Aerodynamic heating furnace

An aerodynamic and heating furnace technology, which is applied in the direction of heating devices and other non-combustion heat generation, can solve the problems of single application method, low heating efficiency, and no involvement of small heating devices, and achieve simple maintenance, high heating efficiency, Effect of heating method safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

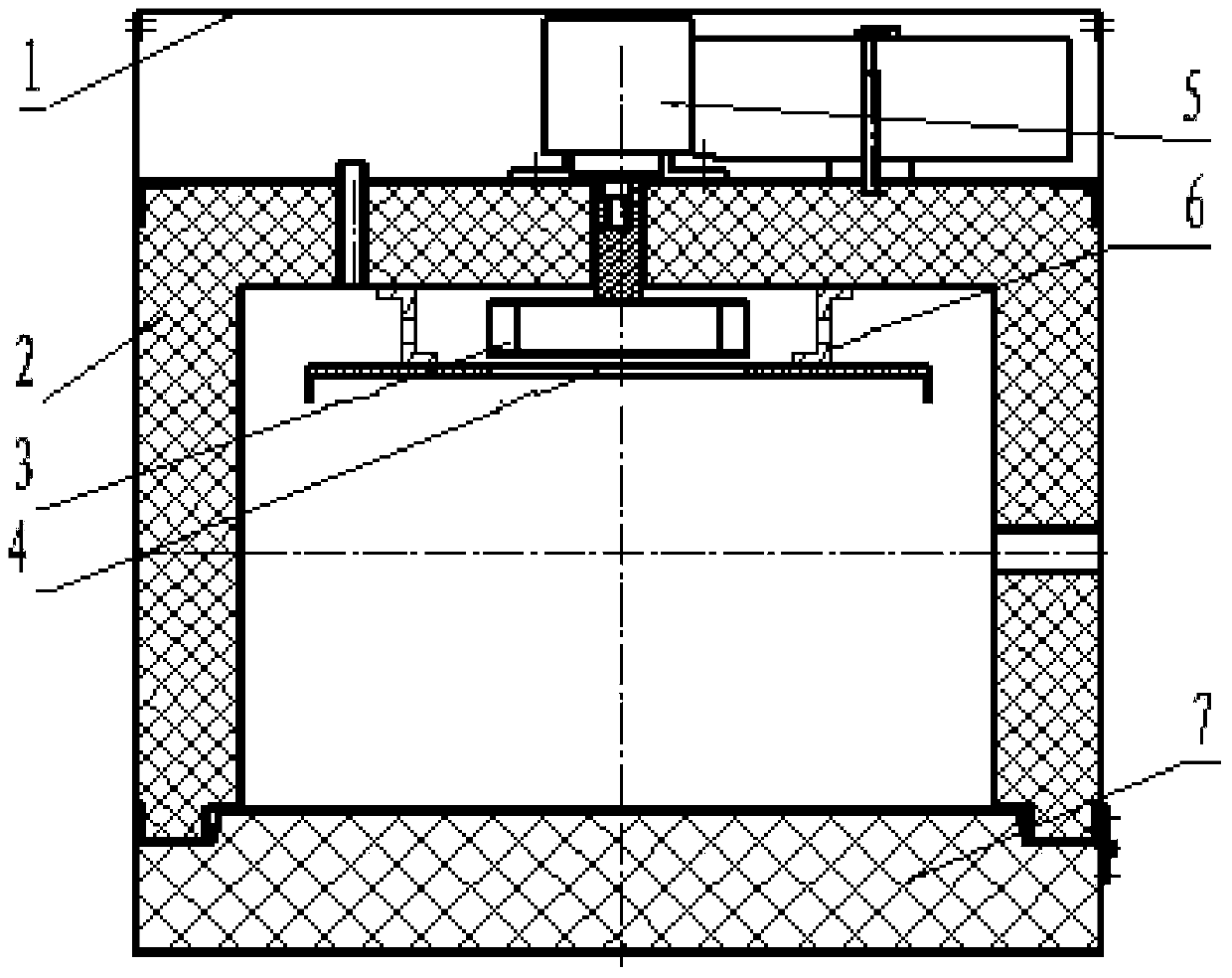

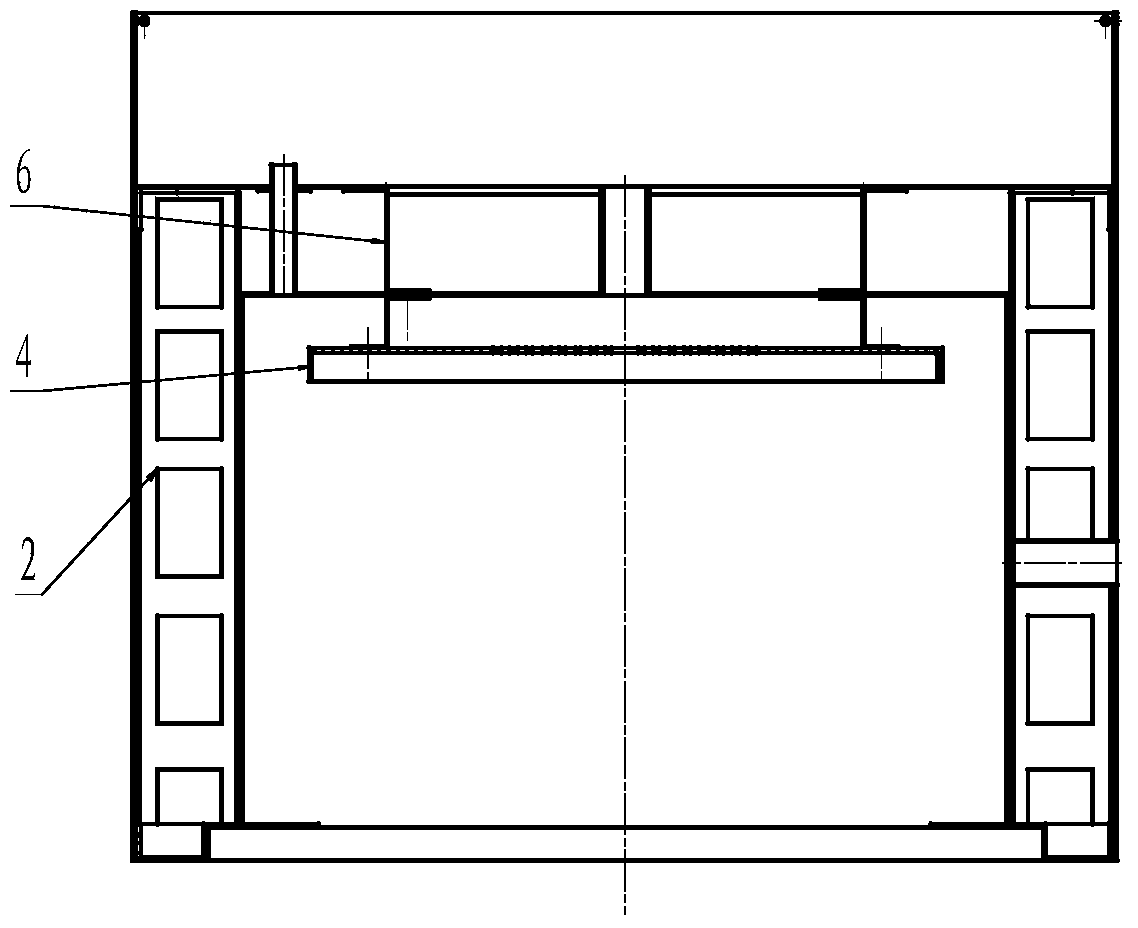

