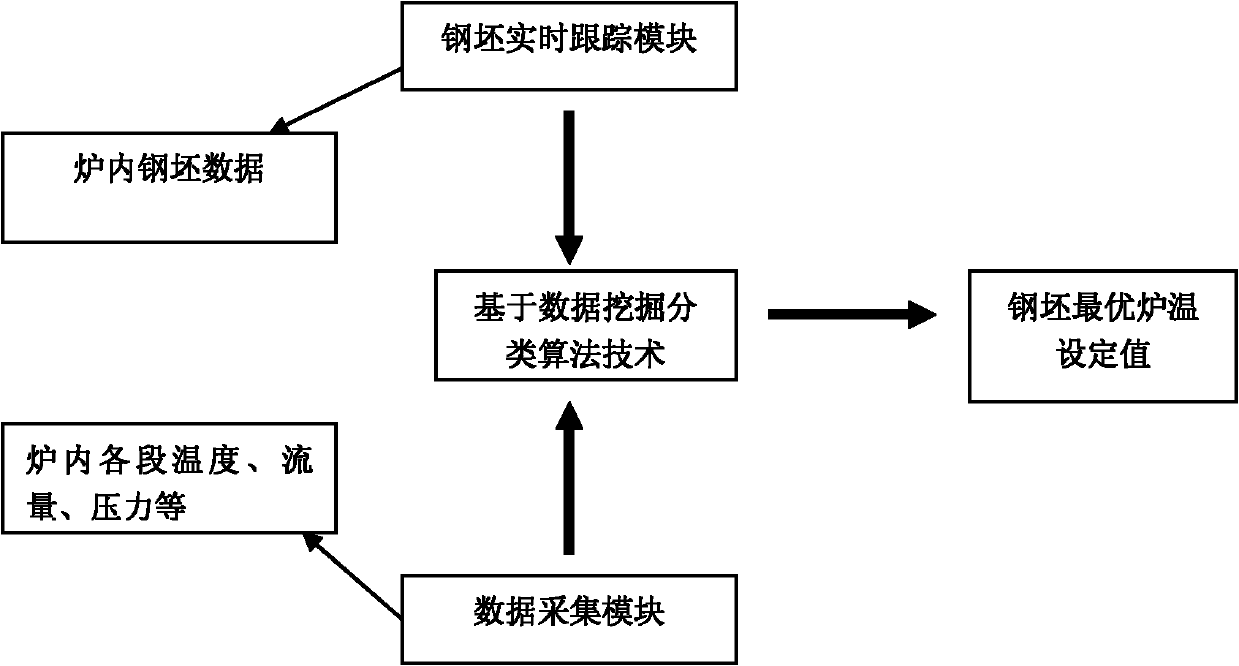

[0040] The steel rolling heating furnace occupies an important position in the iron and steel enterprises. Its task is to heat the steel slab so that the temperature and temperature distribution of the steel slab meet the rolling requirements. Especially for special steel enterprises, there can be more than a dozen types of steel in the heating furnace at the same time, and the heating systems corresponding to each steel type are not the same, so how to find the optimal heating furnace temperature control system is It is the main means to determine the heating quality of the heating furnace and energy saving and emission reduction.

