N-polarity nitride template, N-polarity nitride device and preparation method of N-polarity nitride device

A nitride and nitride layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor material quality and partial polarity reversal of N-polar nitride materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

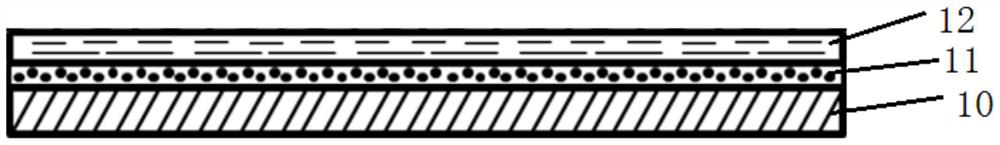

[0053] The embodiment of the present application also provides a method for preparing the above-mentioned N-polar nitride template, including the following steps:

[0054] S1. A substrate is provided, and the substrate is ultrasonically cleaned in acetone, ethanol and deionized water respectively, and then cleaned with N 2 Blow dry; then place the cleaned and dried substrate in a plasma cleaner to further clean the surface of the substrate and set aside;

[0055] S2. Prepare a transition metal oxide on the surface of the substrate. The specific preparation method is: prepare the transition metal oxide material on the surface of the substrate by powder thermal evaporation or solution spin coating, which can be controlled by thermal evaporation or Spin-coating process parameters to achieve transition metal oxide films with different thicknesses;

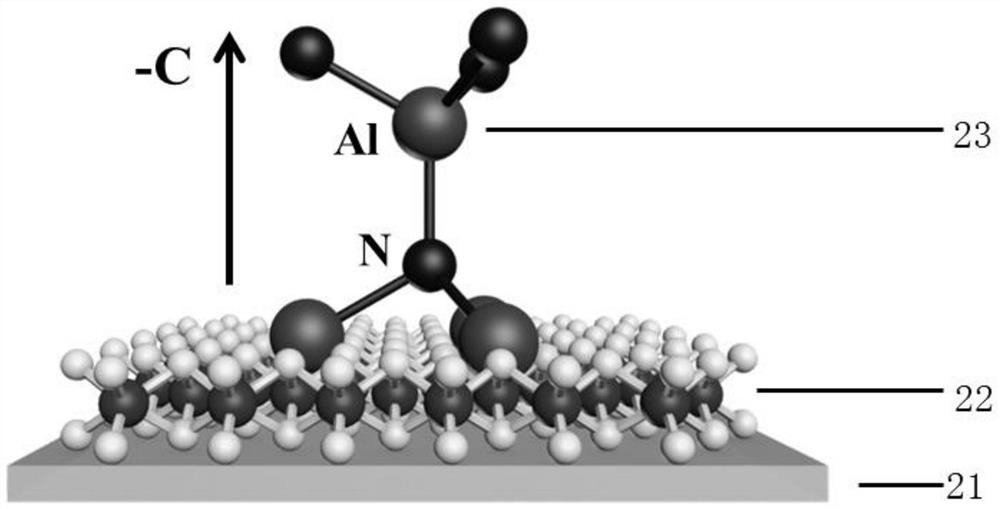

[0056] S3. Sulfurize the transition metal oxide to obtain a transition metal dichalcogenide. Specifically, place the substrate prepa...

Embodiment 1

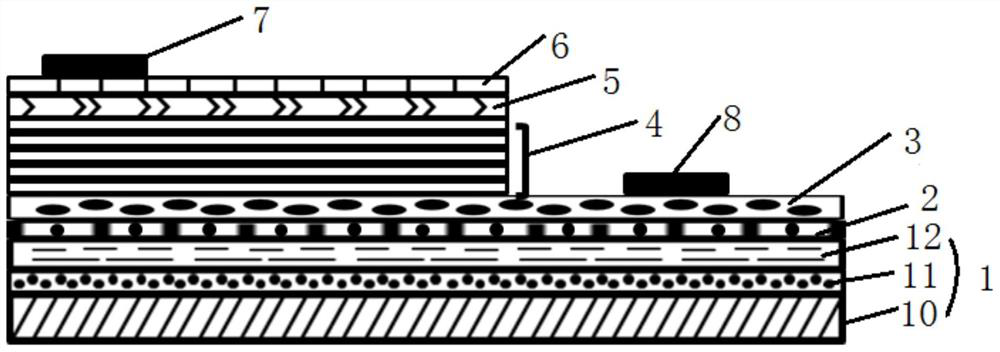

[0089] A method for preparing an N-polar nitride device, comprising the following steps:

[0090] A1. Place a 2-inch sapphire substrate in acetone, ethanol, and deionized water for 5 minutes, respectively, and ultrasonically clean it with N 2 Dry the surface of the sapphire substrate with an air gun, and then dry it in a blast drying oven at 120°C for 10 minutes to remove residual moisture on the surface; place the dried sapphire substrate in a plasma cleaning machine, and feed O with a flow rate of 50 sccm. 2 , glow treatment at 50% power for 5 minutes to further clean the surface of the sapphire substrate;

[0091] A2. Deposit 2nm MoO on the surface of sapphire substrate by vacuum thermal evaporation 3 , annealed at 200°C for 30 minutes in the atmosphere to make the MoO on the sapphire substrate 3 The film can be fully oxidized and denser; the annealed sapphire MoO 3 Place the S powder in the low-pressure chemical vapor deposition equipment with dual temperature zones, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com