Partial premix combustor

A technology of premixed combustion and mixing zone, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., and can solve the problems of short mixing distance between gas and air, incomplete mixing, and high combustion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

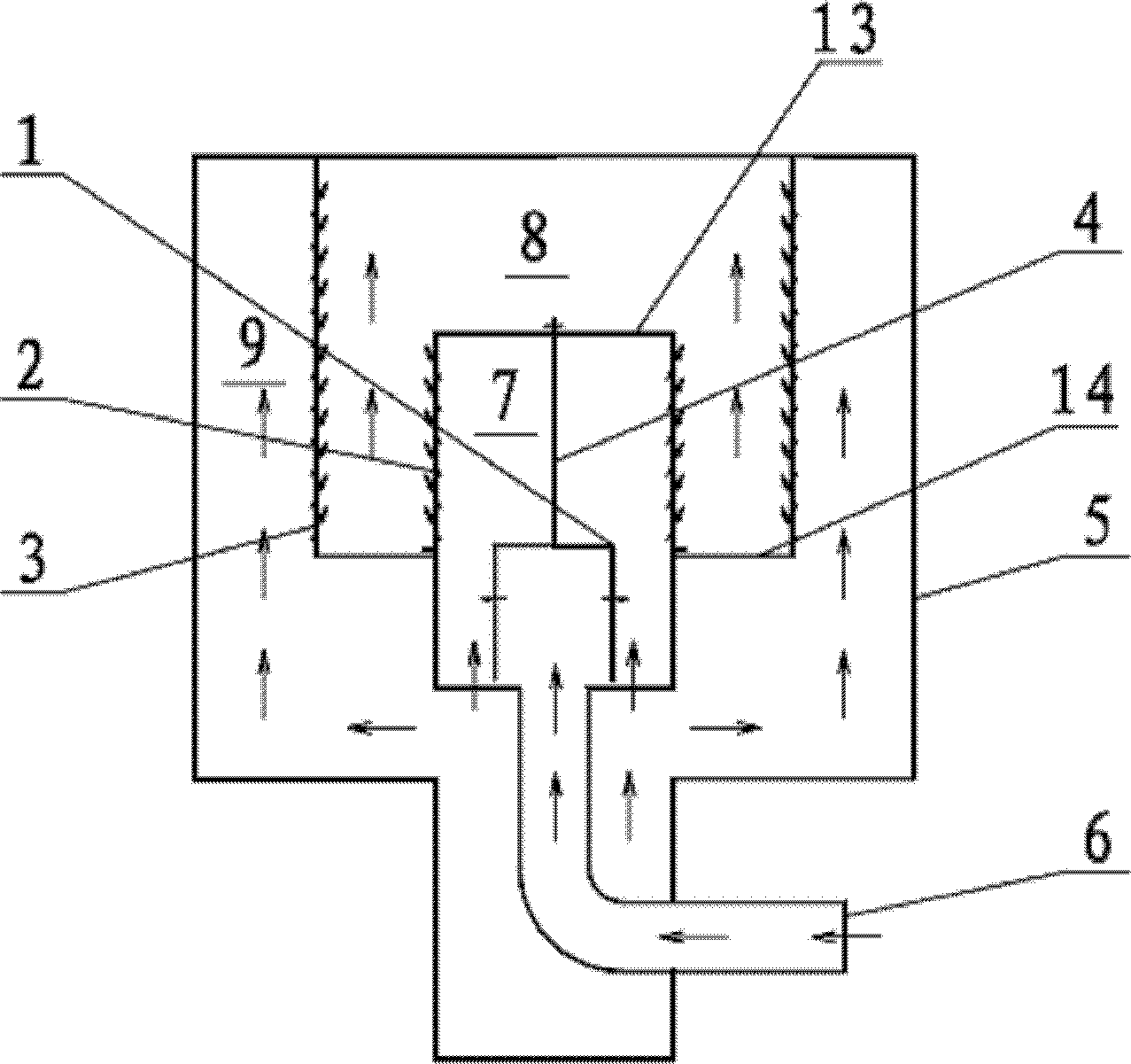

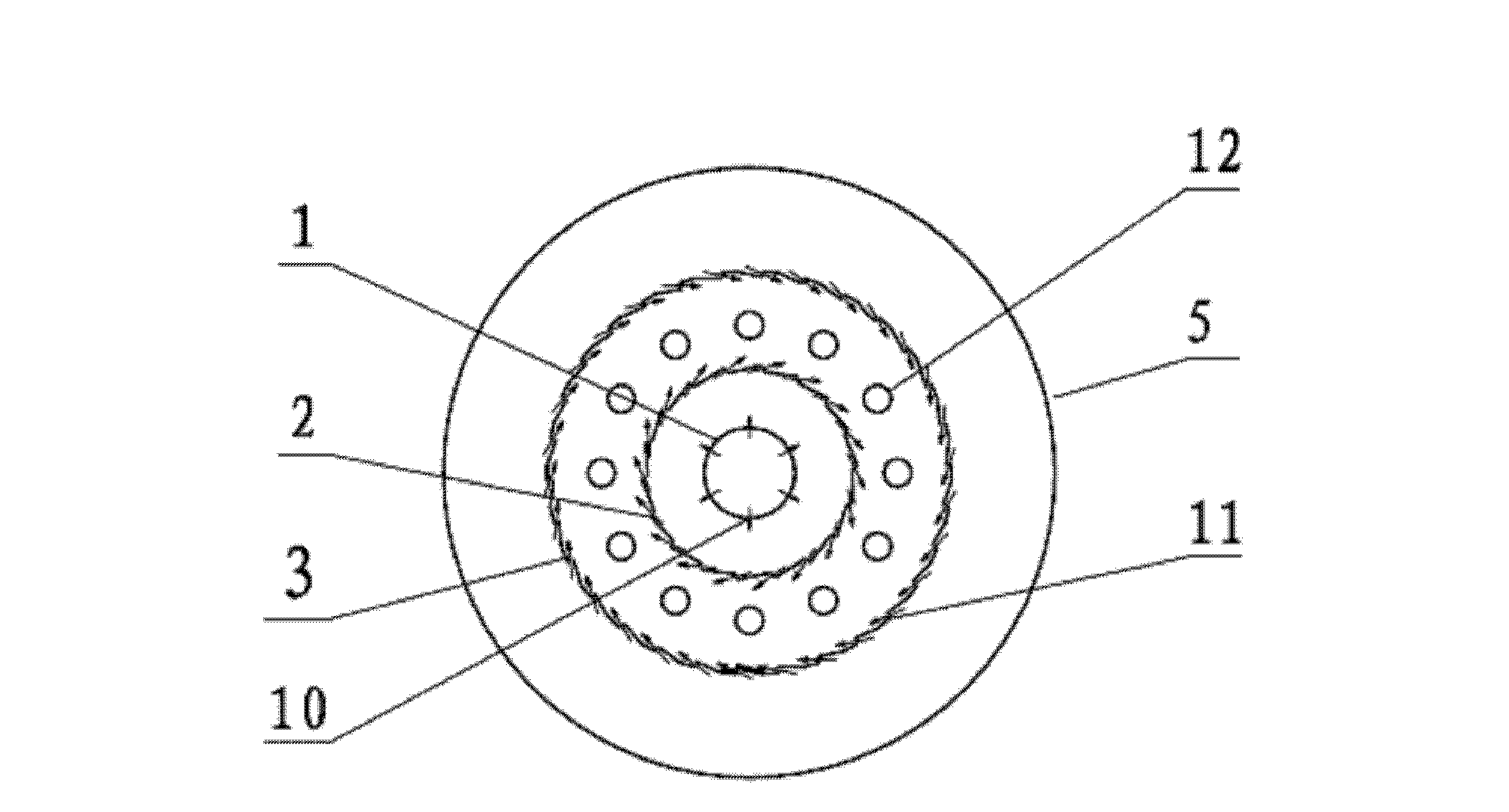

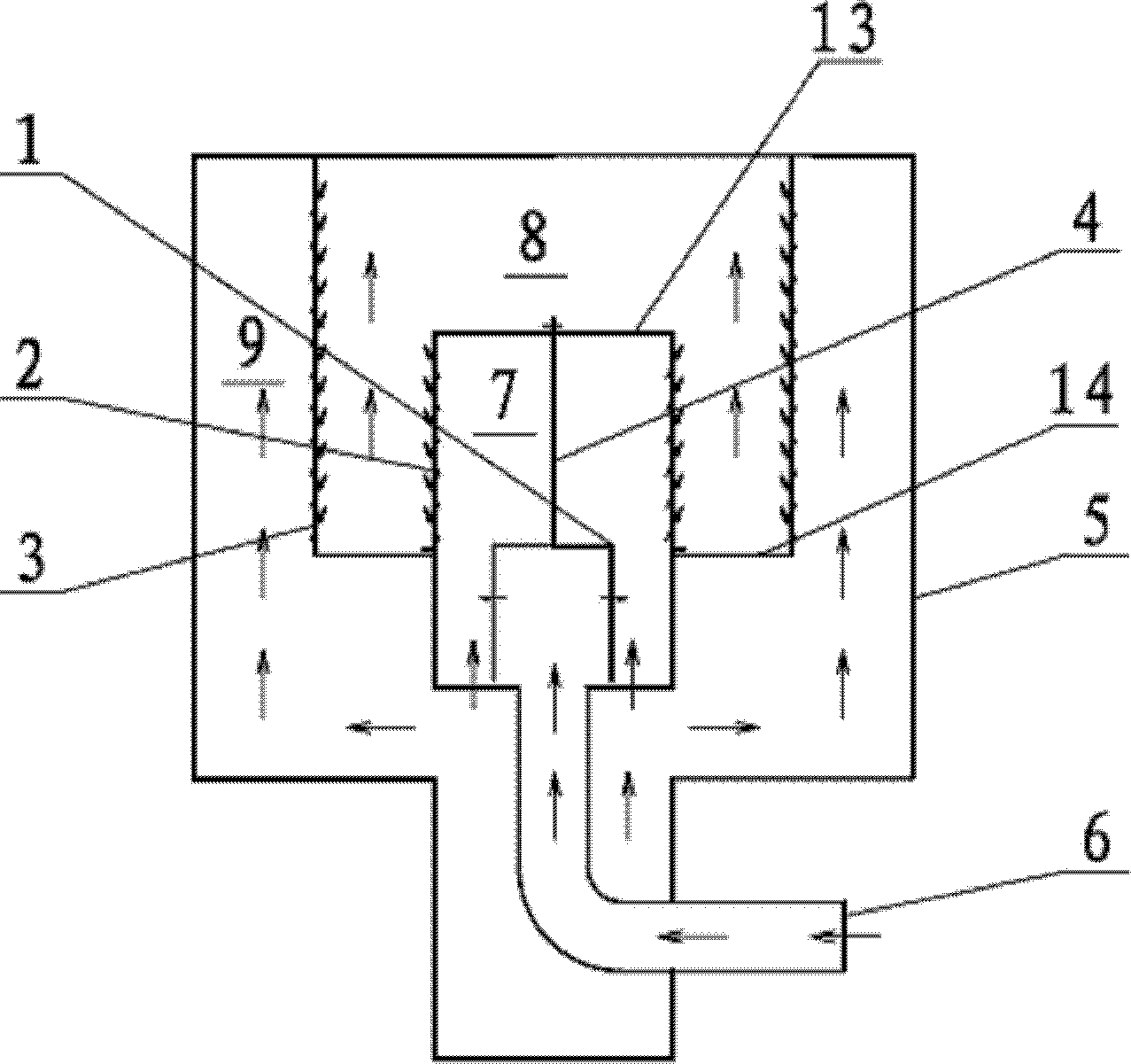

[0031] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0032] Due to the limitation of space, the mixing distance of gas and air is very short and cannot be fully mixed, resulting in incomplete combustion and high combustion noise

[0033] Blast diffuser burners have limited space, and the mixing distance between gas and air is very short and cannot be fully mixed, resulting in incomplete combustion and loud combustion noise.

[0034] The fully premixed burner overcomes the above-mentioned shortcomings of insufficient combustion and high combustion noise, but has the following disadvantages: the flame adjustment range is small, and a stable gas source needs to be provided; Fire tendency; if the space of the burner is limited, the design of the mixing area of gas and air is also difficult to achieve the purpose of fully mixing the two.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com