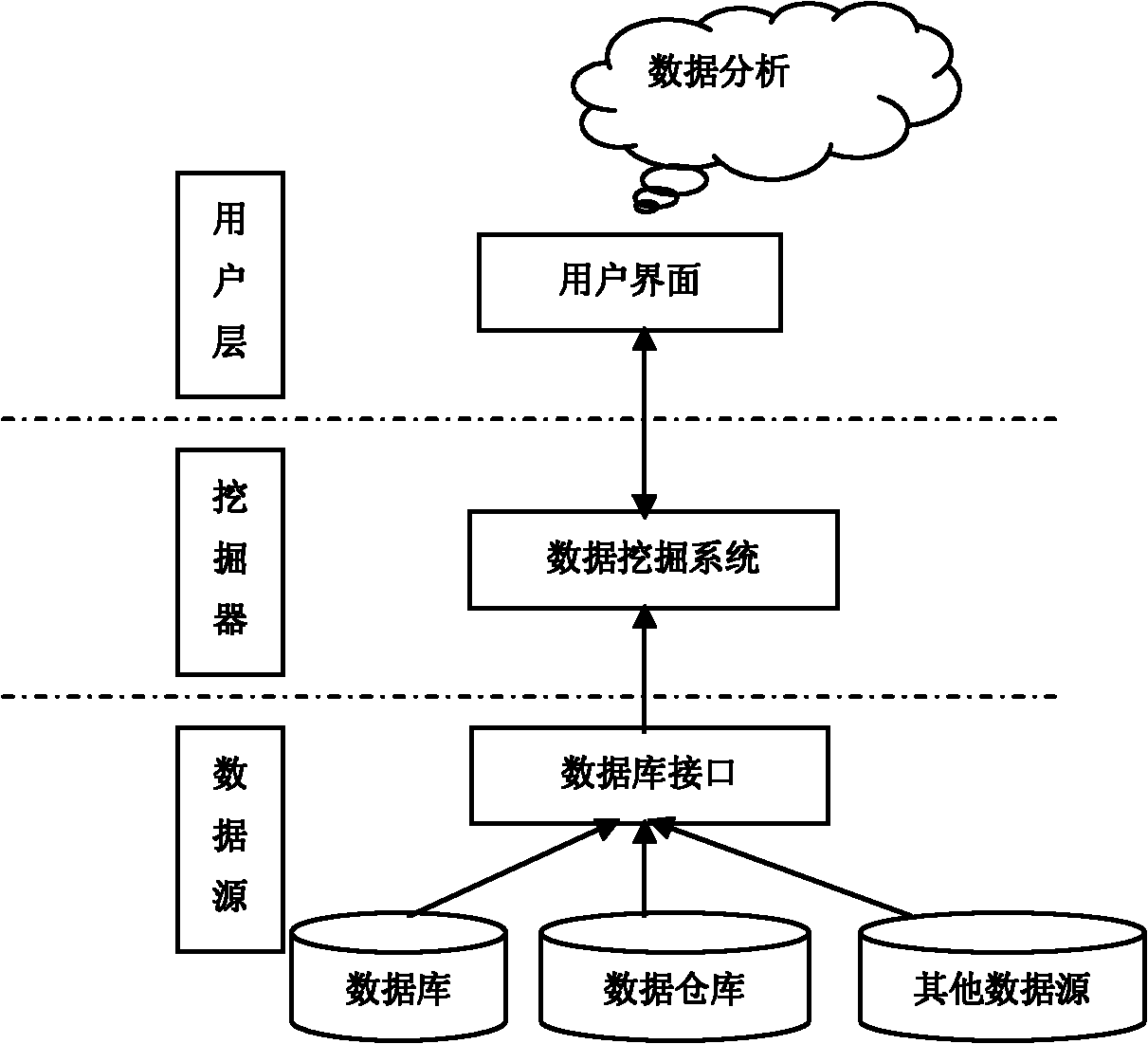

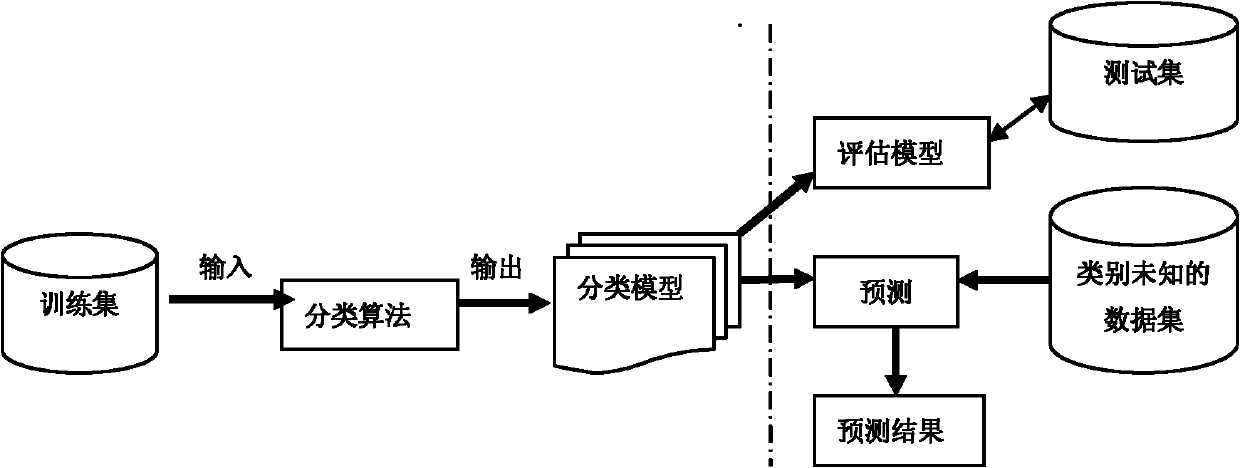

[0041] In the process of optimizing the optimal furnace temperature based on data mining, the present invention selects the data that objectively reflects the billet in the heating process as the mining object, and uses the data mining algorithm to find the optimal furnace temperature setting corresponding to different billets from the historical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com