Low-exhaustion high-efficiency energy-saving combustor

A high-efficiency energy-saving, burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient mixing of gas and air, and achieve the effect of reducing combustion noise and reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

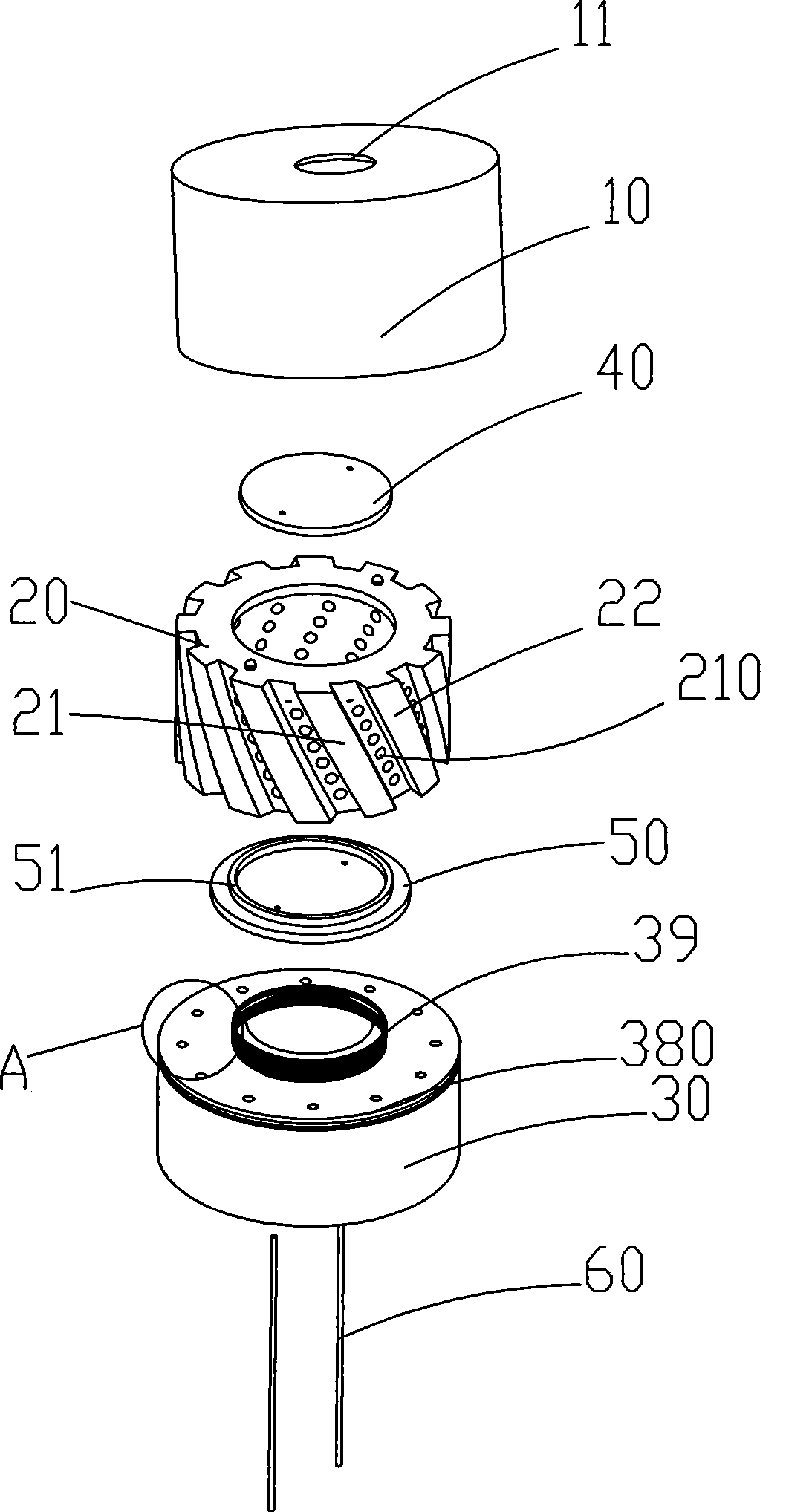

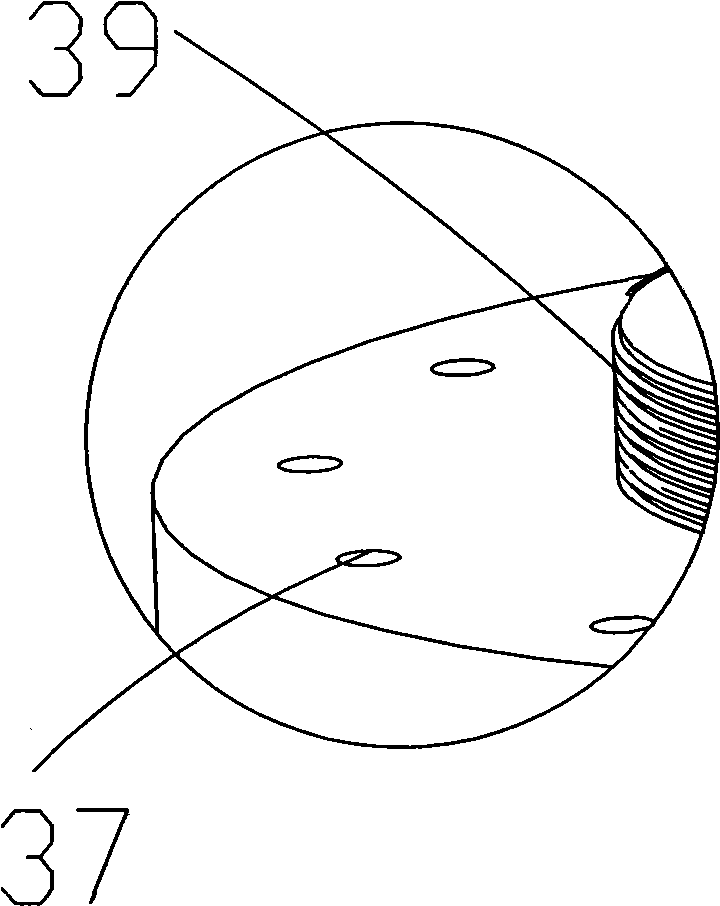

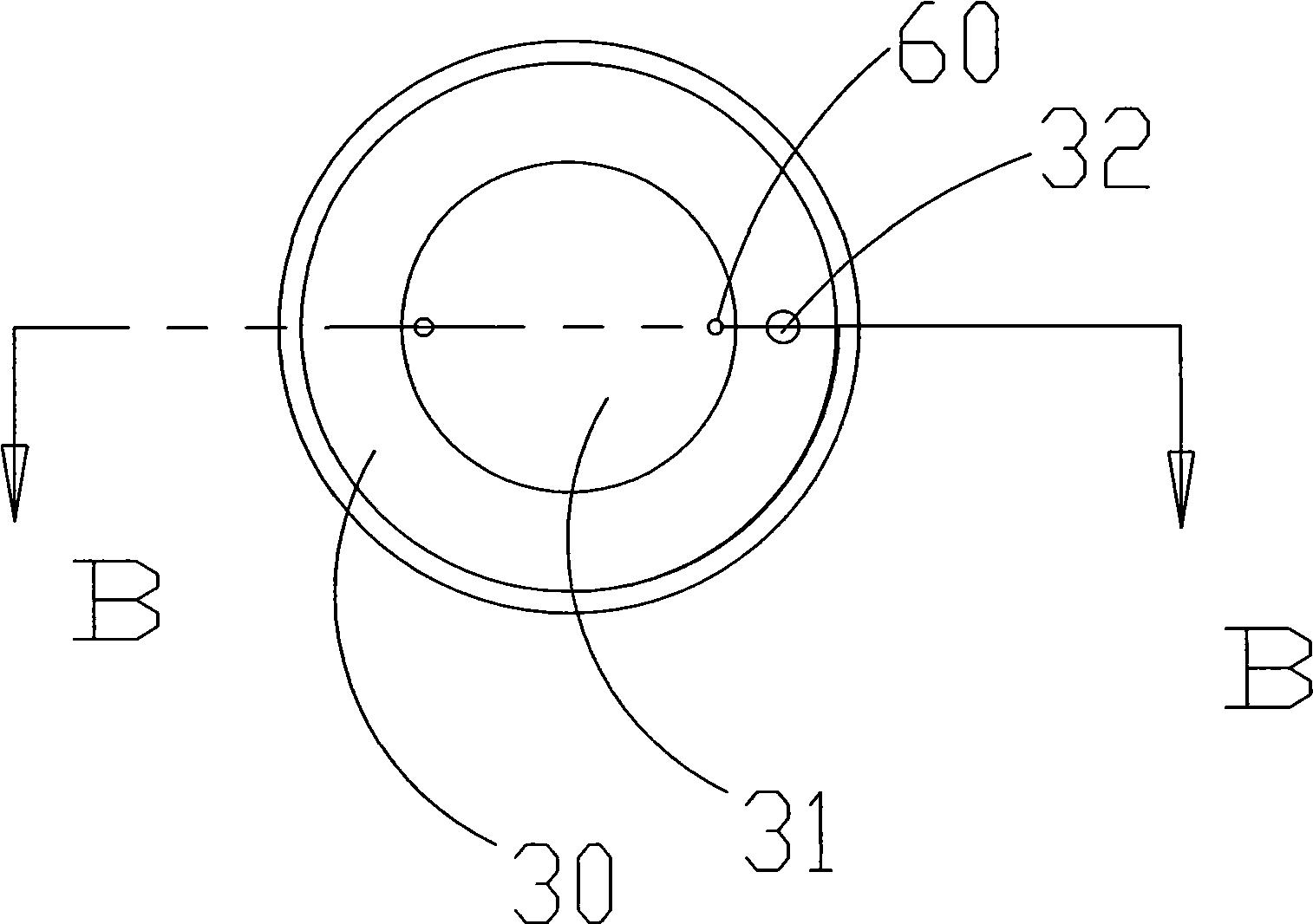

[0028] Such as figure 1 As shown, an embodiment of the low-emission high-efficiency energy-saving burner of the present invention includes a gas distribution box 30, an air dispersion and gas mixing device 20, and a burner head cover 10, wherein the gas distribution box 30 is circular and includes The central hole 31 and the box body, the box body is cylindrical, its upper surface is distributed with gas outlet holes 37 for dispersing gas along a circumference, and the lower surface of the box body has an air inlet hole 32 for connecting gas. The central hole 31 is circular, its outer part is annular, and the upper part 39 of the annular is externally threaded. The outside of the central hole 31 and the box body together form a cylindrical gas diffuser chamber 38 for dispersing gas. In order to fully disperse the gas, the gas outlet holes 37 can be evenly distributed.

[0029] The air dispersing and gas mixing device 20 is cylindrical, and the air dispersing and gas mixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com