Test device used for testing sealing performance of metal pressure vessel

A pressure vessel and detection device technology, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of prolonging the detection time, large influencing factors, and difficult measurement operation, etc. Achieve the effect of avoiding delay, simple operation and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

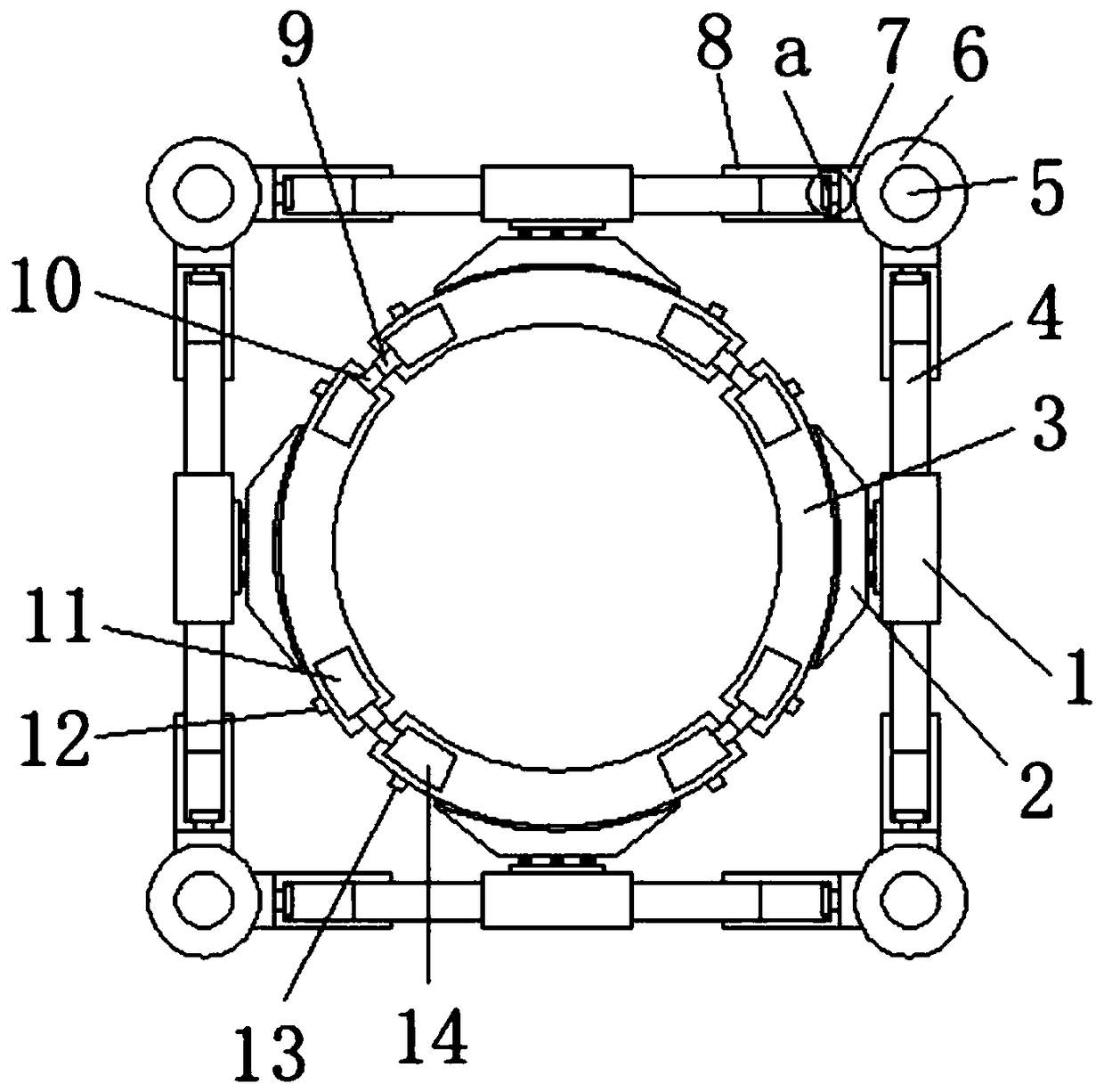

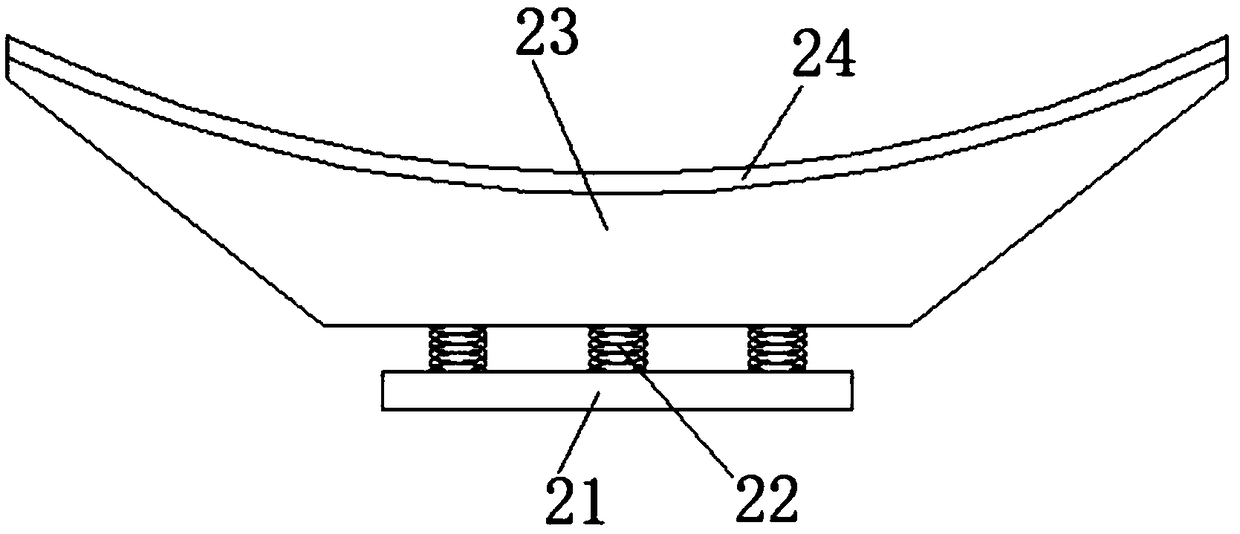

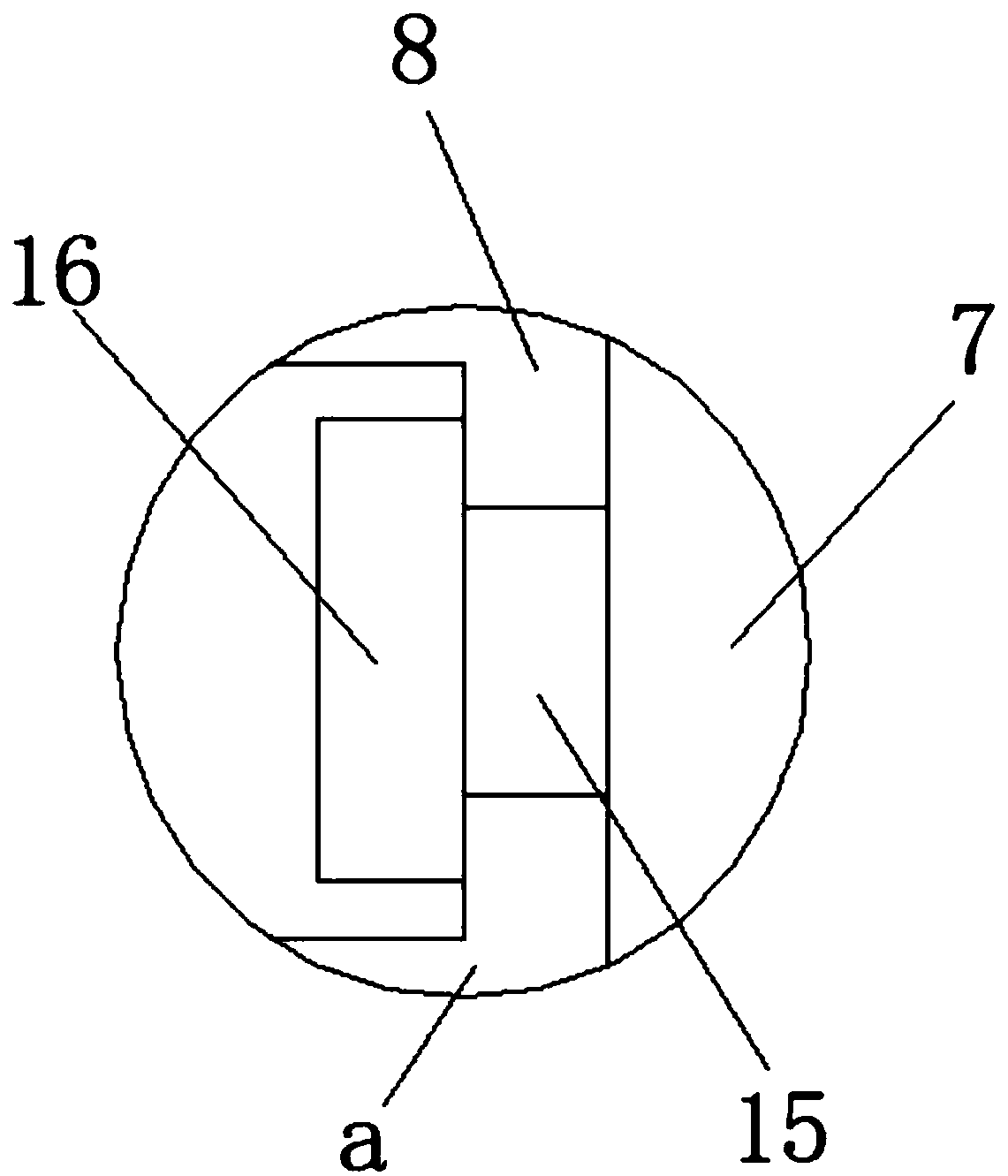

[0023] When in use, the base cylinder 1 and the welded threaded rod 4 are effectively combined and installed with the fixed corner seat 6 and the base 7 carried by itself and the rotating threaded cylinder 8, so that the inner ring sleeve 3 is closely attached to the outer wall of the pressure vessel, and then the circuit Connect the first pressure sensor 9, the second pressure sensor 10 and the universal ammeter 5, pressurize the pressure vessel, and when the rated pressure is reached, the pressure vessel is deformed at this time, record the readings of the universal ammeter 5, and then regularly observe the universal ammeter 5 , to carry out the numerical observation, so as to carry out the tightness detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com