Safe mixing device of hydrogen-containing mixed gas and mixing method thereof

A mixing device and mixed gas technology, applied in mixing methods, mixers, fluid mixers, etc., can solve problems such as hidden safety hazards and difficult technical implementation, and achieve the elimination of gas blocks, improvement of hydrogen dissolution level, and safe and reliable use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

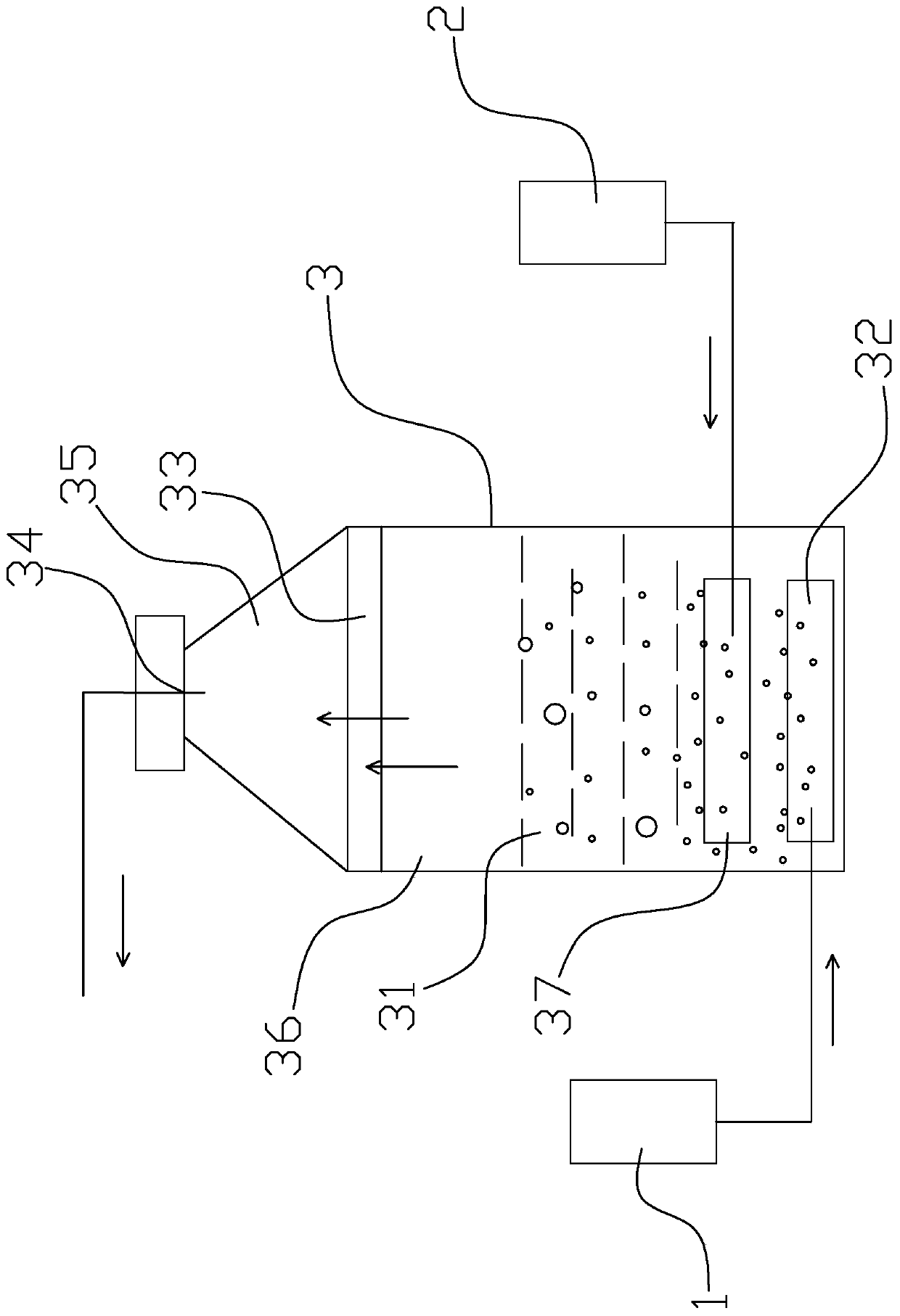

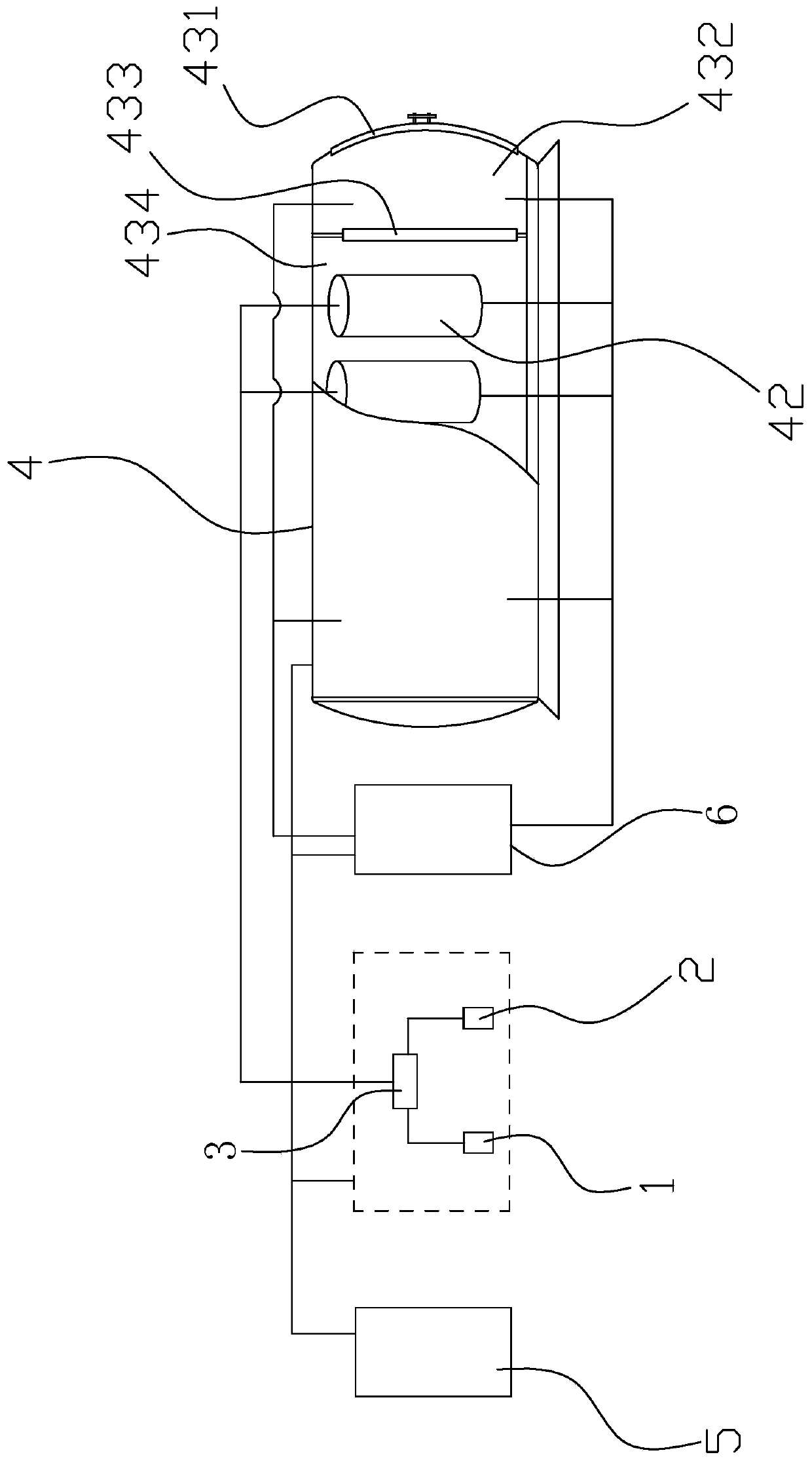

[0042] Embodiment 1, the air flow dispersing device selects filter material

[0043] All filter materials have the physical characteristics of being porous and selectively permeable to the medium. Taking the honeycomb porous material as an example, since the porous material is immersed in water, hydrogen or auxiliary gas is input from the gas source, and when entering the gas mixing tank 3 from the gas outlet of the hydrogen supply part 1 or the gas outlet of the gas supply part 2, first After the filtering structure, a mixture of water and gas is naturally formed, and a large number of fine air bubbles are generated to realize the cutting and breaking of a single airflow.

[0044] This kind of filter structure can also be a solid particle filter material such as fine gravel laid on the gas outlet of the hydrogen supply part 1 or the gas outlet of the gas supply part 2 . The filter material is submerged below the water surface of the gas mixing tank 3, and covers the gas outl...

Embodiment 2

[0045] Embodiment 2, the air flow dispersing device adopts a honeycomb structure

[0046] The gas outlet of the hydrogen supply part 1 or the gas outlet of the gas supply part 2 can also be connected with a cylinder or box with a honeycomb structure, then the hydrogen or auxiliary gas enters the gas mixture through the pores on the cylinder wall or the box wall In the water body of the tank 3, a large number of air bubbles are formed to realize the cutting and breaking of the airflow.

Embodiment 3

[0047] Embodiment three, the air flow dispersing device selects the stirrer with spiral blade

[0048] The air flow dispersing device can also use an agitator with a helical blade, and the blade agitates the input air flow to realize the cutting and breaking up of the air flow. The power of the agitator is provided by the airflow, and the airflow impinges on the agitator to make the helical blade of the agitator rotate. Of course, the agitator can also be equipped with an external power source, such as a motor, to forcibly drive it to rotate, without the air outlet of the hydrogen supply part 1. 1. The airflow direction of the air outlet of the air supply part 2 is required, and a more high-speed and efficient stirring and mixing effect can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com