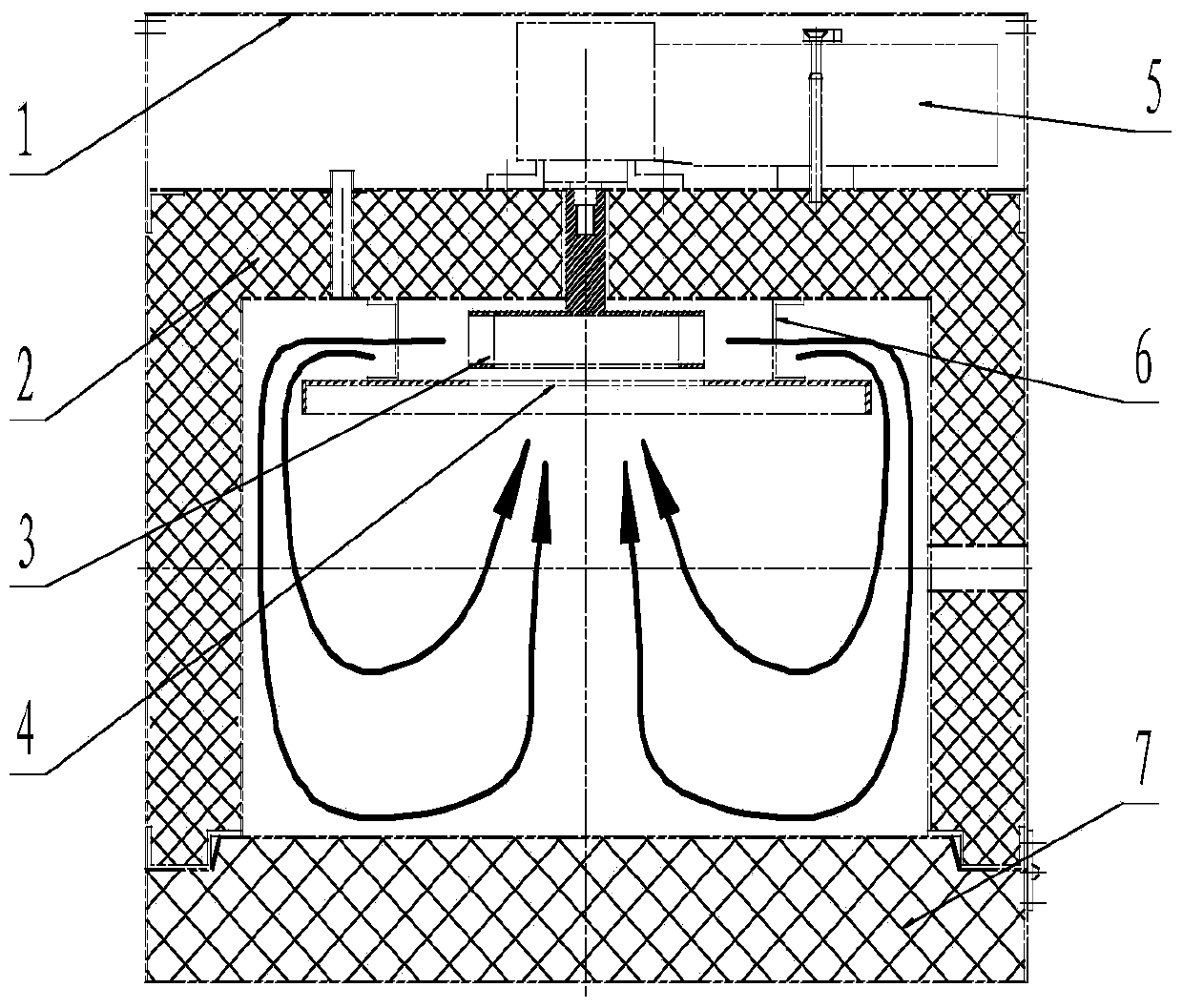

[0028] Such as figure 1 As shown, the present embodiment includes a rear protective plate 1, a furnace body 2, an impeller 3, a deflector 4, a motor 5, a deflector support 6, and a furnace door 7. The back cover 1 is for concealing the motor 5 to ensure the overall appearance is beautiful, and is a plate structure; the furnace body 2 is a square structure, and the motor 5 adopts a shaft-end air-cooled motor. The impeller 3 adopts a centrifugal impeller.

[0029] The body of furnace 2 is a frame structure. There is a mounting hole for the impeller shaft in the middle part of the rear wall plate of the body of heater 2 . The motor 5 is fixed on the outer surface of the rear wall of the furnace body 2; the output shaft of the motor 5 is connected with the impeller shaft. The impeller 3 is located in the furnace body 2 . The deflector 4 is installed in the body of heater by the deflector bracket 6, and is fixed on the inner surface of the rear wall of the body of heater 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com